Selecting the right filament for your 3D printer can be a daunting task, as there are so many options available. Two widely used filaments are PETG and TPU. Both materials offer unique benefits and drawbacks. PETG is a popular choice known for its strength and durability. On the other hand, TPU is valued for its flexibility and impact resistance.

To give you a clearer idea of the differences between these two materials, imagine a 3D printed storage container made of PETG. The container is strong, rigid, and capable of withstanding external force. In contrast, picture a 3D printed shoe sole made of TPU. It’s flexible, providing comfortable movement and impact resistance.

In this article, we’ll provide an in-depth comparison of PETG and TPU filaments, highlighting their printing performance, mechcanical properties, and other essential factors to consider when choosing between them. With this in mind, let’s dive in!

The Basics

Let’s take a closer look at the two different materials and explore their basic attributes.

PETG

Polyethylene terephthalate glycol-modified (PETG) is a thermoplastic polymer known for its chemical resistance, strength, and transparent qualities. It’s primarily sourced from crude oil, and the chemical components – glycol and terephthalic acid – are then heated and mixed to form raw PETG plastic.

PETG has grown in popularity in the 3D printing space due to its durability and strength. PETG filaments are popular for making a variety of 3D printed objects, such as mechanical parts, figurines, toys, and common household items. Its high impact strength and resistance to high temperatures, UV rays, water, and chemical solvents make it an excellent choice for printing parts that will be subjected to frequent wear and tear.

PETG can be more challenging to print than other materials like PLA, as it requires high temperatures and is prone to over-adhesion and stringing. However, it remains a versatile filament that can be used for many different applications.

TPU

Thermoplastic polyurethane (TPU), is a flexible rubber-like material with excellent impact resistance, durability, and elasticity. It’s made by combining a polyol with a diisocyanate through a process called polymerization.

TPU is often derived from petroleum-based sources but can also be made from renewable sources such as plants or waste biomass. The production method can vary depending on the manufacturer and their specific processes. It’s commonly used for creating flexible parts such as phone cases, shoe soles, and certain automotive parts. Its main advantages include flexibility and resistance to impact and abrasion. TPU also has excellent layer adhesion and can produce highly detailed prints.

