Filament Factors

You most likely know a thing or two about filament, the material at the core of FDM 3D printing. It’s the spooled material that’s melted by your printer’s hot end and then extruded layer by layer to build parts.

There are hundreds of different filament brands out there, and they aren’t all the same. Filament has a wide range of different qualities, depending on the specific material it’s made from and several other factors.

In this article, we’ll be going over what filament composition is, why it differs between products, and its effects on 3D printing. We’ll also be discussing some other factors to keep in mind when buying filaments, like material, tolerance, value, and more.

Composition

Filament composition is essentially the ingredients list that makes up the end product that gets wound around the spool. Generally, filaments are named for their primary material, so you can be fairly confident that a spool of PLA is almost entirely made up of polylactic acid.

A filament’s composition starts in the filament production process with the raw materials. These consist of the primary material and any additives that have been manufactured (or recycled) and then shredded into pellets. These different types of pellets are placed together in an industrial blender to ensure that they’re well mixed.

After the pellets are blended, they’re melted into a gooey substance and then shaped into their final string-like form. Virtually all FDM filaments, including PETG, ABS, and PLA, are made similarly.

Rarely will you find 100% “pure” filaments, as most have additives blended with the primary material. Additives are common and might seem like a compromise on quality, but this is not necessarily the case. Some additives serve a key purpose, like to change a filament’s color or enhance a filament’s properties, but we’ll get to that later.

However, additives are also sometimes used in a filament’s composition to reduce the cost of production. Manufacturers can mix in no-value-added, inexpensive additives that dilute the (more expensive) primary material. This allows manufacturers to use less of the primary material for every filament spool, thus decreasing the cost per spool.

Additives

Additives in a filament’s composition can have different impacts on the final product. As we’ve mentioned, certain additives are used to improve a filament’s look or use, while other additives are used by manufacturers to save money and add no value.

There are many different additives: some bring the properties of different types of plastic while others introduce entirely new materials. Non-plastic additives are sometimes used to create composite products, like the additives used to make wood, metal, and even marble filaments. These additives can also give the filament extra properties, like conductivity.

Plastic additives are generally intended to give a filament special properties to optimize it for a certain function. A good example of this is the additives used to make PLA+ or other filaments with high strength and durability.

On the other hand, some additives add no value at all to filaments. These “filler” materials are used by manufacturers so that they can use less of a primary material per filament spool, reducing the production cost.

Recycled filament is perhaps the most impure filament of them all, as it’s composed of repurposed materials, broken down in order to be given a new life on a filament spool. Recycled filament is still made from the material in the name of the product, but there can be a slight variance in the purity because the recycled plastics don’t have the exact same material composition.

While it’s difficult to find and name each additive in filaments, some manufacturers do publish the composition of their products. You can sometimes find the filament composition in the safety data sheet (SDS), but even then it’s not always clear. For example, MakerBot gives a fairly comprehensive chemical breakdown of their PLA, while Prusa Research lists only that their Prusament PLA is composed of PLA “with additives”. (This is not to say that there’s any requirement for companies to publish every additive that goes into their filaments, only that if you did want to know what’s in there, it’s not a simple process to determine.)

Effects

The “purity” and precise composition of a filament can have a significant effect on the printing process and the properties of a printed part. A more diluted substance will demonstrate the named material’s properties to a lesser extent, but that might be the manufacturer’s intention. This is the case when materials that are challenging to print are combined with more straightforward filaments for a more accessible final product.

