This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

An End-uring Filament

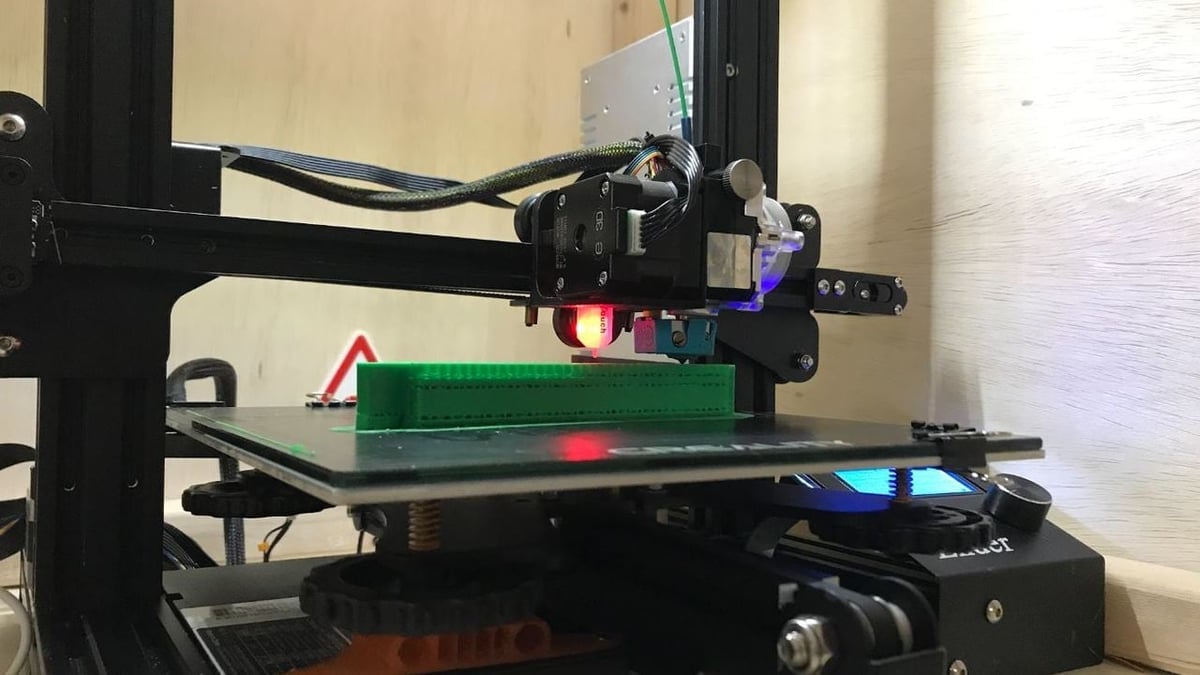

Ender 3 (V2/Pro) ABS Settings: 4 Easy Tips

Try ABS on your Ender 3 (V2/Pro)! Check out 4 easy tips to get your ABS settings right and your prints looking great!

Advertisement

Advertisement