In today’s desktop 3D printing market, the two most popular realms are fused deposition modeling (FDM) printing and resin-based printing. While generalizations and assumptions can be (and are) made about their differences (e.g. FDM’s cheaper, resin’s better for details) there are a few more things to know before you make up your mind and decide to go for one over the other.

In this article, we’ll take a dive into the differences between the two, discussing technologies, materials, individual strengths, price ranges, and so on.

By the way, if you want to use the tech without setting up shop, check out Craftcloud by All3DP, where you can upload your model, select the materials and manufacturer, and have your 3D print delivered to your doorstep, hassle-free.

But for now, it’s time to read on to find out which type of printer is right for you!

FDM Printing

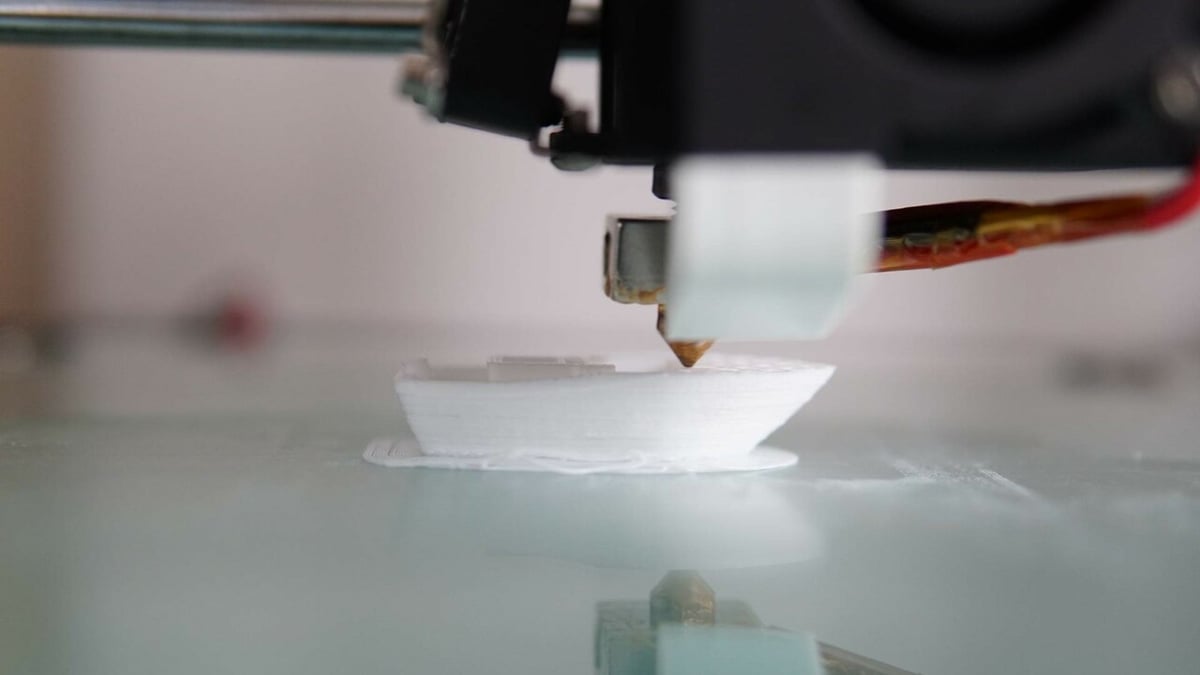

FDM 3D printing is a specific 3D printing technology that falls under the broader additive manufacturing category of “material extrusion”. As the name implies, any machine falling under this category extrudes material in specific patterns to produce a final shape, with FDM using molten plastic (sometimes combined with other materials) as its extrusion medium.

FDM works very similarly to a hot glue gun: A solid strand is pushed into a hot nozzle that melts it and allows it to flow and be laid down in flat layers. In the case of a printer, these movements within a layer are accurately directed along (for the most part) the X- and Y-axes of a Cartesian coordinate system. The first layer is deposited on a print surface, cooling and solidifying quickly. Another layer is then added on top of the last one, and the process is repeated, building a 3D object slowly, layer by layer.

