From print-at-home hobbyists to industry professionals, many users need to get their work done quickly. They may be dealing with large volumes of printable files or may simply need to cut down on lengthy printing times. What they (and we) would like to know is, how we can print faster.

When referring to speed, most users are talking about how much overall time it takes to print their items. In technical terms, when we talk about 3D printing speed, we mean the rate at which the printhead moves while printing. This can be expressed in various units, but mm/s is the most common for speed (velocity) and mm/s2 for acceleration.

In this article, we will discuss the most important factors that play key roles in the speed of 3D printers. Then, since printing speed can’t really be compared across technologies, we will go over each one individually. For each technology, we’ll also showcase some of the fastest 3D printers we’ve come across as of 2023!

Factors that Influence 3D Printing Speed

Technology

The starting point to define how 3D printing speed is influenced is related to the technology used, as each one has specific characteristics.

FDM

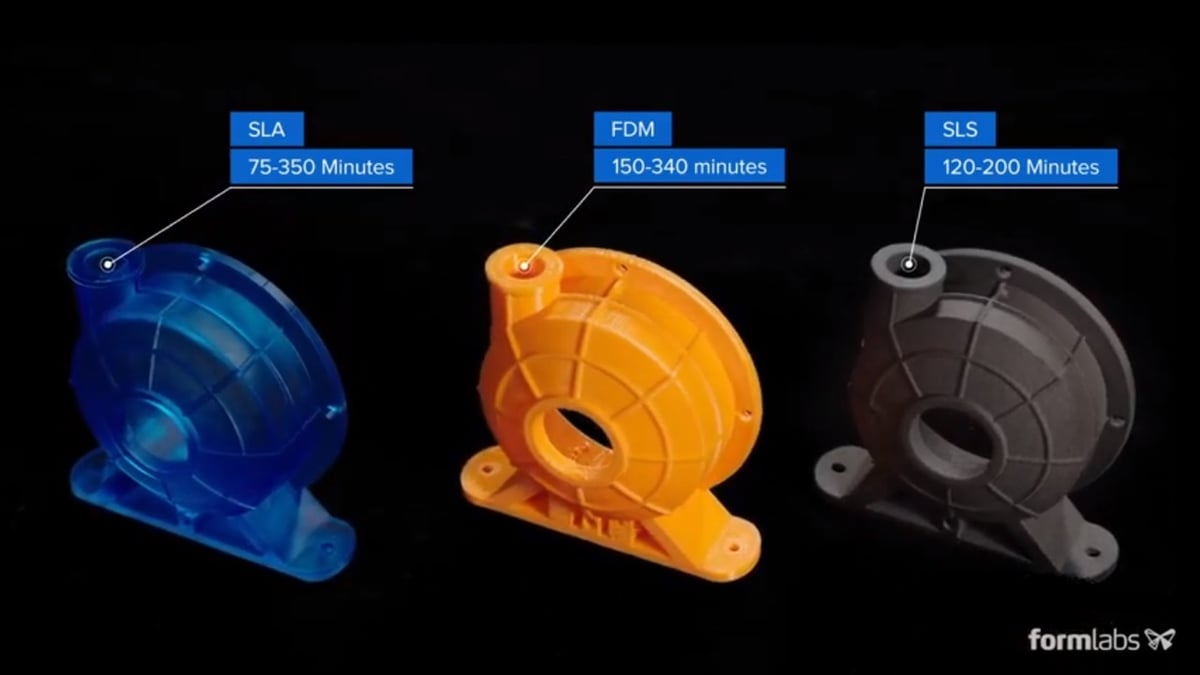

Fused deposition modeling or FDM uses solid materials of different types. In a nutshell, with FDM 3D printing, filament is melted and the model is made, one layer on top of the previous one at a time. This technology can be fast for small parts (e.g. a hose adapter), though it is usually slower than other technologies for medium-sized parts (e.g. a pump housing) or multiple-part objects (e.g. razor heads). Speeds even vary quite a bit within FDM, as different filaments have different requirements for best results.

Resin (DLP, LCD, & SLA)

While all three, DLP, LCD, and SLA, use resins for printing, what separates them from each other is how they expose the resin to light. In a few words, with resin 3D printing, the resin is in a vat, the light source cures a layer, and the bed moves upwards; another layer is cured, and so on. Typically, DLP and LCD technologies are faster than SLA because in the latter’s case, one spot is cured at a time, while whole layers are cured altogether when using the former. That said, this shouldn’t be considered an absolute fact since there are many influencing factors.

