Springs are everywhere, but they usually go unnoticed until they’re no longer working.

They’re in our pens, our cars, our toys, and even in our mattresses. If you’ve ever had a bed frame with a squeaky spring, you know just how annoying they can be. But fear not, intrepid DIY hobbyist! With 3D printing technology, you can now design and print your very own springs, and eliminate that pesky squeak forever.

In this guide, we’ll go over the different types of springs, the best way to design them, and how to select the right materials to ensure they’re strong and durable. And to wrap things up, we’ll list a few projects to draw inspiration from or to get started 3D printing your own springs.

So buckle up, because by the end of this guide, you’ll be a spring-printing pro!

Types of Springs

The spring type and material will have an impact on its function and application. Understanding the different types of springs can help you choose the right one for the job, so let’s start by looking at different types of springs, how they work, and where they can be found.

- Compression springs, for instance, are designed to resist compressive forces and store energy in the compressed state (a.k.a. when they’re contracted or squeezed). They’re commonly found in suspension systems, mattresses, and automotive engines, where they provide cushioning and support. When you think of a spring, you probably picture one of these!

- Extension or tension springs are designed to resist tensile forces and store energy in the extended state (when they’re stretched). These springs are frequently used in trampolines, garage doors, and toys that have shooting mechanisms, where they provide tension to keep parts together or hold them in place. Essentially, when you pull them apart, they want to contract back together.

- Torsion springs are similarly designed to resist twisting forces and store energy in the rotated state. They are commonly found in mousetraps, clothespins, and hinges, where they provide rotational force or torque. They often look like spirals!

- Constant force springs can be used to provide a constant amount of force over a long extension range. These springs are commonly found in retractable tape measures and window shades, where they provide a steady amount of tension while being extended or retracted. They usually take the form of a tight roll.

- Belleville disc springs are designed to provide a large amount of force in a small space. They’re often used in valves, clutches, and aircraft landing gears, where space is limited, but a high force is required. You may not have seen one of these before – for reference, they look like stacked discs in alternating positions.

- Wave springs are designed to provide a compact and lightweight solution for tight spaces. These springs are often found in medical devices, automotive transmissions, and aerospace applications, where space and weight are critical factors. The unique shape of wave springs allows them to provide similar force to other types of springs, but with less material and a smaller profile. For reference, they look like washers that have been bent into a wavy shape.

There are some springs that we haven’t included – like leaf springs – which can sometimes be difficult and impractical to 3D print. However, most common spring types can be 3D printed!

Why Print Them?

An advantage of 3D printing springs is that you can easily incorporate them into complex designs. Since a 3D printer is much more versatile than other manufacturing equipment, you can make them in all sorts of shapes and sizes that you wouldn’t find elsewhere.

Plus, you can choose from several materials like nylon or carbon fiber to cater specifically to your own project, budget, and setup.

If you’re designing your own models that incorporate springs, it’s easier than ever to create a design that makes the spring more subtle.

For instance, many bobbleheads are created with the spring showing, which is substantially easier to manufacture in bulk. Instead, you could model a version of the bobblehead that hides the spring for a sleeker design.

On the other hand, if you want the spring to show, there’s a sea of different filament colors and materials to add a personal touch. Of course, this is just one example, but the possibilities are endless!