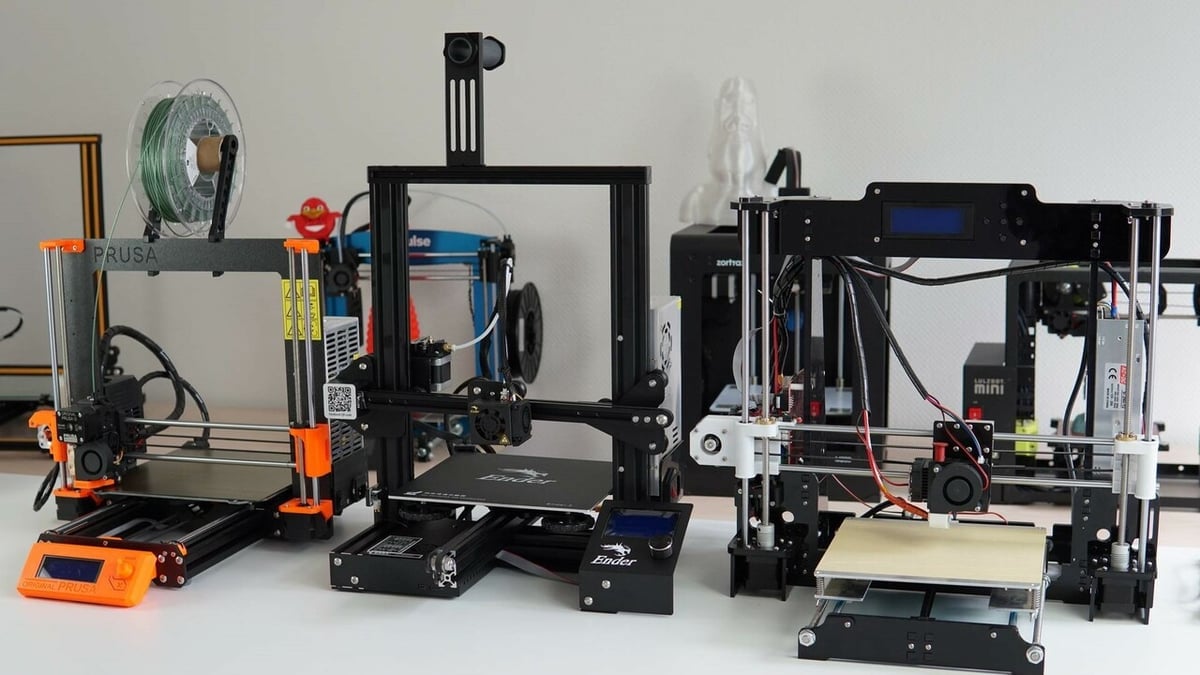

Unlike resin printing, where there are various approaches to the actual printing process, with FDM printing, the hot plastic extrusion and deposition process is fairly similar across all machines. This is why all FDM printers technically belong to the same technology. Nevertheless, there are of course different types of FDM printers, with the most popular style being the rectilinear printer (a.k.a. “Cartesian” printer, although that can be confusing).

The area where the biggest changes come into play are in multi-material printers, which are capable of printing multiple colors and materials in a single print. Additionally, some single-extrusion FDM printers can be upgraded with additions like Prusa’s MMU 2S and the Mosaic Palette 2S Pro.

Resin Printing

“Resin printing” is more of an umbrella term for 3D printing technologies that fall within the additive manufacturing category of vat polymerization.

Most resin printers have a container with a clear, flexible bottom sheet, also called a vat, which is filled with a photosensitive resin that cures, or solidifies, when coming into contact with UV light. A build platform is then submerged into the vat and a light source beneath the clear bottom cures the resin according to a specific pattern, binding the hardened first layer to the platform.

The build plate then moves up to create space for the next layer and allow new resin to flow in between the previous layer and the bottom of the vat. This new layer is then cured via the light source, and the process repeats until the finished 3D object is created.

The differences between types of resin printers lie in how the light is generated and applied to the resin. These technological differences mean that each of the following types of resin printing is its own technology.