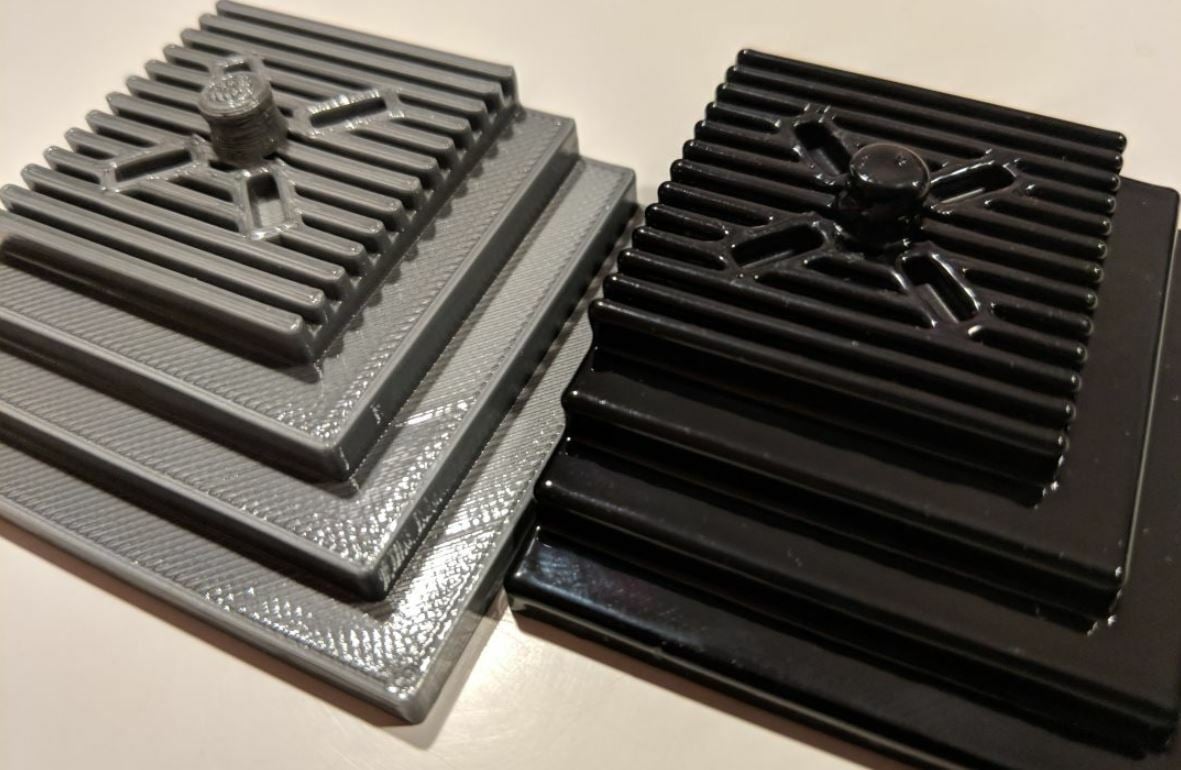

One example of the impact of filament composition is that a less-concentrated ABS filament is not as receptive to being acetone smoothed, as seen in the picture above. The product used on the left included additional ingredients for ease of printing, with the result that the usually effective smoothing process wasn’t as successful.

Material Factors

A filament’s purity isn’t the only element that you should look for when deciding on your next filament purchase, as there are many other points of difference between brands. In this section, we’ll list some of the other major factors that you should look for when buying filament.

Compatibility

The first step to being happy with your filament is to make sure you’re buying the right type of filament for the job and for your printer. Different materials are suitable for different purposes, so you need to consider whether your part has a functional or an aesthetic purpose, for example.

Regarding printer compatibility, the most basic consideration is whether your printer has a heated bed. Some materials can only be printed on a heated platform, so this will narrow down your choices. You’ll also need to consider the quality of your printer’s nozzle if you’re looking to print with abrasive materials like carbon fiber composites.

The filament should also be the right size; if your printer takes 1.75-mm diameter filament, that’s the only size you can print with (unless you’re willing to upgrade your hardware). Another aspect of printer compatibility that many people forget about is spool size. This means making sure that the filament roll you purchase can definitely fit on your printer’s spool holder.

Tolerance

Another point of comparison between filaments is the width tolerance, which refers to the maximum variation in width throughout the spool (sometimes also called dimensional accuracy). This value is commonly provided by the manufacturer and is usually expressed as an approximate number.

A value of “±0.05 mm” indicates that the filament never deviates more than 0.05 mm in either direction from the stated width. If the filament diameter isn’t very consistent and has a lot of wider and narrower portions, it indicates a lack of quality. Variations in width mean the volume of material being pulled by the extruder is inconsistent, which can lead to extrusion issues, clogging, and affect the quality of the printed object.

