3D printing can be an incredibly powerful tool for helping you to realize your designs. But to take your ideas from digital to physical, your printer will need the right software companion and file format to make it happen.

Maybe you’re just getting started, and you’re overwhelmed by so many steps, names, settings, forks, and alternatives. Maybe you’ve got a few prints under your belt and you want to keep on learning.

Here, we’ve listed all the different types of software that will come in useful as you design and print a part. Of all the software types we’ll discuss, only one of them is absolutely necessary. However, we’ll also cover the optional software tools that will enhance your printing experience.

While some of the programs included are meant for fused deposition modeling (FDM) rather than resin-based printing, we’re also including suggestions for the latter in case that’s your setup.

Let’s get started!

Mandatory

The Bare Minimum

Technically speaking, the only thing you truly need to print your 3D model is G-code, the programming language that plots specific coordinates on the print bed where your model will be manufactured.

Although the G-code format is used on both FDM and resin 3D printers, the same G-code file is unlikely to work on two different printers. No two printers are alike, and their specific G-code files most likely contain different commands based on the control board used or the bed dimensions when homing. For these reasons, it’s safest to create your own G-code files for each model you want to print.

This means that the only type of software you truly need to get your 3D printer running is the slicer, which is the software that takes a 3D model and “slices” it into G-code. This is the bare minimum because you can always source free STL files on file repositories like Thingiverse, Printables, MyMiniFactory, and more, so designing your own parts to print isn’t necessary.

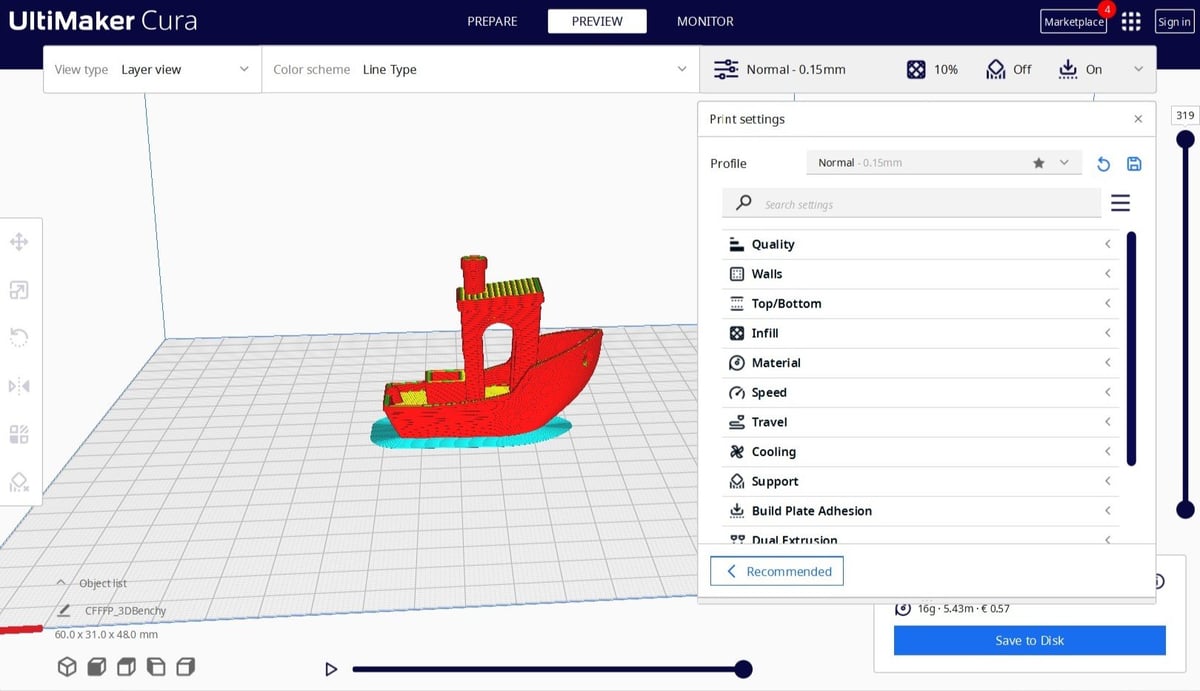

FDM Slicers

While G-code contains the mapping commands to print 3D models, it’s slicer software that can take a 3D model and make it comprehensible to your printer. It ultimately acts as a converter from STL to G-code, and then previews the path of the print from start to finish.

