This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

A Nicer Slicer

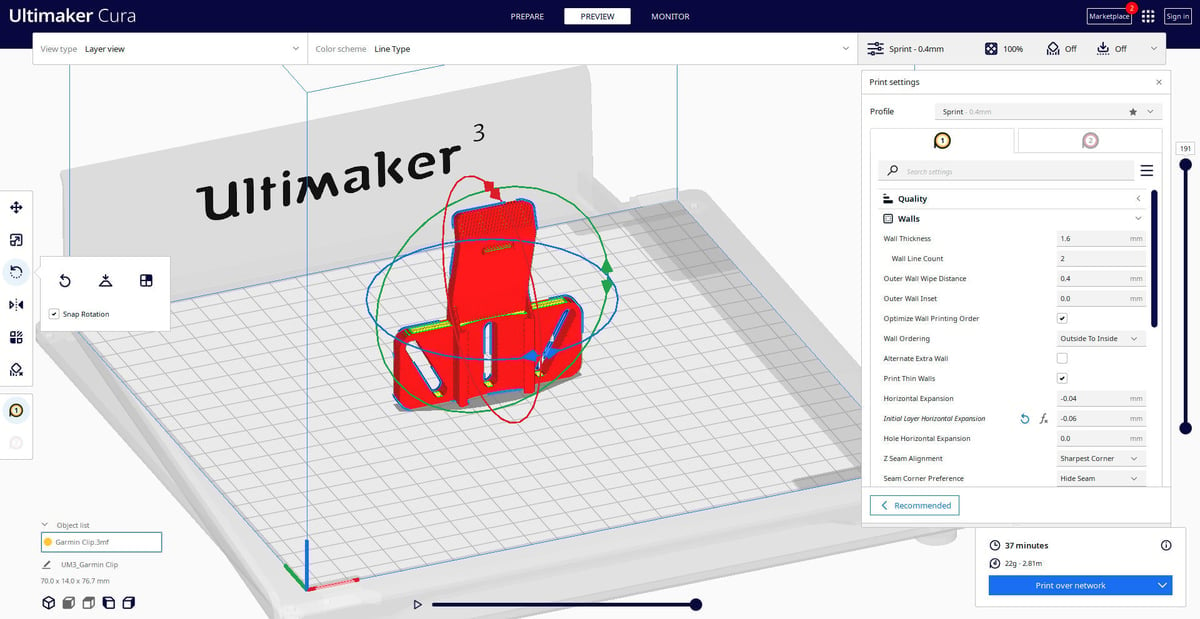

Cura Settings Decoded – An Ultimaker Cura Tutorial

Discover the hidden features of the Cura slicer software. We'll show you how to take your 3D printing to the next level for perfect prints!

Advertisement

Advertisement