Today, there are hundreds of different 3D printer models on the market. These machines cover many technologies (e.g. FDM, SLA, SLS), motion systems (e.g. i3-style Cartesian, Delta, Polar), brands, features, and other classifications.

3D printers can also significantly vary in price depending on their features and target audience. For example, an extremely precise printer that can reach very high nozzle temperatures will likely be on the more expensive side and will be more appealing to businesses and professional users. When looking for a 3D printer to buy, it’s important to recognize your needs and to consider the corresponding price range before making any calls.

Of course, macro classifications of printers, especially their technology, can vastly affect price without offering much better features than a printer that uses a different technology. For example, an SLS 3D printer typically costs thousands of dollars. However, if you don’t plan to print special polymers and metals that aren’t compatible with other 3D printing technologies, you’re probably better off buying a less expensive FDM or SLA printer.

While a machine’s printing technology is fundamental, there are many other considerations you should keep in mind when looking for a printer. You can read more about what to look for in a machine (e.g. compatible materials, ease-of-use features, etc.) in our guide to buying a 3D printer.

In this article, we’ll discuss many factors related to 3D printers’ cost. We’ll go over the target users for each group, the typical characteristics of these machines, additional costs that might be associated with each level (such as expenses for maintenance and materials), and more.

DIY & Budget: $100-$300

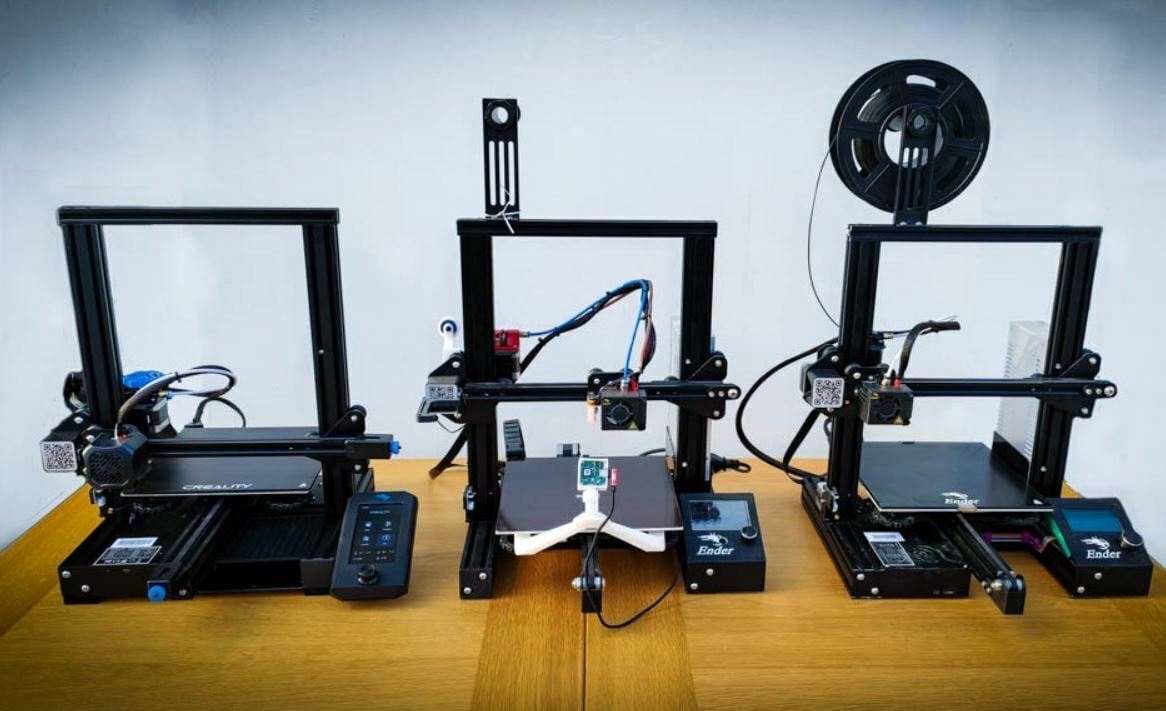

The first category consists of DIY and budget machines, which typically cost anywhere between $100 and $300. These printers are usually best for individual makers just getting into 3D printing. While they aren’t really known for their reliability, they’re a relatively inexpensive way to get into the 3D printing hobby.