There’s a huge choice of 3D slicers, some offered by 3D printer manufacturers, others maintained by the open-source community, and some a bit of both! Here are some good FDM slicers to start with, but if you’re working with a resin printer, check out our list of the best resin printer slicers.

UltiMaker Cura

UltiMaker Cura is one of the most commonly used open-source slicing programs. But don’t let the simple interface and free download fool you – under the hood are hundreds of settings that can be individually tweaked. Cura is the perfect tool for beginners and experts alike, as it has presets for easy, intermediate, and advanced difficulty levels. We have many articles about Cura to help you get started, including a thorough guide to slicing.

PrusaSlicer

PrusaSlicer is another incredibly popular slicing software that utilizes and builds upon its predecessor, Slic3r. Its support for multi-material prints, wireless connectivity, and presets for third party printers easily make it a versatile option as your go-to slicer. Maintained by several Prusa Research developers, PrusaSlicer continues to improve with multiple new updates each year. In the spirit of the open-source initiative, you can even contribute to its development by reporting bugs or proposing changes on GitHub!

Optional, but Good to Have

Modeling Tools

There’s nothing wrong with 3D printing premade files, but at some point, you might start looking for ways to adapt or create your own models. To do that, you’ll need some 3D modeling software to turn your ideas into 3D printable files.

