This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Get a Grip!

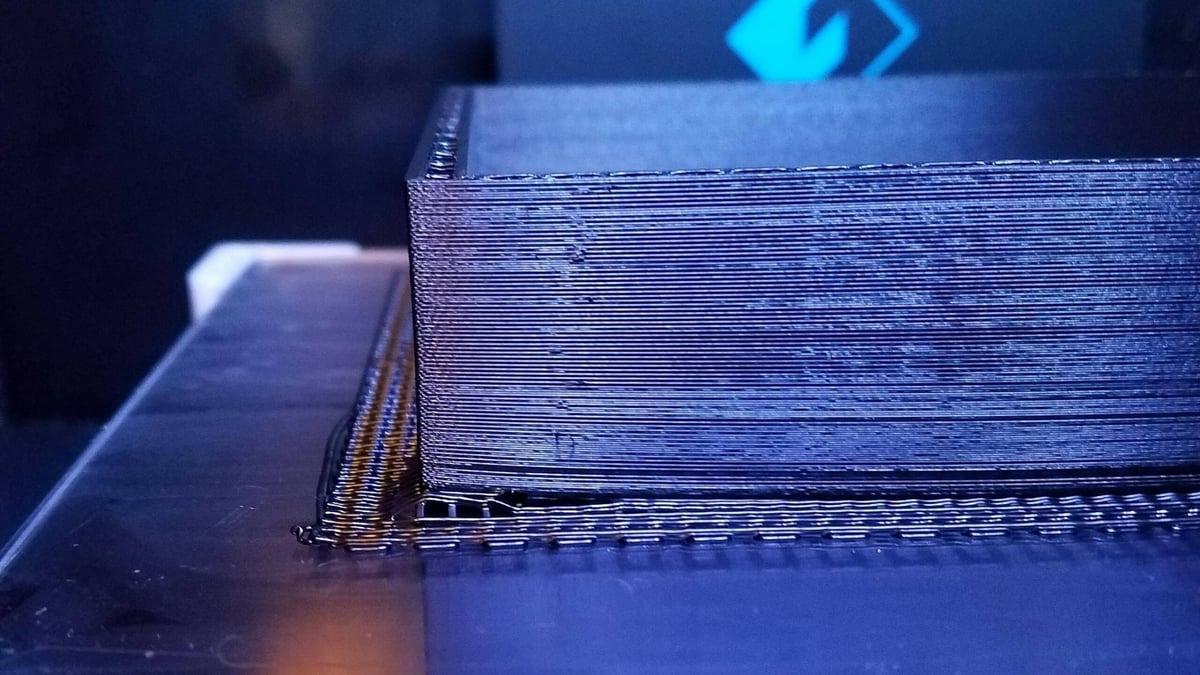

3D Print Warping: PLA, PETG, ABS – 3 Easy Fixes

If 3D prints cool unevenly, they can curl away from the build plate. Check out three easy ways to fix 3D print warping with PLA, PETG, & ABS.

Advertisement

Advertisement