In the early days of 3D printing, FDM makers were limited to printing one material at a time because there was only one nozzle. With the development of dual extrusion in the last few years, makers now have the power to print parts composed of two or more materials. Those who have dual extruders most commonly use them to speed up large projects, print with multiple colors, and print with water-soluble supports.

While seemingly complicated, the basis of printing with dual extruders is much the same as it is with single-extruder FDM 3D printers. Dual extruders are made of the same control modules, stepper motors, belts, tubing, build plates, and hot ends that single extruders use, just more of each. The differences that do exist are automated by the printer and accounted for in slicing software.

Although dual extrusion printers can make support removal and creating beautiful prints easier the intricacies in their design, and the need for two extruders can result in double the maintenance.

In this article, we’re going to cover the types of dual extrusion printers and how they work as well as the benefits and downsides of working with this type of device. We’ve also got some dual extruder printer recommendations and tips for getting the best possible prints from these feature-packed machines, so stick around!

Types of Dual Extrusion

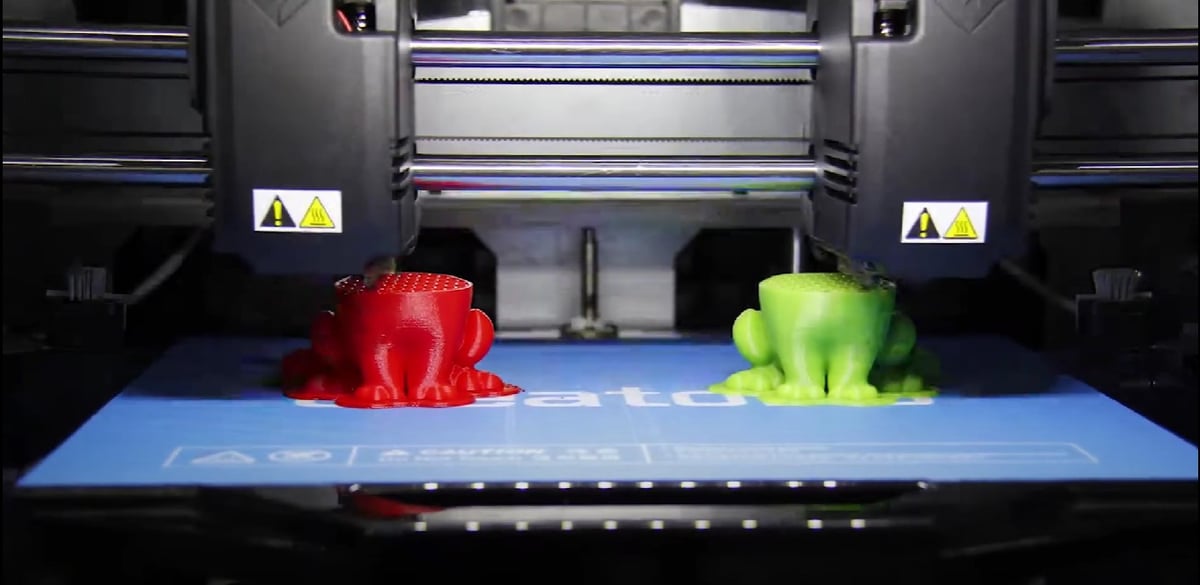

The first dual-extrusion printers looked and worked very similarly to the basic single-extrusion printers we are familiar with. These printers had a single print head with two nozzles that were great for printing two different colors in the same model or using dissolvable supports. This type of printer is said to have a dependent dual extruder.

Compared to single-extruder printers, the movement of two extruders changes how a model is sliced. The printer will require its own slicer profile to account for the second extruder and its reach within the print volume. Some dependent printers may incorporate Z-axis movement of the print bed to minimize filament tangling and reduce the workload on the heavier printhead.

