Boldly Go Bigger

With 3D printing, you can make everything from chainmail to Harley Quinn swag. However, when it comes to impressive 3D prints, printing an object that’s larger than your build volume (in multiple prints) can lead to some amazing things.

This article is all about inspiring you to dream big. It comprises some large printing projects that are genuinely impressive for a number of reasons. To help you sort through them, we’ve divided the list into four categories: Star Wars, transportation, just for fun, and miscellaneous.

For each project, we’ll give you a brief overview and summarize all of its most important aspects. Unfortunately, not all of them have download files available, but there are still plenty of choices for you to try your hand at.

While you’re checking out the list, if you think you’d like to make a big print but don’t have the means to do so, or if you would prefer a professional to do the job for you, we recommend you take a look at Craftcloud by All3DP.

In the meantime, let’s get to those projects!

Star Wars

Believe it or not, some of the most inspired 3D printing enthusiasts out there are also Star Wars fans. To start off our celebration of big and beautiful prints, let’s dive into everyone’s favorite space-opera epic.

R2-D2

Many Star Wars fans dream of building their own R2-D2 unit. Before 3D printing, this was just a pipe dream. But now, there are entire websites dedicated to the task, like Astromech.

In most cases, this still requires a lot of time and effort. However, a relatively simple method of creating R2-D2 has arrived thanks to Michael Baddeley, who came up with this space companion for you to print and impress your friends and family.

In addition to this 3D printed R2-D2, there are additional Star Wars printable droids available, like the D-O droid. There’s even a Facebook group dedicated to the builds by Mr. Baddeley, which can help you figure out what your next project will be.

- What is it? A life-size R2-D2

- Who made it? Michael Baddeley

- How was it printed? (Unknown)

- How much material did it take? 3-4 kg of Hatchbox PLA for the dome, with much more for the entire body

- Which post-processing techniques were used? Sanding, puttying (with copious amounts of Bondo), and lots of perseverance

- Where to find it? Michael Baddeley’s Patreon

Jabba the Hutt

This mighty Jabba the Hutt is one of the biggest movie props we’ve seen printed on standard-sized 3D printers. This massive space alien was printed by Cults user MightyJabba after having it commissioned as a 3D model.

Given the incredible size of this model, in order to minimize the filament needed, it was printed with fairly thin walls (about 1 cm), which made assembly and alignment quite delicate. To complete the project, parts needed to be sanded and glued together with super and epoxy glue as well as filled with putty.

- What is it? A life-sized Jabba the Hutt

- Who made it? MightyJabba

- How was it printed? Primarily on a Creality CR-10 and some similarly-sized printers

- How much material did it take? Between 35 and 40 kg of PLA in various colors

- Which post-processing techniques were used? Sanding, gluing, puttying, and painting