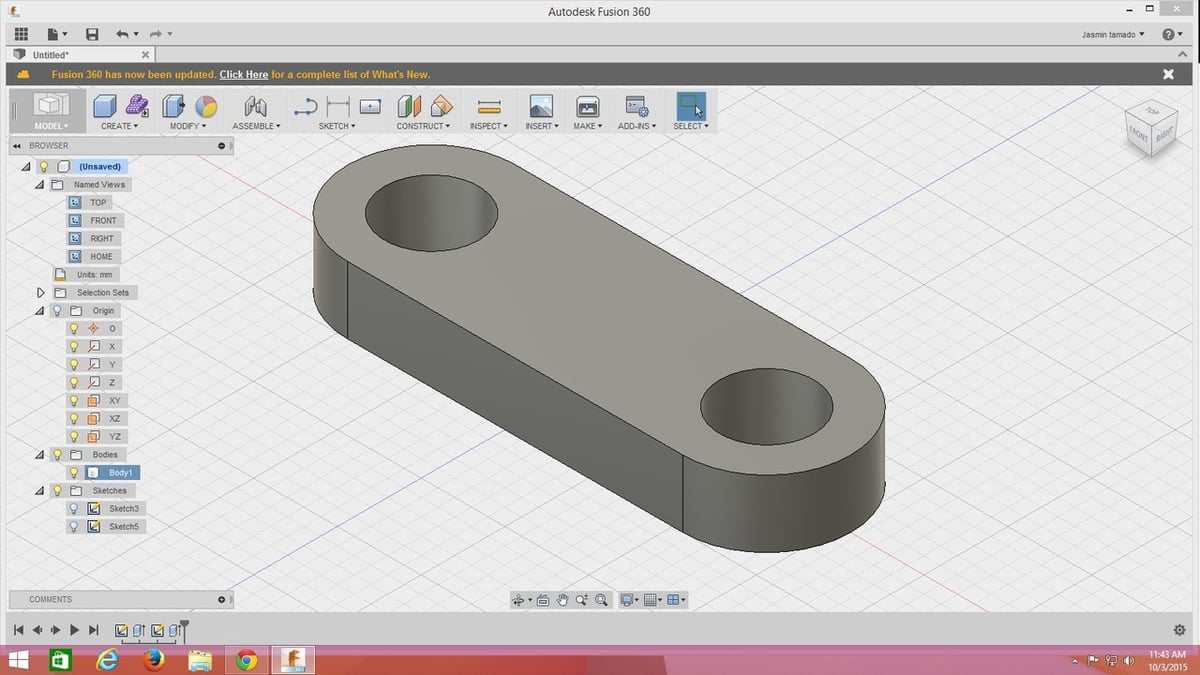

Known as computer-aided design (CAD), there are so many CAD options to choose from, whether you’re a beginner, more experienced, or you’re looking for the perfect program to specifically design for 3D printing. To make things easier, we’ll start by explaining what parametric and direct modeling are, so that you can consider which one might work best for you.

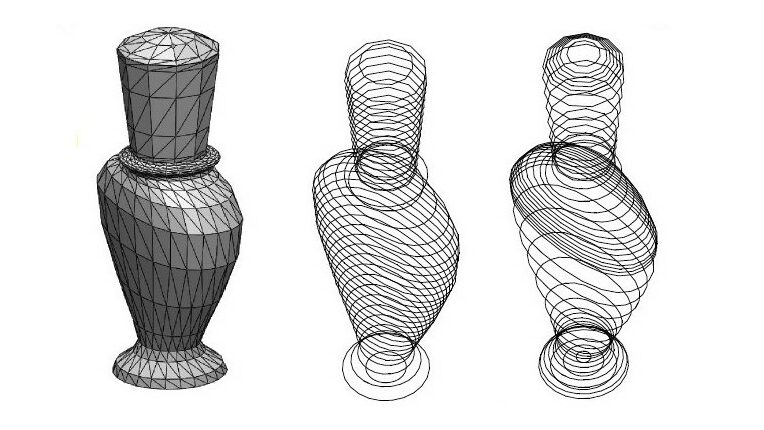

Parametric vs. Direct Modeling

The parametric modeling approach to CAD is based on the geometry of a model and its dimensions. These simple shapes are continually modified or edited over a sequence of steps, creating a “history” or dependencies that will affect the outcome of the model. Similar to time travel, if you were to go back and modify a past dimension, all future features that depend on this dimension will change as well. Direct modeling is the opposite, in that it doesn’t rely on strict geometry or dimensioning to change your model. Similar to sculpting with clay, you can simply alter the shape of the model by pressing or pulling it in any direction. This type of CAD software is primarily used to create organic curves in an aesthetic or artistic capacity.

Tinkercad

Tinkercad, by Autodesk, is a great, browser-based 3D modeling tool for beginners. It’s not a very powerful tool, but it’s very easy to get into, combining basic geometric shapes to create more complex models. If you’re interested, you can get started with our tutorial.

FreeCAD

FreeCAD is an open-source, community-developed CAD tool that allows you to create models by specifying parameters that can be accessed and modified later, providing more design freedom. It also comes packaged with some finite-element analysis tools for engineering simulations. If you’re interested, we have a FreeCAD tutorial for 3D printing.

Blender

Open-source and developed by hundreds of contributors, Blender is a free but professional 3D modeling tool for creating sophisticated 3D models, among many other things. It’s one of the most powerful 3D printing software tools available, for design and mesh editing alike. We have a whole list of tutorials to get you started with this advanced tool, including one specific to 3D printing.

ZBrushCoreMini

The free version of the widely used ZBrush software, ZBrushCoreMini was designed with new users in mind, while giving them the creative freedom to sculpt whatever they can think of. Despite being the free version of its predecessor, ZBrushCoreMini offers 12 different sculpting brushes, 8 materials, and various features to easily add fine details to your models.

