Keeping it simple, you can’t 3D print pure rubber. But why not?

This is due to how rubber is made. Broadly speaking, synthetic rubbers start out, just as many other polymers do, as small molecules derived from petrochemicals. These get converted into long-chain polymers that then undergo further processing, including vulcanization. A cross-linked chemical structure is the result of this processing and is the key to giving rubber its tough and durable properties.

Rubber is a thermoset polymer, which means it can’t be re-heated or reformed, unlike thermoplastics like PLA or ABS. Heating a thermoset polymer will simply burn it, and potentially release harmful fumes as well.

That said, you can easily print flexible materials on an FDM or resin machine. Both technologies operate rather differently from one another, but both have their own advantages.

In this article, we’ll go over different flexible materials as well as a few suggestions on how to use them depending on your 3D printing technology of choice. Then, we’ll include some popular brands to consider.

The Flexible Scene

There are many flexible materials available, but the following are the most commonly known and used. Their acronyms are short and sweet – compared to the mouthfuls that are their full name:

- TPU: Thermoplastic polyurethane

- TPE: Thermoplastic elastomers

- TPC: Thermoplastic copolyester

Among the characteristics of flexible filaments, the benefits include elasticity, durability, strength, flame-retardancy, as well as food safety, and anti-bacterial properties in certain formulations. Given long-term skin contact approval, flexible filaments are a great choice for 3D printing prosthetics and, for example, watch bands or other complements for wearable electronics. Among the different flexible filaments available, you can also find options made from 100% recycled material.

On the other hand, flexible resins are a type of UV-cured 3D printing resin that mimics the properties of rubber. They’re known for creating firm but flexible parts, and the Shore hardness of the resin can be related to their pliability (or stiffness). But what is Shore hardness?

Shore Hardness

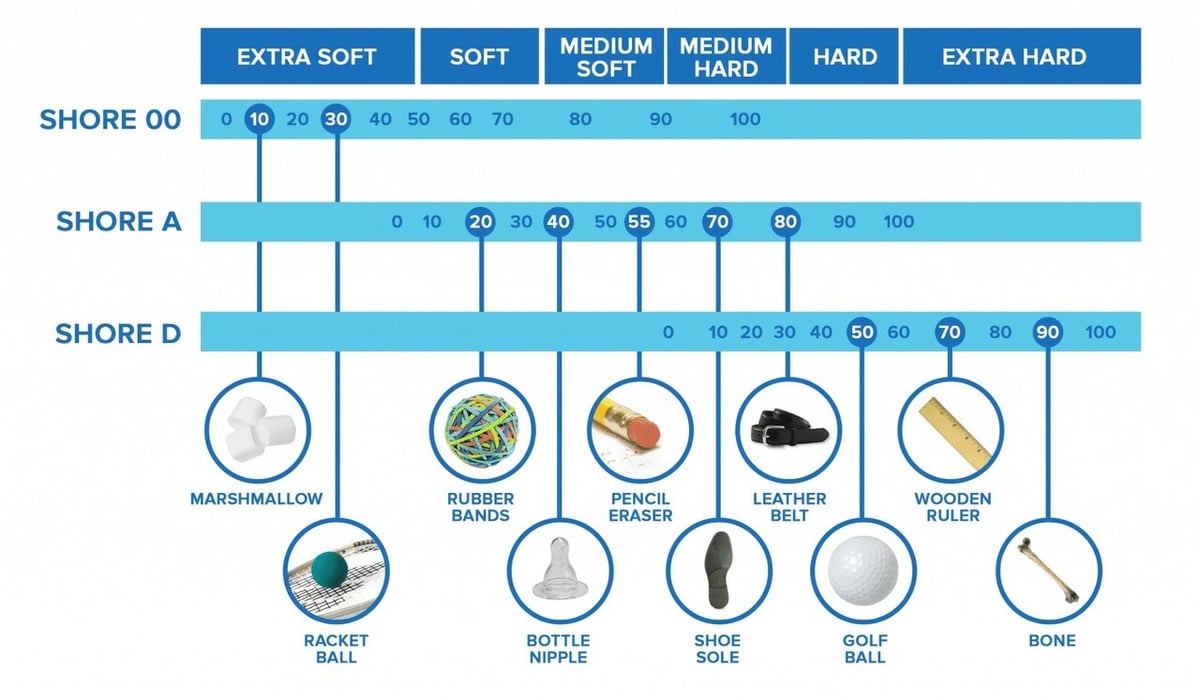

Shore hardness is measured with a durometer and used to quantify the hardness of a material. A durometer test is relevant for soft and flexible plastics, while a Rockwell test is used for more rigid materials like polycarbonate.