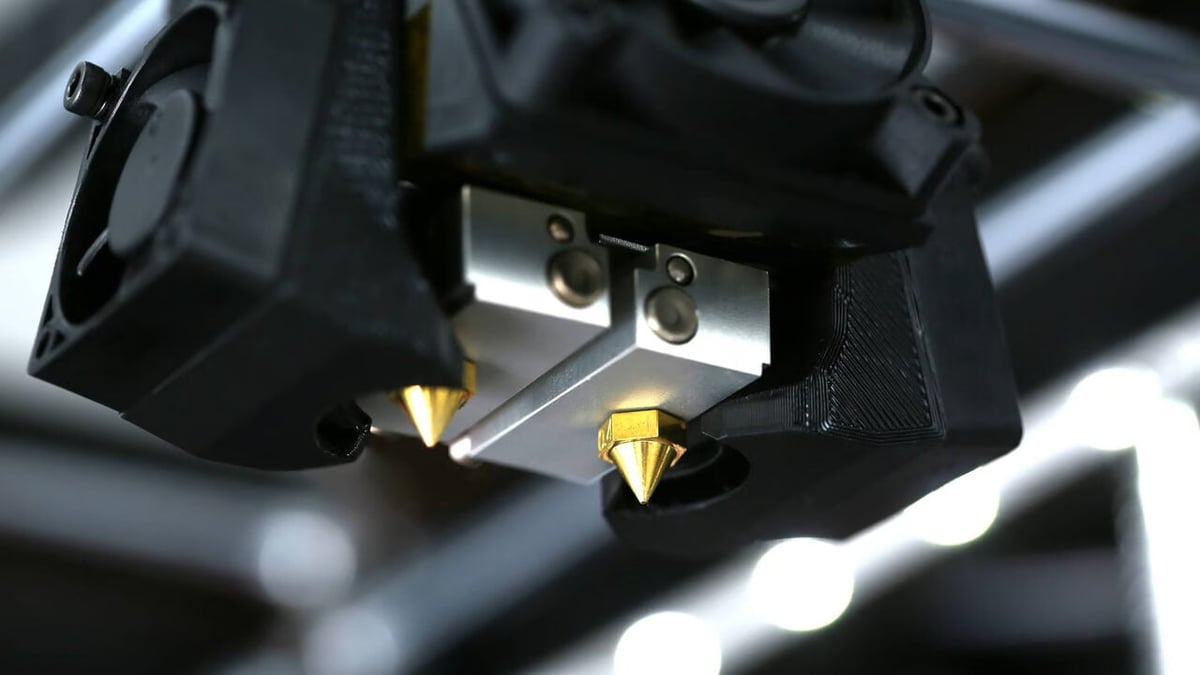

Another quirk of this type of printing is that levelers are required to raise and lower the individual nozzles relative to each other. This allows the first nozzle to glide over the existing printed structure while the second nozzle prints, preventing the first extruder from dragging over the print. However, the close proximity of the two nozzles could lead to oozing defects and couldn’t fulfill the initial promise of rapid printing speeds.

The second, and now most common, iteration of dual extrusion printing uses two separate print heads that can move and operate independently from each other, known as independent dual extrusion (IDEX). Most of the dual extrusion printers on the market today are IDEX, so let’s take a closer look at what this type of printer can offer.

Independent Dual Extrusion

The independent movement of the print heads of IDEX printers comes from each having its own stepper motor. This allows the second print head to be out of the way of the active print head and the printed part. The second print head is free to move and print simultaneously, though it is still constrained to the same Y-axis on most hobbyist IDEX printers.

As a result, IDEX 3D printers have unique modes that allow printing objects simultaneously if the build volume allows. Some examples of these are:

- Mirror mode: One may often see this mode advertised as being able to print a mirrored pair of models on the two halves of the print volume, doubling one’s output. The extruders should have no issues with overlap as their movements are synchronized.

- Duplicate mode: For printing two different models in parallel, IDEX printers use dual mode. There will be some size limitations as the models must be properly spaced and the speed will be determined by the slowest layer at a time.

- Dual mode: To combine two different colors or materials in a single printed part, IDEX printers work in dual mode. Each hot end gets heated to the appropriate temperature and takes turns laying down filament.

