Additive manufacturing (AM), also called professional or industrial 3D printing, is a relative newcomer in the larger manufacturing industry. Nonetheless, it has quickly reached commercial viability and has one of the widest application ranges out of all manufacturing methods.

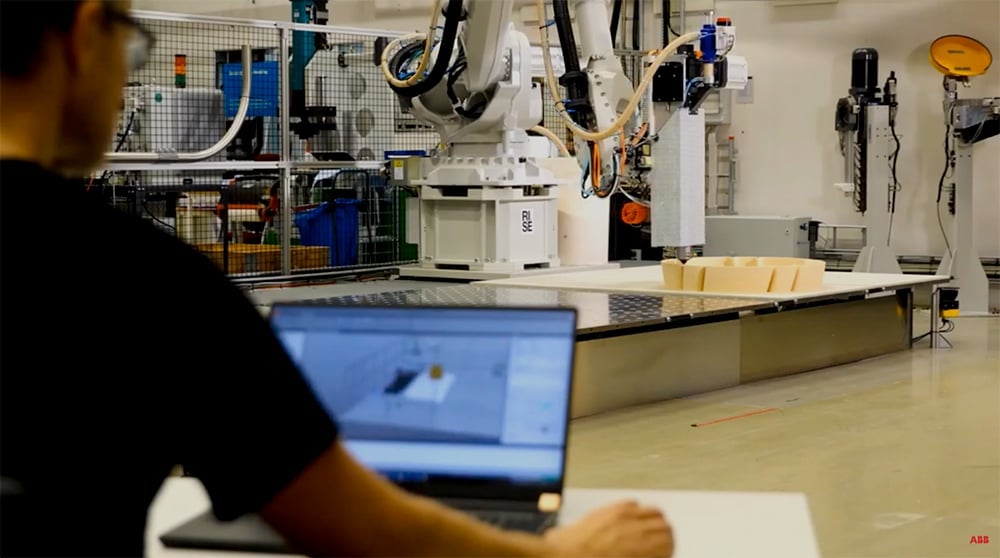

Today, additive manufacturing is an $18 billion industry that has found a home in the production facilities of aerospace and automotive giants, within militaries and hospitals, at architecture and industrial design firms, in the workshops of small manufacturers, and in the labs of research institutions and universities.

Former US President Barack Obama, in a national address, called 3D printing a technology that has “the potential to revolutionize the way we make almost everything”. The European Union is funding several projects to advance 3D printing as the future of sustainable manufacturing while new additive manufacturing centers are opening up across Asia.

No matter what business you’re in, additive manufacturing can be the better choice to make products, parts, tools, and prototypes that are more efficiently designed, lighter weight, more economical, customized, and produced faster compared to molding, milling, joining, sculpting, and forming, in practically every industry.

Additive manufacturing also enables you to reclaim the making of your products and parts from faraway factories and overcome supply chain disruptions, eliminate stockpiles of inventory that may never be used, and print on demand exactly what you need now.

Let’s take a look at what additive manufacturing is, why governments and industries are investing millions in it, and how it can help your business innovate and thrive.

Additive Manufacturing's Basics, Pros & Cons

Additive manufacturing, as the name implies, adds material, layer upon layer, until the desired shape of a part is achieved, effectively creating the part out of “nothing”. It does this using a variety of technologies. Some additive manufacturing methods extrude plastics from a nozzle, some use light to solidify liquid plastics in a vat, some use lasers to join particles of powdered material into a solid shape, and there are many more approaches. But what they all have in common is that they “add” material in layers, rather than “subtract” material from a larger piece.