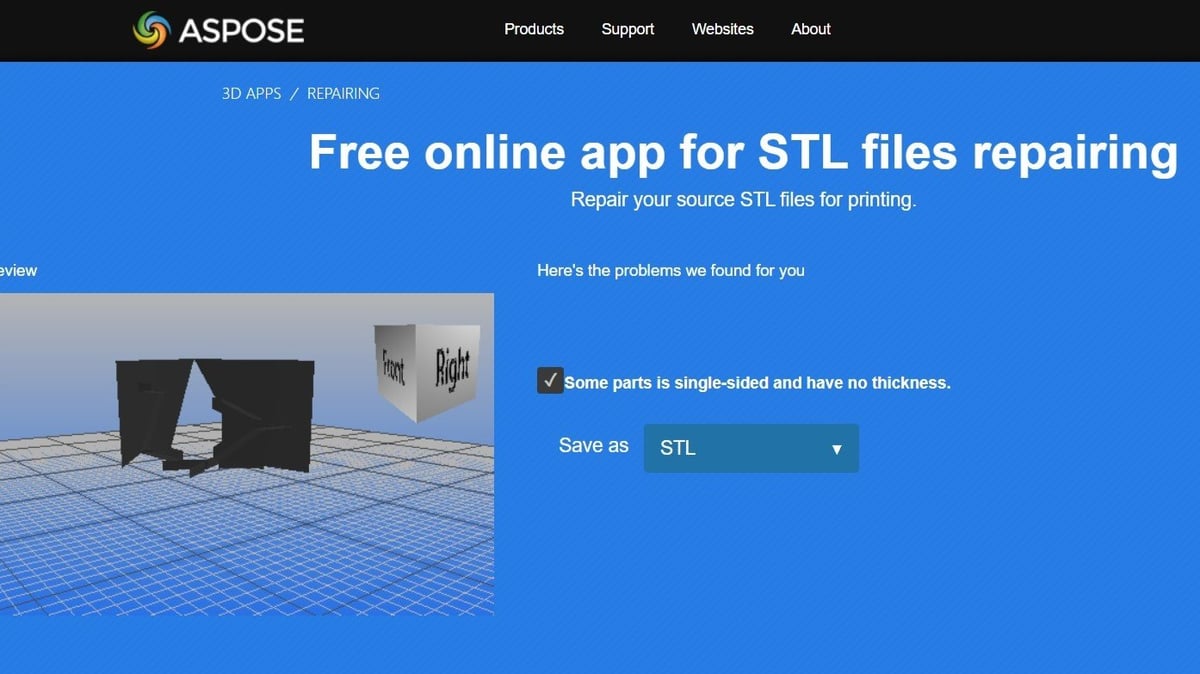

STL Repair

Occasionally, you may bump into the odd 3D printable mesh file that has some errors that trip up your slicing software or 3D printer. In that case, you’ll need to use mesh repair software to fix the file. Mesh repair is a great companion to your slicer because it helps refine the composition of the model by smoothing or filling in holes and surfaces that would have caused an error while slicing.

Certain 3D modeling tools, such as FreeCAD, SketchUp, Blender, and Autodesk’s Fusion, to name a few, have mesh tools included. But, in case those don’t fit your needs or skill level, there are some specially designed mesh repair programs out there as well. Below are a couple of our top picks.

Meshmixer

Autodesk Meshmixer is a free design tool where you can sculpt and perform mesh repairs effectively. It can analyze, automatically repair, and modify meshes. It’s loaded with easy-to-use, 3D printing-oriented tools, making it a top choice among 3D printing enthusiasts. Check out how easy it is to use with our beginner’s tutorial. It’s also important to note that as of 2021, Meshmixer is no longer maintained by Autodesk, but is still available to download and widely used in the 3D printing community.

Netfabb

Autodesk Netfabb is a professional, commercial tool directed specifically towards additive manufacturing. It features a host of powerful tools for preparing and repairing 3D files for 3D printing, including automatic part packing, automating print tasks, and creating simulations of the printing process. As of 2021, the tool has been integrated into Fusion and is, at time of writing, available in Premium, Ultimate, and Local Simulation versions. You can download a free trial for Fusion and any of these, or apply for free educational access, although only the Premium version is available. Netfabb’s mesh repair protocol is also integrated into some slicers, such as PrusaSlicer (depending on the version and OS).

