Slic3 That Design

One of the reasons we love 3D printing is that you can create almost anything without being super knowledgeable in the fields of machinery or programming. In the printing process, the slicer is software that translates a digital 3D design into instructions for your printer to properly 3D print a model. You simply input values and, voilà, your printer is “programmed” to carry out your specifications.

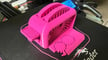

The Ender 3 series of printers (original, Pro, and V2) are some of the best hobbyist 3D printers available and Slic3r is one of the most popular slicers, so why not use them together?

When you’re working with a slicer, the profile settings and options allow you to change how your 3D printer, in this case, an Ender 3, prints a file. Slic3r even has a premade printing profile for your Ender 3 version that can produce some great prints right off the bat.

In this article, we’ll explore the most important Slic3r settings to tweak in order to achieve high-quality prints on your Ender 3. Let’s jump into the most basic settings first.

The Basics

Before you slice, make sure that Slic3r is in sync with your Ender 3 as well as the filament you’re using. You can do this by checking that the “Printer Settings” page in Slic3r matches your Ender 3’s parameters. (If you’re using OctoPrint, you can plug in the IP address on this page, as well.)

You’re mainly ensuring that the “Bed Shape” tab is set to 220 x 220 mm and that the nozzle diameter in Slic3r is the same as the one on your Ender 3. Unless you’ve modified or changed nozzles, it should have a 0.4-mm nozzle.

Another important part is that your filament settings should match the filament you’re using. You can go to the “Filament Settings” tab and check that the diameter is 1.75 mm (or set it to whatever the diameter is of the filament you’re using).

If all these numbers are the same between Slic3r and your Ender 3, then you’re ready to get deeper into the optimal settings!

Speed

Let’s start with speed, as it’s one of the most critical settings when 3D printing. Slic3r gives you many options for speed, so you’ll have complete control! You’ll find them all in the “Speed” section of the “Print Settings” tab.

Print Speed

Let’s focus first on your Ender 3’s print speed, as this is what determines how quickly your printhead moves while actually printing and pushing out (extruding) material. Essentially, print speeds should vary based on the material you’re using. For example, if you’re printing with TPU or another flexible filament, the speed should be significantly slower than if you’re printing with PLA or ABS.

You’ll also want to slow down your printing speed if you feel your printer is messing up because it’s going to fast. Depending on what’s happening, Slic3r allows you to adjust the speed when printing perimeters, infill, bridges, or supports.

Another thing to keep in mind when creating your perfect Ender 3 Slic3r profile: You’ll want to adjust for material-specific settings, which we’ll discuss in more detail in the following temperature section.

Travel Speed

Next, travel speed is the speed your Ender 3’s print head travels at when it’s not extruding. Slic3r allows you to change the travel speed by adjusting the “Speed for non-print moves”.

This speed is typically set above 100 millimeters per second. We suggest leaving it on the default setting and adjust based on how well your Ender 3 handles the default speed.

Fan Speed

Fan speed is also super important and can refer to how fast any one of your Ender 3’s four fans (mainboard, power supply, hot end, and part cooling) is spinning. You’ll find these under the “Filament Settings” tab in the “Cooling” section.

Specifically, your mainboard fan should always be on as your stepper motor drivers can get pretty hot and cause problems if not kept cool. If you’re experiencing heat creep, you should turn your hot end fan speed up. For general troubleshooting, 3D print some temperature tests and change your part cooling fan speed accordingly.

Extrusion Speed

Finally, we have the extrusion speed, known in Slic3r as the “extrusion multiplier”. This determines the rate at which filament is passed through the extruder. You can find this setting in the “Filament Settings” tab.

Theoretically, the extrusion multiplier should always be “1”. However, for many reasons, this isn’t the case with the Ender 3s, so the extrusion multiplier allows you to adjust the percentage of filament that comes out. Typically, this is a value that should only be changed after all other potential issues have been ruled out. And even then, one shouldn’t go below 0.9 or above 1.1.

Temperature

Temperature is probably the most important setting of all. From the beginning of the RepRap movement, avid 3D printer users struggled with the issue of temperature on their printers. Given the significant role temperature plays in how a 3D printer functions, you want to get this setting as accurate as possible.

Filament Matters

Determining the correct temperature starts with knowing the type and brand of filament. For example, you can’t print polycarbonate at the same temperature as PLA, because the materials have different properties. A good suggestion is to check with the filament manufacturer and see what they recommend for the hot end as well as the bed temperature. After that, the community can also be a big help.