Material hardness falls into three different Shore scales:

- Shore 00: Used for extremely soft materials such as gels and rubber

- Shore A: Used for flexible rubber and rigid plastics

- Shore D: Used for rigid plastics and hard rubber

For general reference, 3D printing flexible resins usually have a Shore hardness of around 80A, which, as seen above, is similar to a rubber shoe heel (harder than a shoe sole) or comparable to a leather belt.

Knowing the Shore hardness of the material you’re printing with is useful if, for example, you’re printing a mold. You’ll know that a softer material with a Shore hardness of around 30-40A will produce a flexible mold that you’ll be able to easily extract things from. If the mold is too rigid, then the removal of the part can lead to the part breaking or cracking.

Filament

Printing with Flexible Filament

To ensure the best results, there are some things to think about when it comes to printing with flexible filaments.

To begin with, keep your filament as dry as possible. This is a given for all filaments, regardless of whether you’re using flexible filament or not. If you don’t prevent moisture from entering your material, air pockets will form within your filament, and you’ll get a poorly extruded result. Proper storage and drying techniques, such as a dry box or dryer, are great ways of ensuring that a material is ready for printing.

For the printer itself, it’s best to use direct extrusion. While it’s not gospel, using direct extrusion over a Bowden feeding system for flexible filament is recommended. And to avoid adhesion issues, opting for a glass bed may be the way to go for a successful first layer.

When it comes to the settings, a good way to go is to reduce overall retraction within your slicer settings. When printing with flexible filaments, you may find that they produce a lot of stringing or curl up around the nozzle. When it comes to TPU, a good retraction setting is about 2-4 mm. Keep in mind that if you retract too much material too quickly, it won’t have enough time to complete a full retraction due to its elasticity!

And last but not least, slow down your travel speed. To ensure a flexible material will get a good connection to your build tray, you need to print slowly. TPU can print well with a speed of 25-35 mm at a temperature of 215-222 °C.

Filament Options

Now that we’ve gone over what to consider when printing flexible filaments, let’s take a look at three of the best options that you can buy today.

Ninjatek

NinjaFlex has a Shore hardness of 85A, yet it’s very flexible, soft, and squishy. The filament claims that it’s chemically resistant and ideal for fasteners and protective cases due to its high toughness and abrasion-resistant properties. It also offers an excellent amount of elongation before fracturing.

NinjaTek also offers Cheetah TPU as a fast-printing flexible option. There’s also Armadillo as a rigid, tough, and highly-resistant filament, and, on the other end of the spectrum, Chinchilla is soft and perfect for skin-contact applications.

ColorFabb

ColorFabb’s nGen Flex is a flexible material suitable for tougher jobs. It has superb layer-to-layer adhesion and it also allows users to print at 40-60 mm/s, which is a major bonus for flexible materials. nGen Flex is excellent at resisting high temperatures, which makes it ideal for prosthetics, apparel, and tools.

VarioShore is another interesting offering from ColorFabb that has a variable softness depending on the printing temperature. The secret is a foaming additive that only activates at temperatures above 200 °C.

Recreus

Filaflex filaments from Recreus are available in various hardnesses, including 70A (ultra-soft), 82A (original), and 95A (medium flex). Specializing in TPU and flexible filaments, Recreus’ Filaflex line is a fan favorite with excellent bed adhesion and stretchability.

Recreus also produces a few other flexible filaments, most notably Reciflex, which is created from 100% recycled material from the footwear industry and their own production scrap. It’s not easy to find another producer making completely recycled flexible filaments!

