This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Go Glass

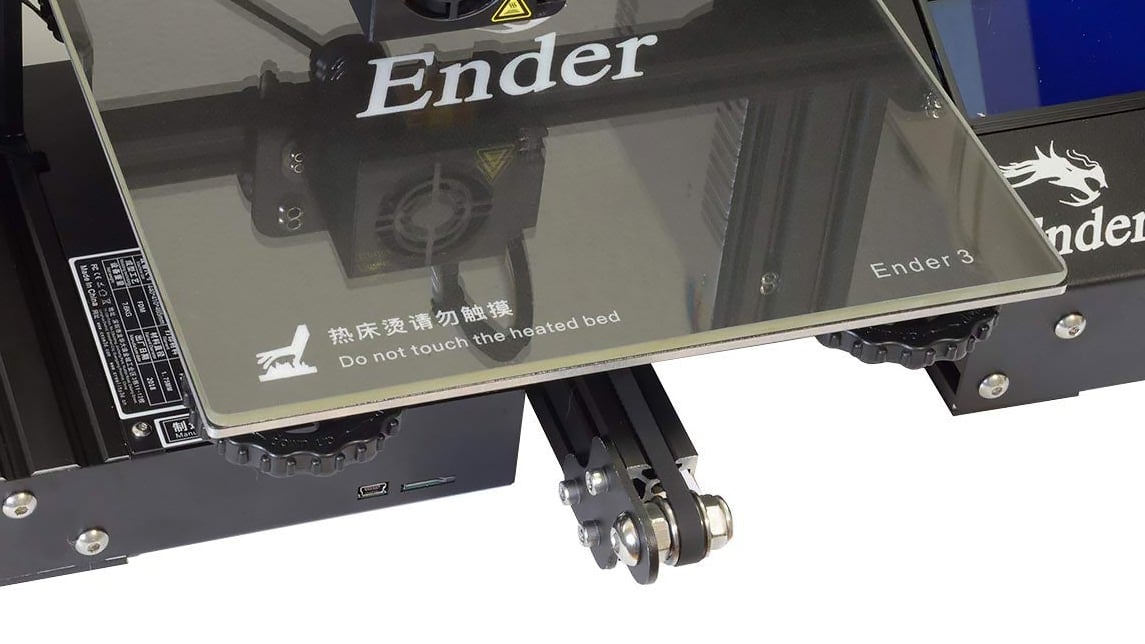

3D Printer Glass Bed: What to Consider & Which to Buy

The ideal build plate depends on what you want to print. Discover the benefits of a 3D printer glass bed and learn what to look for.

Advertisement

Advertisement