Aspose

There are quite a few browser-based options in case you don’t want to download a program or you’ve only got one file you need to repair, and Aspose is one of those that gets the job done. Simply upload the STL, preview the repairs as suggested by the site, and convert and download the repaired model as an STL, AMF, or OBJ. While it’s understandable that Aspose – along with most browser-based repair platforms – won’t have as many dedicated tools and offer as much customizability for the repairs, they’re still great solutions if you’re in a rush.

Remote Print Control

If you’re doing a lot of heavy 3D printing, you may want to consider some print management software to control your 3D printer(s) and manage your print sessions. These typically include built-in 3D printer control and monitoring, file slicing, and print releasing all in one platform to streamline the 3D printing process.

These programs are helpful if you need to run unattended prints or want to control or monitor your prints wirelessly. In order to enable access to your printer controls remotely (over a network), many print management software run with an additional Raspberry Pi or other internet-enabled option connected to your printer’s control board.

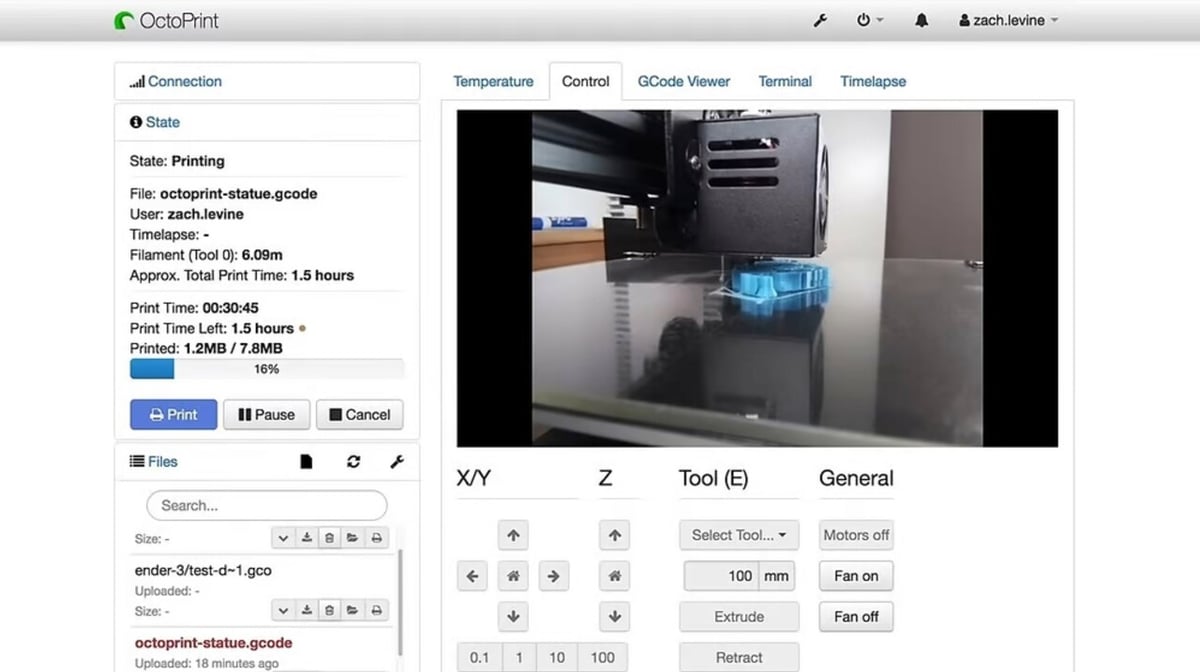

OctoPrint

OctoPrint, developed by Gina Häußge, is one of the most popular print management tools available. It’s a web-based interface, running on a Raspberry Pi connected to your 3D printer, that allows for detailed printer control, monitoring, slicing, and wireless printing. With a whole host of plug-ins available, it’s an incredibly powerful tool for getting all your 3D printing done in one place. Get started with our quick setup guide.

