When it comes to 3D printing, knowing which filaments you can or should use for a given project is essential. You want to make sure that you choose a material consistent with the properties you desire for your model.

If you’re trying to print something like auto parts (bumper coverings, side mirror housings) or outdoor decor and accessories, using ASA is a better choice than, for example, PLA, which isn’t the most resistant when it comes to changing temperatures.

If you’re using ABS for functional prototypes, you may want to consider ASA instead for its increased resistance against the elements, chemicals, and UV light. But, if you want to print a toy, using an easy-to-print filament that is durable, like PETG, is key.

ASA and PETG are two very popular filament types among hobbyists nowadays due to their increased impact, chemical, and temperature resistance compared to PLA.

Read on to learn the ins and outs of these two filaments, their applications, and where you can buy them.

The Contenders

Before looking at the differences between ASA and PETG, we should take a look at them separately and consider their advantages and disadvantages.

ASA

ASA stands for acrylic styrene acrylonitrile. It’s very similar to and easily comparable with ABS, but there’s a key difference in their chemical structures that makes ASA much more UV-stable, thus increasing its resistance to sun exposure. It can be post-processed with acetone and is highly resistant to various chemicals and water. ASA’s primary purpose was to replace ABS and be more user-friendly. However, it’s still not as easy to print with as PETG.

ASA can require a heated chamber or some protection against drafts. For smaller prints, you may be able to get away without an enclosure, although larger prints will need one to keep the air around the filament warm and at an even temperature. ASA also requires higher printing temperatures than PETG, so an all-metal hot end is ideal.

PETG

PETG is a modified form of PET (polyethylene terephthalate). It’s modified with glycol to lower printing temperatures and reduce crystallization, which can make the plastic more brittle. PETG is chemical- and impact-resistant like ASA, but to a lesser degree. There are also food-safe options when it comes to PETG, depending on the manufacturer.

Unlike ASA, PETG filament doesn’t require a heated chamber and will rarely suffer from warping, making it easier to use. Just like ASA and ABS are often compared, the same applies to PETG and PLA. In this case, PETG has a higher temperature resistance and can be used for prints that will sit in a hot car or outside for hours. On the other hand, PLA is arguably the easiest filament to print with but is relatively sensitive to external conditions. Although, it does also have some food-safe options.

Printing ASA

To print ASA, your hot end should be capable of temperatures from 240 °C to 260 °C. A PTFE-lined hot end will work, as those can be used up to 260 °C, but it may not be a good idea for longer printing times, as the PTFE can start degrading at 250 °C. You can try using different varieties of PTFE tubing, such as Capricorn XS Tubing. It’s designed for 3D printing and can be used at higher temperatures, around 260-270 °C. See Capricorn’s data sheet for more information on safe temperatures.

The bed should be capable of temperatures between 90 °C to 110 °C, similar to ABS, although note that it’s always important to check your filament manufacturer’s guidelines for the required temperatures. These are often found on a label on the spool.

Similarly to ABS, very minimal (to no) cooling is suggested for printing ASA. While 5-10% cooling speed may improve overhangs and overall print quality, opting to have the part cooling fan off may lead to better results.

Manufacturers will (almost) always have printing profiles for their filament, so using those is the best way to ensure your filament prints well. In general, printing ASA at around 50-60 mm/s should lead to the best print quality, although it’s worth noting that this material may require slightly more retraction than PLA, around 0.5-1.5 mm.

Printing PETG

When printing PETG, your hot end can vary between 220 °C and 265 °C. PTFE-lined hot ends typically start breaking down at 260 °C and can also start breaking down if held at 250 °C for long periods of time, so it’s best to be careful. That said, it’s advised to print with PETG with a PTFE-lined hot end in a well-ventilated area.

PETG has a low tendency to warp. Thus, bed adhesion with PETG usually won’t be an issue. However, PETG can often stick too well and rip chunks out of a glass bed. If you’re using a spring steel PEI sheet, we recommend opting for a textured surface, as PETG can rip the coating right off a smooth surface. Use a glue stick or blue painter’s tape if you only have glass and smooth PEI beds available to provide a protective layer that the filament can stick to. That said, textured PEI sheets don’t require anything special. The bed temperature can vary between 50 °C and 85 °C.