LCD Printing

The most accessible form of resin printing is called LCD printing (also known as MSLA printing). An LCD printer uses a powerful UV light source that can illuminate an entire layer at once. This light is selectively blocked and let through by a liquid-crystal display (LCD) screen sitting above the UV light. The LCD displays a negative image of the layer to only let light pass where the resin needs to be cured.

Using this technology is said to sometimes decrease print quality because the resolution of the LCD screen will determine the resolution of the print. In return, LCD is also the fastest type of resin printing. LCD printers are by far the cheapest types of resin printers and are therefore more suitable for beginners and hobbyists.

SLA Printing

The very first type of resin printing (and, indeed, the first type of 3D printing) is SLA, which stands for stereolithography.

This technology is very similar to LCD printers, however, the light source used is a laser. This laser is aimed around the vat by a motor-controlled mirror that can change its reflection angle. The laser traces over the resin in the shape of the current layer, much like a regular FDM 3D printer nozzle traces a new layer point by point.

This technology is often more expensive than LCD because of the increased complexity and number of moving parts, but it typically boasts a high resolution.

DLP Printing

The last popular resin printing technology is DLP printing, which makes use of a digital light processing (DLP) projector. The technology is quite similar to LCD printing in that a whole layer is exposed at the same time. The difference between the two is how the light hits the resin in a specific shape. Specifically, the projector flashes an image onto an array of mirrors, which in turn direct the reflected image onto the bottom of the vat, without the need for an additional screen to block off unnecessary light.

This printing method is the least common of the three mentioned here, as its printing quality is affected by the resolution of the projected image, often leaving small pixels on a finished print. From a “historical” perspective, DLP printing could be said to have paved the way from SLA to LCD printing.

Materials

By nature of how they work, there are big differences between the materials used for FDM and resin printing. However, within each of the two groups, there is a lot of variety.

FDM

The main requirement for an FDM printing material is that it has a thermoplastic base. These materials come in the form of a long plastic strand, with a 1.75- or 2.85-mm diameter, wound up on a spool.

The most popular type of material is called polylactic acid (PLA); it’s the most used filament due to its ease of use and high quality. The material is also close to odorless and one of the least environmentally harmful 3D printing materials. There are plenty of things that can be printed with PLA, including models that can be in contact with food, assuming one opts for properly certified brands.

Another very popular material is polyethylene terephthalate glycol-modified (PETG). This material is, similarly to PLA, very easy to use, but has much better mechanical properties, like a higher strength and increased flexibility. The main difference is that PETG prints at around 245 °C, while PLA prints at around 200 °C. PETG is great for a variety of uses, including models that are exposed to varying weather conditions or that require more strength or durability.

Some more advanced FDM materials, such as ABS or carbon strand-filled nylon, need special printer and safety setups before successful use. These materials often require higher nozzle temperatures than PLA and a heated print bed to prevent the material from shrinking while cooling.

These advanced materials also benefit from an enclosure surrounding the print area. Enclosures not only keep the internal air even but also prevent any harmful fumes from escaping. These can have many negative effects, from simply smelling unpleasantly to being harmful to the respiratory system. To prevent this, many high-end machines with enclosures have built-in filtering systems that will filter the internal air and remove particles.

The versatility offered by filaments and the printing technology behind them shouldn’t be underappreciated: Wood, silk, marble, transparent, glow-in-the-dark, color-changing, and rainbow, just to name a few PLA options, as well as plenty of different combinations with carbon fiber, metal, PC, nylon, and even recycled filaments, mean that FDM prints can take many different forms and uses.

It’s also worth noting that filament needs to be stored properly and might even need to be dried before use, as most are hygroscopic.

Resin

With resin printers, the material selection is a bit more limited but still very versatile, ranging from regular plastics to castable, flexible, and water-washable ones. All resins are stored in either a UV-resistant bottle or bag, which prevent UV rays from entering and hitting the liquid, which would harden the resin before use.

Different resins will have different print settings, like exposure time – something that can also be affected by the color of the resin.

It’s worth noting that, while some brands offer more variety of colors, to get a multicolor print, you would need to print the parts separately (maybe adding a locator pin first). Alternatively, one could dye the resin for different results.

The technology used can affect the resin selected. Resins cure differently depending on the light’s wavelength, and as such, correct compatibility has to be checked depending on the printing setup. SLA lasers generally emit waves of around 395 nm, while LCD and DLP printers have a wavelength of about 405 nm.