Printers that fall into this category, such as the Ender 3 V2 or Elegoo Mars 2, are popular among makers, and there exist many user groups for the popular DIY budget printers (e.g. Reddit). Unfortunately, the reason for this is that these types of printers may often break and require manual fixing, which is especially true for the FDM printers. You should anticipate having to work on budget FDM printers a lot to achieve decent print quality.

Resin printers haven’t penetrated this category to the same extent as FDM printers but that’s changing rapidly with excellent additions such as the aforementioned Elegoo Mars 2 or Voxelab Proxima 6. They offer fast printing with monochrome LCD and the build volumes aren’t too restrictive, especially for entertaining hobbyists’ uses. Similar to FDM 3D printers, most can be accessed with third-party slicers, but some only allow proprietary software.

The machines in this category typically lack high-quality features for performance and user experience. As such, don’t bank on finding many 3D printers in this price range with auto-bed leveling, full-color LCDs, or top-quality air filters or purifiers on resin enclosures.

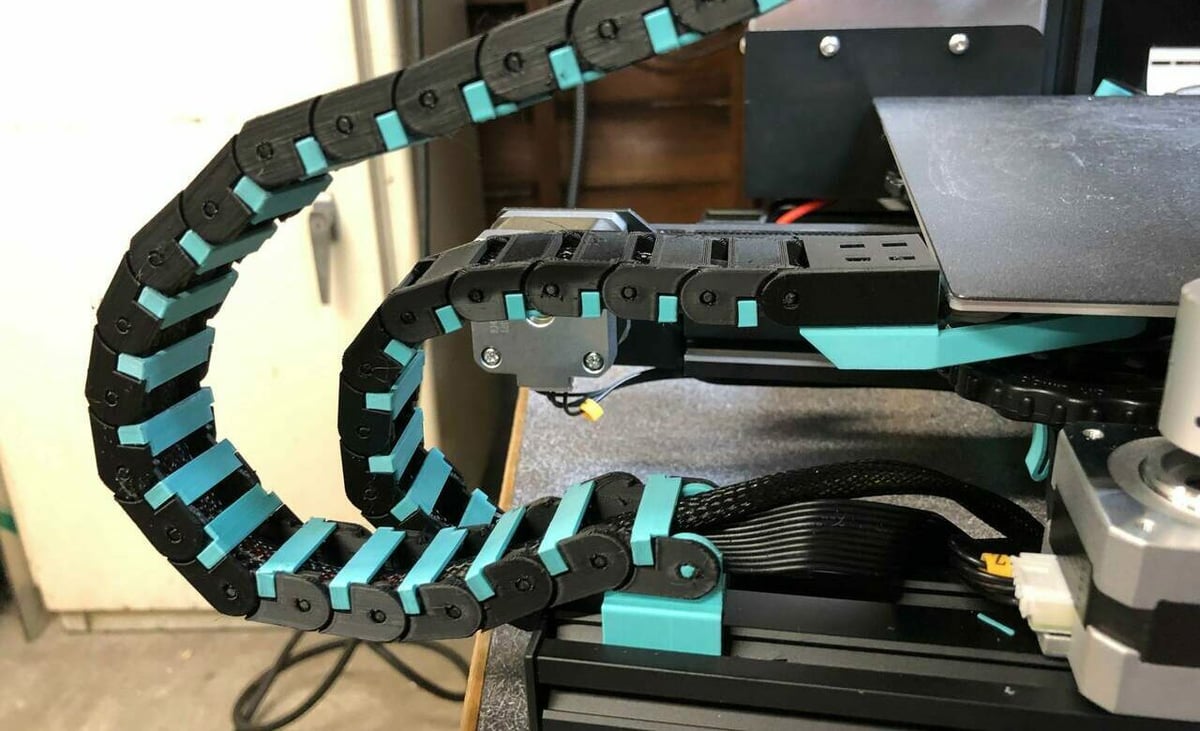

As these printers don’t come with too many additional features, many users choose to upgrade their machines with add-ons. On FDM machines, makers often add auto-bed leveling sensors or upgrade to a new nozzle, usually costing an additional $20 to $100.

