When it comes to 3D printing, talking about resolution is a lot like talking about performance when it comes to cars; it’s relative, it can be subjective, and it covers a range of possible measurements.

High resolution means fine detail to some, while to others, it means a smooth surface finish. You may also see high resolution as a measurement of overall print quality. To throw more confusion onto the topic, the word resolution is often used interchangeably with precision or accuracy, even by printer manufacturers.

There are some standards when it comes to resolution, which vary depending on the type of 3D printer you’re using (filament, resin, powder, etc.), but know that when it comes to resolution, the highest isn’t always an easy answer. Let’s dive in a little deeper.

Different Ways to Measure Resolution

High resolution is a quality most referred to in resin technologies, such as stereolithography (SLA), digital light processing (DLP), and liquid crystal display (LCD), so the majority of this guide covers resin resolution.

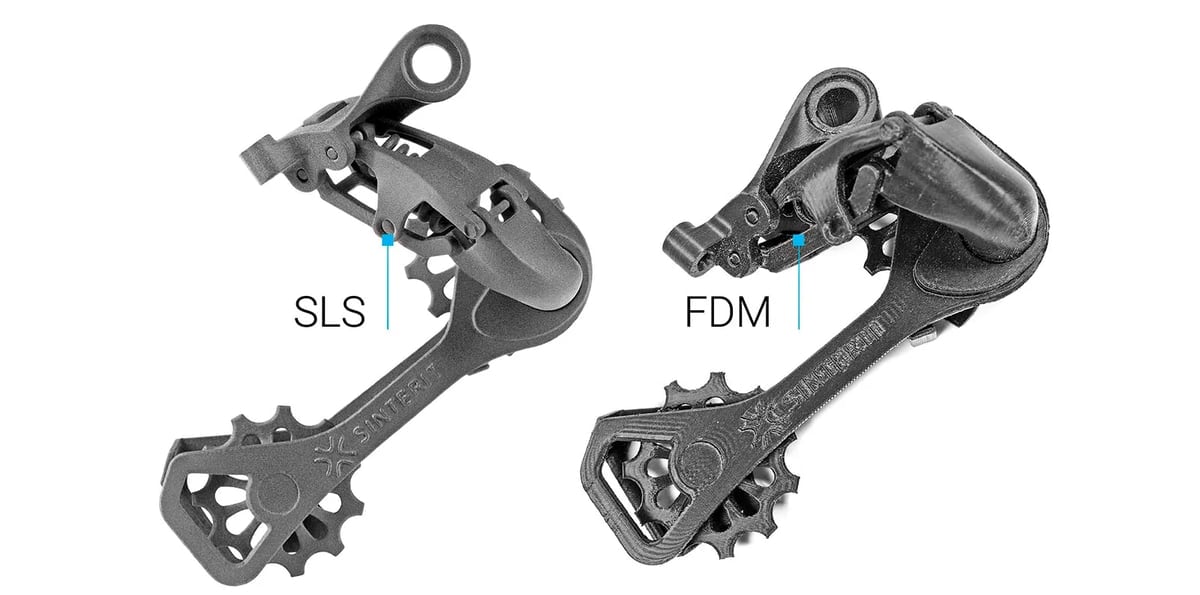

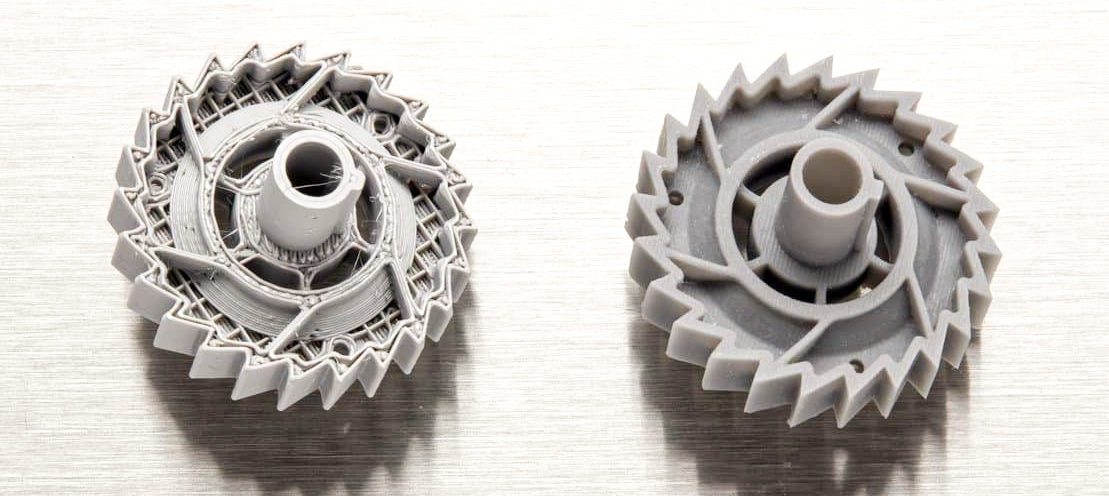

With resin 3D printers, the resolution is typically given as a horizontal (XY) measurement, whereas with fused deposition modeling (FDM) and powder bed technologies, the resolution is usually a vertical (Z) measurement or simply the layer height.

Despite how you may interpret resolution, it usually refers to the smallest artifact a 3D printer can controllably and repeatably create. There are instances when a printer manufacturer will list a “theoretical” resolution they’ve determined is possible with their machine, but for resolution to be a useful quality, it should reflect something that’s practical and predictable.

Resolution is often confused or used interchangeably with the terms below, which are also important, but not how we’re defining resolution.

- Minimum feature size is the smallest noticeable feature you can have either recessed into or sticking out from a surface. It’s linked to resolution but is typically slightly larger since it’s a visual attribute.

- Accuracy is usually represented in a measure of how much the 3D printer can miss its target resolution, such as how accurate your aim is in darts. For example, an accuracy of 2 microns means the print can be off-target by 2 microns in any direction. An accuracy of +- 20 microns may be acceptable for one application but not for another.

- Precision is a general term that typically encompasses layer height, accuracy, resolution, and other factors. It is not a numerical measure of any particular print attribute. High precision is a general claim of manufacturers.