Resin

Printing with Flexible Resin

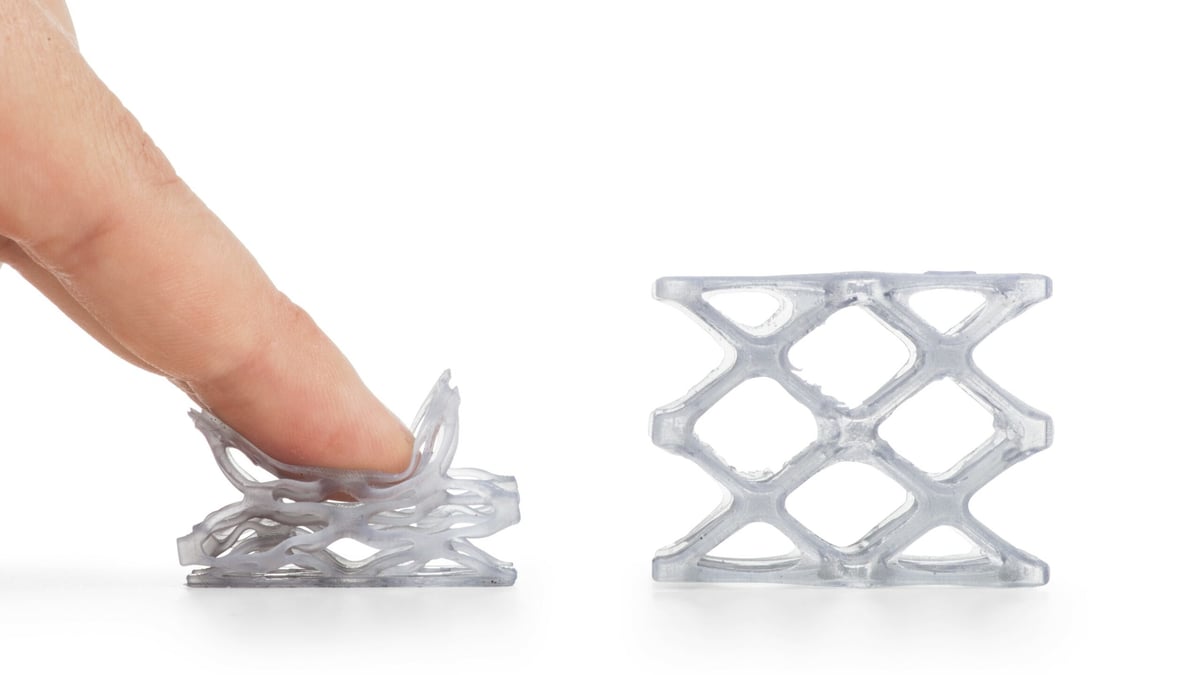

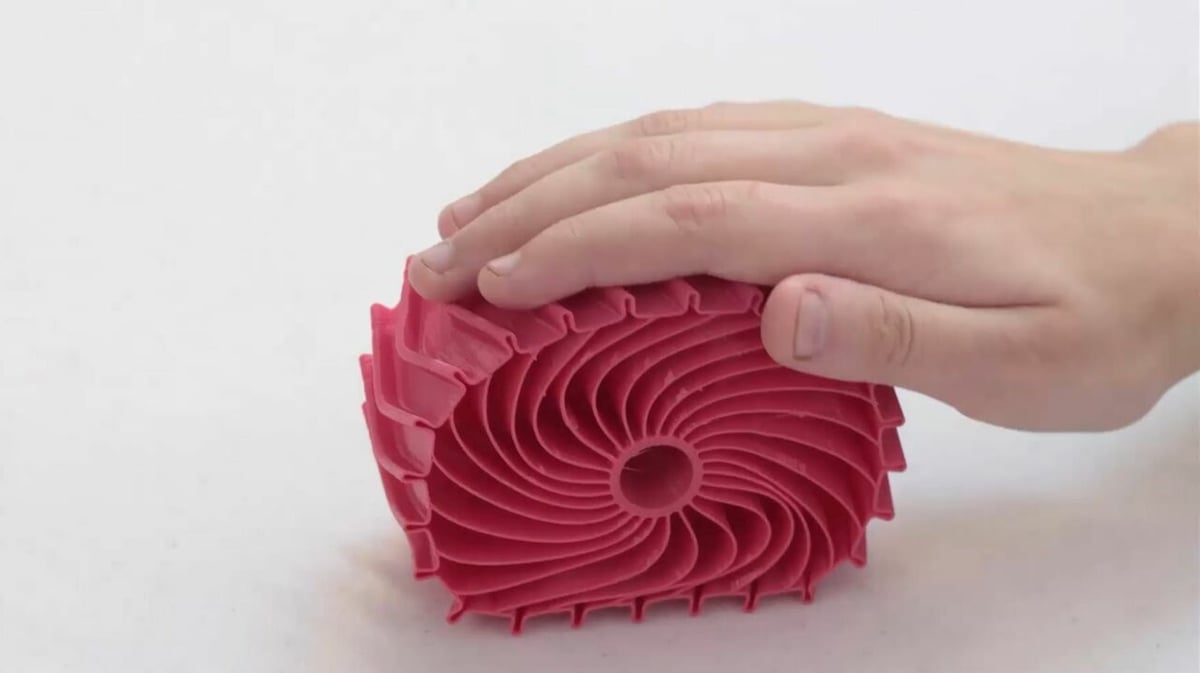

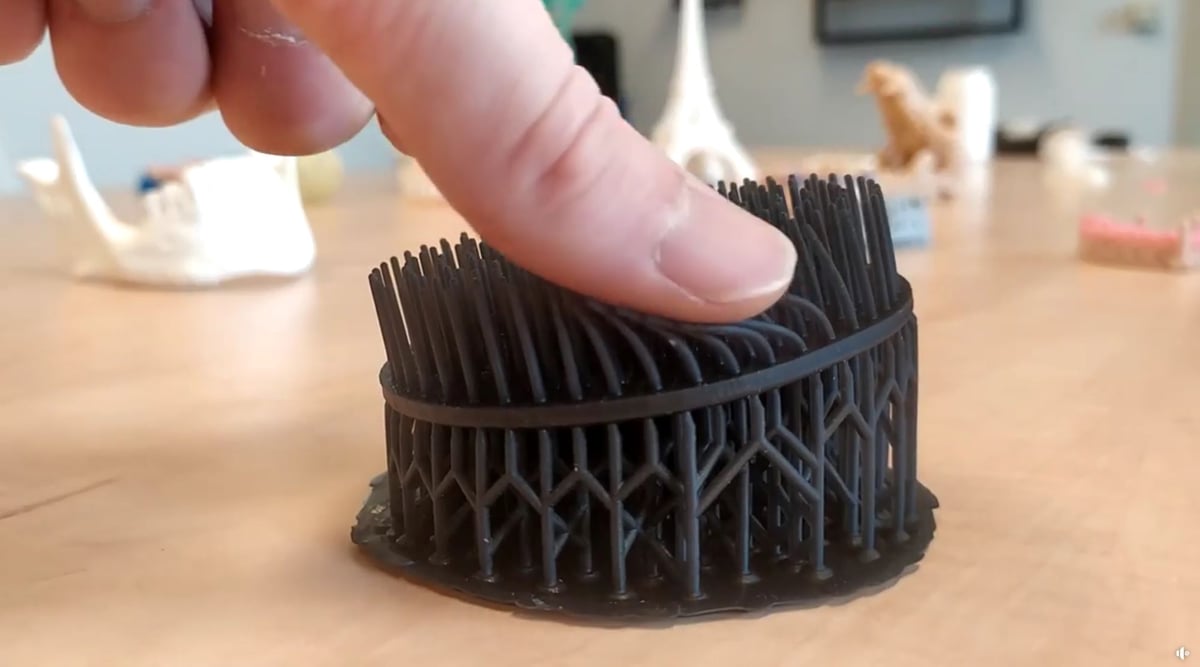

Flexible resin has elastomeric properties, which means it returns to its original shape after deformation. Depending on the size of the walls, prints may be more flexible (thin walls) or more rigid (thicker walls).

