This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Baby, It's Cold Outside

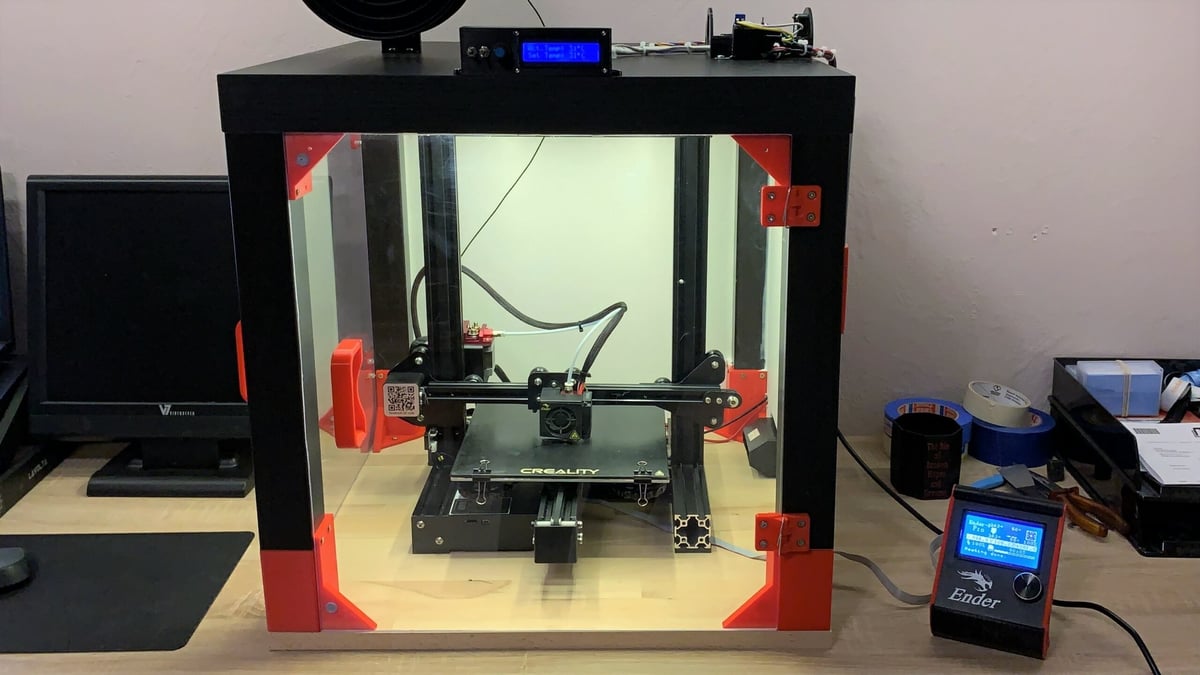

The Best Ender 3 (V2/Pro) Enclosures: 8 Simple Solutions

Expand the printing options of your Ender 3 (V2/Pro)! Whether you build or buy, read on to see the best Ender 3 enclosures.

Advertisement

Advertisement