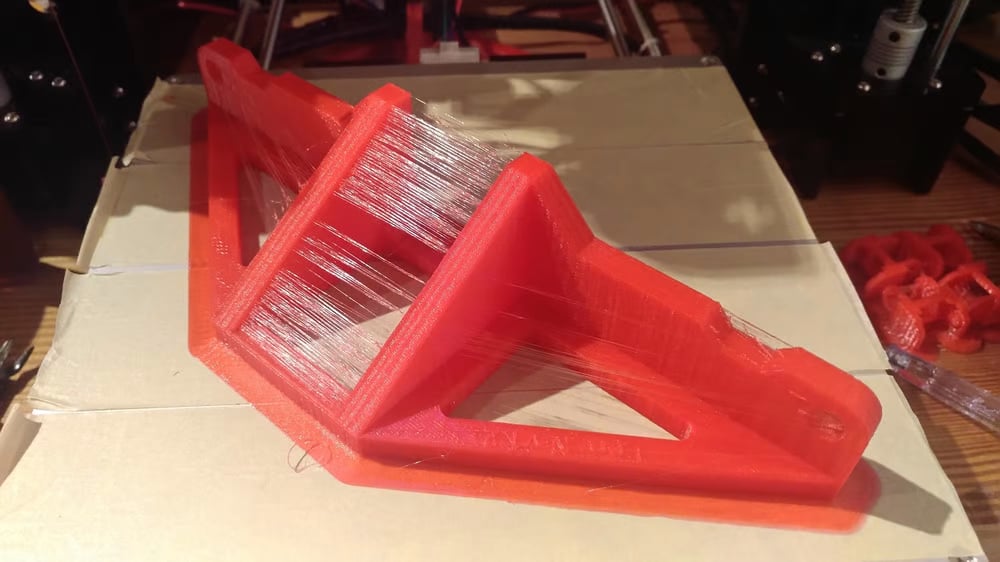

When it comes to retraction, opt for 6-7 mm when on a Bowden extrusion setup and 3-5 mm on a direct one. The higher temps increase oozing and stringing, and retraction length is more important than speed (the default slicer settings work well).

Always check your manufacturer’s guidelines for printing temperatures and printer profiles; you can tweak them as needed.

Mechanical Properties

When deciding between filaments, you want to make sure that the filament you’re using fits your use case.

ASA

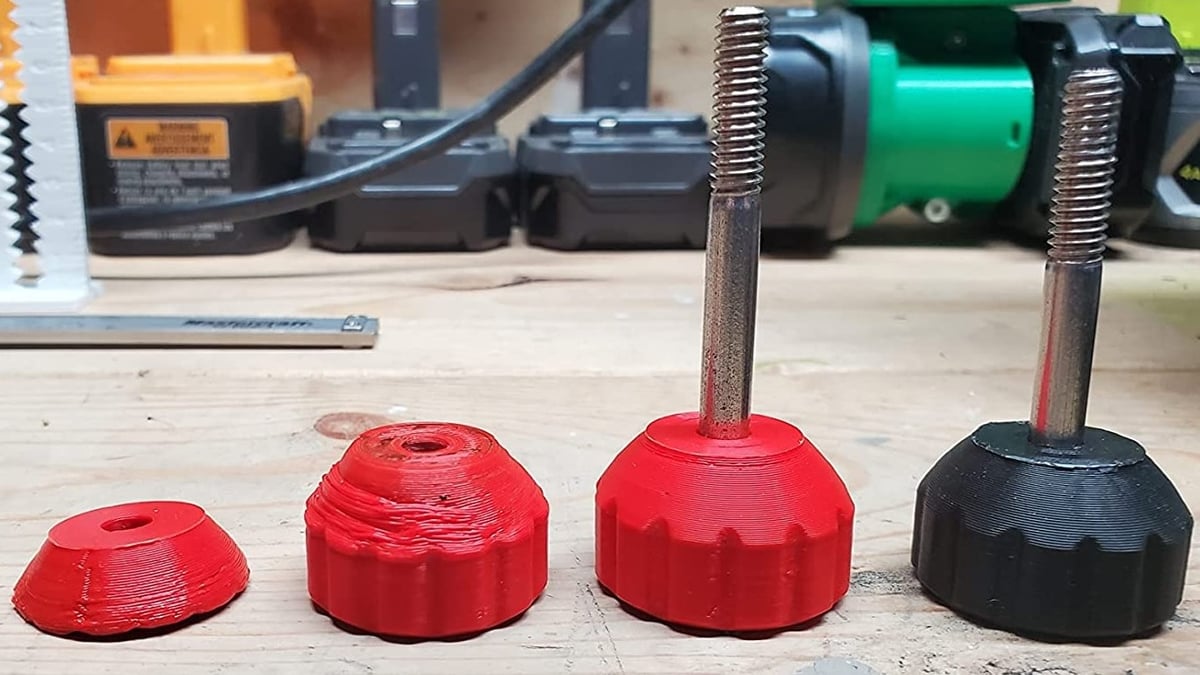

ASA shares many properties with PETG, notably its ductility, and chemical and impact resistance. However, as mentioned before, ASA is also UV-stable. This makes ASA one of the best choices for prints that need to withstand the elements. It also has a high resistance to water and high temperatures. You can print accessories for bikes, such as bells and mounts (they can get wet and muddy in the rain very quickly).