Possible upgrades for resin 3D printers are less extensive in comparison to FDM printers; that doesn’t stop you, however, from making DIY user experience improvements such as a filtered enclosure.

Some post-processing work is required to achieve perfect resin 3D prints, and this is an area where upgrades can assist. Curing chambers are especially helpful and one of the most popular complimentary upgrades. A good one can range anywhere from $65 to upwards of $250.

One of the best parts of DIY and budget printers is that they have relatively low ecosystem costs, meaning that materials, replacement parts, maintenance, and other expenses shouldn’t be a significant setback. Part of the reason why these machines don’t cost much is that they use inexpensive parts, so replacing components is cheap.

For example, makers using MSLA machines should expect to replace parts such as the FEP sheet, the screen, and possibly even the build plate after prolonged use. Depending on the replacement part, the cost ranges from $25 to $80.

On the 3D printing material front, FDM printers in this price range can usually print the most basic materials, such as PLA and PETG. Still, for higher-temperature materials (e.g. ABS, ASA), the compatibility depends on the temperature limits of the specific printer.

Contrary to the material restrictions of FDM printers, resin printers – regardless of price range – can print most photopolymer resins as long as the resins cure with 405 Nm wavelength. Some resins, however, are specifically geared to certain light sources. The brand Liqcreate, for example, offers resins tailored to SLA and DLP 3D printers, MSLA and DLP, as well as resins compatible with all three technologies.

DIY and budget 3D printers usually accept any brand of filament (or resin), so you can go as low as you want. Inexpensive filaments go for about $15 to $25 per kilogram, while standard resins start around $40 per liter. And any work done on your printer (e.g. fixing it) is typically free because you have to do it yourself.

- Target customer: Individual consumers, people new to 3D printing, budget hobbyists

- Typical compatible materials: PLA, PETG, some PLA-based composite filaments (e.g. glow-in-the-dark PLA), any photopolymer resin compatible with your resin 3D printer’s light source

- Examples: Ender 3 (Pro/V2), Anycubic Mega S, Biqu B1, Elegoo Mars 2, Voxelab Aquila, Nova3D Bene4 Mono, Voxelab Proxima 6

Advanced Hobbyist: $300-$1,000

Next, while advanced hobbyist printers are more expensive than DIY and budget 3D printers (usually $300 to $750), they typically offer many benefits that you may find worthy of the extra dough. Under the $1,000 mark, these printers are popular and useful for individual users who have experience working with 3D printers. Small businesses may also find the printers in this price range useful for small operations.

As you might assume given the higher prices, the machines in this group tend to be more reliable. You can expect to have to do less tinkering, but don’t throw out your toolset just yet because an occasional problem is foreseeable.