- Tolerance is a word you’ll see in the descriptions of professional and industrial 3D printers where it’s critical that printed parts can be produced to the required specifications with precise dimensions. Like precision, the tolerance of a 3D printer is not a numerical measure of any particular print attribute, but it can be equated with accuracy. If your part specifications require a 2 mm tolerance and your printer boasts a .5 mm accuracy, then it can be relied on to achieve the required 2 mm tolerance.

3D printer manufacturers may use different terms for the same quality and may not even reveal certain measurements, such as layer height or resolution. Are they trying to obfuscate and mislead you with vague terms and the various ways they present data on 3D printer technical spec sheets? Not at all.

Lacking any industry standards for spec sheets, manufacturers aim to explain their machine’s attributes in a way that plays to its best features. Plus, and more importantly, with thousands of 3D printers on the market, it’s less important to compare spec sheets than it is to consider your application, budget, schedule, materials, and other factors.

However, resolution in 3D printing is clouded in mystery, so we aim to provide some clarity on what it really means.

3D Printing Resolution by Technology

Although we are mixing some apples and oranges here since the resolution is measured differently according to technology, here’s an overview of what a ranking of some of the main 3D printing technologies according to resolution, smallest to largest, might look like.

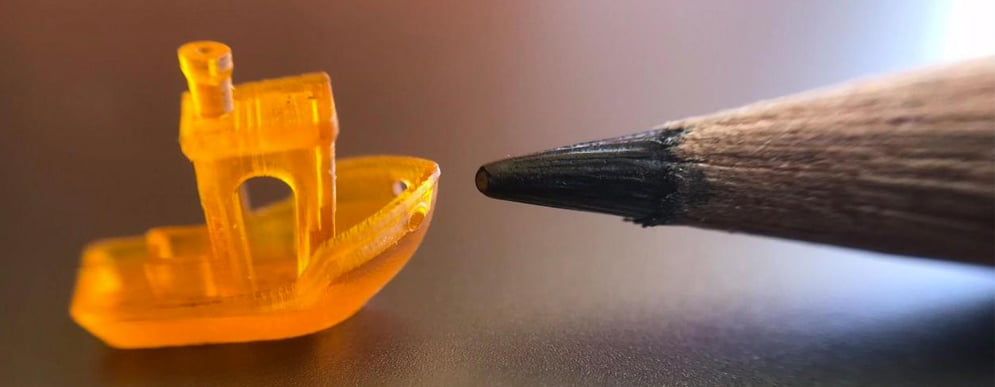

Micro 3D Printing in a Class of Its Own

The smallest possible resolution 3D printers would be in the micro 3D printing category. Here the resolutions are around 20 nanometers or 0.00002 mm, which is about 5,000 times smaller than the width of a human hair and also about 5,000 times smaller than the resolution of the typical desktop 3D printer. This is certainly overkill if you’re looking for fine detail on your product prototype.

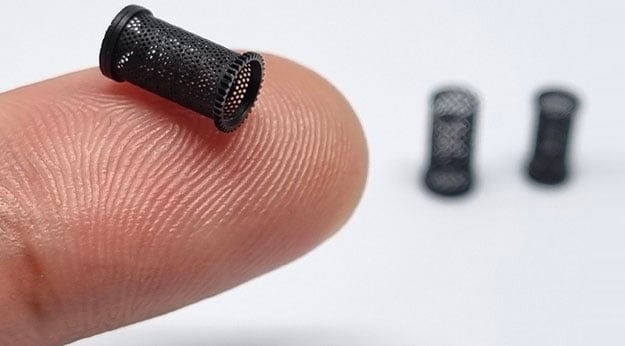

Micro 3D printers are often used for electronics in chip making. In fact, in 2023, the Indian Institute of Science-Bangalore announced it was working on developing a 3D printer for high-performance optical devices for AR/VR headsets, SLR cameras and smartphones, that wouldn’t need

for medical devices like heart stents, and very specialized precision manufacturing. If this scale is what you’re looking for, we have a full guide to micro 3D printing linked below.

Instead, let’s look at other high-resolution 3D printing technologies used by dental professionals, manufacturers, and hobbyists: resin (also called vat polymerization), filament (known as FDM), selective laser sintering (SLS), and selective laser melting (SLM) also know as metal laser powder bed fusion (LPBF), the highest resolution you can get in metal – outside of metal micro 3D printing.