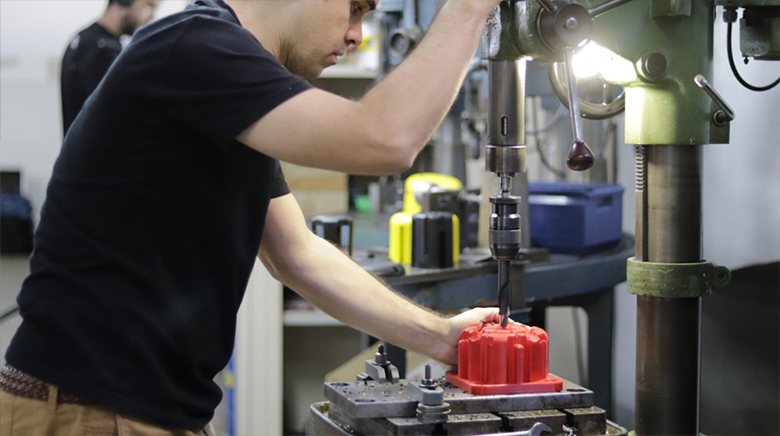

Although the terms additive manufacturing and 3D printing are often used interchangeably, that’s not exactly correct. 3D printing is a major process step in additive manufacturing, but AM covers much more, from the initial digital part design through to polishing and other post-processing steps. In other words, it encompasses all the processes necessary to manufacture objects, not just the 3D printing.

The exact components in the AM process depend on the type of technology (more on that later), but in general, all AM technologies offer the following advantages when compared to traditional subtractive manufacturing.

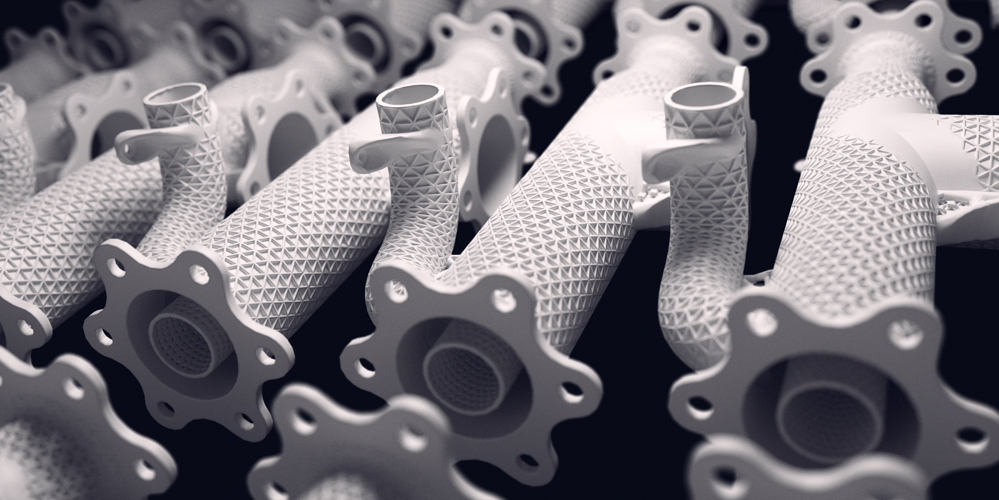

Making Previously Unmakable Shapes

Additive manufacturing can make shapes and parts with complex geometries that traditional manufacturing can’t create, such as complex internal channels, lattice-filled closed spaces, and solid interlocking pieces. This ability has revolutionized product design, enabling engineers to rethink how parts can be improved with new shape possibilities.

Fabrication Without Tooling, Molds, or Dies

A 3D printer can make virtually any shape without changing or adding any tools or parts. It can even make a batch of different shaped parts at the same time. This benefit means every printed part can be unique and customized.

An Eco-Friendly Process with Nearly Zero Waste

Because 3D printers add material instead of remove it, there’s very little to no waste from the process. Often, any excess material can be reused to make the next part. 3D printers can use post-consumer plastic as material to make new products offering an attractive solution for recycling. Additive manufacturing is an especially attractive method when using expensive materials, such as titanium or certain industrial polymers because you need less raw material to create a product.

Eliminating Part Assembly

To manufacture an assembly with moving parts such as an engine block or a gear system, parts are individually made and put together. With additive manufacturing, assemblies can be printed in a single build thus eliminating time and labor, and reducing the introduction of errors or weaknesses during the assembly process. This is especially important with aerospace components, such as rocket fuel injectors, that can be 3D printed in one piece with no vulnerable seams.

