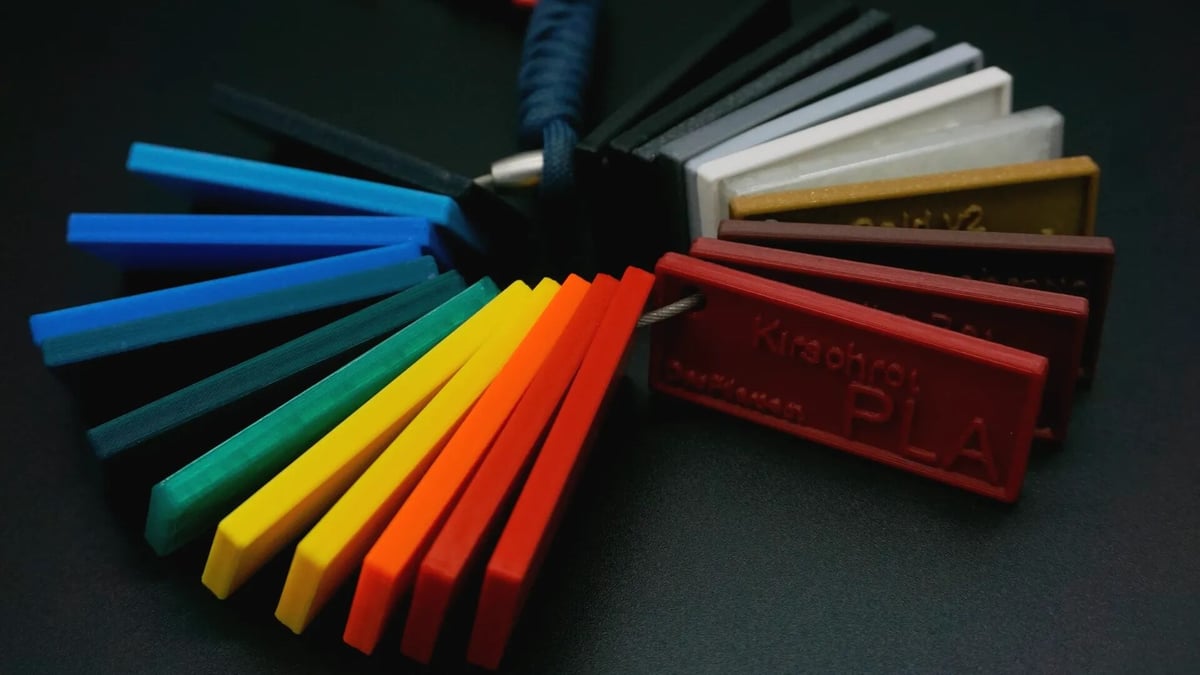

PLA, ABS, and PETG are some of the most popular and readily available filaments out there. But just because they’re readily available doesn’t mean they’re equally suited for every printing job.

While PLA is the easiest to print, it’s not the strongest. ABS is often used when increased durability in a part is desired, but it can be smelly. PETG is a popular choice when food safety is required and it has great material properties. Printing it, however, can be a stringy affair.

In this article, we’ll take a closer look at the benefits and drawbacks of all three materials. We’ll also do a quick comparison of their respective print and material properties, pointing you along the way to other resources with more detailed information.

PLA

The most popular of the three materials, polylactic acid (PLA) is a plant-based plastic material, which uses corn starch as its raw material. As a thermoplastic polymer made from renewable raw materials, many claim it’s biodegradable but it’s more accurate to say that it’s industrially compostable. And there are a variety of types of PLA: from PLA+ (or tough PLA) to wood, carbon fiber, and metal composites among many other options to pick from or put to different uses.

Benefits

PLA is extraordinarily easy to print. It will generally flow out of your 3D printer’s nozzle without any clogging issues, and compared to other filaments, PLA has a relatively low print temperature. Perhaps the biggest benefit of printing with PLA is that it’s cheap: 1 kg of PLA will cost you $25 to $30.

Drawbacks

PLA filament tends to deform or melt in high-heat situations, making it impractical for parts that require heat resistance. This even applies to hot environmental conditions, such as a car dashboard on a sunny summer day.

Another drawback of PLA is that it’s a brittle material. Upon impact, it has the tendency to shatter. As such, it’s less sturdy than ABS or PETG, making it better for aesthetic uses rather than mechanical ones.

ABS

Acrylonitrile butadiene styrene (ABS) is an opaque thermoplastic that’s commonly found in household and consumer products. After PLA, it’s one of the most popular filament types and is readily available from a variety of manufacturers. Beyond 3D printing, ABS is also well suited for injection molding and machining.

Benefits

ABS is strong, tough, and durable. It has good resistance to heat and impact. The material can distort and bend before breaking, making it well-suited for items that get used often in day-to-day life.