Highest Resolution Resin 3D Printer

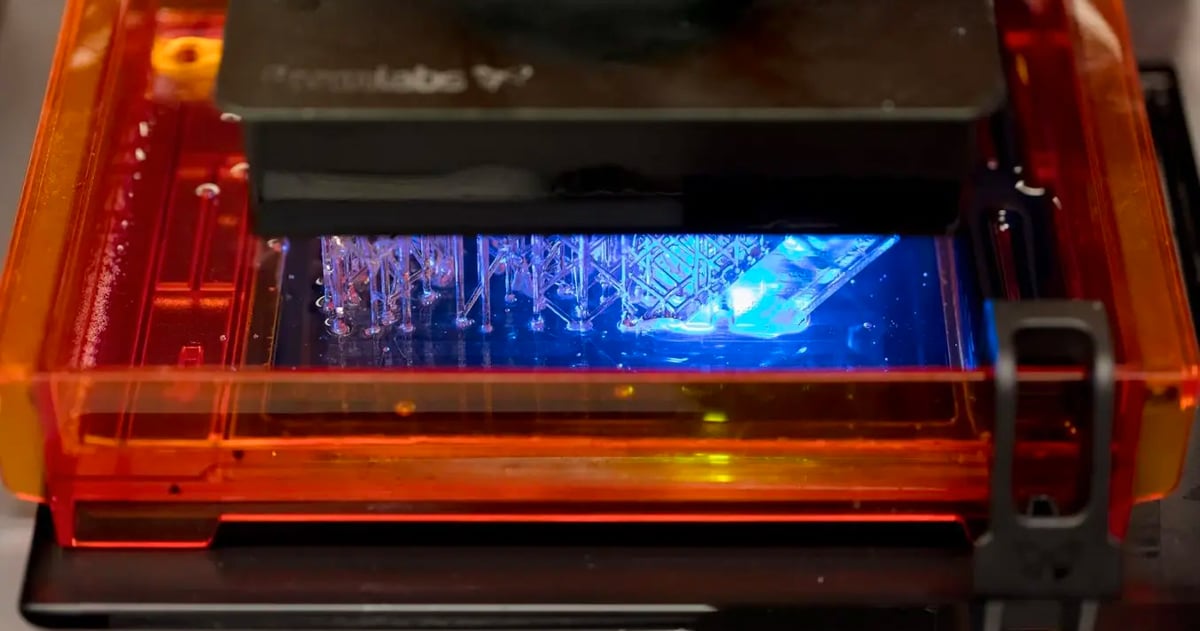

Resin printers come in different technology sub-types, but all work by selectively curing UV-sensitive liquid polymer one layer at a time. Since the resin is cured horizontally and then the layer slice is raised vertically (or lowered vertically, depending on the printer), this technology can claim both an XY and a Z measurement.

You may be familiar with an XY measurement in two dimensions as a pixel, such as the pixel resolution of your phone screen. In 3D printing, a pixel with a height or a 3D pixel is called a voxel.

A voxel resolution measurement isn’t common for 3D printers since horizontal resolution in resin 3D printers can be smaller than vertical. Therefore, most resin 3D printer makers promote the horizontal (XY) as their machine’s resolution benchmark, such as the “51-micron XY resolution” on the Elegoo Jupiter 6K, while sometimes also providing the Z resolution.

In fact, Z resolution in resin 3D printers is hard to put a definitive measurement on. Most resin 3D printer manufacturers put a layer height (Z) number on their spec sheets somewhere between 1 and 10 microns. What this means is that their Z-axis stepper motor (the mechanical part that controls the build plate) can make these size steps. In theory and also in practice with professional machines, resin machines are able to make these small layers. However, the biggest influence in having a good Z resolution is actually how the machine’s light source and settings work together.

To make these fine layer details, your resin has to absorb and block the perfect amount of light to cure one layer, but not cure too deeply that it affects multiple layers. If it cures too deeply, then you can have “through-cure” or bleeding, and your current layer will still be exposed and polymerizing parts of your previous layer. So a good resin (preferably a slower one), perfectly dialed-in settings, a light source in tip-top shape, and z-axis stepper motor precision is all needed to achieve a small and reliable Z resolution.

In the end, pixel size is a far easier metric to measure and communicate, so it is becoming the default for resolution.

Here we look at the three most common resin, or vat polymerization, technologies: LCD, DLP, and SLA.

Battle of the 6K, 8K, and 12K Resolution

When shopping for a liquid crystal display (LCD) resin 3D printer (also known as masked stereolithography or MSLA) you’ll see ads boasting 6K resolution or 12K resolution. But what does that mean?

First, let’s look at how LCD printers work. LCDs use an array of UV LEDs as a light source to flash onto an LCD screen (like the one pictured below), which acts as a mask, only letting light through in certain areas. The light that gets through is shaped like a horizontal slice of the 3D models and cures the resin on the build area in that shape. This build area is then moved one layer to stop additional curing of the polymer before flashing the next 2D layer that is cured to the first. Eventually, after many layers, the 3D object is formed.

For example, the Phrozen Sonic Mega 8K has an LCD screen that has 7,700 pixels on its width and 4,300 pixels on its depth. (The 8K in the name comes from the fact that the width of the LCD is almost 8,000 pixels.) To determine pixel resolution, you need to know how big the actual LCD screen is because just knowing how many pixels across doesn’t tell you about resolution. A pixel isn’t a consistent unit of measurement. If you line up 7,700 pixels across a 100 mm wide screen you’ll have smaller pixels than if you lined up 7,700 pixels across a 200 mm wide screen.

This is why buyers get so frustrated by claims of “stunning 11,520 x 5,120 resolution.”

The pixel size of the Phrozen Sonic Mega 8K is 0,043 mm, which can also be expressed as a horizontal resolution of 0.043 mm or 43 microns (µm). By comparison, the Anycubic’s Photon Mono X 6K has 5,700 pixels across its LCD screen, but it has a smaller screen, so its pixel size is 0.034 mm. This translates to a horizontal resolution of 34 microns, which is a higher resolution than the Mega 8K. Large LCD printers, like the Mega 8K with a build volume of 330 x 185 x 400 mm, typically feature a lower resolution than the smaller LCD printers, such as the Mono X 6K (197 x 122 x 245 mm).

For this reason, 4K, 6K, or 8K is not an indication of resolution. Look, instead, for pixel size, which is often listed as the resolution and represented by a number, such as 22 microns.

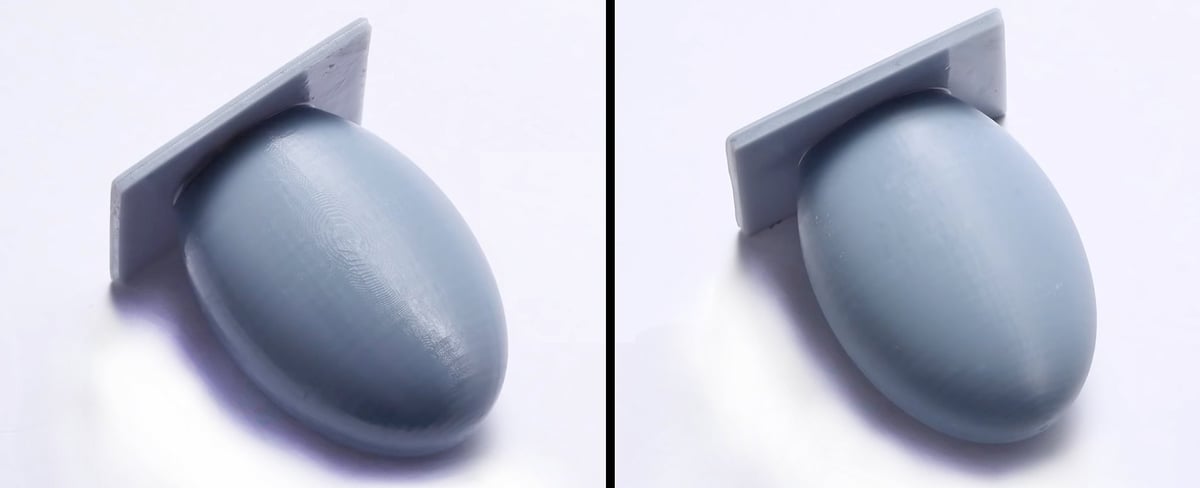

The light shining through the LCD screen is in squares, which, coupled with layer height, produces cubes (or near cubes). The effect on your solid model is a surface that looks like it was made with tiny Legos. Yet most parts appear far smoother than this, why? With a high-resolution 3D printer, the cubes (also called voxels) are so small you can barely see them with the naked eye, but there’s another technology at work, antialiasing, which is a function of your printer’s slicing software.