Resolution & Quality

FDM and resin printing tend to differ in the quality and resolution of their finished prints. These factors range from general appearance to the quality of small details but also include mechanical factors like strength.

FDM

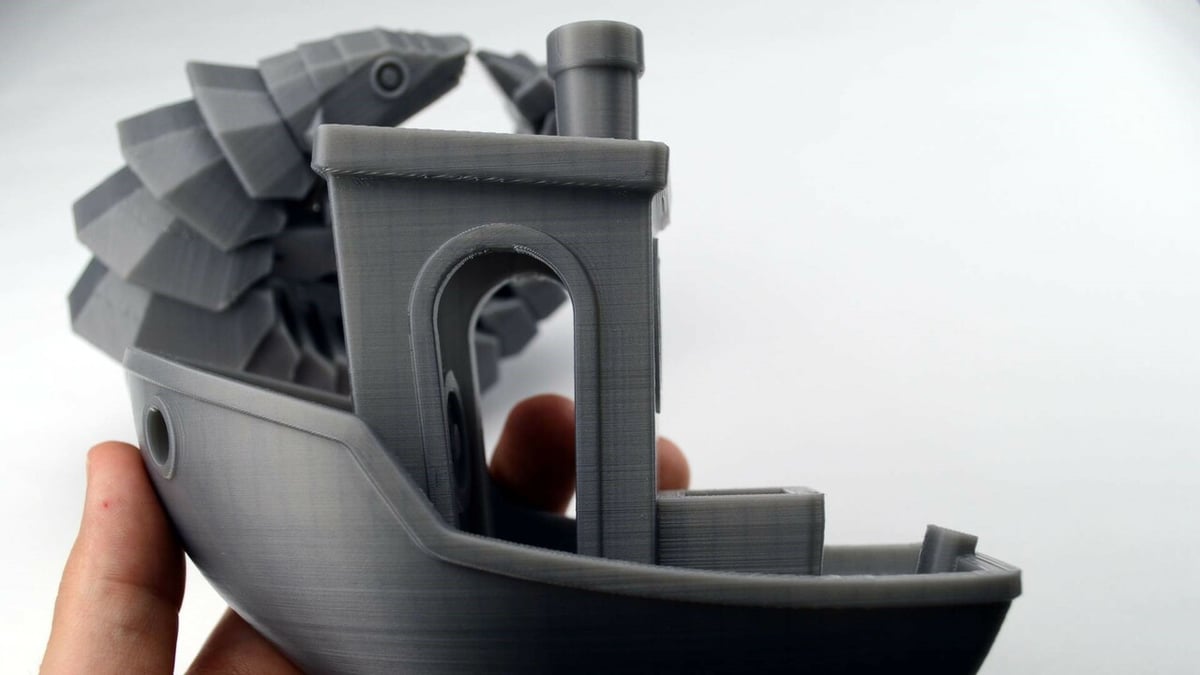

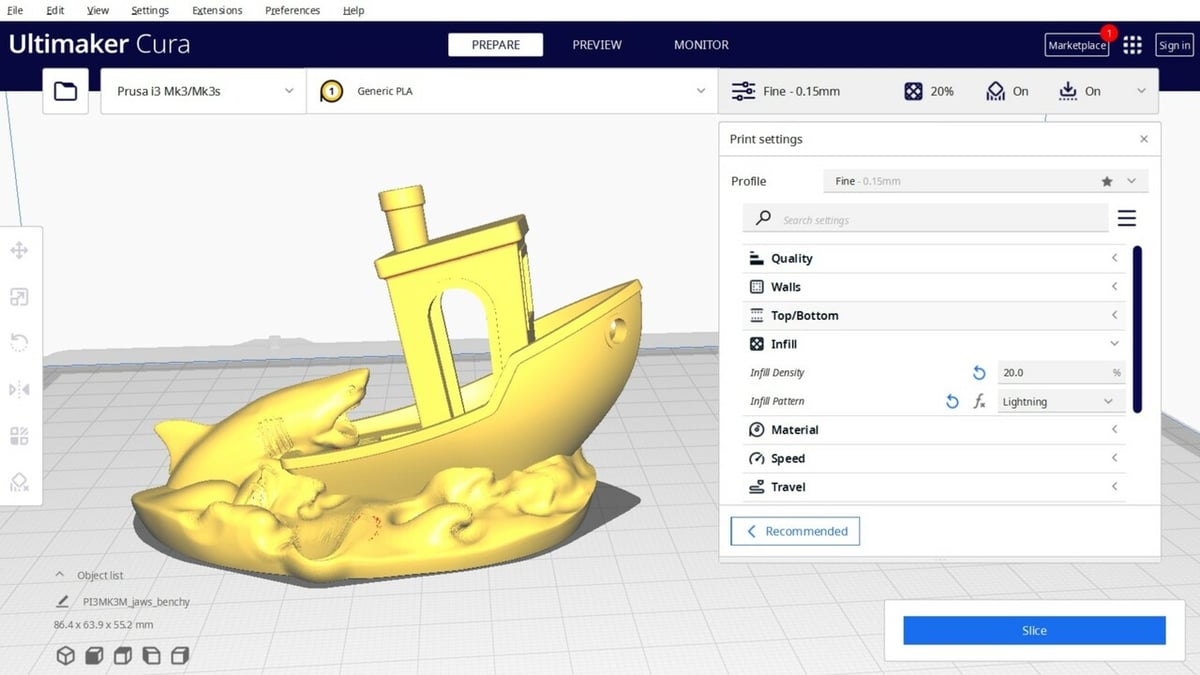

One of the most obvious differences between FDM and resin printing is resolution. Because FDM printers use molten plastic layers to create models, results tend to be less precise and accurate, as material is typically deposited in lines that are 0.4 mm in width. The actual layers are also large in comparison to resin printing, ranging from 0.1 to 0.35 mm per layer. This layer height creates visible lines on all surfaces and often prevents FDM-printed parts from being used as final models.

To resolve the issue of visible layer lines, a finished print can be sanded or even smoothed using solvent vapors. These methods can make FDM prints appear completely smooth, but take time and skill to do well and will also fade out small surface details.

Another quality of finished prints is their strength. On this stage, FDM generally performs better than resin printing and, depending on the material being used, is affected by certain print settings. For example, using a high infill percentage, an appropriate infill pattern, and an increased wall thickness will make a part stronger, but in turn, print time will be increased.