Most ASA filaments are extremely unsafe for use with food. Typically, it’s about as toxic as ABS for that purpose, and using ASA in direct contact with food or drinks of any kind is dangerous. Do not use it for any food-related purposes.

PETG

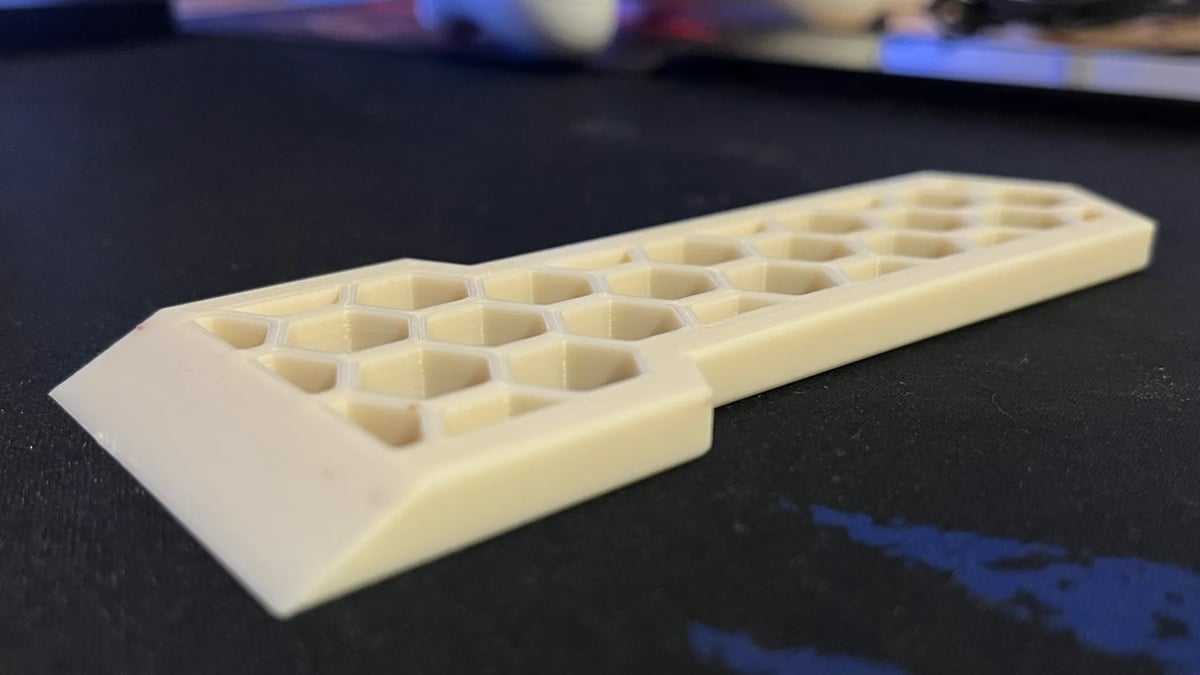

PETG is ductile, and therefore, if you bend a part made out of PETG, it’ll bend instead of snapping instantly. It can also resist high temperatures, so leaving it in the sun won’t deform it.

PETG doesn’t shrink post-printing either, meaning your prints will remain dimensionally accurate. This makes PETG a useful material for functional items, like parts for another 3D printer or gears.

Another useful property of PETG is its food-safe characteristic. PET is used in many plastic food-safe items, and PETG is PET modified with glycol, which is not harmful to humans. There are PETGs out there that are rated food-safe by government entities. Of course, it’s not all just about the filament, so a bit more information is warranted.

More Differences

Having gone over the similarities and differences between PETG and ASA, there are a few more things to consider, such as recyclability and printing safety.

PETG is recyclable at major recycling centers, while ASA is not. Additionally, printing PETG will produce very little fumes compared to ASA.

ASA releases toxic fumes during printing that can be harmful to human and animal health. Printing in a well-ventilated area is a must. ASA will almost always require some sort of enclosure to print without warping. A cardboard box or even a photography tent can work in a pinch, but opting for more involved solutions may be worth it.

When it comes to post-processing, ASA can be smoothed with acetone, just like ABS, using vapor. This means that you can often get very smooth, glossy-looking prints with ASA if done right. The post-processing may even add some water resistance due to layers fusing together.