- Where to find it? Cults, Thingiverse

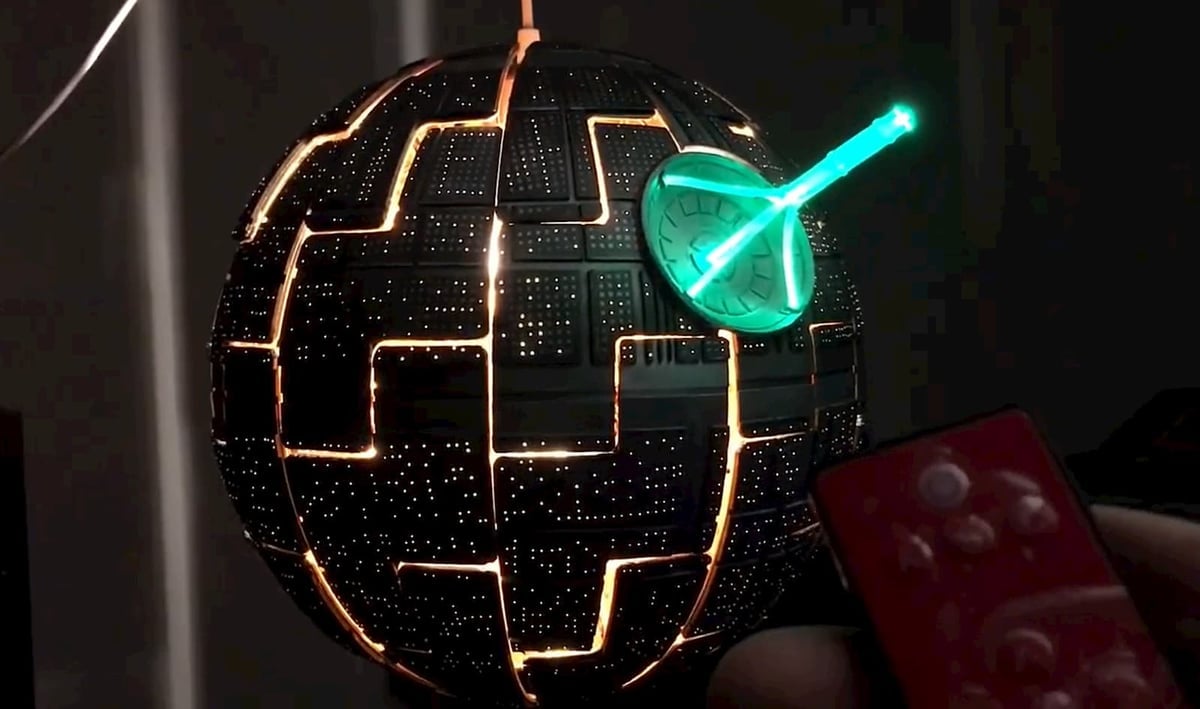

Death Star Lamp

This Death Star lamp is made from a modified Ikea lamp (PS 2014), which turns a simple purchase into one that can help you crush the rebellion once and for all.

Several people have made different builds of it, ranging from minimal effort to motorizing it so it’ll explode on command (check out the video below).

- What is it? A modified Ikea lamp that looks like the Death Star

- Who made it? dagoma3D

- How was it printed? On a GeeeTech MeCreator 2 and a Creality CR-10

- How much material did it take? A bit over 1 kg of PLA

- Which post-processing techniques were used? Very little, although one can always sand, paint, and motorize to their heart’s content

- Where to find it? Thingiverse

Transportation

These next few projects are less surprising in their scope. After all, it’s hard to make anything useful for a vehicle without it being big.

Yet, that doesn’t make them any less cool. Get ready for some fully-functional prints!

Hard Top for a Car

Don’t have money to fix up your car? No problem – now you can just print the part you need! This hardtop for a Mazda Miata is maker ehutch7 pushing the envelope of what 3D printing can do.

The file for this isn’t available online, but we would imagine it’s something that would have to be custom-designed or scanned from an existing car. The make was 3D printed in 14 separate pieces using PLA on a CR-10 S5 3D printer, and it took over 700 hours to print.

It isn’t clear what legalities are involved with 3D printing your own car parts, however, there are several Facebook groups such as 3D Printing – Auto and Moto and 3D Print My Ride to get you started, should you choose to go down this route.

Car Spoiler

When most people think of printing something big, they don’t often think of something functional as well. Amazingly, John Hinkel thought of both and created a car spoiler print to make a mold for a Subaru BRZ.

John printed the part with PLA on a Hyrel Engine 3D printer in 20 separate pieces. In order to ensure proper fit, a significant amount of post-processing was needed, including sanding, copious amounts of Bondo, heat forming, and super glue to put every piece together.

John is hoping to fine-tune this print to achieve good functionality for the car using carbon fiber before he makes custom files available to the public.

- What is it? A car spoiler test piece mold for a Subaru BRZ

- Who made it? John Hinkel

- How was it printed? In 20 pieces on a Hyrel Engine

- How much material did it take? Approximately 2 kg of Inland PLA

- Which post-processing techniques were used? Sanding, print coating, puttying, heat forming, and super gluing

- Where to find it? (Unavailable)