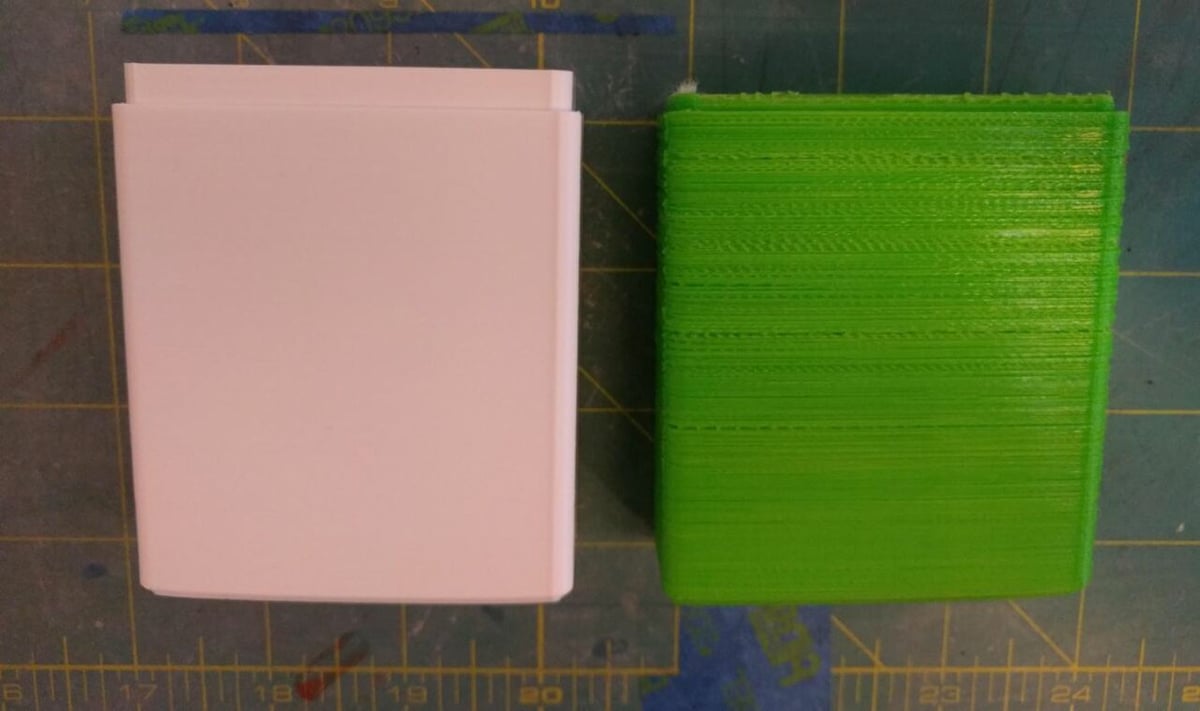

A fairly standard filament width tolerance is ±0.05 mm, but some brands do better (e.g. Hatchbox advertises ±0.03 mm; Prusament promises ±0.02 mm). Basically, a lower number means greater dimensional accuracy, which is a good thing! However, high manufacturing precision often comes at a price, which leads us to some other considerations to keep in mind when deciding which to buy.

Purchasing Factors

There’s more to think about than just the material properties of a filament. Other factors affecting your purchasing decision include special features, value, and reviews, all of which can be very helpful when deciding what filament is right for you.

Special Features

By special features, we mean the particular qualities a filament has been designed to offer. Certain filaments are meant for printing easily, while others are meant for printing durable parts. Some of these features are typically associated with specific filament materials, like how nylon is known for its toughness, but the existence of composites and enhanced filaments means it’s not always that clear cut.