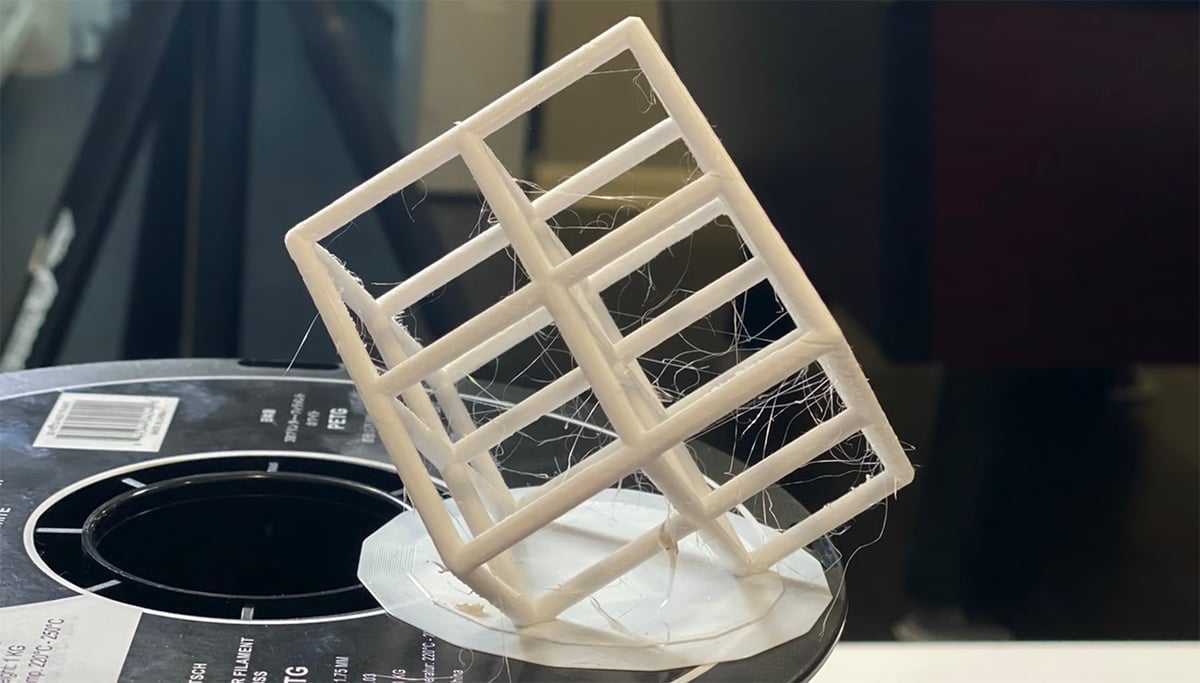

However, TPU’s flexible nature presents some challenges when 3D printing. The flexibility can make it more difficult to achieve precise and accurate prints. The material’s rubber-like consistency can result in issues such as slippage, excessive stringing, and in some cases difficulty in maintaining proper layer adhesion. These challenges arise because TPU tends to deform and stretch during the printing process, making it harder to control the flow of the material and maintain the desired shape.

Many creators find that using a direct extruder, where the extruder is located close to the hot end, yields better results compared to a Bowden extruder. The direct extruder allows for more precise control, reducing the risk of filament slipping or jamming.

Printing

There are several print issues to consider for both PETG and TPU. Generally, PETG will be easier to print than TPU, although it can also be challenging to work with and requires fine-tuning to achieve nice results.

Bed adhesion is usually the first critical issue makers face. PETG typically requires a heated bed at around 50-80 °C and benefits from an adhesive layer on the bed, such as glue or painter’s tape. Without a heated bed in this temperature range, adhesion will suffer and your prints will likely warp. On the other hand, TPU is not as prone to warping, since it’s more flexible and prints at a lower temperature. It typically prints best with a heated bed between 30-60 °C.