Resin

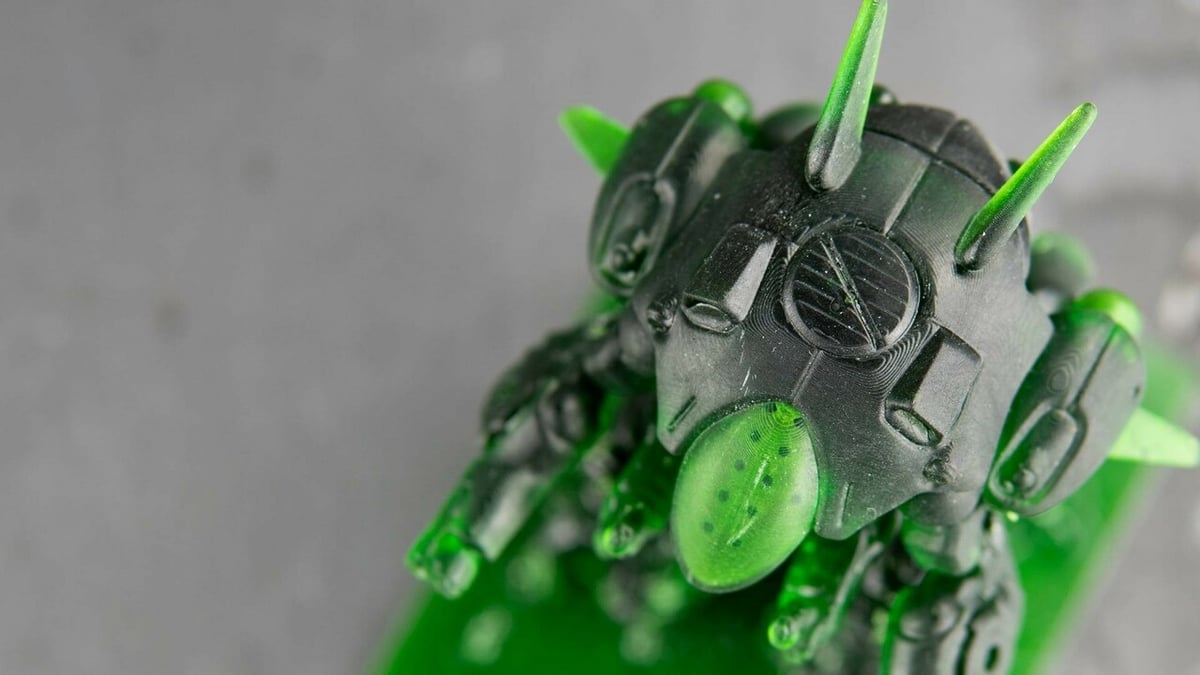

On the other hand, resin printers generally create a much higher detailed model. For this reason, resin printing is great for miniatures or high-detail models that are worth the extra effort.

Because of the technologies, layer heights are incredibly small, ranging from 10 microns (0.01 mm) to 100 microns (0.1 mm). The standard layer height is 50 microns (0.05 mm), around a quarter that of FDM printing. XY resolution is also in this range.

This tiny layer height enables the printing of incredible details and high-quality objects, with finished prints often having no signs of the layers themselves, but rather looking like one smooth solid piece of plastic. The finished prints can also be sanded to achieve even greater smoothness, but this step is unnecessary in most cases, as the layers are already so small.

When it comes to strength, tough resins produce printed parts that are generally stronger than FDM ones. However, it’s a tricky comparison because it depends on which FDM materials they’re being compared to.

Speed

Another big difference between FDM and resin printing is print speed. This is dependent on many factors, including the specific technology used and the print settings.

FDM

The time it takes for an FDM printer to finish a print depends mostly on the size of the object being printed, as well as the selected layer height, infill, and speed. Simply put, the larger the item and the smaller the layer height, the longer the print will take, and vice versa.

Another setting that affects print time is the density of the infill. The higher the density of the infill, the more filament needs to be laid down by the printer and the longer the print takes.

Resin

When it comes to resin printing, the print time is a bit more straightforward. With LCD and DLP printing, layers are cured quickly due to a whole layer being solidified in 2 to 10 seconds, no matter how much resin is being hardened per layer. With SLA machines, the print time is significantly longer, as the laser needs to travel to every point.

Other variables that affect print time are the Z-axis height, the layer height, and the time it takes for the printer to move the print bed up and back down for the next layer. Nevertheless, assuming one is using an LCD printer, resin printing can be said to be significantly faster than FDM printing in most cases.

Ease of Use

The ease of use of a 3D printer is a concern for beginners and advanced users alike, as more work leads to more time spent not printing (or doing other things). Across the various FDM and resin technologies are numerous advantages and challenges.

FDM

FDM printers are generally easy to use and therefore quite beginner friendly.

After loading filament, starting the print is pretty much all that needs to be done. After the print is done, it should be easy to remove and can in most cases immediately be used as intended. Some prints, like watertight containers, may require either very precise settings or some form of coating to get them fully ready to use. And as mentioned above, post-processing may be necessary to achieve a particular aesthetic.

Naturally, there are still some problems with FDM printers, including stringing, warping, and elephant’s foot. FDM machines typically require more maintenance and calibration to prevent these problems from occurring.