Many 3D printers can be upgraded to have similar capabilities of dual extrusion. Let’s briefly review the difference between dual extrusion and multi-material upgrades.

Dual Extrusion vs. Multi-Filament

The original concept of dual extrusion as a form of multi-filament FDM printing left many makers wanting more. This has led to the development of multi-filament or filament-changing 3D printers as well as IDEX. All of these techniques allow multiple colors and materials to be combined into the same 3D print.

Filament-changing printers and filament-blending printers make up what is known as multi-color printers. Generally, these printers are optimized to create visually appealing multi-color (single-material) prints. This often allows them to be simplified and use a single nozzle.

Multi-material printing is a broader category that includes printers that can print more than one type of filament. This requires hardware upgrades such as a hardened nozzle to print wood-filled or nylon filaments or multiple tool heads to print at various different temperatures simultaneously.

We’ll take a closer look at multi-material options in a bit, but for now, let’s weigh the pros and cons of dual extruder printers.

Pros

Dual extrusion printers can be used for more than just making pretty prints. Here are a few other things dual extrusion printers bring to the table:

- Dissolvable supports are the most used advantage of dual extrusion. These are supports that can be washed off instead of peeled or pried away, like PVA, which dissolves in water, and HIPS, which dissolves in limonene. This is extremely useful because it eliminates the need to remove supports and also ensures that no support marks are left on the final print.

- Strengthened infill is an overlooked aspect of dual extrusion printing. Printing infill with stronger materials is a great way to improve overall part strength without sacrificing looks or using a high infill percentage. One nozzle is used to print the majority of a print with PLA or ABS, for example, while the other prints only specific areas using a carbon fiber-based filament. For the best adhesion between the infill and outer layers, opt for a carbon fiber-filled version of the same material that the rest of the object is printed with.

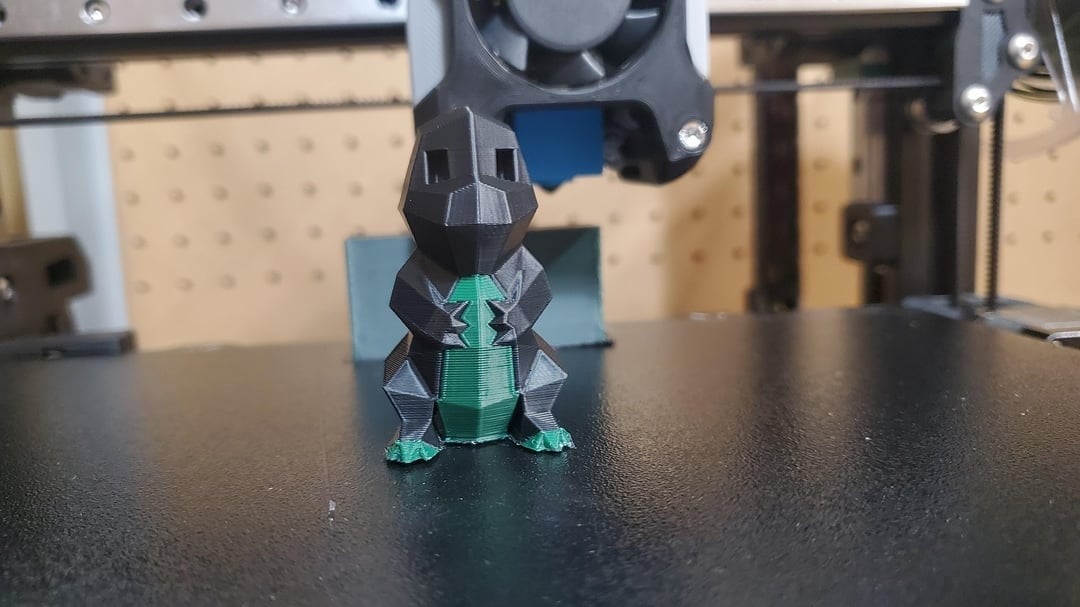

- Colors are the most visually obvious advantage of dual extrusion. A well-printed model made with multiple colors could save a maker hours in painting and drying. Some slicers allow printers to create gradient effects or transitions between two colors. There are lots of cool multi-color prints you can try.