On-Demand Production Reduces Inventory

The ability to 3D print parts quickly and as needed eliminates the need to wearhouse dozens or hundreds of spare parts that may never be used. Business are often forced to order multiples of parts and minimums when they only need few because of the constraints of modern manufacturing economies of scale.

In-House Production Eliminates Supply Chain Vulnerabilities

With traditional manufacturing, business may have only a handful of suppliers for parts and products. This leaves them open to supply and demand price pressures and shipping disruptions caused by everything from geo-politics to pandemics. In-house manufacturing eliminates the reliance on outside suppliers and pollution-generating shipping.

Economical Unique & Customized Products

With traditional manufacturing, creating 100 like products is often less expensive than creating one unique product. Not the case with additive manufacturing where each product or part can be unique. This gives business that rely on offering tailor made products, such as custom-fit sports equipment, an edge. Customized and unique products are also critical in the healthcare industry where patient-specific prosthetics and implants have shown to improve outcomes.

Low Barrier to Entry

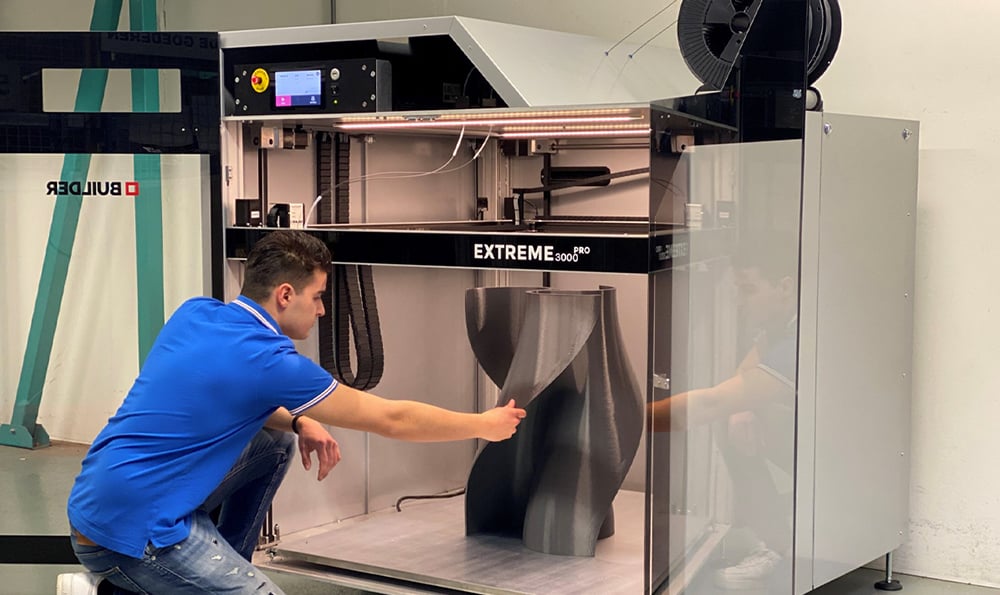

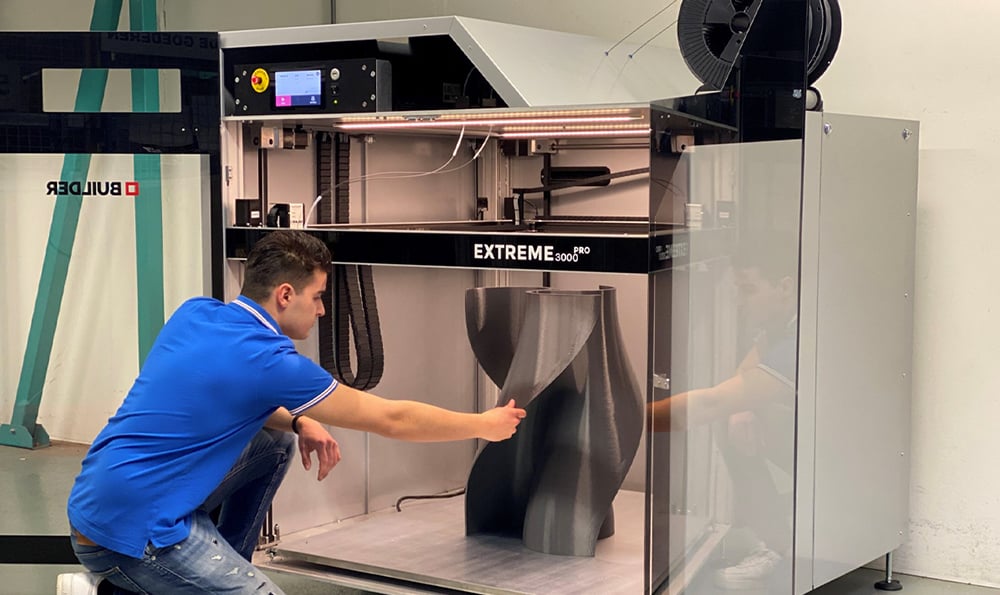

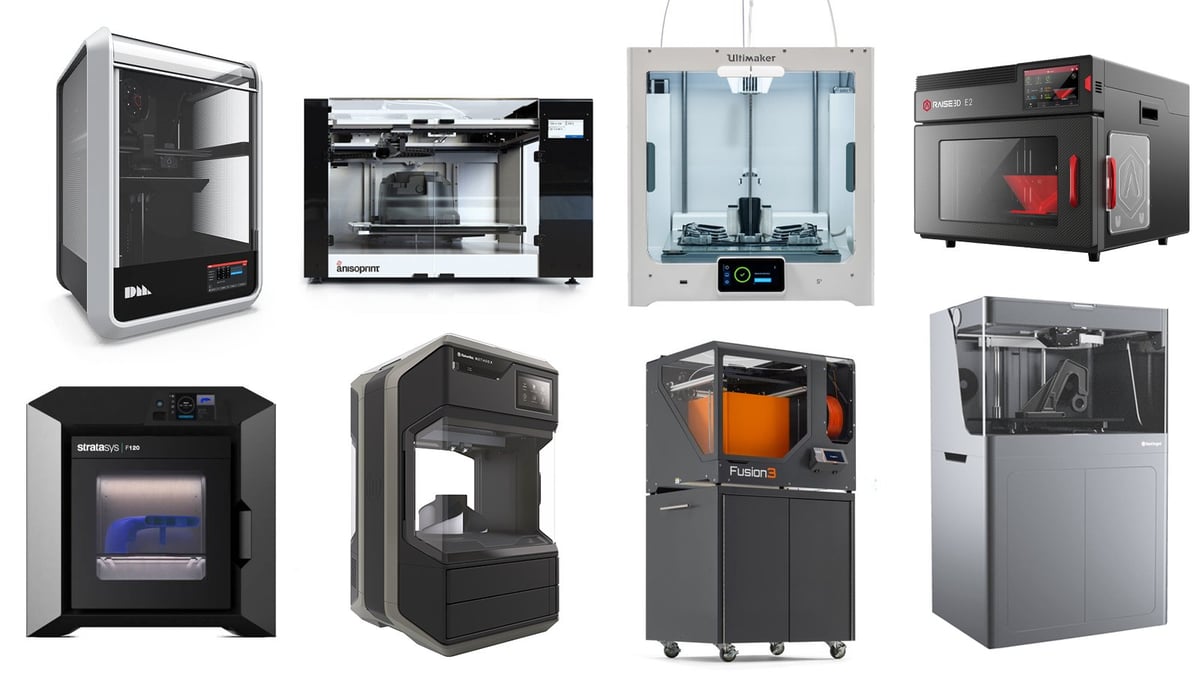

Professional 3D printers start around $10k and are largely automated, making in-house manufacturing possible for a huge number of businesses that once relied on outsourcing. For example, small manufacturers can now 3D print their own jigs and fixtures, architectural firms can now 3D print their own models, industrial designers can now 3D print their own prototypes, and hospitals can now 3D print their own medical models.