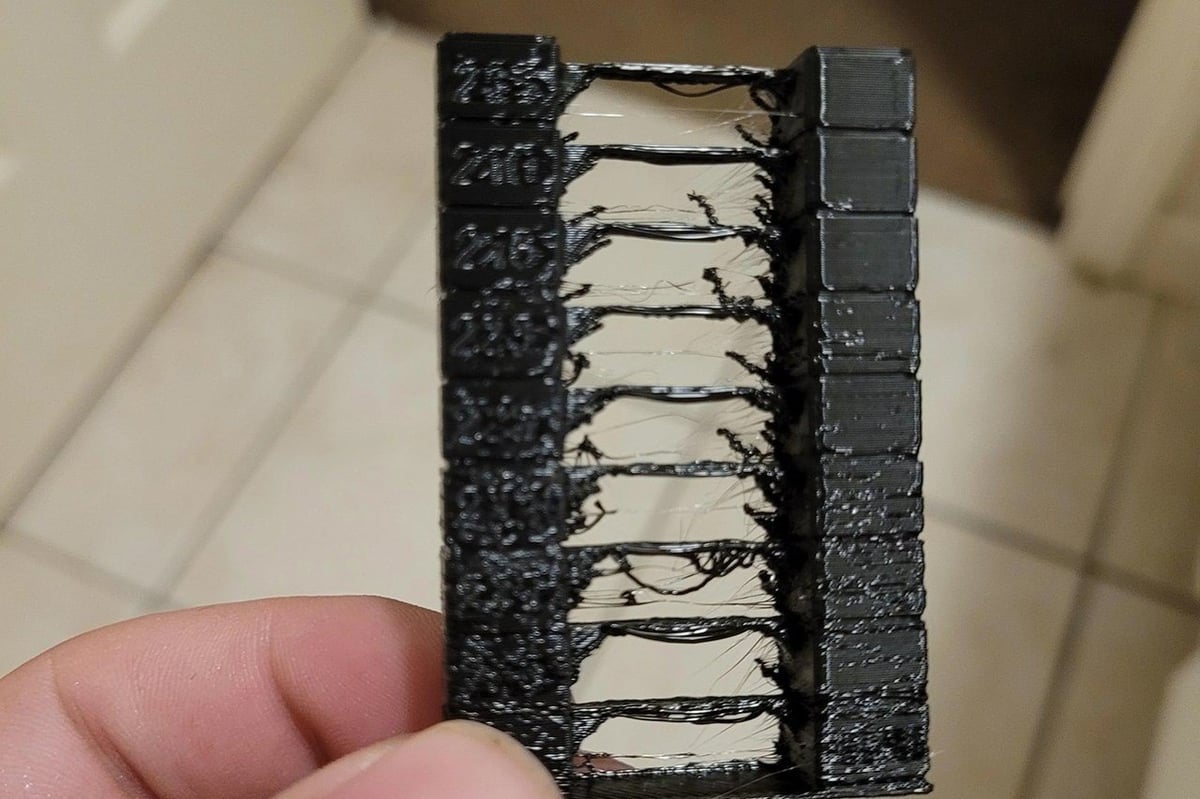

In terms of printing temperature, PETG generally requires a higher temperature between 220-250 °C. The best temperature for TPU ranges from 210-230 °C, but more flexible versions may require higher temps. If the temperature is too high, you’ll likely see stringing. If the temperature is too low, the extruder will skip. You may need to play around with your settings to achieve optimal results.

Print speed is another critical factor to keep in mind for these materials. PETG prints best at moderate speeds, whereas TPU is best printed slowly. This is because TPU is a more flexible material and requires more time to cool between layers. Since the material is so flexible, it’s prone to bending and stretching as it comes out of the extruder. If this is an issue, you can reduce the extrusion speed.

Many makers find that initial speeds between 40-60 mm/s works well for PETG with a wide range of printers. Those with a well-tuned machine can try going even higher. On the other hand, TPU requires a slightly slower print speed. Most find that starting out with a speed of 30 mm/s provides the best results.

Mechanical Properties

PETG and TPU have distinct mechanical properties that make them suitable for different applications. As mentioned, PETG is known for its strength and durability, thanks to its strong layer adhesion. It’s often used for functional parts that need to withstand stress and pressure.