When printing on your resin machine, ensure that your build plate is level, that you have adequate ventilation, and that your work surface is covered with paper towels in case of splashes. Resin printers are also known to produce volatile organic compounds (VOCs), which can cause respiratory issues if inhaled, so a secondary enclosure or an air filter may also be worth considering.

If you’re going to print a curved item like a watchstrap, then you should design it so that it prints with that shape. Otherwise, it will always want to return to the original flat orientation.

Printing your parts at a slight angle will help reduce elastic stress within your part, which will help it conform to the desired shape. When curing your flexible resin, it’s also recommended that you source curing settings directly from the resin supplier.

You can also print with a 50/50 mix of flexible resin and normal resin if you wish to experiment with how you can alter the rigidity of the final product.

Resin Options

We’ve included our top picks of flexible resin below. These materials have been chosen with a mix of practical and hobby-based designs in mind.

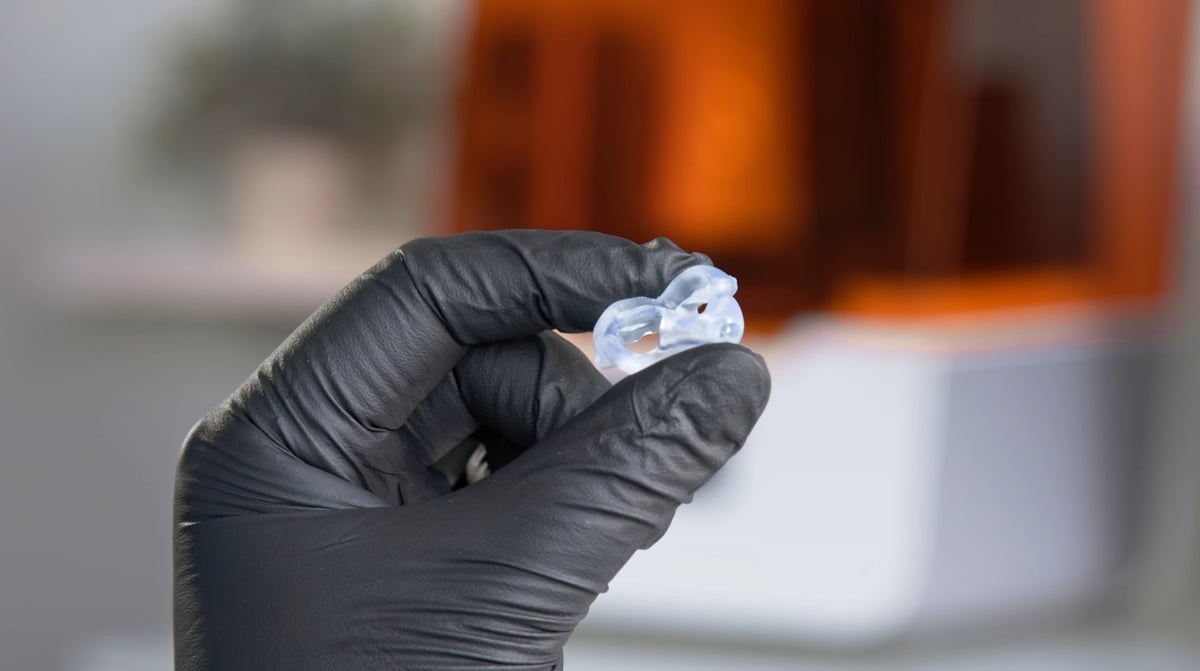

Formlabs

Formlabs’ Flexible 80A has a Shore hardness of (you guessed it) 80A, which is significantly harder than some, once post-processed. This makes this resin ideal for functional, everyday objects, such as gaskets and watch straps. Its hardness mixed with its durability allows for an expensive but very reliable resin.

Keep in mind that Formlabs’ resins are intended for SLA printers, not DLP and LCD. Always be sure to check the active wavelengths and compatibility of a resin before purchasing.

