Layer by Layer

There are lots of exciting things happening in the 3D printing world. Printers using ultra-violet (UV) light and mirrors to create parts or even lasers! Here, we’re going back to basics and will discuss the three main 3D printing technologies and briefly describe a few others.

While each technology is different in many respects, they all have one thing in common: 3D objects are created by fusing layers of material, one on top of the other. That’s why all sorts of different kinds of machines can be called 3D printers. 3D printing is one type of additive manufacturing (AM), a technology that has revolutionized and is revolutionizing the manufacturing world.

If you’re interested in getting something printed, be sure to check out Craftcloud by All3DP.

With that, let’s begin our printer tour!

Fused Deposition Modeling (FDM)

If you’ve seen a 3D printer at your local library, school, maker space, or even workplace, you’ve probably seen a fused deposition modeling (FDM) 3D printer. 3D printers that use this technology are typically much cheaper, easier to operate, and more versatile than other types of AM machines. They’re used in numerous fields that need to produce prototypes rapidly including architecture, education, and robotics.

How Does a FDM 3D Printer Work?

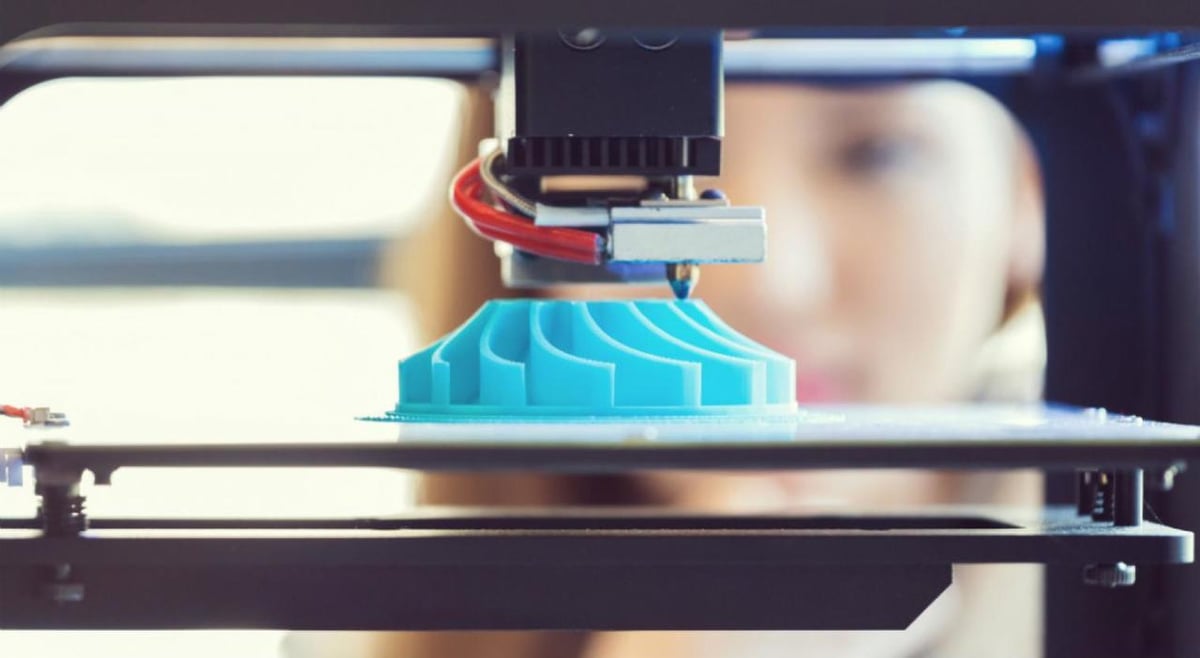

Basically, an FDM 3D printer uses a geared motor, called an extruder, to push a plastic filament through a heated nozzle. The heated nozzle melts the plastic filament and the molten plastic is then deposited onto a build platform. After the plastic is extruded, it cools and solidifies to form a layer.

The print head, which includes the nozzle, moves along predetermined coordinates (from 3D printing software called a slicer) in order to properly form each layer. After one layer is printed, the print head moves up, in order to repeat the process and form another layer. Fused filament fabrication (FFF) 3D printers also use this 3D printing process to create parts.