Hot End Temperature

Hot end temperature affects how the material will come out. Temperature settings can be found in the “Filament Settings” tab in Slic3r, and there are two sets of temperatures. The first set for the normal temperature and the second for the first layer temperature.

The first layer temperature should always be a little bit higher to ensure that the first layer isn’t under-extruded. A too low hot end temperature can cause under-extrusion and too high of a hot end temperature can cause over-extrusion, so somewhere in the center is best.

Bed Temperature

The bed temperature affects how well the material will adhere to the print bed. You’ll find this setting just below the “Extruder”, listed as “Bed”, also with both “First layer” and “Other layers” temperature inputs.

Like the hot end, you’ll be taking the type of filament you’re using into consideration. For example, a filament such as ABS should have a higher bed temperature to ensure the print sticks to the bed.

Infill

Infill is another important factor in developing the best Slic3r profile for your Ender 3. Out of all the infill setting options, there are two things we recommend focusing on: density and pattern choice.

First, adjusting the infill density greatly affects the strength of your print, as the number is what percentage of the object 3D printed will be solid. For example, 50% infill will be half solid, 0% infill will be hollow, and 100% infill will be completely solid. You can find “Fill density” under the “Print Settings” tab in the “Infill” section.

The second major strength factor is the infill pattern. Slic3r offers 13 patterns, all of which help determine the strength of your 3D printed object and the speed at which it prints.

If speed is your primary consideration, go with one of the “Rectilinear” patterns. “3D Honeycomb” or “Gyroid” are good for strength in all directions. And flexible objects tend to benefit from patterns like “Concentric” and “Hilbert Curve”.

Skirt & Brim

Bed adhesion is one of the most common problems with an Ender 3. One way to help fix this problem is through your printer profile, and Slic3r offers some great ways to make your print stick to your print bed better: skirts and brims. You can find the settings to activate them in the “Print Settings” tab under the “Skirt and brim” section.

A skirt is a perimeter that doesn’t connect to the print but surrounds it. Though a skirt doesn’t directly help your print stick better, it improves your chances of good adhesion.

By printing a skirt before printing the actual part, the motion and extrusion allow your hot end to establish a smooth flow. It’ll also let the hot end clear any gunk from inside before printing the critical first layer.

Another reason to print with a skirt is you’ll know if your Ender 3’s bed is correctly leveled and that your printer isn’t messing up in any way.

A brim connects to your print and is a single layer that surrounds it. Brims more directly help your prints stick to the print bed by increasing the size of the base.

Layer Height

Adjusting layer height, the thickness of each layer, is usually a struggle between detail, speed, and strength. You can adjust these settings in the “Print Settings” tab under the “Layers and perimeters” section.

A larger layer height will result in a faster and possibly stronger print, while a smaller layer height allows for greater detail. Although uncommon, very large layer heights will require a nozzle that’s wider than the standard 0.4 mm.

Smaller layer height is ideal for detailed models like miniatures. Printing with a smaller diameter nozzle allows you to print with an even smaller layer height and get more detail.

The Perfect PLA Profile

Now that we’ve gone through the main areas of settings you can adjust, let’s take a look at some specific settings for your Ender 3’s Slic3r profile. When printing with PLA, we recommend the following for the best prints:

- Print speed: 55 mm/s for normal models; slower for more detailed prints

- Travel speed: 120 mm/s (and up)

- Extrusion multiplier: 1

- Hot end temperature: Follow the filament manufacturer’s recommendation; increase or decrease in increments of 5 °C

- Bed temperature: 60 °C normally works well for all PLA filaments, but if you’re experiencing adhesion issues, increase in increments of 5 °C

- Infill density: Depends on the part, but 20%-40% for normal parts and 60%-100% for stronger parts

- Infill pattern: Depends on the part

- Bed adhesion type: Printing a skirt is always recommended and many models can benefit from a brim if you have no concern for extra print time and filament use

- Layer height: 0.2 mm is a good layer height that’s strong and has adequate detail

Naturally, the above is just a starting point. Every printer is unique, and the same goes for filament and models. Any time you use recommended settings, you should consider them as initial values to try and then adjust them based on the resulting performance.

Is That It?

The settings we’ve discussed are of course not every single setting that might improve print quality. Depending on your material and print, there are plenty more settings that you should change to get the best Slic3r profile for your Ender 3.

A good piece of advice for changing your printer profile is to never change more than one setting at a time. That way, you can see how the print changes depending on what you adjust.

It’s also smart to do test prints with your printing profiles. You can find some good options in our article about the best models for test prints.

Remember to make material-specific setting adjustments and never give up on your printer!

License: The text of "How to Find the Best Slic3r Ender 3 Settings" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.