Antialiasing is used in digital photography, computer graphics, and other applications to smooth the edges of any media made with pixels. In 3D printing, it’s a matter of controlling the amount or the type of light allowed to hit a voxel of resin. If the light is less than, say, full blast, the voxel will not become a fully cured cube, but rather a semi-circular cured oval-shaped voxel. If an edge of fully cured voxels is like a staircase, antialiasing is like putting pillows on each stair to give the appearance of a slide.

In your slicing software, you control the amount of antialiasing (also called greyscale) and the associated measures, such as blur, which is how many outer layers will be influenced by grayscale. Too much antialiasing and blur, and your print will actually lose detail. Done right, antialiasing and blur (or pixel manipulation tools) give your prints an overall better visual appearance that can look like higher resolution.

Antialiasing and blur are used with other resin technologies, too, such as DLP and SLA.

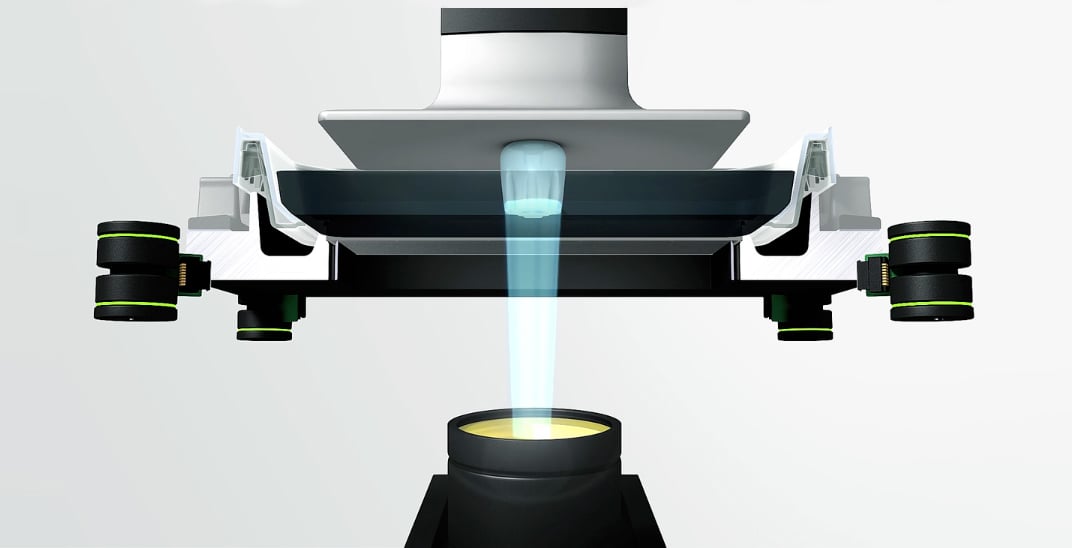

You may be familiar with DLP projection technology as used in movie theaters or office projectors.

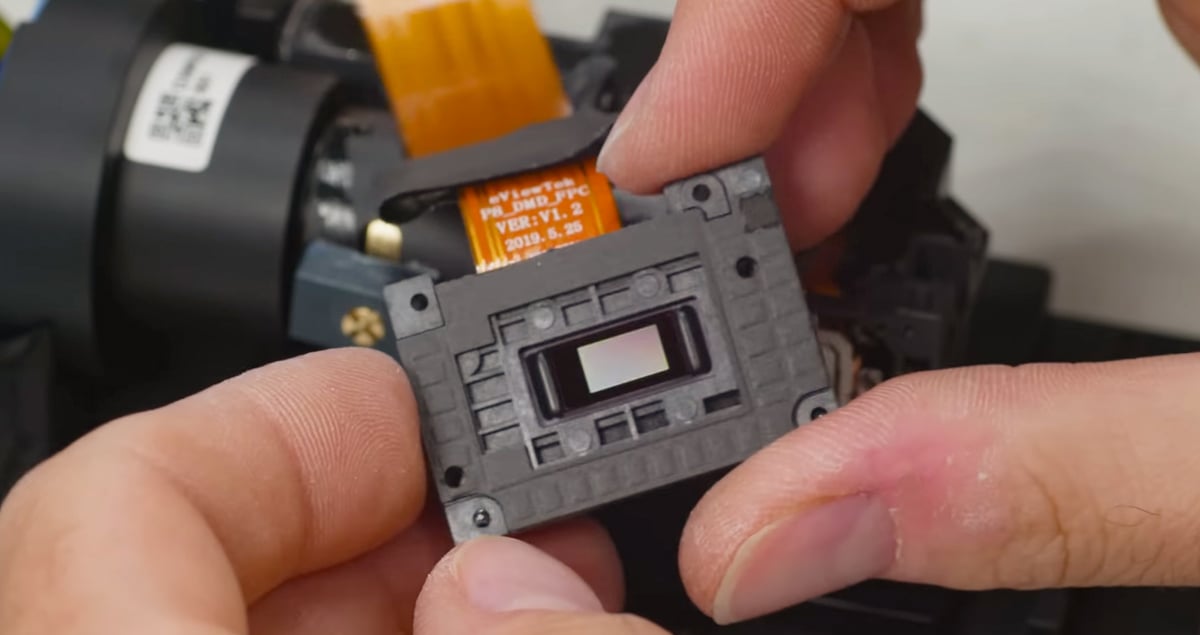

DLP in 3D printing uses a DMD, which is made of tiny mirrors that either direct light to the resin or off to the side and out of the way. Each square-shaped mirror represents a pixel in the projected image.

