This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

10 Top Tips

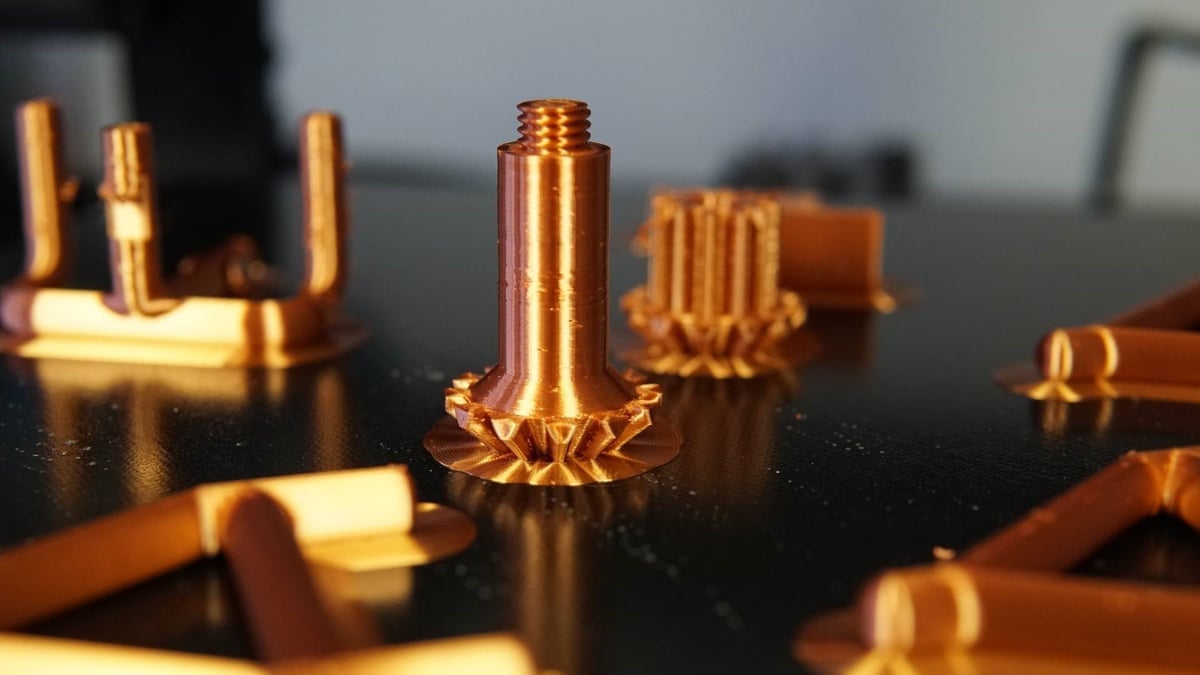

3D Printing Tips: How to Improve 3D Print Quality

Perfecting 3D print quality can feel like a long journey, but it's worth it. Check out these 3D printing tips to improve print quality!

Advertisement

Advertisement