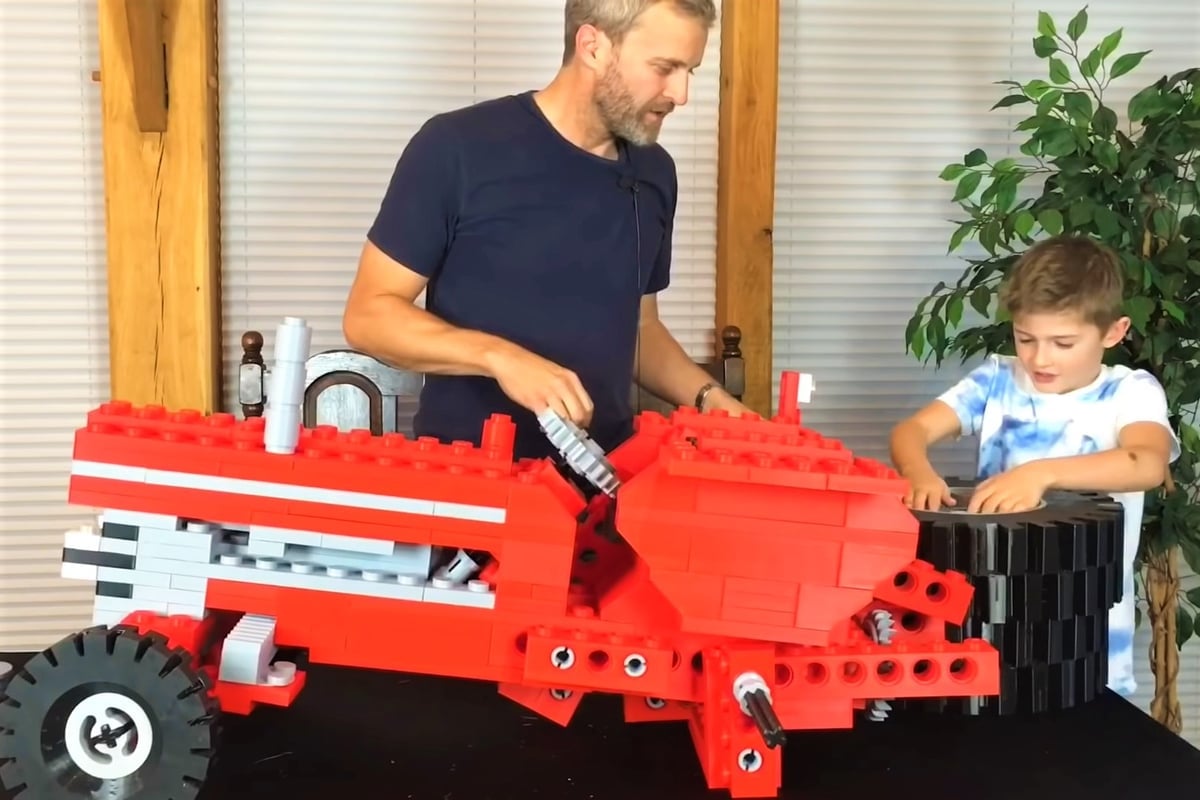

Plastic Brick Tractor

Many kids grow up playing with Lego. The fun plastic blocks can transport a child to different worlds and help them learn how to build things. Wouldn’t it be great if you could scale things up a bit to make an adult Lego set for yourself? Well, Matt Denton has done just that by creating this gigantic Lego tractor. It’s so large, one of the wheels are bigger than his kid’s head!

What’s truly amazing about this build is that Matt even made a functional three-point hitch to attach additional farming equipment. In order to get the parts to have correct tolerances, a soldering iron was used to form some parts.

Additionally, he added bearings to allow several parts to spin freely. Sadly, many of these Lego builds are no longer available due to Lego copyright claims, however, they’re still quite impressive and fully capable of capturing the imagination.

- What is it? A Lego brick tractor

- Who made it? Matt Denton

- How was it printed? In 400 hours on a Lulzbot Taz 6, a Lulzbot Taz 5, and a Lulzbot Mini

- How much material did it take? (Unknown amount of Polymaker Polylite PLA)

- Which post-processing techniques were used? Most notably, some soldering as well as adding bearings

- Where to find it? (Unavailable)