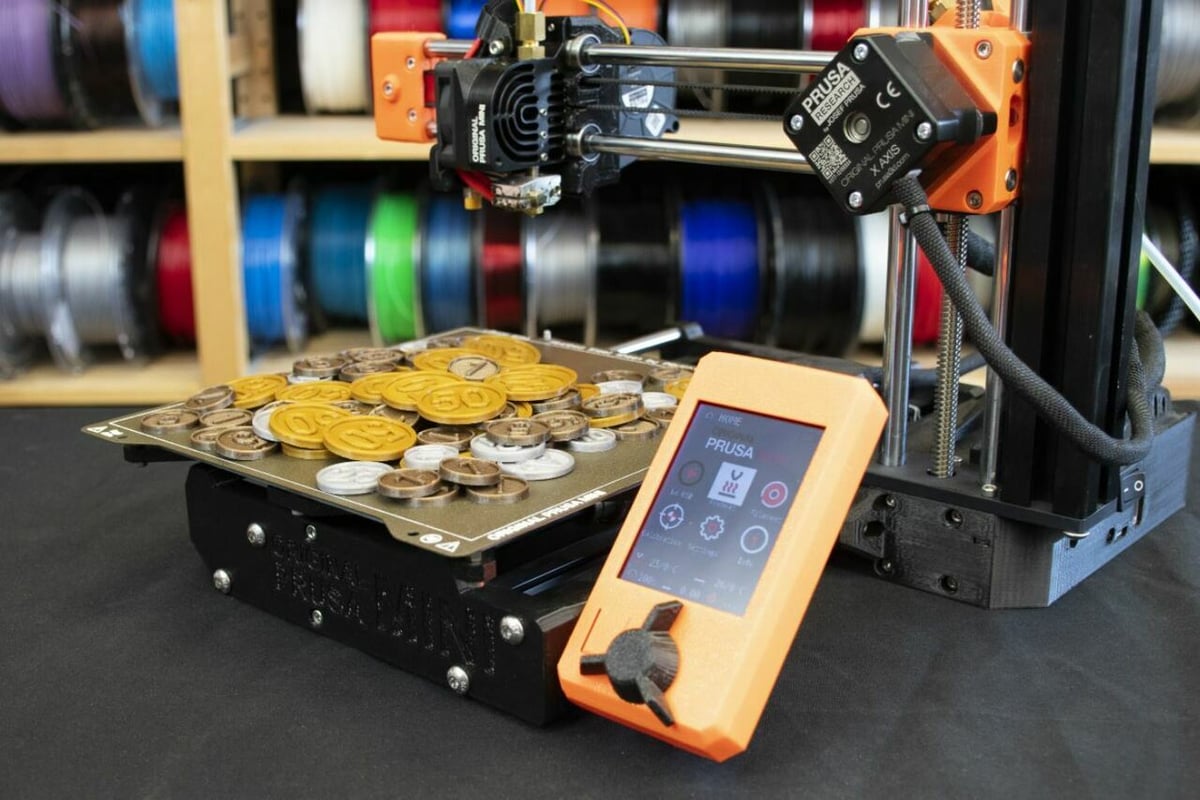

Our favorite reasonably priced resin printer falls in this section, the Elegoo Mars 3, while FDM options include the famous Original Prusa i3 MK3S+ and Creality CR-6 SE, both known for their many extra features. Other bonuses are the increased build volume and improved resolution for ultra-detailed prints, making them worth the modest added cost.

Most FDM printers in this category can handle almost all popular traditional 3D printing materials, from PLA to nylon. This group’s compatibility with some higher-temperature FDM materials means that more useful parts can be printed, such as models that will be exposed to the elements.

Resin printers in this category should function with all photopolymer resins as long as the resin is compatible with the printer’s light source and curing wavelength. The extra features and build volume also mean you should be able to print for longer amounts of time without running into issues because the parts used on these printers are usually of higher quality.

As you might expect, advanced hobbyist 3D printers have a slightly higher ecosystem cost compared to DIY machines, but it’s still relatively low compared to that of the more expensive machines. That’s because printers like the Prusa MK3S+ still use somewhat inexpensive components, so they’re still cheap to replace but they’re also more quality controlled, so you don’t have to replace them as often.

These printers can also handle whatever brand of filament you throw at them, allowing for a range of prices for materials. As for add-ons, advanced hobbyist machines usually come with a fair amount of integrated features, but many users still spend between $30 to $300 on other, more costly upgrades, like a Raspberry Pi board for printer control or a multi-material unit.

- Target customer: Experienced individual consumers, small businesses

- Typical compatible materials: PLA, ABS, PETG, PLA-based composites, TPU, nylon, any photopolymer resin compatible with your resin 3D printer’s light source

- Examples: Original Prusa Mini+, Anycubic Photon Mono X, Original Prusa MK3S+, Creality CR-6 SE, Creality CR-10 V3, Anycubic Mega X, Phrozen Sonic Mighty 4K

Professional & Performance: $1,000-$5,000

Third, this next price range has a mixed target audience, including experienced and professional individuals as well as small and medium-sized businesses. These printers fall in a weird price range, one that’s on the higher end for an individual consumer but that’s not too much to spend for a business. Nonetheless, these printers are great all-around machines that offer many professional features to yield high-quality prints.

