This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

In Form

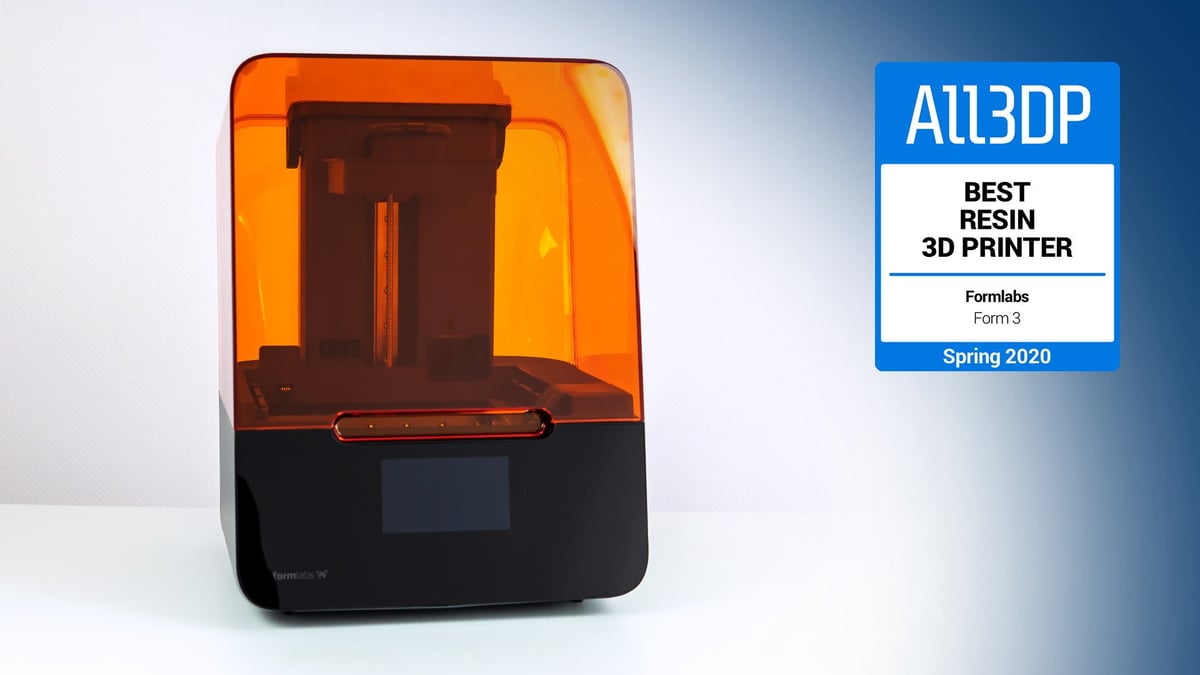

Formlabs Form 3 Review: Best Resin 3D Printer 2020

Rating

The Formlabs Form 3 is the successor to the famed Form 2. Our current top pick for "Best Resin 3D Printer", check out our full review to learn why.

Advertisement