SLS

SLS or selective laser sintering is a 3D printing technology that uses unsintered powder and doesn’t need any support structures. SLS uses a laser (e.g. fiber laser, diode laser, CO2) to selectively sinter particles of a polymer powder together, layer-by-layer. It is famous for its industrial applications to create strong and durable parts. Therefore, you should proceed with this technology if strength is your priority over time.

MJF

Multi-jet fusion is a rather new high-speed technology developed in 2016 by HP. It uses powdered thermoplastics to create high-quality parts in fine detail. It is similar to SLS since both are based on powder bed fusion. However, Hubs states that MJF prints faster than SLS, and PolyD claims it is approximately 10 times faster. The main reason for this fast speed is that this technology enables whole layers to be printed at once using infrared rather than point-by-point with a laser, as in SLS.

Model & Print Settings

Factors that influence 3D printing speed could be complex and even contradictory. Users need to weigh their pros and cons carefully before choosing which ones to modify.

Slicing Software Speed Settings

Various printing speed settings can be adjusted in slicing software, such as Cura or Simplify3D for FDM and Lychee or ChiTuBox for resin-based printing. However, there is a trade-off between speed and quality. Altering these without making other adjustments, such as jerk and acceleration, has the possibility of turning out lower-quality parts.

The difference between speed and acceleration has to be mentioned. While we won’t go into the physics of it, let’s use an example to explain the difference. In FDM, your printhead can’t leap from 0 to 40 mm/s in an instant, it needs to accelerate to that speed. If acceleration is set to 10 mm/s2, then after 1 second, your printhead will be moving at 10 mm/s and after 2 seconds, it will be moving at 20 mm/s. When acceleration is set too high, it can cause the printhead to jerk, which can shake a print off the bed, miscalibrate the machine, or worse.

Size of the Print

Obviously, larger parts will have more layers with greater cross sections and their printing times will be longer. You should note that in certain printing technologies such as LCD and DLP, height is more important than width because, when a model becomes taller, its number of layers (and thus, printing time) increases. Looking at LCD or DLP and FDM, because the former harden layers at 2-10 seconds, they can be said to print faster than the latter, given that it has to lay down the whole layer. That said, there are still a few more factors in play.

Quality of the Print

This means how closely and to what extent the printed part conforms to the 3D slicer model and whether or not they are similar enough.

Model Complexity

Compared to a single solid body, a highly-detailed model composed of many constituent parts can be more complex, and will likely take longer to print. Also, it’s generally a good idea to print finer details slower. Lastly, we need to know if supports will be needed for parts that have excessive overhangs.

Model Resolution

This factor is based on how many layers the model has. Thinner layers mean higher resolution, and, thus, more time to print. Conversely, a low-resolution model has thicker layers and can be printed faster. Depending on the intended use, it’s worth noting that the different technologies also have different possibilities for layer heights. FDM can usually go for 0.05-0.1 mm as the smallest layer height, while resin-based 3D printers can go for 0.01-0.05 mm (or 10-50 microns).

Model Infill

The infill is what’s inside the model, and, depending on the technology and material, it has a direct effect on weight, strength, and durability. For FDM, infill has a variety of patterns and percentages, and they can be altered to avoid unnecessary use of filament, to decrease printing times, or to offer as much strength as possible. When it comes to printing resin, infill can also affect its durability, although it’s not such an important factor and it’s generally advised not to use unless the part in question is meant for functional use rather than decoration.

Other Factors

And, as mentioned, there’s more to 3D printing than the actual 3D printing. A few more factors include…

Preparation

This is the time you take to set up the 3D printer. Various 3D printers have different setup times. For example, the Sintratec Kit can take up to four days to build and install. Having a clean build plate for an FDM machine will also give the best chance for a strong first layer, and FDM machines need to be calibrated more often than resin-based 3D printers.

Post-Processing

There can be various activities carried out on the model in the post-processing step after it is printed. Support removal affects all technologies that opted for them. For FDM specifically, more activities can be painting, sanding, and smoothing, whereas for resin prints, these refer to excess resin removal and post-curing. While resin-based 3D printing may be faster in general terms than FDM, the time required to wash and cure the models can’t be minimized, as it can, in some instances, take up to 24hs.

SLS also has some post-processing involved, from waiting for the build chamber to cool down to removing the loose powder (and collecting it to reuse it), so there are a few more minutes (or hours) that have to be added to the whole process.

Manufacturers like HP have their own post-processing stations for removing 3D printed parts from the powder bed when it comes to MJF. The duration of post-processing will depend on your expectations from the printed part’s appearance as well as mechanical properties such as strength, rigidity, or temperature resistance.