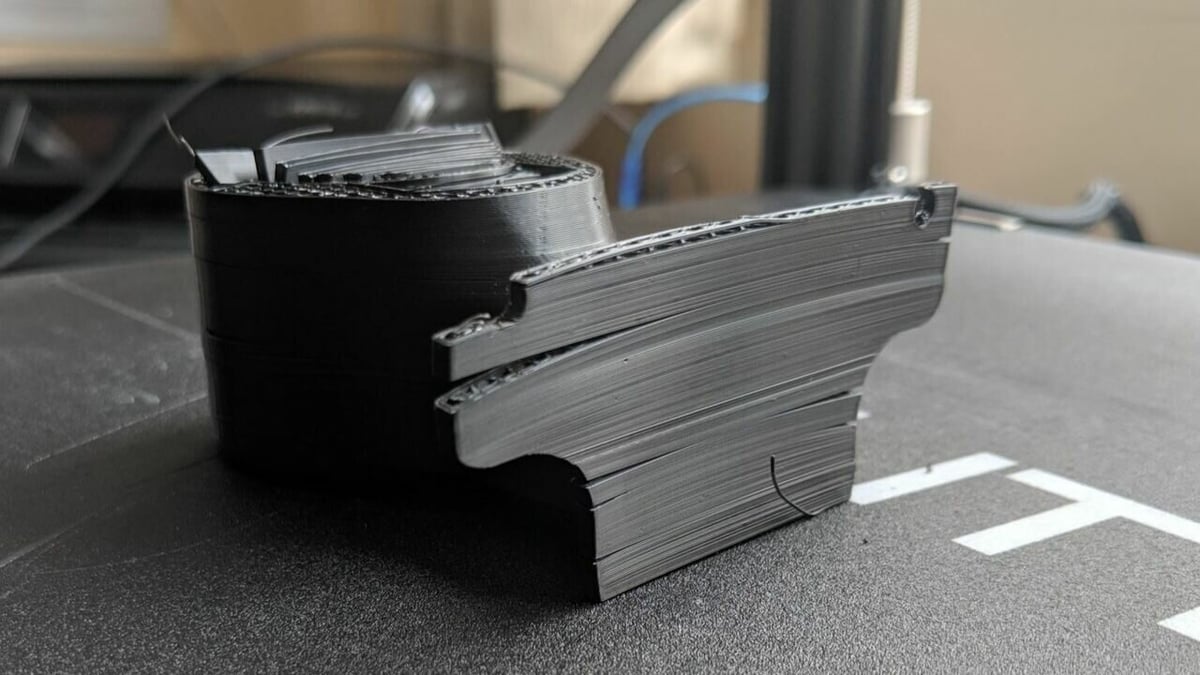

This can be seen with “Pro” and “Plus” versions of filament, which tend to have better properties than their standard counterparts but are still made from the same material. The image above shows a special polycarbonate filament holding up 150 pounds without even bending.

Value

When choosing what filament to buy, remember to look for good value rather than the very cheapest option. In other words, try to find a filament that has a reasonable price for its material type, tolerance, and special features.

You should make sure you’re getting a fair price by looking at the amount of material you’re getting (by weight or length). There are different price ranges for different materials, too, so you should look at a few similar filament brands to ensure that you aren’t overpaying, or potentially even underpaying!

Reviews

If you’re not familiar with the manufacturer or want a second opinion, you can turn to online reviews of the filament in question. Although we all know that some reviews might not be genuine, sites that require reviewers to have actually purchased the product, or that clearly state which reviews are from genuine purchasers (such as Amazon), should be fairly trustworthy.

Additionally, for a more in-depth source of feedback for a filament, consider relevant forums and YouTube reviews. It’s always a good idea to see what other people think of the filament to determine if it’s right for you, but try to find the most trustworthy and unbiased sources.

Final Thoughts

We’ve listed some of the main things to look for in a filament, but there are always other factors to think about. Ultimately, the most important consideration is how you plan to use the filament. For example, if you want to print with a flexible material, you’ll want to look at the Shore hardness of the material to see if it’s the right level of flexibility for your project.

It’s also worth considering buying smaller spools or samples before committing to a full-sized spool of filament. Fillamentum is one brand that offers samples and even swatches, but there are many others. This means you can experiment with a new material or brand before spending too much money on buying a full spool.

If you’re unsure about where to start, don’t worry! You can always check out some of our many articles on the best brands of different filaments.

Lead image source: Titan Robotics

License: The text of "3D Printing Filament: What to Look for Before Buying" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.