Currently, in professional DLP 3D printers, you’ll see a 1920 x 1080-pixel DMD chip, which can also be called just 1080p of full HD or 2K (because the number of pixels across is almost 2,000). In some consumer-level machines, you’ll find a 1280 × 720-pixel DMD chip. As a side note, you may have heard that DMD maker Texas Instruments had planned to debut a 4K chip last year. Unfortunately, the company had to cancel its expected serial production of that DMD, but expects to have a new version available in early 2024. This means that we may see far higher resolution DLP 3D printers (or, more likely, far larger DLP 3D printers) on the market in 2024.

Most desktop DLP 3D printers have a fixed XY resolution (between 35 to 100 microns), but some enable you to adjust the projection distance between the light engine and the resin layer. This distance, just like making shadow puppets on a wall with a flashlight, affects the level of detail that can be achieved.

The light reflected by the mirrors on the DMD passes through projection optics, which help focus and shape the light into a beam. Because the mirrors direct light only where needed, DLP can produce crisper edges than LCD. With LCD, tiny bits of light can bleed around the edges of the masked pixels on the screen, plus the screen can never block 100% of the light.

DLP printers also have higher light intensity (up to 16 watts) than the light sources in most LCD printers and some DLP printers enable you to adjust the light intensity.

Although highly accurate, the light in square-shaped pixels produces jagged edges where a curved edge should be in what’s called stair stepping. This is also found in LCD printers. Smaller objects have fewer issues with stair stepping, but larger parts can have pronounced voxel edges.

Are crisper edges higher resolution? Not necessarily, but the crisper your stairs, the more opportunity you have to manipulate the pixels using antialiasing, blur, and another technology called pixel shift to create a seemingly higher resolution and finer representations of features and contours. In fact, some printer manufacturers proclaim a print resolution half the size of their pixel.

How is this possible and what are 4K and 8K DLP printers? To answer this, you must understand pixel shift.

Pixel-shift (also called pixel tuning and extended pixel resolution and Xpanded Pixel Resolution or XPR), unlike antialiasing, is not purely a software feature, it is also a mechanical one. And it’s how DLP printers with a 2K DMD chip can claim a 4K or 6K resolution. It’s also used in other media you may know, such as digital cameras, where it provides a high-res mode that’s more than the resolution of your camera.

By slightly shifting the position of the DMD between each layer, a single layer is subject to multiple exposures of light incrementally. This enables the light to fully cure pixel areas that are exposed to long durations of light, say 8 seconds, and partially cure pixel areas that receive less light.

You’ll see this referred to often as sub-pixel resolution, whereas the actual pixel resolution is called the native resolution. Some printers enable you to select native or sub-pixel resolutions per print job. This technique effectively increases the apparent resolution of the projected image by creating additional data points within each pixel.

For example, ETEC’s Extreme 8K DLP machine features an electromechanical system that allows for a tiny amount of tightly controlled motion in sub-pixel distances in both of its 2K DMD chips (yes, there are two DMDs in this 3D printer), resulting in its 8K resolution claim. The Extreme 8K’s XY pixel size, with pixel tuning, is 100 microns, which is higher than some LCDs, but it has a much larger build volume (450 x 371 x 399 mm), so it can produce very large, very high-resolution parts.

Light engine maker In-Vision launched a DLP projector in 2021 that it says can produce an 8K image because it can pixel-shift both horizontally and vertically, but it hasn’t been incorporated yet into any commercially available 3D printers.

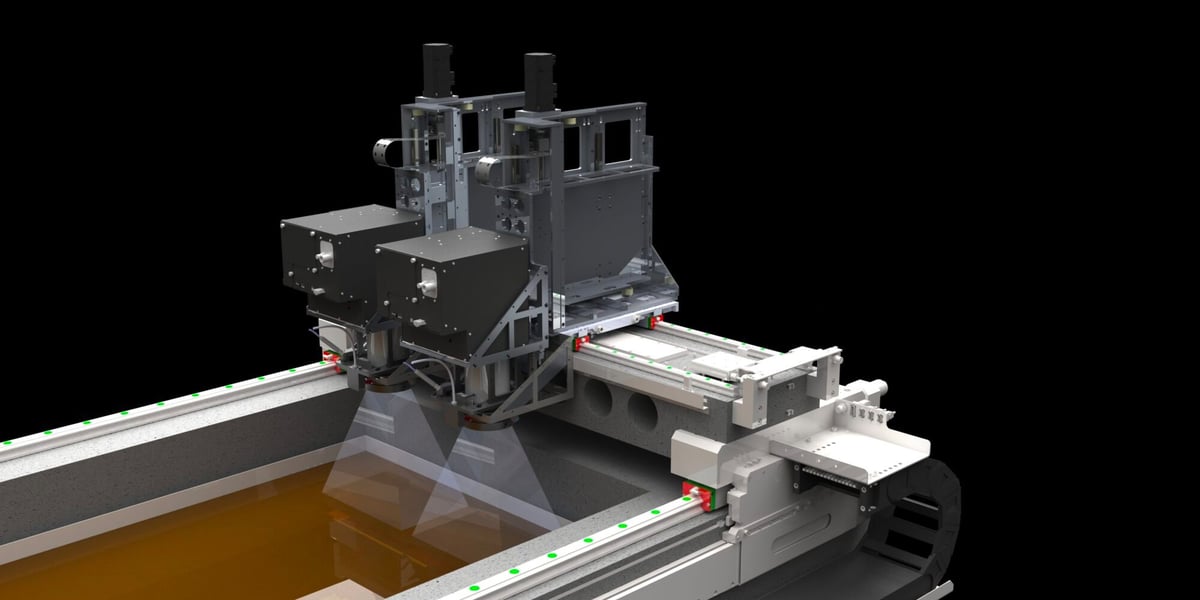

Other professional and industrial DLP printers boast various pixel-tuning technologies, such as Prodways’ Movinglight, or Dynamic Exposure from In-Vision, where the projector head moves over the building area while exposing the resin.