The Number of Machines

If you have multiple machines, you can significantly reduce the print time for large volumes and batch printing. There are limitations though. Each printer will require its own space and attention. Even for a mid-sized producer, for example, two Massivit 1800 printers cannot fit a small room together due to their huge dimensions and build volumes.

Shipping Time

If you’re making use of a 3D printing service, once your finished part is ready, this last factor comes into play. This could vary based on company policies and the shipment type and service (e.g. FedEx, DHL, UPS) it employs. For example, Xometry uses three types of shipment orders – Expedite, with 1-day shipping time; Economy, with 2-day shipping times; and Standard, which can take anywhere from 5 to 10 days.

Technologies & Detail

FDM

There are two major factors that influence the speed of printers using this technology. Firstly, there is the material that you will be using. The melting points and malleability of your material will dictate how quickly you can go. In general, you will find that the typical print speed for PLA filament is about 60 mm/s; for ABS, it’s 60 mm/s; for PETG, it’s about 50 mm/s; for nylon, it’s about 40 mm/s; and for TPU, it’s about 20 mm/s.

The next major factor is the size of the aperture from which your material is extruded. The larger the nozzle of your 3D printer, the more filament extrusion occurs and thus, print time will be shorter. However, you should take into consideration that if your model has many fine details, you might want to stick to smaller nozzles for higher resolution. The difference is like using a blunt pencil versus a freshly-sharpened one.

Besides the material and nozzle, post-processing can also add time to your overall production process, especially when compared to resin or SLS printing.

Known Fast Printer

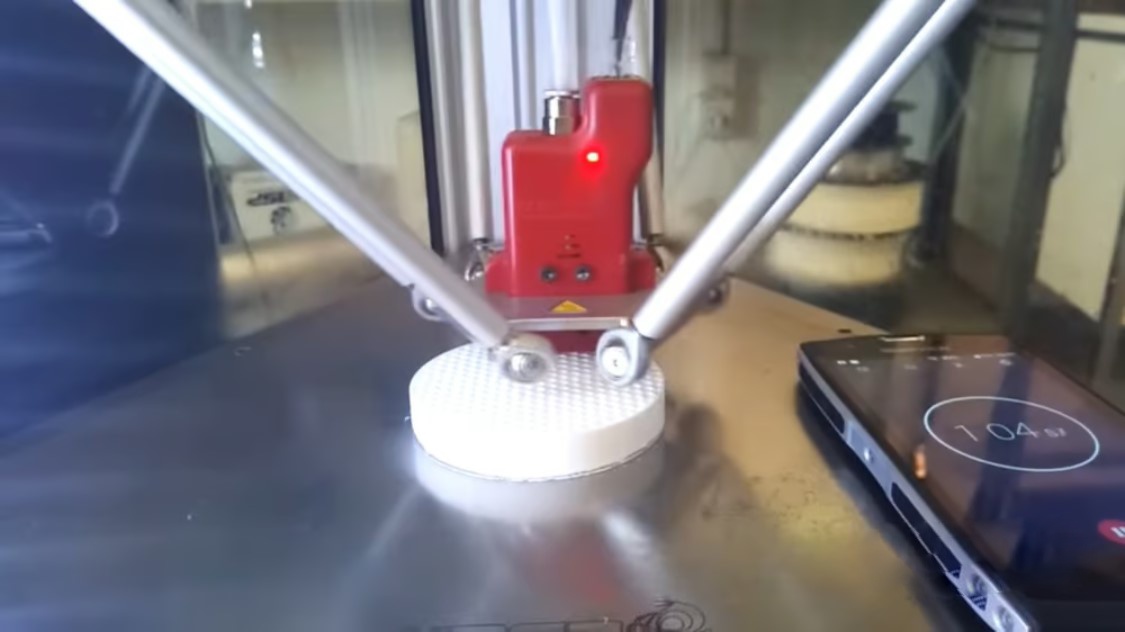

The Delta WASP 2040 Turbo 2 has been reported to reach print speeds as high as 1,000 mm/s, making it the fastest printer in the world so far. Its selling price is about $3,500. However, some Reddit users of this printer have mentioned problems with its extruder slipping and increasing the pressure on the filament causing extrusion issues. They have also mentioned the poor design of its heater cartridge.

Resin-Based Printing (LCD, DLP, SLA)

In resin-based printers, layer thickness (discussed in the Speed Factors section) is one of the primary factors. To reiterate: When the model layers are thinner, the printer will have to print more layers to achieve the same total height and it will take longer, even accounting for faster cure times. Adding to this is the time it takes to move the print bed between layers. We don’t recommend changing print bed speeds to be faster, as this greatly increases the likelihood of a failed print.