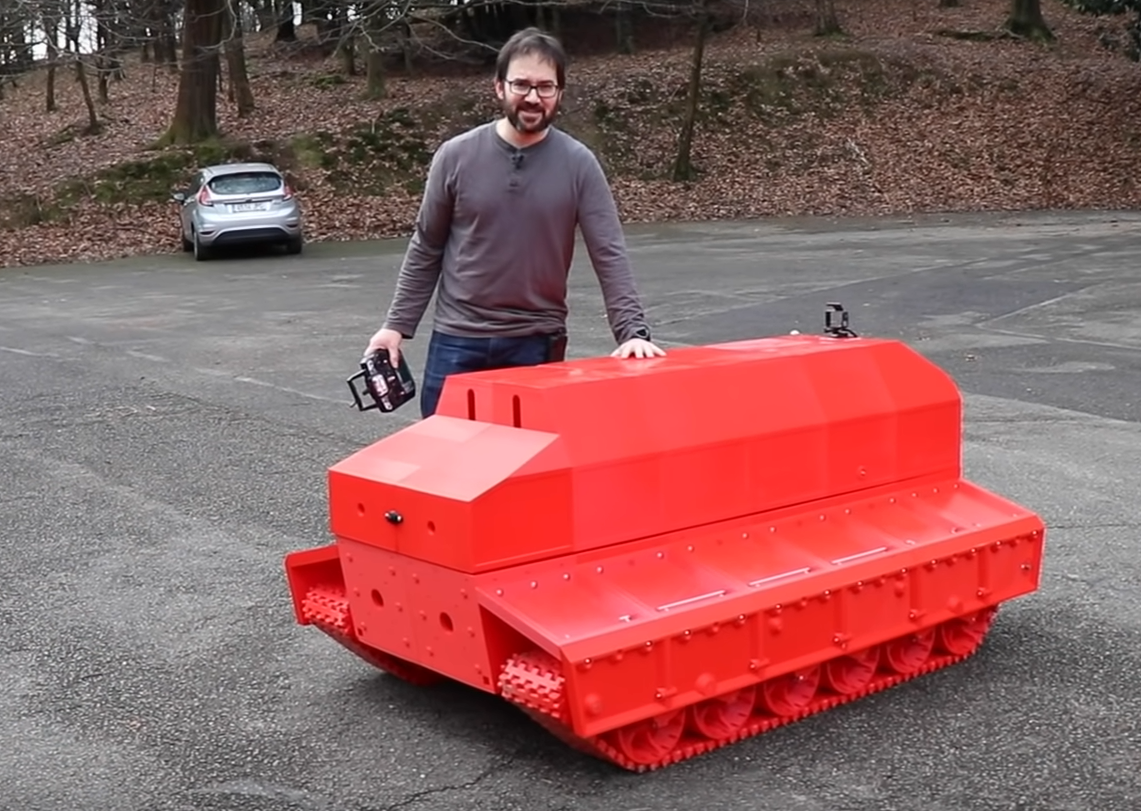

Tank

When it comes to gigantic 3D prints, one print that cannot be denied is Ivan Miranda’s 3D printed and ridable tank. This test footage shows how easily the tank plows through large tree branches without even slowing down.

This tank took over 1,200 hours to print and includes lots of additions, like motors and metal rods for reinforcement. The entire vehicle weighs 120 kilograms, including motors and other metal supports.

Amazingly, after a failed test, Ivan turned the current up to 100 amps at 24 volts, which as he says, “adds up to insane,” but that “it seems that insane works better”. Whatever it takes, we really want to build one of these.

- What is it? A 3D printed tank suitable to hold an adult

- Who made it? Ivan Miranda

- How was it printed? Given this video, maybe on a CR-10

- How much material did it take? Between 80 and 100 kg

- Which post-processing techniques were used? Drilling, tapping, grinding, and gluing

- Where to find it? (Unavailable, but eventually Ivan Miranda’s website)

Just for Fun

Sometimes bigger really and truly is better! The following projects were put together by people who wanted to take their passion to the next level.

Hulkbuster Suit

When you think of gigantic 3D prints, you may not think of cosplay as being a great source, but this print by James Bruton has our jaws on the floor. If the size wasn’t impressive enough, it’s a fully-functional, wearable costume, with several parts being 3D printed, such as the helmet and coverings.

Given that it needed to be strong and functional, many of the interior parts needed to be reinforced. Foam parts were also used to ensure that the suit could be light and strong enough for continual wear.

All of this adds up to a build with amazing quality, and the movement is also very natural. We’re excited to see what he builds next.

- What is it? A life-sized wearable Hulkbuster suit

- Who made it? James Bruton

- How was it printed? In several hundred pieces on a Lulzbot Taz 6

- How much material did it take? (Unknown amount of ABS and Ninjaflex)

- Which post-processing techniques were used? Mainly sanding and painting for the 3D printed parts (with foam parts added for reinforcement)

- Where to find it? (Unavailable)

Rosie the Riveter

To create a gigantic 3D print, you generally need a gigantic amount of filament, but that can be pricey. One method of getting around the cost is to crowdsource, with other makers each donating a small piece. That’s exactly what happened with this Rosie the Riveter statue, which was made by We the Builders and featured on Adam Savage’s Tested.

Rosie took over 700 makers and 2,625 separately-printed pieces to fully complete. One interesting aspect of this project (and many others) that have been done by We the Builders is that not every piece has the same tolerance. As a result, adhesives and a custom 2 x 4 frame were used to give Rosie some structural integrity.