The other factor is related to the mechanism that controls the mirrors that direct the laser. These mirror galvanometers direct the lasers to the correct coordinates focusing the light upward through the bottom of the tank and curing a layer of resin. As you can imagine, a $200 SLA 3D printer has, let’s say, a more economical galvanometer setup than a $100,000 SLA 3D printer. How accurately you can point the laser plays a large part in resolution.

XY resolution is again the benchmark for SLA 3D printers. This resolution is a combination of the laser’s spot size and the increments by which the laser beam can be controlled. For example, the Formlabs Form 3 3D printer features a laser with an 85-micron spot size, but because of the constant line scanning process, the laser can move in smaller increments, and the printer can consistently deliver parts with 25-micron XY resolution.

This means that laser-based machines, given high-quality optics, can more accurately reproduce the surface of a part even if the laser spot size is larger than the DLP pixel size.

Most SLA 3D printers have a fixed laser, but some, like the 3D Systems dual-laser SLA 750 and the Stratasys Neo line, have variable laser focuses, such as 150 to 600 microns, which enables you to control where fine detail is placed on the part.

So, which resin technology has the highest resolution?

Sheer numbers don’t tell the whole story, and it’s hard to make a straight-line technology comparison among resin 3D printers. In the three resin technologies we just explored, there are widely varying price levels for what could be considered the same resolution, which underscores the fact that there’s more at play in print quality than resolution.

When it comes to picking a high-resolution resin printer, the differences among various manufacturers (consumer, professional, and industrial) are more significant than the differences between technologies. A resin 3D printer purchase takes into account resolution along with accuracy, speed, cost, material options, and more.

Highest Resolution FDM 3D Printers

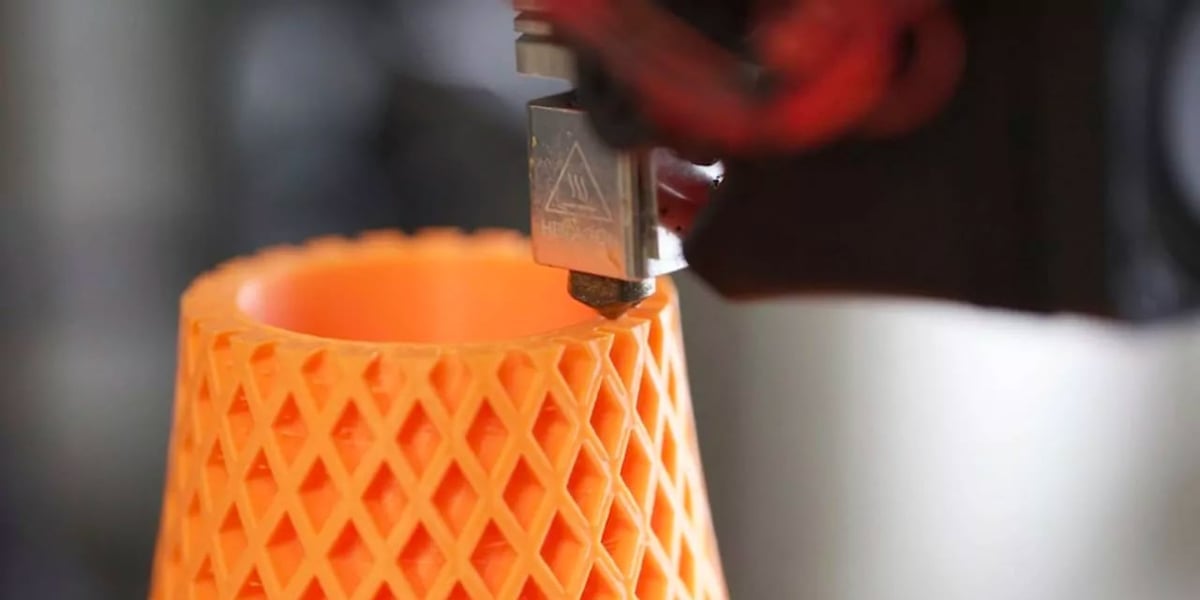

3D printers that use filament continuously extruded on the XY plane and therefore the XY resolution is a measure of how precisely the printer mechanics can move horizontally. This measurement, however, isn’t commonly listed on the spec sheets of FDM printers under the industrial level, leaving the only widely used measure of resolution for this technology as Z or layer height.

Accuracy is a more common measure in FDM 3D printing, which is an indication of XY resolution not a measurement of it.

Dimensional accuracy figures on a 3D printer spec sheet, such as +/- .2 mm, typically come from test printing and measuring. For example, the +/- .2 mm dimensional accuracy of the UltiMaker Method series FDMs comes from printing a suite of models across many machines many times and then using a scientific measuring machine that measures the dimensions of each part and compares it to the dimensions in the CAD model.

Because layer height is seemingly the only widely used measure of resolution in FDM 3D printers, the lower the layer height, the better the resolution of your parts. Simple, right? Not so fast.

Yes, layer height is resolution (it’s even called layer resolution), but arguably, there’s little reason to go below 50 microns, even though some printers boast a 10-micron layer height. Again, the thickness of a human hair is around 70 microns.

A 50-micron resolution is achievable with a wide range of consumer and professional FDM machines today, which prompts printer makers to shift the focus from resolution to other measurements that differentiate their machines, such as the Swiss-watch precision of the mechanics (stepper motors, belt teeth, gears, etc.) that control the printing. These lead to high levels of accuracy, which is often called positional resolution, as mentioned above. Some printer makers may never even mention layer height.

In fact, there are so many considerations affecting achievable layer height in FDM printing, such as material, temperature, nozzle size, environmental vibrations, and, of course, software settings, that a mass comparison of layer height isn’t very useful.

Instead, couple layer height with accuracy.

Unlike most resin technologies, FDM slicing software, such as Cura and PrusaSlicer, offers the option to change layer height throughout a print. The software will apply a smaller or larger layer height, depending on the features of the model. For example, the layer height will get smaller for more detailed parts and larger for more featureless sections.

If you need a 10-micron resolution, you may want to consider switching to another technology.