- Functional combinations are emerging as filaments are becoming cheaper. Things such as breadboards contain plastic and metal to act as an organizational interface for a simple circuit. By combining normal filament with conductive filament, makers can create simple circuits.

Cons

The advertised benefit of dual extrusion printers has always been “double the extruders, half the print time”. This is to a certain degree true, but situationally dependent. One of the greatest promises of IDEX printing has been “double the extruders, half the print time, and we really mean it this time!” It’s safe to say that dual extrusion is not the answer to high-speed printing.

Here are a few other things you should keep in mind:

- Increased maintenance is the largest concern because there is twice as much that can go wrong during a print. Whether you’re replacing parts as they age or unclogging extruders, the time will add up. If you’re an experienced maker, it’s best to select a dual extrusion printer made by a manufacturer you’re familiar with.

- Increased printer cost is the natural consequence of increased device complexity. While less of a concern than in the past, you’ll still have to shell out some big bucks for large-format or high-speed devices. When considering build volume, you may find that you’ll get more for your money if you buy two budget, single-extruder printers compared to one dual-extruder printer.

- A large footprint for less build volume is a major downside to dual extruder 3D printers in general. Due to the combined movement of two extruders packed into a typically enclosed printer, you’ll find you need a lot of workbench space to fit the device while still being limited to a build volume similar to or smaller than that of single-extrusion printers.

- High filament use is not to be forgotten when considering dual extrusion. To prevent oozing, many printers utilize clean-up structures such as walls and towers. These ensure a defect-free surface on your printed part, but leave you throwing away more.

- More time is needed to optimize settings for all of the different kinds of filament out there. In addition to the typical calibration you would need to do for a new filament on a single-extrusion printer, having the other hot end sitting nearby dripping filament while waiting for its turn adds more complexities. It would be wise to ensure that both extruders are perfectly calibrated before you start printing.

Printers

When it comes to buying a dual extrusion printer, it’s important to remember that your time has value, so selecting a printer from a brand or style you’re familiar with will go a long way in saving you time during troubleshooting and repairs. With that said, here are some printers worth considering:

- Tenlog TL-D3 Pro (~$520): One of the most popular dual extrusion 3D printers. This is a great printer for experienced makers, but some users complain their customer service can be hard to reach. This printer is an IDEX with a build volume of 300 x 300 x 350 mm that is not fully accessible to both extruders.

- Qidi Tech X-Pro (~$300): The Qidi dual extrusion is an enclosed, cheap, and smaller printer option. The extruders operate together in one dependent assembly over a build volume of 230 x 150 x 150 mm accessible to both. It’s great for printing small parts, toys, and figurines. Users report that this printer is easy to set up, and there are good Simplify3D profiles out there already.

- Flashforge Creator Pro 2 (~$450): This IDEX printer has a moderate price and a small build volume of 200 x 148 x 150 mm, but both extruders can reach the entire build plate, and it comes with an enclosure. Additionally, Flashforge is not new to dual-extrusion printers and has the most online information and how-to videos that can help users maintain their devices. If you have a problem with these printers, it’s likely someone has made a video on how to fix it in the past.

- Sovol 3D SV04 (~$430): This is a moderately priced IDEX printer that comes with the more common Cartesian frame look. Overall, it has a good value and may be more familiar to those who work with single extrusion devices. It has a decent build volume of 300 x 300 x 400 mm, although it’s not fully accessible to both extruders. Users report a relatively quick setup.

- Kywoo3D Tycoon (~$850): This printer is known for its sturdy build. Being IDEX, it has a fair build volume of 260 x 300 x 350 mm, although the area is not fully accessible to both extruders. Some users complain that it lacks good profiles for even Cura, but if you’re more of a setting customizer, then this printer can be a reliable tool.