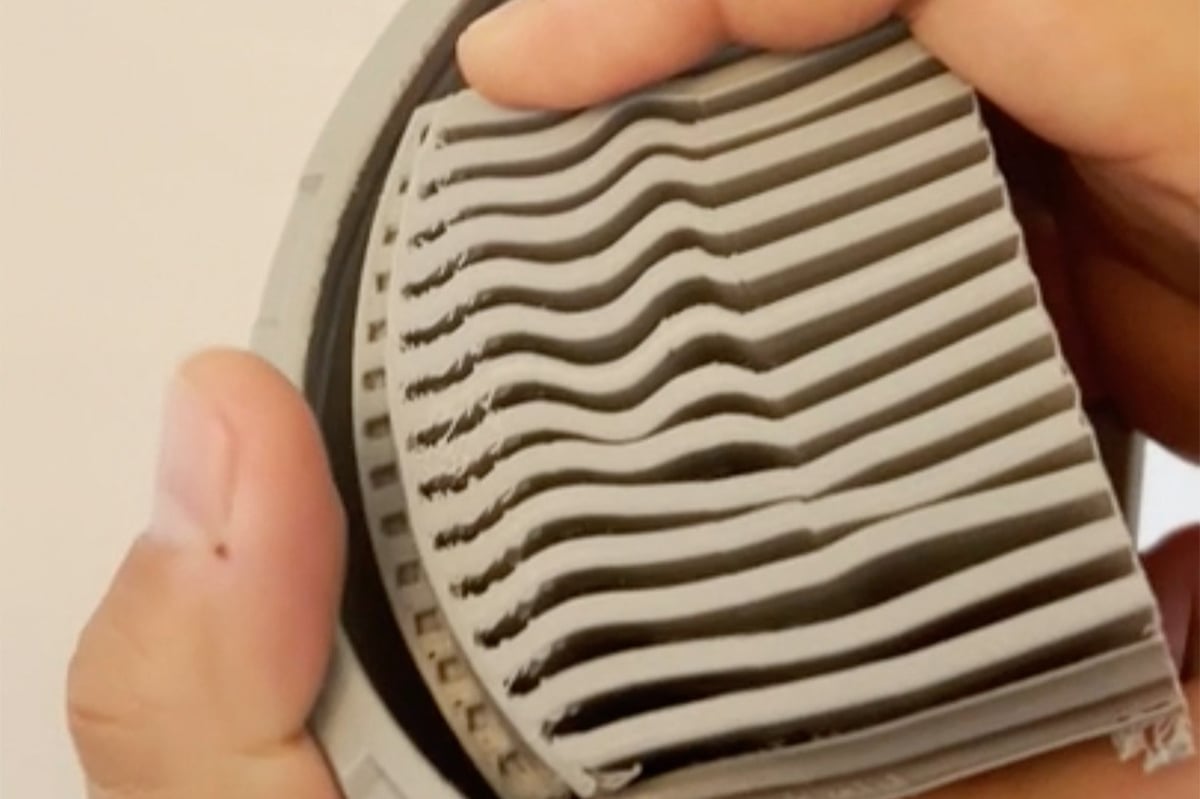

While PETG is more flexible than PLA, it’s still not as flexible or scratch-resistant as TPU. PETG will be more rigid than even the least flexible TPU filaments. TPU is a great choice for printing applications where shock resistance and elasticity are a must, such as wearable devices and prosthetics.

PETG offers good chemical resistance and is suitable for printing parts that will come into contact with certain chemicals, oils, and solvents. While TPU is not as chemically resistant as PETG, it’s flame-retardant, food safe, and even has anti-bacterial properties. PETG is more resistant to UV rays than TPU, making it ideal for printing outdoor parts that will be exposed to sunlight.

In addition, both materials can be transparent or come in a variety of colors, but PETG generally offers better clarity than TPU. PETG is also easier to dye, which you’ll have more color options to choose from. If you want to print a part in a specific color, PETG may be the way to go!

Other Differences

As you can probably tell by now, there are some clear differences in printing requirements and the mechanical properties of PETG and TPU. And the differences don’t end there. Read on for qualities that set the two materials apart.

Post-processing

Post-processing refers to any additional work that makes your 3D printed parts stronger or look better. As mentioned, TPU is known for its flexibility, which can make post-processing challenging, especially when trying to remove support structures without damaging the print.

PETG, on the other hand, is easier to post-process. Support structure removal is less of a challenge, and the print may even have a shinier finish out of the printer. However, PETG can be prone to stringing, which will require additional post-processing work to clean up.

Despite the differences, both materials can be post-processed using popular techniques like sanding. PETG responds relatively well to polishing compounds, such as Brasso. This technique smooths layer lines and enhances the effects of sanding.

If you want to paint your 3D printed parts, keep in mind that it’s best to use a paint specifically formulated for flexible materials or use a primer designed for TPU to improve adhesion.

Environmental Impact

It’s difficult to say whether PETG or TPU is more environmentally friendly, as both materials have their own advantages and limitations.

PETG comes from crude oil, which is not the most environmentally-friendly material. This means it’s not biodegradable and can contribute to environmental contamination if not properly disposed of. However, it’s recyclable, provided you can find a recycling center that will take it.

TPU, on the other hand, is often obtained from renewable sources such as plants or waste biomass. It’s also biodegradable under certain conditions, making it a preferable alternative for some applications. It’s worth mentioning that the TPU production process might still have environmental consequences, and it’s not always easy to recycle or dispose of it properly.

Ultimately, neither filament is particularly kind to the environment. The better choice depends on a variety of factors, such as the availability of recycling and disposal options and the specific filament brand in question.

Food Safety

If you plan to print anything that will come into contact with food or drinks, it’s important to first consider the food safety of your filament. Both PETG and TPU are generally considered to be food safe because they don’t release toxic chemicals when used normally. However, additives used to color the filaments may not be food safe. Therefore, it’s recommended to only use filaments that are specifically labeled as food safe.

In addition to the filament, it’s also important to consider the printer itself and the print bed. These may contain residues of adhesives, oils, or other substances that are not safe for consumption. Therefore, be sure to use separate equipment for food-related printing and to thoroughly clean the equipment before and after use to minimize the risk of contamination.