Klipper

Klipper is firmware that has plenty to offer, from input shaping to pressure advance and – you guessed it – remote control. It can run on an external board, such as a Raspberry Pi, to process G-code commands, lessening the burden on the printer’s board. There are quite a few compatible platforms, among which Mainsail and Fluidd are arguably the most popular. Alternatively, you can opt for an Android device and get Klipperoid, or you can purchase Creality’s Sonic Pad, both of which make installing and running Klipper easier.

PrintRun

PrintRun, written by Kliment Yancev and currently maintained by him and Guillaume “iXce” Sequin, is another powerful print management tool. Like OctoPrint, it features 3D printer control, slicing, and print release. With so many settings and parameters available, however, it’s not for newcomers to 3D printing. If you want to try it out, refer to our beginner’s tutorial.

G-code Viewers

Our last optional-but-good-to-have software is a G-code viewer, which is especially useful in scenarios where you only have a G-code file to print with. Most G-code viewers are free tools that allow you to simulate or visualize prints based on the list of 3D coordinates contained in the file you upload. In the event that your slicer doesn’t already have a G-code viewer, an external viewer provides peace of mind by showing you how your G-code files will run.

G-Code Analyser

G-Code Analyser is a browser-based platform that not only visualizes your print, but also can calculate the time, average speed, and total distance traveled during the print when you enter your printer specifications. During the visualization process, models are shown in 2D from an overhead perspective. To the right of the user interface is an interactive slider that shows a specific layer depending on where you drag it.

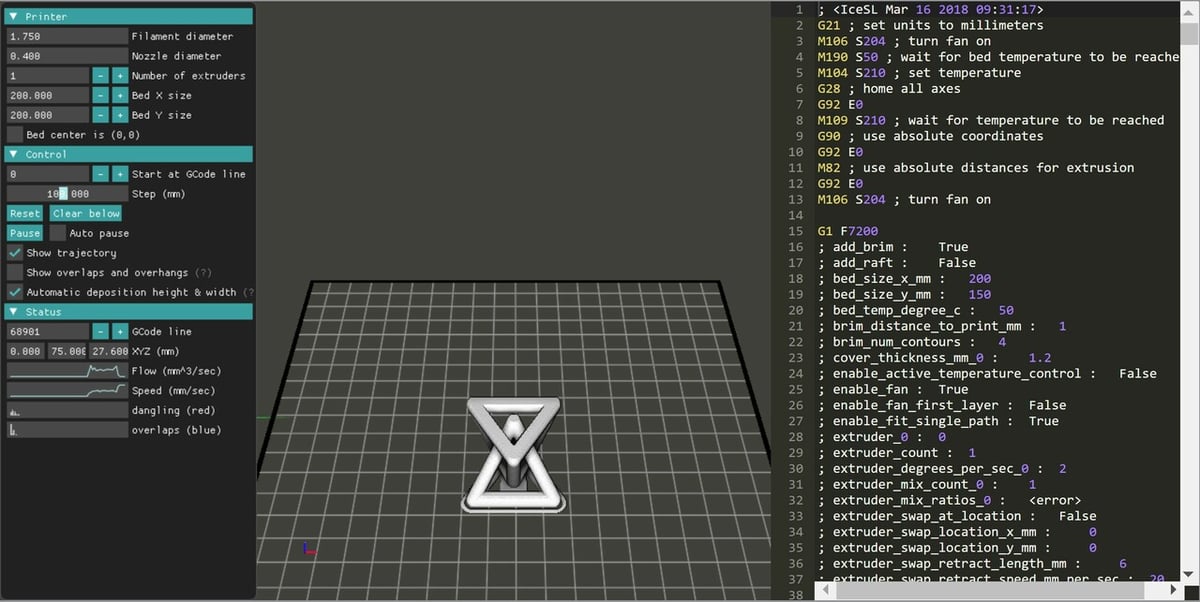

IceSL WebPrinter

WebPrinter is a G-code viewer that’s both online and downloadable, and both versions are free. The user interface simulates the print in 3D as if you were physically watching your print in real-life. Throughout the simulation, WebPrinter also creates real-time graphs and charts that give you some information about the flow and speed of the print.

License: The text of "What Software Do I Need for 3D Printing?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.