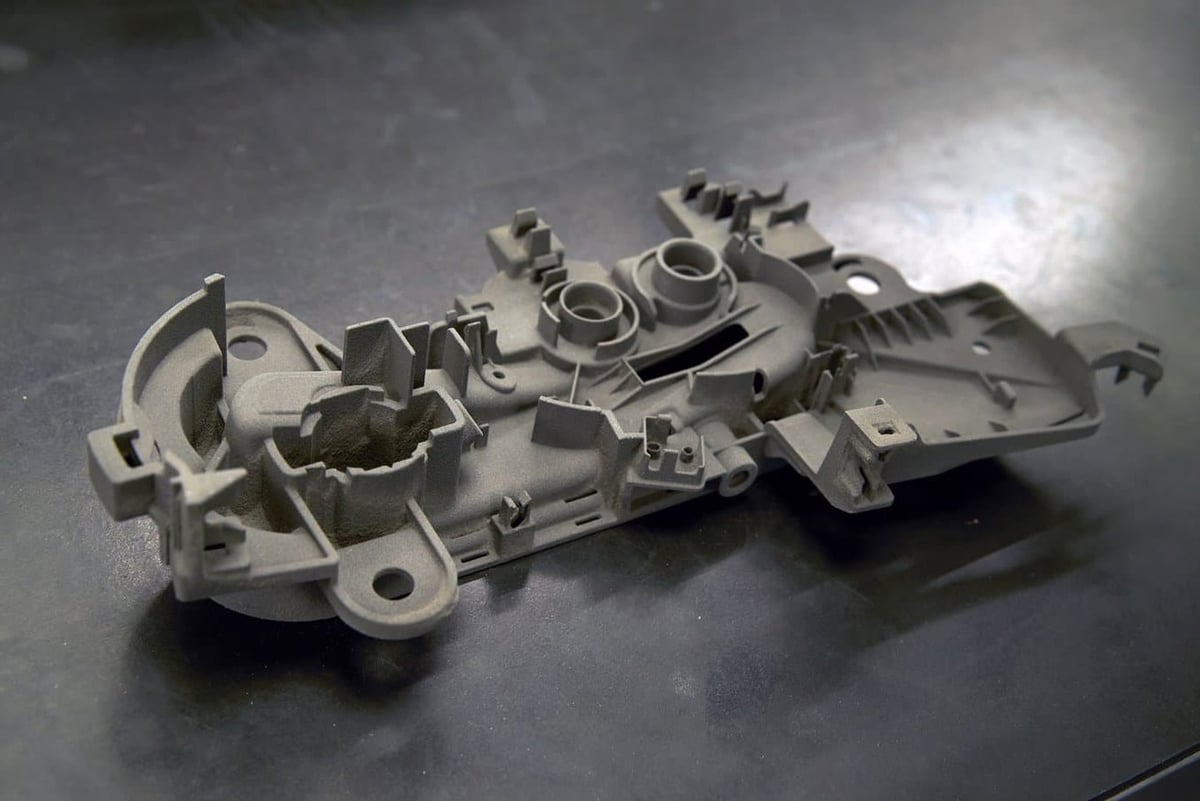

While we’ve left the DIY category behind, one exception that’s worth mentioning is the Sintratec Kit, the most affordable SLS printer option on the market. This kit requires some work and can run a touch higher than other price points in this category but is a great entry point to SLS printing for professionals or performance enthusiasts who are hesitant to plunk down the cash required of most industrial printers. The machines focus on prototyping also fit with FDM printers in this category that are popular with manufacturers, architects, and other professionals for the same purpose.

Resin 3D printers in this category allow for speedy and high-detail prints. The assortment of available resins for them includes resins that cater to generalist users as well as those that are industry-specific (e.g. dental resins and castable resins). On the FDM side, machines in this category often come with industrial features and robust extrusion systems capable of handling professional materials such as carbon fiber, polypropylene, acrylic, and even some metals.

These printers also are packed with other features to ensure your experience is as smooth as possible, like a full-color LCD, more interface ports, Wi-Fi compatibility (remote access), and more. You’ll also find many performance features on these printers that result in high precision and accuracy for 3D prints, such as integrated leveling sensors and other devices.

While users and businesses won’t spend as much on upgrades and add-ons as they might with DIY or advanced hobbyist machines, there are other costs associated with professional and performance 3D printers. For example, many of these machines are confined to a certain brand of material, which usually costs around $50 to $80 per kilogram.