Examples

Now that you know a little more about PETG and TPU, let’s take a look at some example filament brands. While PETG isn’t as popular as PLA, especially with beginners, it’s still readily available in many of the same colors. Far fewer color and specialty options are currently available for TPU filaments. With that in mind, here are a couple of standout brands for each filament type.

PETG Filaments

Often selected as an Amazon’s Choice, Overture PETG is made of premium PETG that’s odorless, easy to print, and offers little shrinkage. It’s known for its toughness, high impact strength, and good liquidity, as it flows smoothly when printing. This filament is available in many different colors, multipacks, and even transparent options.

MatterHackers has been producing filament for some time and has a good reputation in the industry. Their Build Series PETG is affordable and intended for strong, quality 3D printed parts. The best-selling filament is available in a whopping 18 colors, including several translucent options. The bulk purchase options can drive the price below $18 per kilogram.

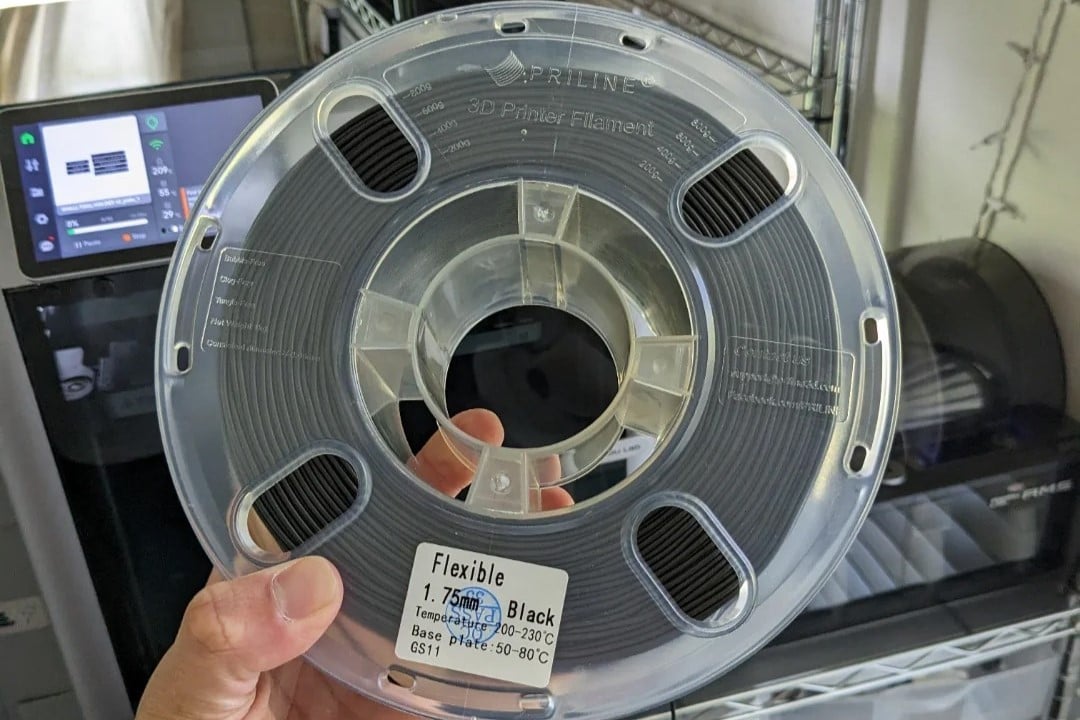

TPU Filaments

Hatchbox is one of those companies that’s known for providing an extensive array of colors for all the filaments they produce. Their TPU is available in 10 different colors, including silver, orange, purple, and blue. With a Shore 95A, this filament is flexible but still on the harder side of the available TPU options.

NinjaFlex TPU almost defies belief. With a Shore 85A, this filament is flexible while also offering amazing stretch and abrasion resistance. The color options may be limited, but the applications are not. From wearables such as watch bands to impact-resistant protective covers and flexible grippers for robots, NinajFlex’s possibilities for creating functional and innovative objects across various industries never seem to end.

License: The text of "PETG vs TPU: The Differences Simply Explained" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.