Highest Resolution SLS 3D Printers

Selective laser sintering (SLS) creates objects out of plastic powder by using a laser. It’s highly accurate, and the layers are practically imperceptible. Manufacturers turn to SLS 3D printing when they want parts or components with a smooth surface finish in a engineering-grade material, such as carbon-fiber filled nylon or flexible TPU.

SLS 3D printer can be faster than FDM and there’s a greater ability to produce small batches of parts in one print cycle. Prints are easy to dye various colors and polish, making them practically indistinguishable from injection molded parts.

Applications range from jigs and fixtures to functional prototypes.

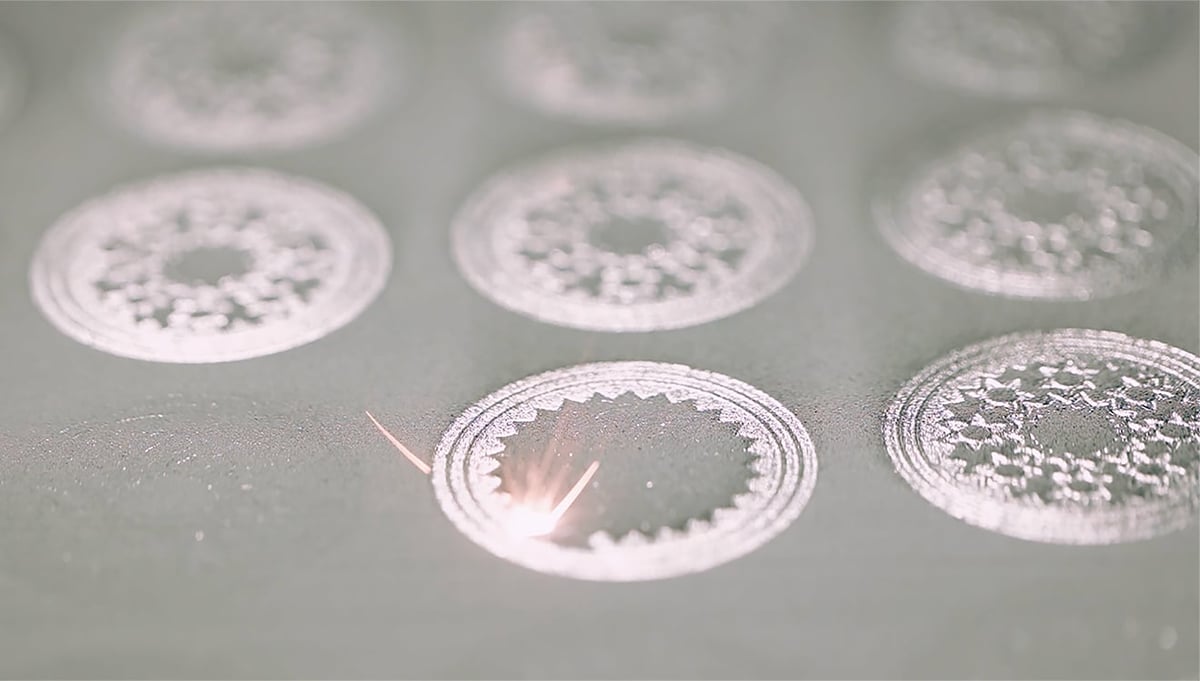

The process starts in the 3D printer when a recoating blade spreads a very thin layer of the powdered material onto a build platform. A laser (CO2 or fiber) then scans the surface according to the pattern laid out in the digital model. The laser selectively sinters the powder and solidifies a cross-section of the object. A new layer of power is spread on top and the process repeats.

The word resolution is rarely seen in the technical specifications of SLS 3D printers, and it can be hard to put a definite number on. Layer height is the main measurable feature used to denote resolution for many SLS printer makers, and 50 microns is considered the standard minimum layer height (outside of micro SLS). The powder materials can have different minimum spreadable thicknesses, which also determines the minimum possible layer height.

Highest Resolution Metal 3D Printers

High precision and tight tolerances are the qualities most sought after in metal 3D printing, even though they are not directly measurable. However, you’ll still see the word resolution thrown around, so we address that here.

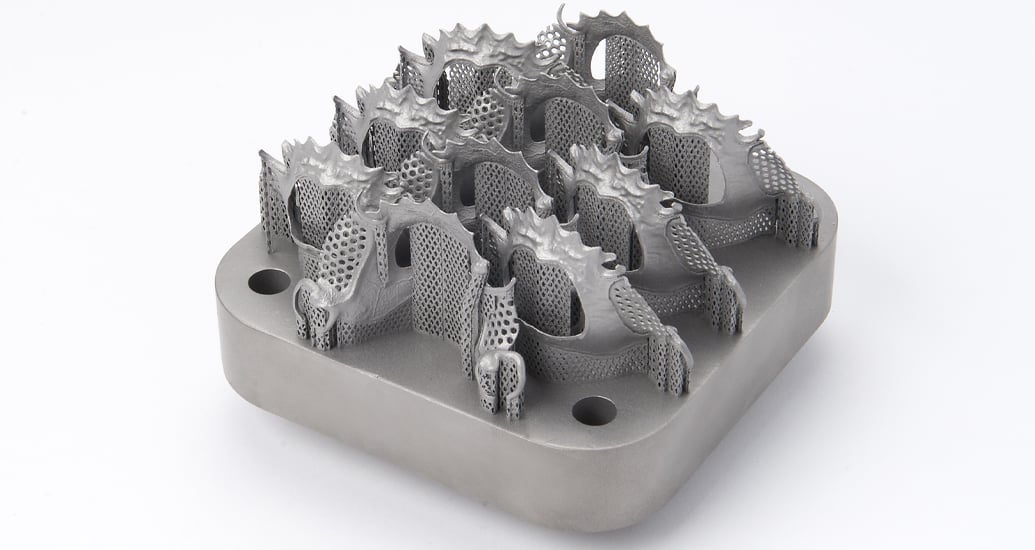

The most popular metal 3D printing method is selective laser melting (SLM) or, more precisely called metal laser powder bed fusion (LPBF). After micro metal 3D printing, it is the highest-resolution metal technology.