Fast, Economical Spare & Legacy Parts

Many older machines, from classic cars to unique pieces of equipment, end up on the scrap heap because critical replacement parts are either no longer available or too costly to produce. Additive manufacturing eliminates this issue with its ability to quickly print any part in any shape. The world’s militaries, for example, are widely using AM to ensure that older equipment can stay at the ready.

Drawbacks of Additive Manufacturing

Additive manufacturing is undeniably a revolutionary manufacturing technique, but some challenges remain:

- Difficulty in scaling production up to mass manufacturing level

- Limited print sizes with most 3D printers

- Some technologies and/or materials require heavy post-processing

It’s worth noting that AM technology is constantly advancing in great leaps, with manufacturers and printer developers coming up with new solutions to existing production issues.

Industries Using Additive Manufacturing Today

Additive manufacturing has something to offer for practically every industry, thanks to its many advantages. However, some major industries have adopted AM earlier than others. Here are just a few large-scale global industries that have realized AM’s benefits.

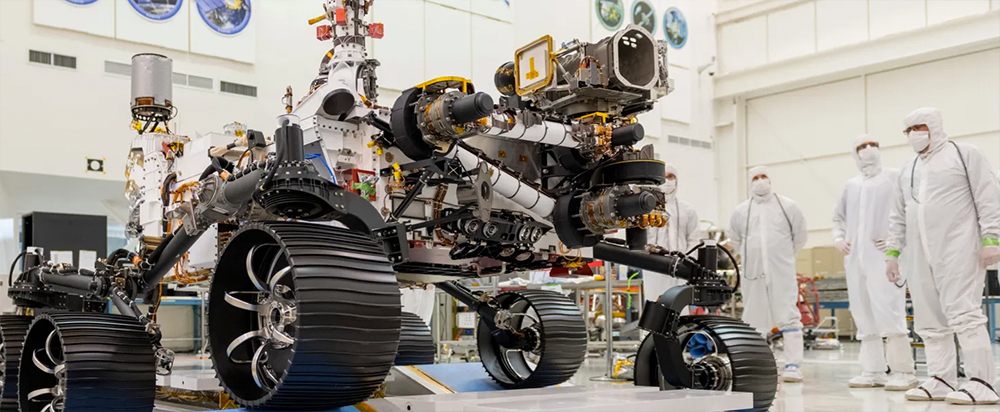

Aerospace & Aviation

The aerospace industry depends on high-performance, lightweight materials and unique part design; two things AM is ideally positioned to deliver. Several AM techniques, coupled with generative design, part consolidation, and material substitution — help aerospace companies reduce the weight of their parts, improve mechanical properties, and lower running costs.

Possibly the single biggest player making good use of AM in this segment is NASA. AM has left planet Earth, and the Perseverance rover currently exploring Mars features additively manufactured parts in its instruments and heat exchangers. NASA has also successfully tested and launched 3D printed rocket engines, and exploring other opportunities as well, including astronaut housing on the Moon and Mars.

AM is also taking flight with commercial airliners. Airbus and Boeing use AM to create lighter and more durable aircraft components, for both engines and passenger cabins.

Automotive

Cars also benefit from weight reduction, since lower weight directly results in lower fuel consumption. But AM also enables them to produce prototypes and final parts with complex geometries faster and cheaper.

Widely used in vehicle production, 3D printed jigs and fixtures that help assembly workers on the line are made in-house far faster and cheaper than in the past.

US auto maker Ford uses AM to create functional parts from brake line brackets to customizable accessories for the new Ford Maverick truck. BMW produced its millionth additively manufactured component in 2018 — a window guide rail for the i8 Roadster. The company says the car wouldn’t have been possible to manufacture without additive manufacturing. Meanwhile, Porsche has launched its Classic service which provides additively manufactured alternatives to obsolete and out-of-production spare parts for its classic vehicles.

Medical

Our bodies are all different, and the medical industry has realized the value in additive manufacturing’s customizability. Thanks to AM, medical professionals are able to quickly and cheaply produce customized, patient-specific solutions for implants, orthotics, and prosthetics.