Plus, as these higher-grade printers are usually more complex than the machines in the previous classifications, maintenance is more complicated. As such, some users and businesses may spend around $50 to $200 on machine maintenance to fix their machines, and even more (like $50 to $100) for replacement parts.

- Target customer: Very involved and advanced makers, small and medium-sized businesses, small and medium-sized manufacturing facilities

- Typical compatible materials: PLA, ABS, PETG, PLA-based composites, TPU, nylon, PC, carbon fiber-filled, CPE, PP, PMMA, POM, some metals, other special polymers, PA 12, TPE, any photopolymer resin compatible with your resin 3D printer’s light source

- Examples: Formlabs Form 3, Ultimaker 3, MakerBot Method X, Markforged Onyx One, Delta WASP 2040 Industrial X, Sintratec Kit

Business & Industrial: $5,000+

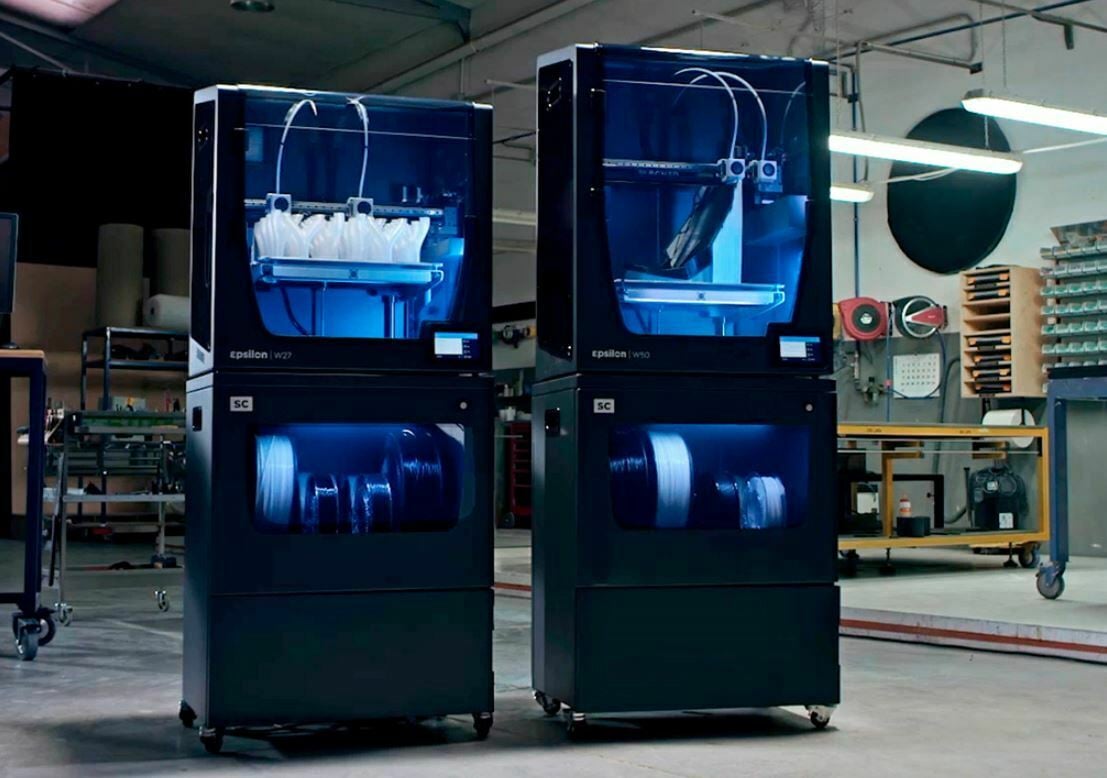

Lastly, the business and industrial 3D printer categories are meant for professional businesses and large-scale manufacturers who need 3D printing to run their businesses. The printers in this category aren’t for your average Joe and can cost anywhere from $5,000 to hundreds of thousands of dollars. Typically, at this price range, you’ll mainly be seeing SLS printers and other special 3D printing technologies (e.g. binder jetting), but, of course, there are still industrial FDM and resin 3D printers.