- What is it? A Rosie the Riveter statue

- Who made it? Todd Blatt and Jen Schachter from We the Builders

- How was it printed? In 2,625 pieces on a plethora of machines and materials

- How much material did it take? (Unknown)

- Which post-processing techniques were used? Gluing and framing

- Where to find it? We the Builders

Giant Duck

Rubber ducks are truly an iconic symbol. They’re so pervasive in society that they’ve even been known to float down major rivers just to make people happy. The Great Duck Project, led by Nick Iacobelli and Jesse Robinson from the Greens Farms Academy in Westport, Connecticut, aimed to create a multicolored rubber duck statue from crowdsourced printed parts, although this duck was never meant to float.

Many different materials printed on many different printers were used for the final make. This included using exotic filaments like wood, metallic, and various multi-colored plastic types. The final product was put together with glue. Exactly how much material they used is unknown, but the duck is mostly hollow with two-inch-thick walls.

It should also be noted that, technically, two ducks were made: one smaller version along with the gigantic six-foot version. Interestingly, this project was inspired by the Great Duck Race, a fundraiser for the Westport Sunrise Rotary club who collaborated with Maker Faire Westport to create the world’s largest 3D printed duck.

- What is it? A giant rubber duck statue

- Who made it? Nick Iacobelli and Jesse Robinson from the GFA

- How was it printed? With many different printers and materials

- How much material did it take? (Unknown)

- Which post-processing techniques were used? Gluing

- Where to find it? (Unknown, but similar files are on Thingiverse)

Spartan Laser

Fans of Halo know that, when the Covenant comes knocking at your door, you need to be ready. Nothing says “I’m prepared” quite like a larger than life-sized Spartan laser.

This monstrously large weapon was designed by MisterChiefCostuming and took over 400 hours and 4.5 kg of filament to print. The main post-processing was done with simple supergluing.

It should be noted that, while the size seems extreme, this is actually fairly accurate since later Spartans are supposed to be much taller than humans. For now, though, it looks rather disproportionate on those of us who haven’t trained to be super soldiers.

- What is it? A Spartan laser

- Who made it? MisterChiefCostuming

- How was it printed? On an Ender 3 Pro

- How much material did it take? Over 4.5 kg of gray PLA

- Which post-processing techniques were used? Gluing and painting

- Where to find it? Thingiverse

Robot

For those of you who want to bring about humanity’s destruction by creating robots that supersede human ability, you’re in luck. This design, created by Gael Langevin from InMoov (an open-source 3D printed life-size robot project) allows makers to 3D print their own robotic companion without breaking the bank too badly.

Interestingly enough, Google translate is integrated into this robot, so like C3PO, it’s fluent in many forms of communication. Although this robot definitely isn’t finished yet, we can’t wait to see the full build and, more importantly, what purpose Snooregood had in mind when creating this mechanical humanoid.

- What is it? An open-source 3D printed robot

- Who made it? Gael Langevin

- How was it printed? On the Flashforge Finder and the Ender 3 Pro

- How much material did it take? (Unknown)

- Which post-processing techniques were used? (Unknown)

- Where to find it? InMoov

Miscellaneous

What list isn’t complete without a miscellaneous category? Here are a few projects that didn’t quite fit anywhere else but were too good to lose.

Ceiling Track System

Not all gigantic 3D prints have to be whimsical or even large enough to block your view. Demonstrating that point is this full-size ceiling track system, which will can better organize your maker space. With it, you’ll be able to hang various shop essentials, allowing you to make to your heart’s content.

Amazingly, this system seems strong enough to handle the weight and manipulation of a large collection hose. The potential use cases are nearly endless, from curtaining off areas to grouping and holding sets of cords.

- What is it? A ceiling track system for holding shop necessities

- Who made it? Nate

- How was it printed? Probably on a Prusa

- How much material did it take? An estimated 125 g per section

- Which post-processing techniques were used? Adding parts like bearings and bolts for assembly