Hospitals, such as the Mayo Clinic in Minnesota, have their own 3D printing departments that produce everything from models for patient education and surgical training to surgical tools.

Dentists, in particular, are widely adopting AM to produce dental aligners, mouth guards, and retainers tailored precisely to the patient’s teeth, chair-side, and far faster than outsourcing to a lab.

AM has also made custom orthotics and prosthetics much cheaper and more available for people living in developing countries.

Additionally, medical researchers are using AM and AM-derived technologies to explore 3D printing human cells and tissues. In the future, they may be able to create organs for transplants without the need for donors.

Military

Military applications touch upon all the industries we’ve mentioned above. It only makes sense, then, that militaries around the globe are making use of additive manufacturing.

The U.S. Army, for example, uses AM for everything from concrete bunkers made with huge robotic 3D printers to 3D printing legacy spare parts for old but functional military vehicles.

In addition, the U.S. Army Research Laboratory has a program to recycle plastic waste into AM materials. Plastic waste is plentiful both at barracks and in the field, and allows the Army to cheaply create spare parts, like vehicle radio brackets, while contributing to removing plastic from the environment.

Consumer Goods

AM offers several benefits to all consumer goods producers particularly when it comes to rapid prototyping. A designer can come up with a new product concept and print out a functional prototype in a matter of hours and be ready with a new product on the market in a matter of weeks.

Rapid prototyping is enabling entrepreneurs and large enterprises alike to accelerate the product development cycle. Multiple versions of a product can be 3D printed in-house at the same time and there’s no limit to materials. Even metal parts and high-performance plastics can be used to create functional prototypes capable of being tested in machinery and automobiles, leading to better final designs.

When it comes to final end-use products, the customizability of additive manufacturing also enables companies to offer an unprecedented level of personalization options to customers. Whether it’s custom fit sports equipment or personalized car interiors or one-of-a-kind jewelry, mass-production no longer means every part has to be exactly the same.

Construction

The 3D printing construction approach promises to build houses faster, cheaper, and more accurately with fewer people. 3D construction companies also say their material will last longer and are stronger than most traditional building materials. With benefits like these, it’s no wonder that 3D printing construction is gaining momentum. In fact, the global construction robot market (something that didn’t exist no long ago) is projected to grow nearly 20% in the next five years.

Skeptics still doubt the viability of 3D printed houses, but with each new project that feeling is fading. 3D printing construction companies today are in the spotlight, as engineers, project developers, and clients try to wrap their heads around this new phenomenon.

AM Materials

There are hundreds of additive manufacturing materials ranging from metals to plastics to ceramics and even food, wood, and biological materials. Several materials are specific to individual technologies, but there’s virtually no limit to the materials that can be 3D printed.

Here on All3DP you’ll find individual guides to each material explaining them all in detail along with their most common applications. Just follow the links below.

Metals

Plastics

Other Materials

Types of Technology

AM is not a single manufacturing method but a collection of many different technologies; each comes with its own advantages, disadvantages, and optimal applications. Additionally, not all technologies are compatible with every kind of material.

For example, dental professionals most often use a 3D printing technology called stereolithography (SLS), also called resin printing, because it can produce finely detailed parts with a smooth finish in biocompatible materials ideal for dental applications. Machine shops often turn to fused deposition modeling (FDM) to 3D print strong carbon-fiber tools to aid in manufacturing. Autoracing professionals are using selective laser sintering (SLS) to 3D print titanium parts that reduce a car’s weight. In all, there are seven major types of additive manufacturing with several more off-shoots and variations of these types.

Here on All3DP you’ll find individual guides to each technology explaining them all in detail. Just follow the links below.

Plastic Additive Manufacturing Methods:

Metal Additive Manufacturing Methods:

Software for Additive Manufacturing

Although it produces physical products, AM is very much a digital technology. Every additively manufactured product begins its life as a digital 3D model, and practically all of them are created with CAD (computer aided design) software.