So, are these printers worth the price? Well, if you’re a huge company that needs 3D printed parts and prototypes daily to function, you’re probably okay with paying a pretty penny for reliability in a machine. Of course, these industrial printers can still break down (all printers can), but this happens less. Unfortunately, these industrial printers usually require maintenance by company-authorized professionals, meaning you can’t fix the machine at a moment’s notice.

Other benefits of these business printers include exceptional ease-of-use features, like an onboard touchscreen tablet with a well-developed user interface. These SLS machines also have tons of performance-driven features, like sensors everywhere to detect any problems and attempt to fix them, integrated filament storage boxes, and enclosures to keep heat in and external factors away. FDM printers in this category boast extruders that can reliably hold temperatures far exceeding what hobbyists will find available in their price range, and added automation to reduce manual calibration.

Industrial printers also boast far more filament material options from PLA to titanium, as well as lightweight, aerodynamic polymers used in rockets. Some of these materials are available to print with because additive manufacturing has advanced well beyond the big three forms of 3D printing.

Selective laser melting machines are one of the most popular new technologies, with machines usually costing between $100,000 to $300,000. Other methods include ultrasonic additive manufacturing, concrete deposition, laser bed fusion, and laser-engineered net shaping. You’ll be lucky to find any of these machines near the bottom of this category’s price range and should instead expect most running six figures with some even passing the million-dollar mark. You can check out our buyer’s guide for more information if your company’s considering adopting one of these new technologies.

These machines all fall into a price category that isn’t realistic for consumers. Most of the websites don’t list a price and instead require contacting a sales rep, reminding consumers that if you have to ask what it costs you probably can’t afford it. The machines, however, are quickly being embraced by businesses in fields including medicine and aviation. With the prices being out of reach for many, there is much anticipation for the price points to fall and the technology to proliferate similar to how the big three – FDM, SLS, and SLA – have.

Although you most likely won’t be getting any of the machines in this category for personal use, it’s a good category to consider if you have affiliations with a business or manufacturing plant. That’s because 3D printing can be a valuable technology to make certain types of products (e.g. parts with variable infill density), and these printers are the top-of-the-line.

As you might expect with industrial printers, they’re less likely to break, but when they do, they’re very expensive to fix due to their high-quality components. Businesses can spend anywhere from $100 to $3,000 on maintenance and replacement parts. Also, materials for these printers cost a lot too. Usually, the machines can only print a certain brand of material, setting back businesses another $75 to $150 per kilogram.

Energy consumption on these top-of-the-line machines is also a cost consideration because these printers’ advanced specs tend to consume a lot more electricity than printers in the previous sections. Energy prices vary by region as well as geopolitical events, so if the machine is used a lot, it can mean an extra $50 to $200 per month for basic use.

- Target customer: Professional businesses, large-scale manufacturing factories

- Typical compatible materials: PLA, ABS, PETG, PLA-based composites, TPU, nylon, PC, CPE, PP, PMMA, POM, aluminum, titanium, many other metals, cement, special polymers, any photopolymer resin compatible with your resin 3D printer’s light source

- Examples: Peopoly Phenom XXL, Formlabs Fuse 1, Sintratec S2, Ultimaker S5, BCN3D Epsilon W50, 3D Systems ProX SLS 6100, XYZprinting MfgPro230 xS, Stratasys F900, 3D Platform Excel, Trumpf Truprint 1000

Final Thoughts

Overall, no matter how much money you’re willing to spend (unless it’s under $100), there’s a 3D printer that fits your budget. While our price groupings suggest that the more you spend, the better the printer you get, this philosophy isn’t always true. For example, when properly tuned, the Ender 3 – one of the least expensive printers available – can perform just as well or even better than machines that cost over $1,000.

For this reason, make sure to research a printer before buying it. Even though the price may seem like the most important factor, make sure to consider the use that you’ll be giving it. Keep in mind the suggested reliability, print quality, and ease of use of the machine, as well as any external and variable costs associated. Lastly, YouTube reviews, blog posts, and articles are a great way to get honest feedback on a printer before you commit to buying one.

License: The text of "How Much Does a 3D Printer Cost?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.