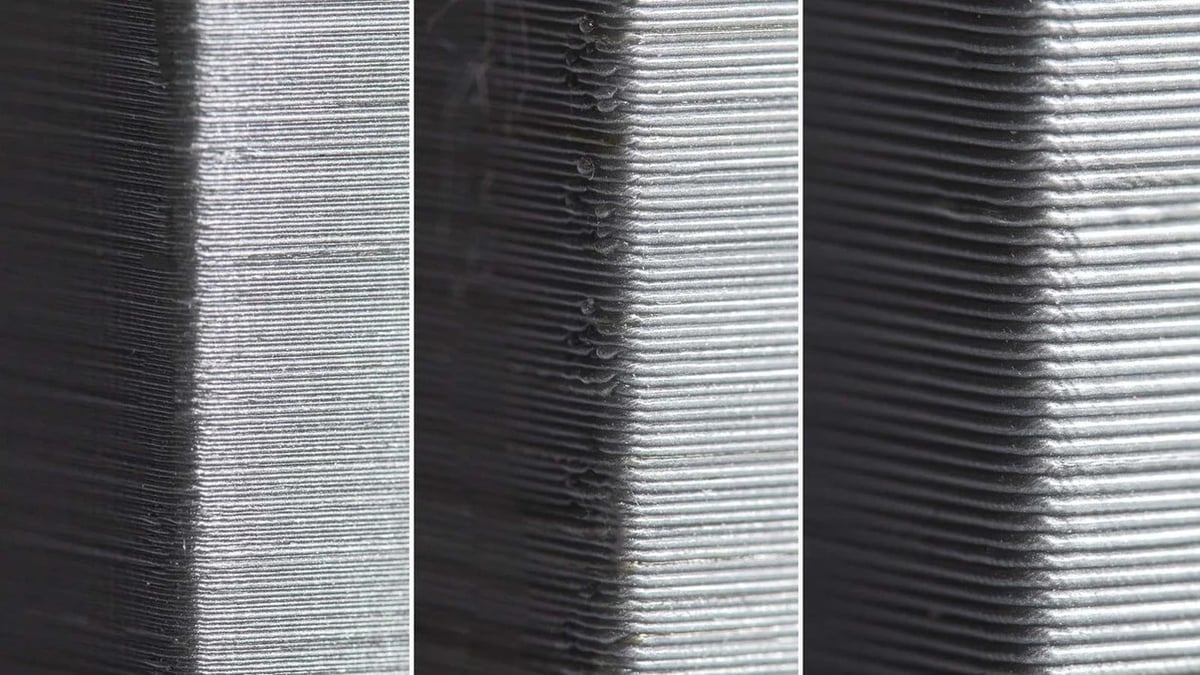

FDM-produced objects usually exhibit fair precision and strength, making it the perfect type of printer for rapidly produced prototypes and medium-stress mechanical parts.

Commercial Options

If you’re interested in learning more about the process, applications, strengths, and weaknesses of FDM 3D printing, be sure to check out our in-depth article that describes FDM printing.

We also have a list of the best desktop 3D printers on the market. Professional-grade machines such as those made by Stratasys can cost over $100,000. However, you can get your hands on a reliable desktop filament 3D printer such as a Prusa i3 MK3S for less than $1,000.

Creality machines, such as the Ender 3, CR10, and Ender 5, are becoming very popular as producers of a wide variety of budget (under $500) 3D printers that seek to rival the print quality of much more expensive machines.

Stereolithograpy Apparatus (SLA)

Stereolithography apparatus (SLA) machines are commonly known as resin printers. That’s because “resin printer” is less of a mouthful than “stereolithography apparatus” and because stereolithography apparatus machines do, in fact, print objects from liquid resin. Resin printers are capable of printing extremely precise parts, making them ideal for applications in numerous industries ranging from jewelry and medicine to art design.

How Does a SLA 3D Printer Work?

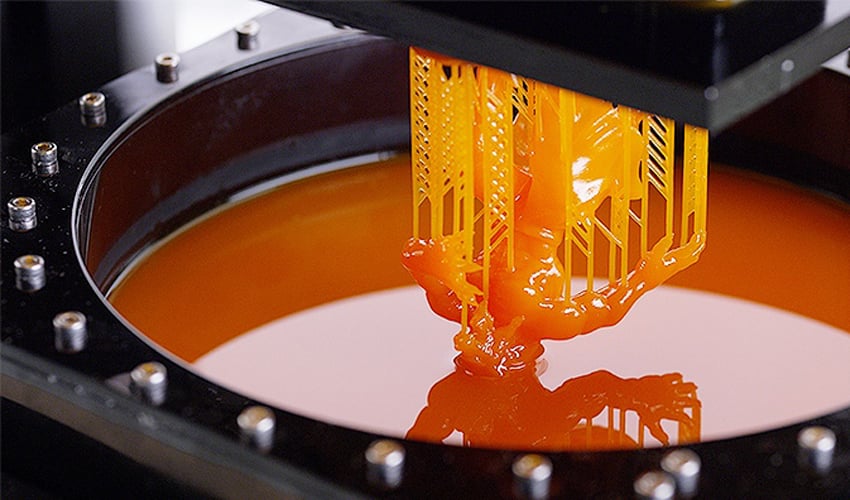

An SLA machine fabricates parts by solidifying photosensitive resins with a laser. The laser is fixed, and it’s directed by a mirror that moves in the horizontal plane to cure regions of resin to a build platform according to the part’s 3D digital file.

The resin is contained in a vat (or reservoir), and as layers are formed, the build platform slowly moves up out of the vat.

Variants

Other 3D printing technologies such as DLP (direct light processing) and MSLA (masked stereolithography apparatus) create parts with a similar process. The main difference between these kinds of vat polymerization technologies is the source of light.