- Snapmaker J1 (~$1,200): This is one of the few high-speed enclosed dual extrusion printers out there. The Snapmaker is IDEX and comes with a decent size build volume for being in an enclosure. The 300 x 200 x 200 mm space is accessible to both extruders. While a good value for increased printing speed capabilities, be warned that any special or filled filaments will constrain you below this speed regardless of its capability. Upgrading to the J1s model includes an additional part cooling fan.

These printers are recommendations for amateurs and hobbyists. If you’re looking for more professionally-oriented solutions, check out our article on The Best Independent Dual Extruder (IDEX) 3D Printers.

Slicers for Dual Extrusion

Choosing the right slicer for your printer can make a world of difference in how much time you spend perfecting your prints. While there are many slicers out there, we’ve narrowed the list down to what we consider to be the best for hobbyists, including beginners and advanced users.

- Simplify3D: This is the most user-friendly dual extrusion slicer out there. It’s not free, but for anyone trying to get dual extrusion printing without a large learning curve, Simplify3D is likely the best bet. Many of the printers on the above list have freely available profiles for Simplify3D, so much of the leg work has already been done for you.

- FlashPrint: This slicer from FlashForge has a user-friendly layout and minimal learning curve. One will also find lots of built-in model editing tools that make it easy to divide STL files and assign extruder tasks. If you don’t have a FlashForge printer, you will need to create your own profile.

- PrusaSlicer: This is a great all-around slicer that is reliable, user-friendly, and works great with multi-filament printing. Since it’s not built for working with a specific dual extrusion printer, you’ll have to do some tinkering to create a printer profile.

- Cura: As one of the most widely used slicers out there, Cura is certainly capable of handling dual extrusion printers as well. Depending on the printer brand, there may be plug-ins or G-code online to help with compatibility. UltiMaker has also posted some tips and tricks on slicing for dual extrusion.

Printing Tips

With more extruders, printing a picture-perfect model may require patience and effort. Here are a few tips and tricks to mitigate risk:

- Level the printheads: Both printheads should be routinely leveled, and nozzles should be of equal length. This will also ensure that one printhead is not too low during movement, which could cause scratching, dragging, clogging, and layer shifts.

- Configure your slicer: Before printing, make sure to configure your slicer software to the correct settings. This starts with selecting the correct printer and enabling both extruders in the printer hardware settings. It’s generally wise to measure the distance between your extruders and make sure it’s reflected accurately in the hardware settings.

- Enable prime towers: With more extruders, there can be more oozing. To help prevent this, prime towers (also called blocks) are likely included in your slicer’s print settings. What this does is create an additional object next to the original object being printed. Every time a layer is printed, the inactive nozzle gets wiped on the tower before switching to the other nozzle. Prime towers are a great choice for taller prints with simple geometry. They use less filament than ooze shields and requires less time.

- Ooze shield: The ooze shield or wall is another way to reduce oozing. A one-layer wide wall is created outside the perimeter of the entire model and catches the remaining material on the nozzle before each layer is printed. While very effective, this method is best for wide prints that cause greater X- and Y-axis travel.

- Tune print settings: Increasing travel speeds will prevent spillage during non-printing movement. Similarly, increasing retraction can also help prevent leaky filament.

- Assign filament wisely: When working with adhesion assistants like rafts, print with one filament you know to adhere well to get that perfect first layer. You can also choose to print internal structures like infill with a stronger filament or one you’d like to use up, depending on the application.