Another factor is the power of the light source. Increasing the power could result in faster print speeds because using a lower UV power requires a longer exposure time to get the desired cured layer thickness for all resins. Although more power causes faster curing, it is acceptable only to an extent since excessive power will cause damage. High-powered UV light exposure over time will damage the LCD mask, contaminate the exposed resin, and cause prints to fail. It can also destroy the chips in DLP printers. Further damage is caused by the excessive heat that is generated. Based on a Reddit user review, a UV power of 40-50 watts range would be an optimal case to reach a good balance between LCD lifespan and layer curing time.

The chemical structure of resins is cross-linked polymers. This means their structure is composed of combinations of monomers, oligomers, photoinitiators, and various other additives. Exposing these chemicals to UV light causes them to change their structure and go from liquid to solid. Variations in these combinations result in different mechanical properties and curing times.

Because of the layer-by-layer nature of LCD and DLP technologies, model geometry doesn’t have as much of an impact as the overall height. Specific to SLA, the model’s geometry does come into play. Because of the point-by-point print nature of this technology (the light source is a laser), it will print a hollow model faster than a solid one.

With this in mind, we come to our next point: print orientation. This is an important factor for LCD and DLP printers because they are printing layer-by-layer. The overall layer height has a tremendous impact on print time. A print laid on its side can usually be done faster than the upright one – though it will not make any difference for SLA.

And finally, post-processing plays a role. This step removes excess resin from the model and provides a final cure. As mentioned before, depending on the complexity, infill, and size of the model, as well as setup, curing times can last 24hs.

Known Fast Printer

The Massivit 1800, as the name suggests, is a massive printer! With a print speed reaching as high as 300 mm/sec, it is the fastest resin printer so far. You will have to contact the manufacturer directly to receive a quote from them for purchasing. A Reddit user working for a company that has used this printer has posted a photo of a two-foot wolf head printed with Massivit 1800 Pro in about 15 hours.

Selective Laser Sintering (SLS)

SLS is a different technology than filament- and resin-based 3D printers, which are more common and popular. Though, it seems to combine the point-by-point nature of FDM and SLA (because it uses a laser to sinter the material) and it uses the layer-by-layer approach of resin printing to apply unsintered powder. This means that model geometry plays an important role, as less cross-sectional area will mean less time.

Additionally, the model’s placement at the bottom of the build area is also an important factor for getting the print to actually start being formed right away. The model should be placed in the lowest possible height of the Z-axis. And, as with resin printing, parts should be oriented to have as few layers as possible. For example, a tube placed horizontally will be printed faster than one placed vertically.

Known Fast Printer

The Sintratec Kit, advertised at about $6,000, can print at a notable speed of up to 24 mm per hour over the entire build volume. Its laser speed maxes out at 650 mm/s, but by default it is set to 550 mm/s. The build volume is advertised as 110 x 110 x 110 mm. However, they recommend 90 x 90 x 90 mm for more effectiveness. Therefore, this should not be your printer of choice for larger parts. But if you have many small parts to print, the layer-by-layer nature of this printer makes it good for reliable batch printing.

Multi-Jet Fusion (MJF)

Since this is the newest of technologies and still in development, there are not many resources about its speed factors yet. Due to technology similarity, MJF must have similar speed factors as SLS. Additionally, the material types that MJF uses should also impact its printing speed. These are the five materials for this technology available at Xometry: Nylon 11 (PA 11), Nylon 12 (PA 12), Glass-Filled Nylon 12, Polypropylene (PP), and TPU 88A.

Additionally, Pick3DPrinter states that because the raw material for this technology is in powdered form, mixing it is challenging and time-consuming. Thus, this can be considered a negative speed factor. There is also a whole host of accessories on offer in order to help with cleaning and cooling parts, which makes us think these are significant time investments.

Known Fast Printer

The HP Jet Fusion 5200 is the fastest of the MJF printers. Developed by HP, it is faster than other models, such as the Jet Fusion 4200. Its maximum printing speed can reach as high as 4,115 cm3 per hour. You should contact the manufacturer directly to receive a quote from them for purchasing, though its price is extremely high. A Reddit user has purchased, unpacked, and used this printer to print some custom items and was amazed at the device and its print results. They posted a video of their printing process which took them 5 hours.

License: The text of "3D Printing Speed: How Fast Do 3D Printers Go?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.