CAD has been around for more than 50 years, and is used in a wide range of industries, from consumer goods to architecture. When creating 3D models for additive manufacturing, designers often will apply the principles of Design for Additive Manufacturing (DfAM). DfAM is a design philosophy that emphasizes designing products with 3D printing in mind from the first idea concept stage.

3D modelers use DfAM principles to draft product models in CAD software. They must account for the properties of the material and 3D printing technology that will be used for the part, such a material shrinkage, while also applying techniques like topology optimization, support planning, and lattice structures to optimize the parts for AM.

Other software that additive manufacturers use include:

- 3D scanning applications

- Print preparation software

- Simulation software

- 3D printer operating systems

The number software might make AM seem complicated, but most 3D printers themselves are straightforward to operate, and 3D printing software developers compete furiously to make their products as automated and easy to use as possible. In all likelihood, once you have a 3D model you can print it with just a few mouse clicks.

Cost of Additive Manufacturing

It’s not feasible to give a single average price point for additive manufacturing because printer and material costs vary wildly between different technologies. Instead, below are some examples of how much running a 3D printer for a year could cost for various professionals.

Of course, you don’t have to own your own 3D printer to take advantage of all the additive manufacturing has to offer. Hundreds of 3D printing services enable you to upload you digital file, select a material, and have your part shipped directly to you. The 3D printing marketplace Craftcloud is a great place to start to find the best services.

3D Printing Architecture Models

An architect looking to print 3D models of building designs would most likely be looking at a desktop-sized FDM or resin printer. You could pay as little as $700 for an Anycubic Photon Mono X, but you’d likely want to go for a more high-end machine that could cost up to $6,000, like the Ultimaker S5. Add to that at least $1,000 annually for materials, and note that resins are more expensive that FDM filaments.

3D Printing Jigs & Fixtures

An automobile manufacturer who wants to create both car interior components and sturdy tools and fixtures parts would likely opt for an industrial-level carbon fiber printer. They are generally rather expensive, costing anywhere from $15,000 to $70,000 for a Markforged X7, for example. Carbon fiber printers are often tied to expensive manufacturer-exclusive materials, so account upwards of $10,000 for materials annually.

3D Printing Metal Replacement Parts

For applications that require you to print in metal, you’ll have to dig even deeper. Be prepared to pay at least $100,000, and for a particularly high-end machine you’ll have to triple or even quadruple that price. The metal powders used in most printers cost around $150-$300 per kilo, and one print job can require up to $4,000 worth of powder. The price tag of a 3D printer may seem high, but when you buy the right printer for your application, you’re likely to see a quick ROI.

Manufacturers in the oil and gas industry have save millions 3D printing spare parts and using 3D printing to repair critical parts that would take months to re-manufacturer.

Where to Learn More

We’ve covered the basics, but this article just touches the surface of AM. There’s much left to learn, but luckily you have plenty of resources at your disposal here at All3DP, the world’s largest platform for information on additive manufacturing.

All3DP offers in-depth articles on all aspects of additive manufacturing and 3D printing. Our expert authors and industry leaders write easily digestible information packages that cover everything from the latest technology, to the best design software and — of course — the best 3D printers for every application.

If you prefer to learn through more practical experience, many universities, educational organizations, and even 3D printer manufacturers offer online and in-person classes on AM. Trade shows are also great places to meet AM professionals who are eager to teach you and demonstrate their products.

When you’re ready to get your feet wet and try additive manufacturing for yourself, consider ordering sample parts from a 3D printing service bureau. Craftcloud helps you compare different printing service providers, technologies, and materials and find the best option for your needs.

Should you already have a certain 3D printer in mind, don’t hesitate to contact its manufacturer. They are happy to produce sample prints to show what their machines are capable of. Many also have extensive online resource libraries where you can learn more about their technologies and materials.

The best way to learn about AM and 3D printing is to dive in and start printing. Through practical experience, you’ll quickly discover how AM can make your manufacturing operation more efficient, faster, and affordable.

Lead image source: The Studio System 3D printer from Desktop Metal

License: The text of "What is Additive Manufacturing? – Simply Explained" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.