Alternatives & Upgrades

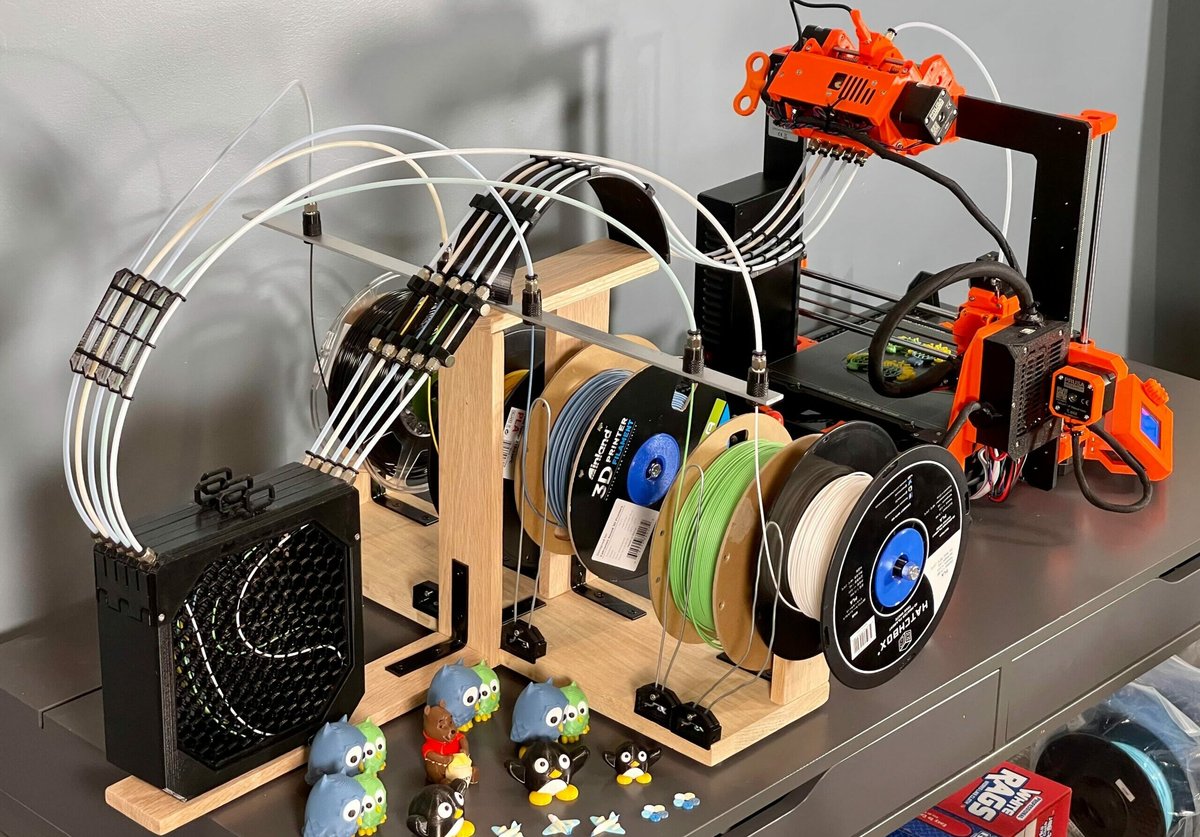

If you already own a 3D printer, and fancy the idea of 3D printing with multiple materials and colors, there are a few different accessories that make it possible to turn “normal” machines into multi-material factories. Some makers have upgraded dual extruders with these upgrades as well, giving dual extruder printers additional multi-material options.

- Mosiac Palette 2, 2S, and Pro: One of the most innovative solutions comes from a Canadian company, Mosaic Manufacturing. Their product is an add-on for 3D printers that basically creates a single filament out of multiple strands. The device slices the filaments and fuses them into a single strand, according to your specifications and the needs of your model.

- Prusa’s Multi-Material Upgrade 2S (MMU2S): If you’re into 3D printing, you’re probably familiar with the Prusa i3 MK3S+. With the MMU2S add-on, you can print with multiple materials on your i3. How many materials, you ask? Up to five! The result is similar to the Palette, but instead of slicing and fusing, the MMU unloads and loads filament, as required.

- 3D Chameleon: One of two multi-material kits designed to be added to a wide variety of open-source FDM printers. The current version is a four-color changing kit that is readily compatible with PrusaSlicer. The 3DChameleon is known to have great customer support.

- SMuFF Multi: This is a DIY option that can handle up to 12 filaments at once! However, there is no assembly kit for this project, which is meant to replace the extruder drive gear of the existing printer, so be prepared for some tinkering to get the SmuFF up to snuff.

License: The text of "Dual Extruder (3D Printing): All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.