This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Getting an A in PLA

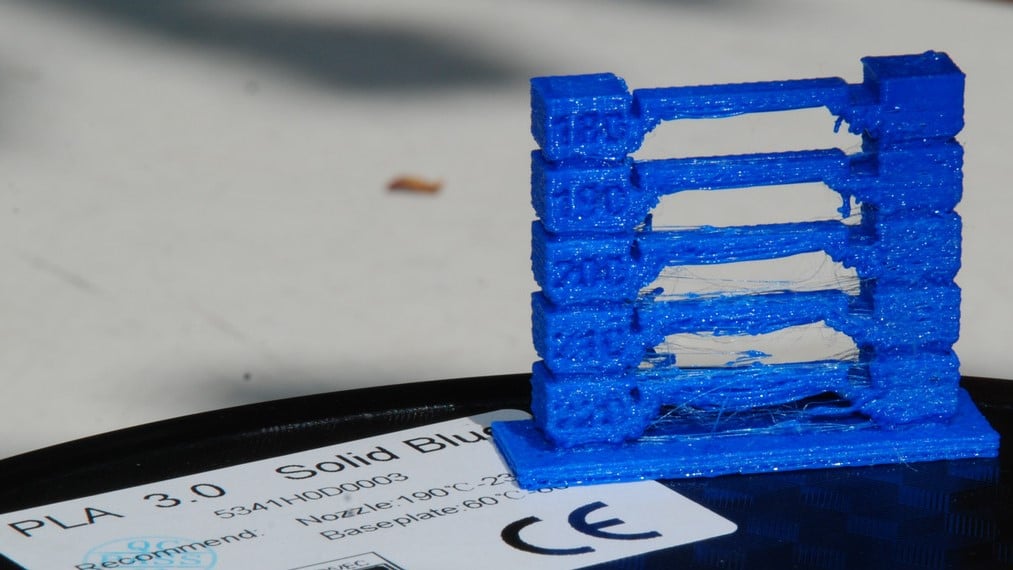

The Best PLA Bed & Print Temperature Settings

Figuring out the best PLA print and bed temperature can be tricky. Check out this quick guide to learn all you need to know.

Advertisement

Advertisement