While SLA printers use lasers, DLP printers use UV light projectors, and MSLA printers use an LED light source to shine UV light through an LCD. MSLA is the cheapest vat polymerization technology due to the low cost of LCDs, so most affordable desktop resin printers use this technology.

SLA 3D prints are very precise, however, they do require a significant amount of post-processing, and are typically not suitable for mechanical parts.

Commercial Options

Thinking about buying a vat polymerization machine? Check out this year’s best resin 3D printers. For a while, resin printers were quite expensive. Formlabs dominated the desktop resin 3D printer market with machines that many everyday makers couldn’t afford.

Now that various vat polymerization processes exist, resin printers are getting cheaper and cheaper. Of course, you could buy a resin printer that costs tens of thousands of dollars, but you can also get one for under $300! The Elegoo Mars, Anycubic Photon, and Phrozen Sonic Mini are gaining a significant amount of popularity for being affordable, yet reliable, machines.

Selective Laser Sintering (SLS)

SLS stands for a space launch system in the world of rockets, but in the world of 3D printing, SLS stands for a powder-based 3D printing technology called selective laser sintering.

How Does an SLS 3D Printer Work?

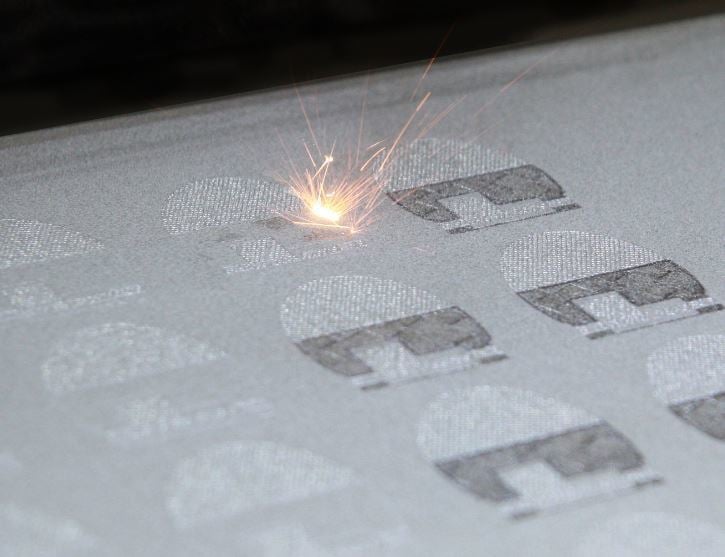

SLS machines work similarly to SLA machines in that they create parts with lasers. However, while SLA printers cure layers of resin with their lasers, SLS printers create thermoplastic or even metal layers by selectively sintering regions of powder.

SLS printers can print parts with extreme accuracy and a wide range of materials, making them ideal for numerous industries. They’re particularly popular with companies that need precise and strong parts, such as in the industries of aerospace, automotive, and even military.

If you want a deeper understanding of this capable technology, check out our article that simply explains SLS 3D printing.

Commercial Options

While both filament and resin printers have become affordable for everyday makers, SLS printers are still quite expensive, selling for well over $5,000 per machine. In addition to the cost of the machine, the materials, tools, and components are also very expensive. Check out our SLS 3D printer buyer’s guide to explore the cost of SLS machines in more detail.

What Else Is There?

As previously mentioned, the three printing technologies we’ve quickly reviewed above are some of the most popular at the moment. To finish off, we’re going to tell you a bit about another three up-and-coming 3D printing technologies that are expanding the capabilities of additive manufacturing.

Material Jetting:

These 3D printers create objects by selectively depositing and curing photopolymer droplets. You can think of this 3D printing technology like an inkjet printer that instead of simply dropping ink onto a piece of paper, drops photopolymers or wax onto a build surface, cures the droplets, and repeats the process on top of this cured layer to eventually finish a print. Material jetting machines such as drop on demand (DOD) printers can even create full-color models!

Binder Jetting:

These printers print parts by selectively dropping a liquid bonding agent to bind regions of powder. After a layer of powder is appropriately bonded, the build platform lowers, and the printer begins to selectively deposit more droplets of the bonding agent to form the second layer. Binder jetting machines can print in full-color, and are able to create metal and even sand parts.

Metal Powder Bed Fusion:

This technology is essentially identical to the SLS technology, however, it’s specifically designed to fabricate metal parts. Direct metal laser sintering (DMLS) and electron beam melting (EBM) 3D printers use this technology to sinter regions of metal powder together with a concentrated light or energy source such as a laser or a high energy electron beam. SLS parts can achieve extremely impressive structural integrity.

Chances are if you have an idea, there’s at least one kind of 3D printer that could make it come to life with extreme precision. If you want to know more about every type of 3D printing currently out there, our 2020 3D printing technologies will give you the latest in this fascinating and ever-evolving field.

Happy reading!

(Lead image source: Makelab)

License: The text of "How Does a 3D Printer Work? – Simply Explained" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.