PETG is a bit different. It doesn’t smooth with acetone, so you’ll have to do it the old-fashioned way of sanding and polishing or using epoxy coatings (which seal gaps in layers, improving water resistance). The only solvents that can be used with PETG to smooth it out are harmful.

Where to Buy ASA

Decided to give ASA filament a try? Here are some great brands to consider.

Polymaker PolyLite

First up, PolyLite ASA is an excellent filament with a low tolerance of just ±0.03 mm. PolyLite provides a lot of information about their ASA filament, including mechanical properties such as tensile strength of 43.8 ±0.8 MPa and bending strength of 73.4 ±2.1 MPa.

This brand of ASA has a glass transition temperature of 98 °C, and the manufacturer recommends drying the filament at 70 °C for six hours before use.

While reviewers have referred to warping, PolyLite recommends using a BuildTak print bed or applying Magigoo, depending on the bed’s material.

With 14 colors to pick from and the well-intentioned spool of recycled cardboard, PolyLite is as good an option as any.

Prusament

Prusa Research, the developers of the famous Prusa i3 MK3S+, also offer their own Prusament filament, which comes in PLA, PETG, and ASA, just to name a few.

Prusament ASA maintains a diameter tolerance of ±0.03 mm, which beats the industry standard of ±0.05 mm. On that note, if you’re on a budget, you’ll be happy to hear that it only costs about $30 for an 850-g spool of Prusament ASA.

Among its other qualities, Prusament ASA is claimed to be very easy to post-process, including smoothing with acetone vapor. That said, Prusa warns against using a textured powder-coated steel sheet because of the extremely high adhesion, which can lead to tears or damage to the bed.

Prusa Research also notes that their filament is great for detail on prints without any stringing (like with PETG). All in all, Prusament ASA is recommended for the brand’s known generally high-quality plastic and tighter tolerances.

Fillamentum Extrafill

Fillamentum, a popular filament brand, offers a great option called ASA Extrafill.

Their filament has a dimensional tolerance of ±0.05 mm, so it’s not the best, but it’s not too bad. At $27 for a 750-g spool, this filament isn’t as expensive as some of the other ones on this list, and you can also find 2-kg spools priced at around $70 if you know you’ll be printing many or big models.

A nice thing is that Extrafill comes in 15 colors, although it’s best to check if your shade of choice is available in the diameter you want; these include 1.75 and 2.85 mm.

The manufacturer also claims this material is recyclable (although it’s not specified how) and RoHS compliant. The drying recommendations point to two hours at 80 °C.

For makers looking for a wide variety of colors, Fillamentum may be the vivid way to go.

Where to Buy PETG

If PETG is your preferred filament, the good news is that there are tons of options on the market. Here are a few to help narrow down your search!

Eryone

Eryone PETG offers a good dimensional tolerance of ±0.03 mm and a reasonable price, at ~$20 for a 1-kg spool. 3-kg spools are also available at ~$60, in case you’re looking to print lots (and lots) of gears.

There are 11 colors to choose from, with 5 additional dazzling galaxy options in case you’re looking for some pizzaz, although these are around ~$10 more expensive per 1-kg spool.

Given the reasonable price for better-than-expected dimensional accuracy, and the options between matte, clear, and galaxy colors, Eryone might be just what you’re after.

MatterHackers Build Series

After selling filament for a long time, MatterHackers have become a household name for makers. The Build Series is the company’s consumer filament line, made to balance cost and quality.

The PETG finds a fair balance between a dimensional accuracy of ±0.05 mm and a retail price of ~$22 for 1-kg spools, although if you’re buying in bulk, the price will decrease for each spool.

With two options of diameters, there are 20 colors available at 1.75 mm and 18 at 2.85 mm, including translucent ones.

For makers who need a range of shades and want to go for a reliable brand, MatterHackers and their Build Series could be the best pick.

Polymaker PolyLite

Polymaker made the cut for its ASA, but its PETG is also worth noting. While the company offers many specializations, PolyLite is its general consumer material that covers the most popular varieties of 3D printing filament.

Polymaker’s PolyLite PETG has a standard tolerance of ±0.05 mm and is priced at ~$23 for a 1-kg spool, and among its 20 colors you can find a few transparent options for the famous PETG look. There are also two diameter options available, 1.75 mm and 2.85 mm, although as with some of the previous brands, not all colors are available for both.

PolyLite PETG is a standard material from a reputable brand, and the cardboard spool is marked so that you can anticipate how much material is left – as handy as the spool can get for organized makers.

License: The text of "PETG vs ASA Filament: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.