Prusa Research

Prusament Resin Flex is made in-house by Prusa Research, so you know it’s made by makers! PrusaSlicer has all its resin profiles integrated, which makes setup for users new to resin printing significantly easier. It also means that they’ll automatically get an idea of the general settings required for resin printing. Prusament Resin Flex, having excellent elastic properties and withstanding heavy impacts, is ideal for modeling and creating casts for jewelry and orthopedic components. It’s very easy to print with and post-process.

Liqcreate

Flexible X from Liqcreate is an extremely flexible resin compatible with DLP, LCD, and SLA printers. The Shore hardness of 55A is softer than some, but it makes this resin ideal for general-purpose hobbyists and makers. Its mechanical properties include excellent elongation and rebound properties, high durability, and good tear strength.

3D Printing Services

Craftcloud

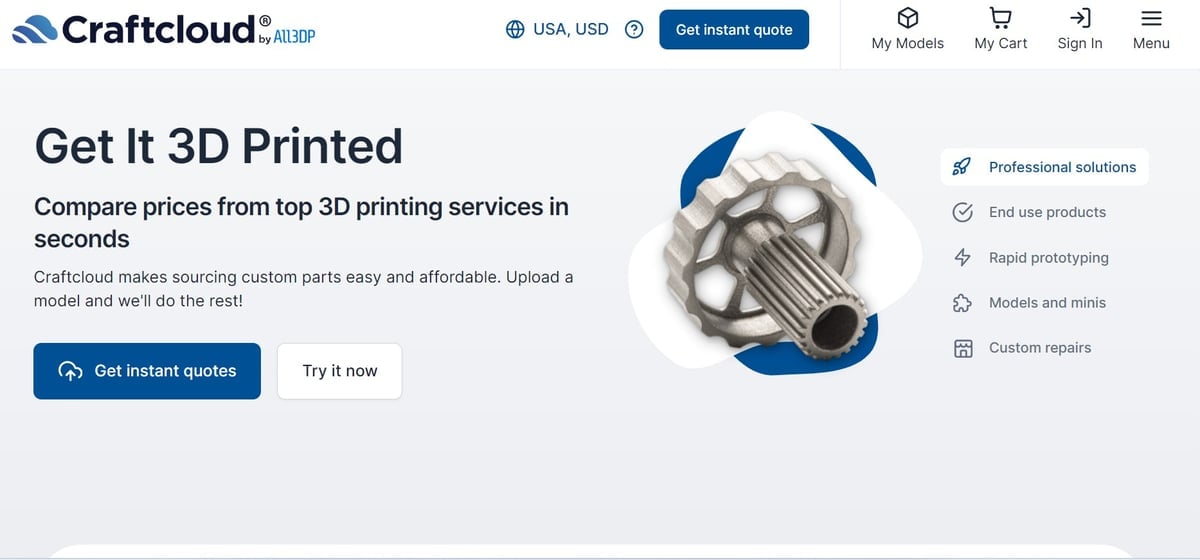

If you want to try out a model without investing in a whole spool of filament or bottle of resin, you can opt for a 3D printing service like Craftcloud by All3DP. As a marketplace for over a hundred 3D printing service providers, all you need to do is upload your 3D model, choose your material and other preferences, such as shop location or shipping speed, and Craftcloud will generate instant quotes for you to browse. By comparing offers, you can be sure you’re always getting the best deal.

Included in their extensive list of available printing technologies and materials are several rubber-like options. A popular choice is powder-based TPU from SLS or MJF printers that have a Shore A hardness of 86-90, closely resembling the mechanical properties of rubber. TPU can also be printed with FDM in over 30 color options and has flexibility correlating to the designated infill amount. In terms of resin options, Flexible Resin is great for rigid-flexible parts with a soft-touch finish, and Elastic Resin can be used for silicone-like properties with a Shore A hardness of 50-65.

For the full range of available services and rubber-like material options, head over to Craftcloud and browse the instant quotes without even needing to sign up. Whether you need one model or a small batch of functional parts, the service providers on Craftcloud are ready to meet your needs.

License: The text of "How to 3D Print Rubber: Filaments, Resins, Services" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.