Designing a Spring

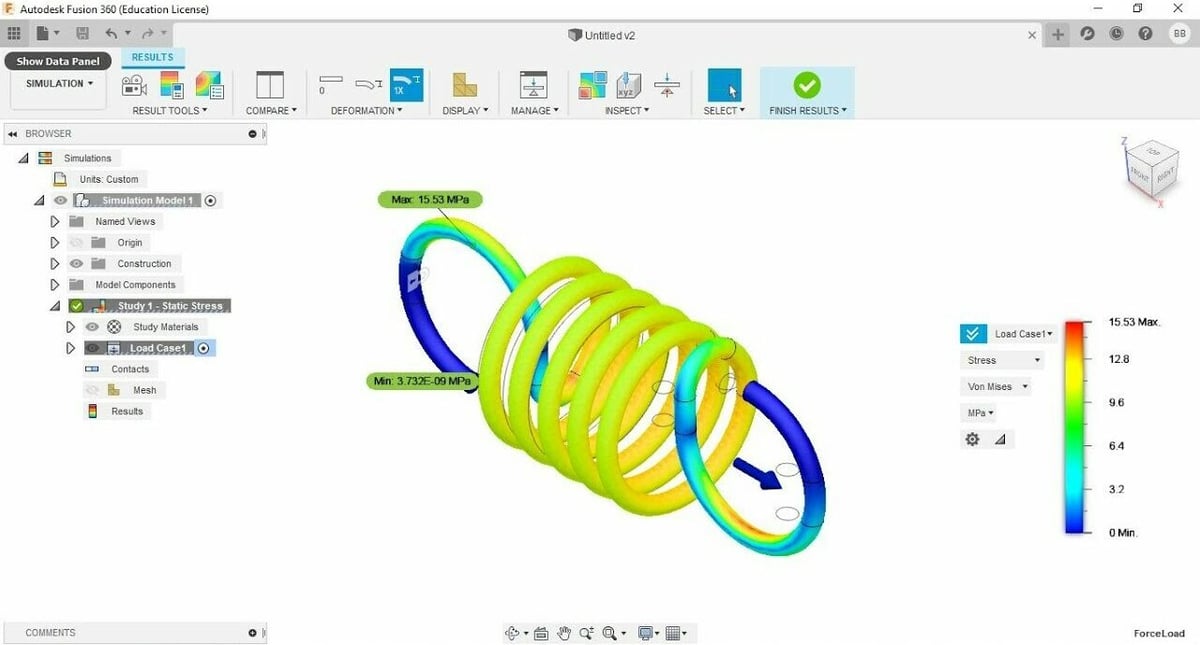

When it comes to designing a spring, it’s arguably better to use higher-level computer-aided design (CAD) software, like Fusion 360, over simpler programs like Tinkercad. This will give you more flexibility and control over the design. However, if you’re new to CAD, Tinkercad is a great option to get familiar with CAD in general.

In any case, before you start designing, it’s important to consider the application of the spring and choose a type of spring that best fits your project. If you’re not familiar with CAD, watching a tutorial on designing the specific type of spring you need would be the way to go.

Once you’ve got your CAD bearings, the Sweep feature in Fusion 360 can be helpful when generating a mesh body relative to a drawn path. This is especially useful for designing springs, as you can draw the path that you want the spring to follow, and then create the 2D sketch of the spring shape that will follow that path. The sweep feature will then take that sketch and extrude it along the path to create the final 3D shape of the spring.

If your spring is relatively generic, you may even be able to find it on a 3D model repository like Thingiverse or one of its many alternatives, and you can simply add it to your design. If your project doesn’t require an accurate spring, some people have found creative ways to make one using filament, a heat gun, and a cylindrical object.

Design your springs with supports in mind. The type of spring you create will need to be printed in a specific way, requiring varying amounts of supports in different areas. Because of this, try to minimize overhangs wherever possible and ask yourself if what you’re modeling in CAD will be a pain to 3D print and post-process, or if there’s a better way of orienting the model in the slicer to make your life easier. Maybe some PVA could help.

No matter what, don’t be afraid to get creative and experiment with different methods for designing your spring!

Choosing the Right Material

Choosing the material is a crucial step in creating the perfect 3D printed spring. All the springs we’ve mentioned can be printed using virtually any material, but the real variable is the stress of the application you’re working with!

Here’s a list of some popular materials and the applications a spring of that material would be best suited for:

- Polylactic acid (PLA) is great for low-stress applications or prototyping, while polycarbonate (PC) is a solid option for high-stress situations, like in cars or planes.

- Polyethylene terephthalate glycol (PETG) is good for low- to mid-stress applications, as it is a fair bit stronger than PLA.

- Acrylonitrile butadiene styrene (ABS) is a popular choice for springs that will experience mechanical or thermal stress, like in robots, toys, or appliances. It’s possible to use acetone to smooth the surface of ABS, but it won’t result in any mechanical advantages.

- Nylon is great for springs that need to withstand impact, like those that can be found in sports gear or medical devices. And if you’re feeling fancy, carbon-fiber-reinforced polymers (CFRP) or glass-fiber-reinforced polymers (GFRP) are top-notch materials for high-performance applications, as those required in aerospace or automotive industries.

- There are also flexible filaments, like thermoplastic polyurethane (TPU) and thermoplastic elastomer (TPE), which can be useful but can be a significant challenge to print.

Choosing the right material will make sure your spring can handle whatever your project throws at it. As you move into materials like nylon and carbon fiber, you’ll have a great strength-to-weight ratio, allowing you to excel in more advanced, high-stress projects. However, these materials can become pretty expensive to purchase, so consider if investing in a whole spool is necessary.

Projects

Now that you know how to 3D print and even design springs, here are some projects that you can try!

3D Printed Bobblehead

Who doesn’t love a bobblehead? This model by Paige Russell is a great showcase of the use of a compression spring. And if you’re brave, most smartphones these days come with lidar sensors, which allow you to make some pretty accurate 3D scans. With some tweaking to the original design, you could 3D print a bobblehead of yourself!

Print-in-Place Spring-Loaded Box

Here’s a great one for those in need of some fun storage solution! This spring-loaded box utilizes a torsion spring to pop the lid open. If this model sounds like a fun addition to your desk, be sure that your 3D printer is calibrated to handle tight tolerances that this print-in-place model requires. If you’d like to design your own box, the designer gives some great tips in the description of the model.

Wind-Up Car

Yet another wonderful example of a torsion spring, this time used for propulsion! Winding up the car by rolling it back twists the torsion spring, loading it up. When you let go, the spring slowly decompresses, and all the potential energy is released as propulsion, moving the car forward.

Clip Peg

Springs don’t have to look like springs to be springs. This is a great example of a flat spring being used for a general-purpose clip. This specific design isn’t as simple as other clips, as it has extra folds that add stability and more of that springy-action we all love!

License: The text of "3D Printed Spring: Tips & Tricks to Print Springs" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.