LPBF 3D printers use high-powered lasers to trace out a cross-section of a part on a bed of metal powder, selectively melting it. A roller then distributes another layer of powder and the next layer is fused to the first. The melted parts fuse together layer-by-layer on a molecular basis until the homogenous model is complete.

Other Factors That Affect Resolution

Your choice of materials has one of the most significant impacts on your resolution, which is why 3D printer manufacturers often provide different resolutions for each of the materials they recommend. There are other factors that affect the resolution you’ll achieve from your 3D printer, including:

- Material quality

- Slicer settings

- Nozzle size

- Machine vibration

- Worn-out or defective parts

If you’re not getting the resolution you once did from your 3D printer, the likely culprit is parts of your 3D printer that may have just worn out. DLP projectors maintain a stable high intensity for only a certain number of hours (around 10,000) before needing to be replaced. LCD screens can start to go bad and burn out after about 1,000 hours of printing, and FDM printers require new nozzles after a period of use.

How Much Does Resolution in 3D Printing Matter?

In one of its excellent guides, resin 3D printer maker Formlabs says that “resolution in itself is often just a vanity metric.”

Resolution alone is not a reason to buy or not buy a particular 3D printer and the industry’s obsession with resolution may, in fact, be a hindrance to 3D printer adoption since it’s vague and often obfuscated, leading to consumer confusion.

Resolution and a range of other metrics combine to produce “quality” parts. This is why comparing spec sheets can be a starting point on your printer purchase journey but should not be the basis for selecting a machine. Instead, start with the qualities of the part you need, what it should look like, and how it should function.

This, of course, is why we’re here. The editors at All3DP have reviewed, hands-on, hundreds of 3D printers to bring you the information that matters, including resolution.

For industrial additive manufacturing machines, hands-on reviews are harder to facilitate, so we aim to present them in guides using apples-to-apples metrics and expert interviews while pointing out each machine’s unique features.

For more on finding the right machine for your needs whether you are a professional or printing at home, check out our Buyer’s Guides, 3D Printer Reviews, and our professional section on additive manufacturing.

Ordering High Resolution Parts

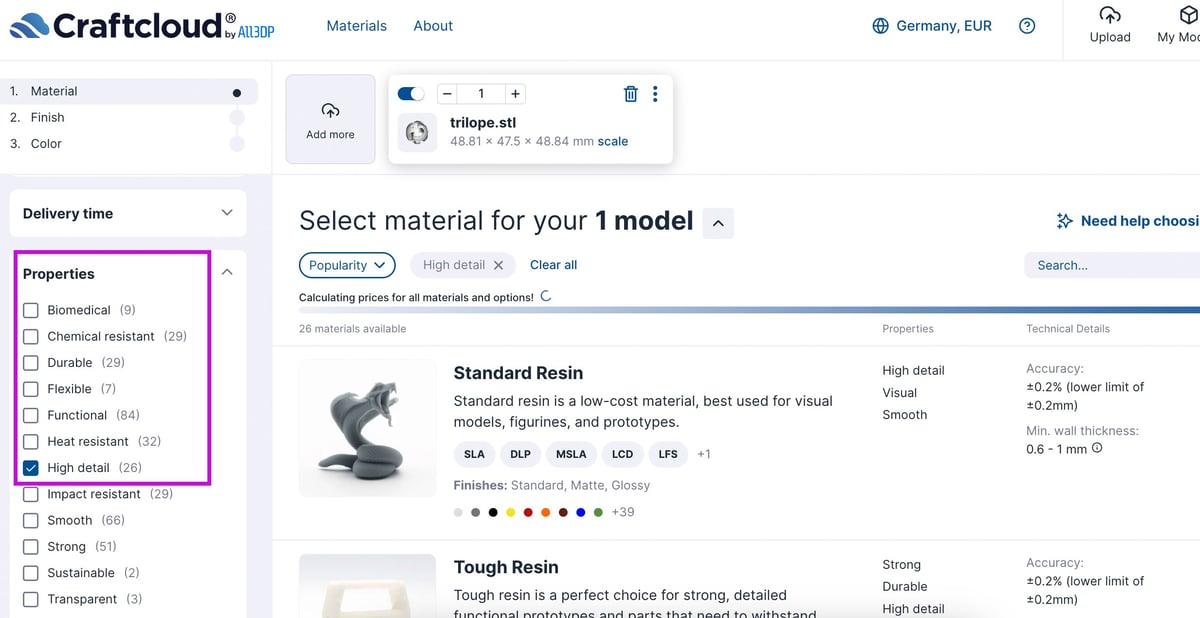

When uploading your part to a 3D printing service, you can select the material and often the method, but you can’t directly select the resolution. So, you need to know a bit about the technology behind your options in order to make the right selection, which we hope you’ve learned here.

If you’re not inclined to set up shop on your own and want to avail yourself of the many 3D printing services out there to print your part for you, look for ones that offer resin technology (LCD, DLP, SLA) for design parts or selective laser sinters for highly detailed functional parts. Many services, like Craftcloud, offer a design guide to help you make the right choice and also offer “properties” of their materials, such as “high detail” or good for visual models. When in doubt, give them a call.

Order the same file in a variety of materials and methods is a good way to benchmark your options and if the print service will tell you which brand of printer they use (most will) you can even test drive some options before purchase. Most print services will not have the smaller, consumer machines because of the size and often the speed, but some local maker shops might.

Resources for Even Deeper on Resolution

If you want to dive into the topic of 3D printer resolution even more, we recommend the great technical articles by resin manufacturer Liqcreate, especially its guide to understanding resolution, a guide to the strongest resins, and an explanation of the properties of a resin or 3D-printed part.

You can also turn to 3D printer and material maker, Formlabs. They have an extensive blog on a wide range of 3D printing topics, including resolution.

Special Thanks To:

- Liqcreate

- Formlabs

- Daniel Hackney, formerly of EnvisionTEC

LEAD IMAGE: Eivor 100mm scale. Printer: Elegoo Mars 2 Pro Resin: Poseidon Grey – Quanton 3D. STL Model by DragunStudion. Print by MalkMotta.

License: The text of "High-Resolution 3D Printers – The Ultimate Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.