This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Prusa, Plus

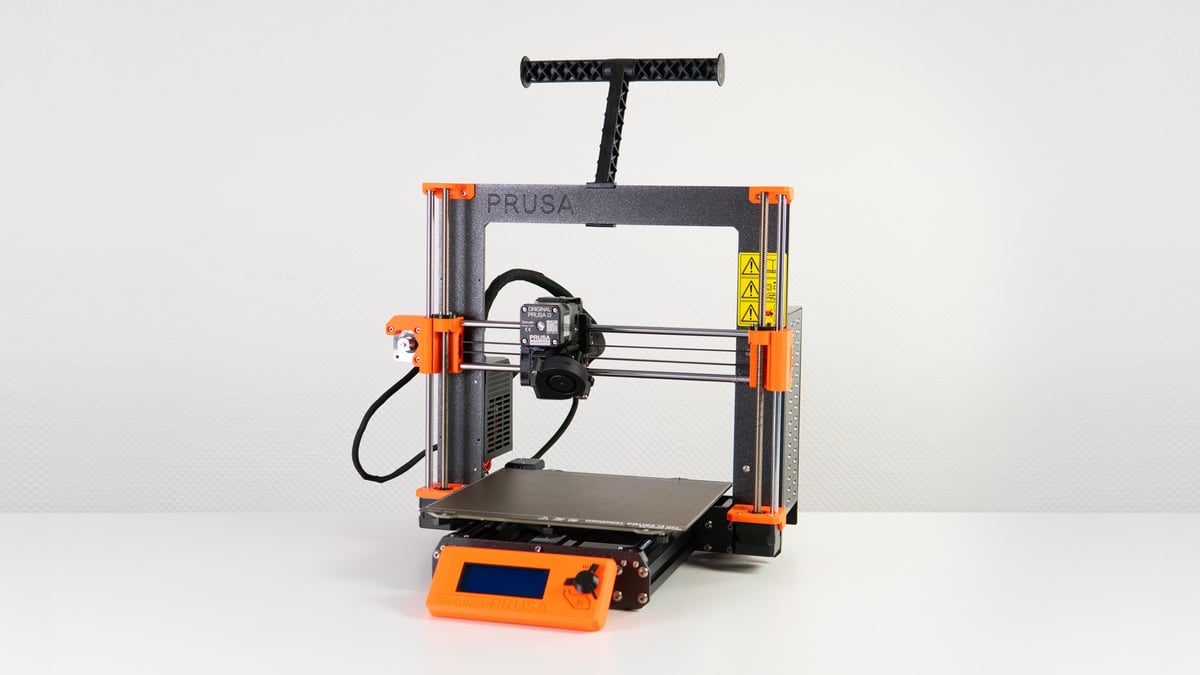

Original Prusa i3 MK3S+ Review: Best 3D Printer Under $1000

Rating

Prusa Research has a new printer out, sort of. The Original Prusa i3 MK3S+ is a lot of what we know, with small design changes and a new mesh bed leveling probe. Read our review to see how it stacks up.

Advertisement

Advertisement