- Where to find it? Prusa Printers

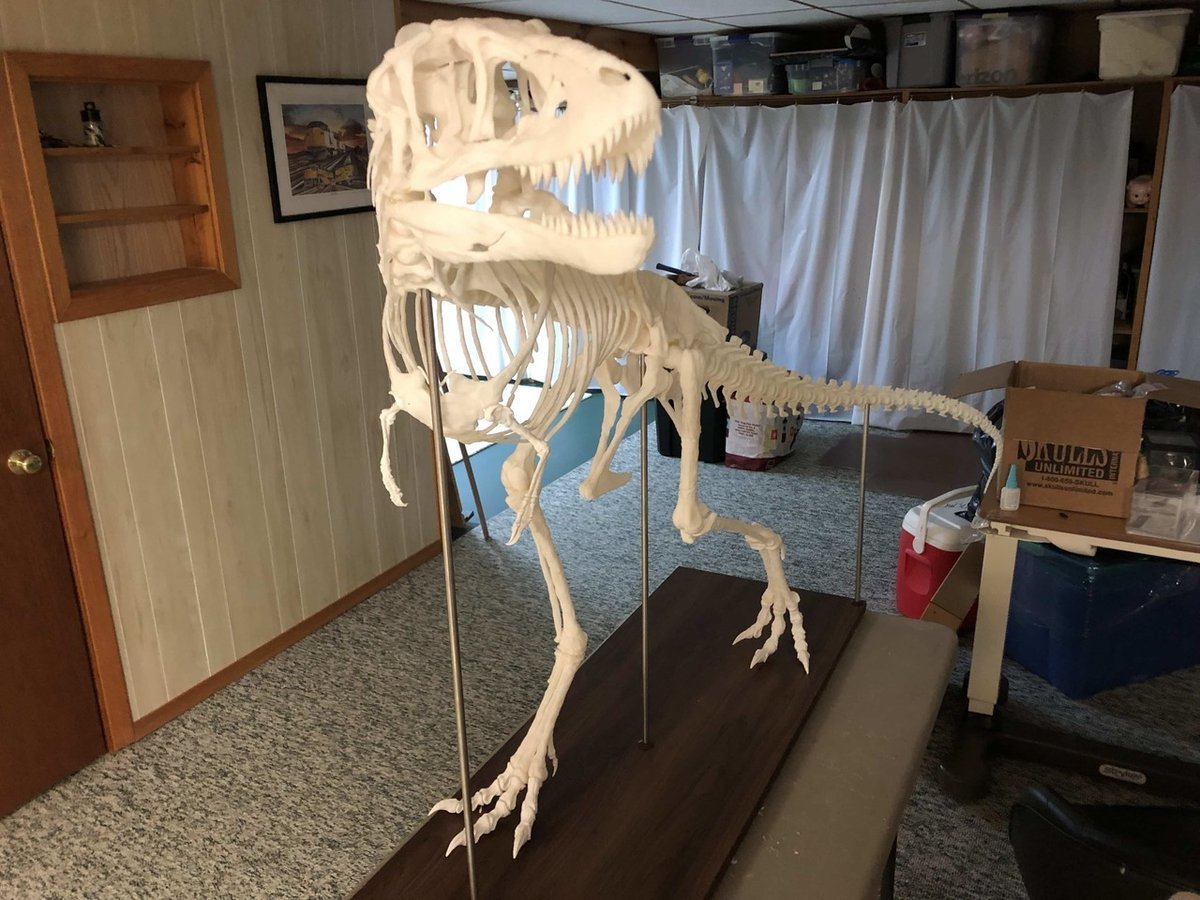

Baby T-Rex Skeleton

Who doesn’t want their house to look like a museum? Cults user Minordisaster23 found a way with this 3D print of a life-sized baby T-Rex skeleton.

It was sculpted with ZBrush and stands 100 cm tall when fully assembled. For post-processing, it could be sanded, but for the most part, it requires little other than assembly and removal of printing supports.

This make involves a complex set of files that are listed on Cults in ten separate pages. We’ve linked to the first page, which should give you access to the rest. With a few more dinosaur prints, you could open your own Jurassic Park in your basement.

- What is it? A baby T-Rex skeleton

- Who made it? Minordisaster23

- How was it printed? On a Prusa i3 MK3

- How much material did it take? Between 4 and 4.5 kg of PLA

- Which post-processing techniques were used? Sanding and assembling

- Where to find it? Cults

Flywheel Turbine

This 3D print is one of the smaller ones on our list, but we felt it deserved to be here because of its big implications both for energy generation.

This 3D printed wind and water turbine is a functional wind generator capable of generating between 1 and 20 volts, depending on the input energy.

Taking a look at the assembly and testing video, it’s clear that this generator is quite useful in that it can be used as a wind turbine, water turbine, hand crank, or flywheel generator with some simple 3D printed tool changes. That makes this little device a versatile and functional 3D print, considering that all the pieces can be printed on a print bed of 100 x 100 x 100 mm.

- What is it? A 3D printable wind and water turbine

- Who made it? Konstantin Tabakov

- How was it printed? On a Creality CR-10

- How much material did it take? Around 300 g of PLA for the generator

- Which post-processing techniques were used? Epoxying

- Where to find it? EnvatoMarket

(Lead image source: Jen Schachter)