Resin

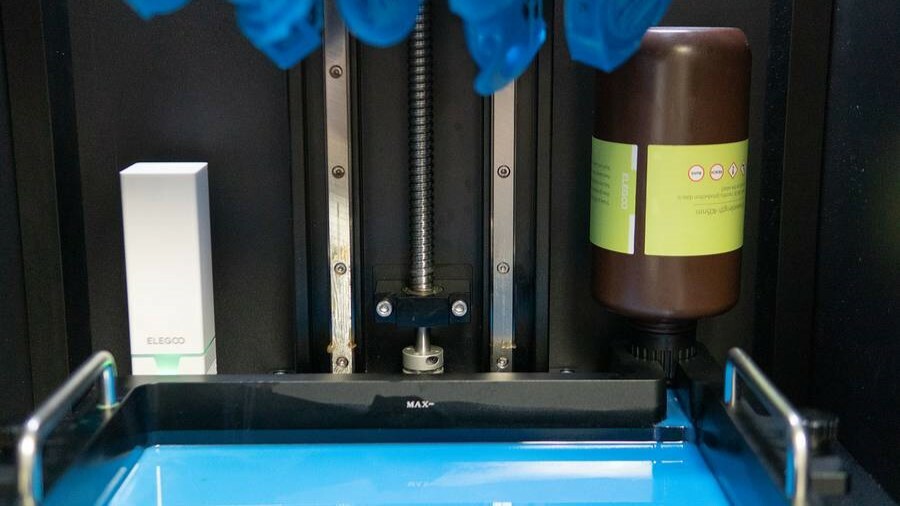

In contrast to FDM printing, resin printing requires a bit more to be safe and successful. Firstly, resin is toxic, meaning it’s not safe to touch, and the vapors aren’t safe to inhale. Due to this danger, gloves and masks are required when handling resin and prints before they’re fully cured.

A key feature of all resin printers is that they have a hood that covers the build area and resin vat. These hoods are often seethrough orange or red plastic. Their main jobs are to block UV rays from hitting the uncured resin in the vat and to protect onlookers’ eyes from the UV light in the printer. Additionally, the hood is meant to keep the toxic and often smelly fumes from spreading.

After the resin is loaded into the machine’s vat, the printing process is relatively simple. But a print newly removed from a printer is still covered in uncured resin. This resin needs to be washed off using a solvent, in most cases isopropyl alcohol. The print then needs to be fully cured under a UV light source like a dedicated lamp or simply the sun to bring it to its final state. After all these steps have been completed, the print can now be handled normally and is no longer toxic.

These extra steps mean that resin 3D printing has a higher learning curve, so it’s not necessarily as beginner friendly as FDM printing. Additionally, the overall workspace will also have to be bigger and equipped with extra supplies and facilities (for curing and washing).

Resin printers have some common problems that lead to failed prints, but these are generally easier to solve than with FDM printers. The biggest failure point is that cured layers don’t stick to the build plate.

And as a final and just as important note, proper disposal of resin is a must.

Price

Another deciding factor is the price of the two printer types. Both can be had for relatively cheap, with machines being available in the 200-dollar range, but as size and quality increase, resin printers get pricier faster than FDM printers.

When it comes to FDM, there are great options under $200, under $300, and under $500, although those with a larger build volume can be a bit pricier. That said, while there are excellent resin printers, for larger ones, prices are at least double those of larger FDM printers. For example, the large-scale resin printer Phrozen Sonic Mega 8K S costs ∼$1,600 with a build volume of 330 x 185 x 300 mm. In contrast, an FDM printer like the Anycubic Kobra 2 Max costs only ∼$570, with a build volume of 420 x 420 x 500 mm.

In addition to the printers themselves, maintenance can be more expensive for resin machines. LCD resin printers require new screens after about 2,000 hours of use, with the price of the screens depending on the size. On the other hand, though less common in the hobbyist market, DLP printers offer around 20,000 hours of use. Meanwhile, the maintenance cost of FDM printers is generally insignificant, as there are plenty of affordable replacement parts.

Which One?

Now to the all-important question: which one is right for you?

In general, if you’re looking to have a machine that you can customize to print a little bit of everything with, FDM is right for you. These machines are perfect for printing a wide variety of objects at a reasonable quality, from large structural brackets that are strong enough to withstand heavy loads, to smaller low-detail models and accessories.

But when it comes to small models and impressive details – prints that benefit from the material’s transparency, strength, or flexibility, or a venture into jewelry printing – resin printing might be the way to go. While the learning curve may be a bit steeper and the initial investment may be a bit higher, it’s still a hobbyist-friendly option.

Making the call in one direction or another (if it’s needed) will basically boil down to this: What do you want to print and what for?

License: The text of "FDM vs Resin 3D Printer: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.