Another benefit is the ease of finishing an ABS print. The material is highly reactive to acetone, so there are smoothing techniques that could be used in post-processing ABS prints.

Drawbacks

Dangerous fumes are released while printing ABS, which makes working with the filament tricky. You’ll need either an enclosure with a filtration system or a separate properly ventilated room where you print.

An enclosure would also come in handy because ABS is very sensitive to temperature changes, which could lead to warping and cracks appearing on the parts. An enclosure would help to maintain the target temperature during printing.

PETG

Polyethylene terephthalate glycol (PETG) is a thermoplastic whose material properties make it a good contender for functional objects. It’s commonly found in water bottles and food containers, and in addition to its base offering, there are also filament composite versions.

Benefits

PETG is widely considered to be a food-safe filament. You can use it to make things that will come into contact with food, like accessories for your kitchen or camping utensils, containers, and more. Nevertheless, it’s best to check the manufacturer’s specifications and incorporate best practices for food-safe 3D printing.

The material is durable and highly impact-resistant. It’s also fairly resistant to UV light, which means it should perform well in outdoor applications.

Drawbacks

PETG filament likes to string during printing. This is due to the high temperature required to print, which allows the filament to flow freely but makes it prone to leaving strings while traveling between two points.

Another drawback, although it is a lesser one, is that PETG is prone to scratching. This may not matter at all to some users but to others, it could be an absolute dealbreaker.

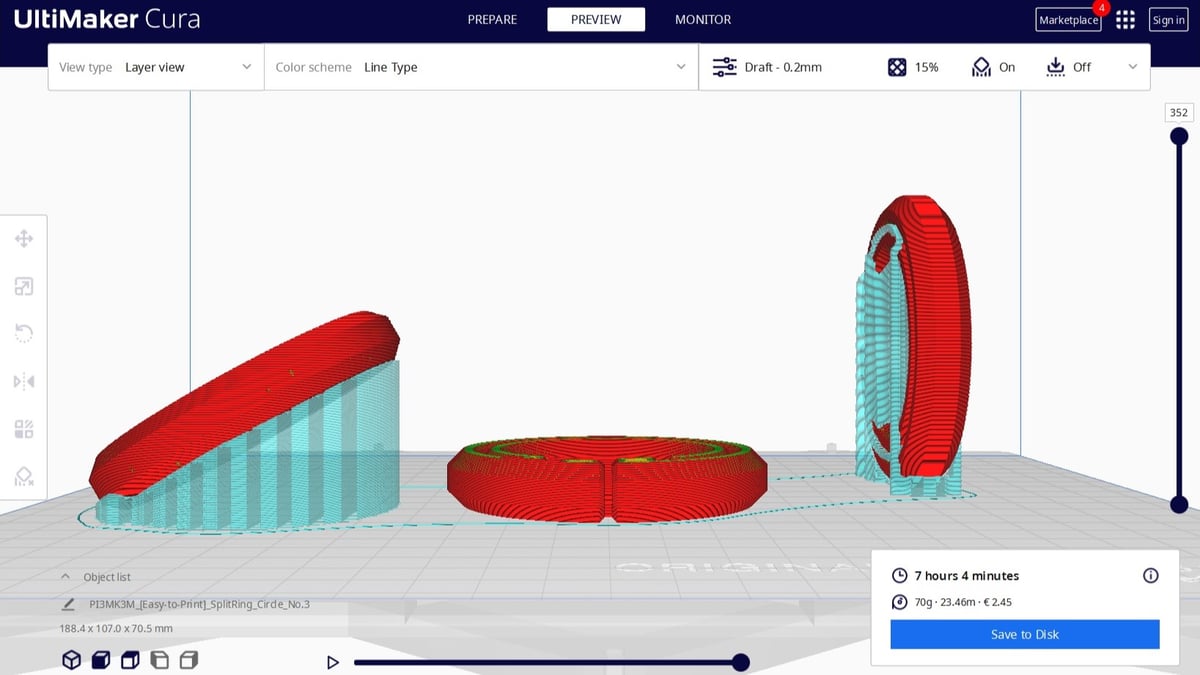

Comparisons

Now that we’ve looked at the different filaments, let’s do a quick side-by-side comparison of the three materials with regard to printing and their general material properties. In case you want to do a deeper dive into any of the topics, we’ll point you in the right direction.

Temperature

While general parameters can be stated, depending on whether you’re 3D printing, for example, a composite material, you’ll want to read the manufacturer’s suggestions.

- PLA: 180-220 °C, no heated bed required (can benefit from 55-70 °C)

- ABS: 210-250 °C, heated bed between 90-110 °C

- PETG: 220-250 °C, no heated bed required (can benefit from 50-80 °C)

Enclosure

Even if the material of choice doesn’t need an enclosure to deliver perfect prints, it can still come in handy for a variety of reasons. And while there are pricey (and worth it) options out there, you can always turn to Ikea for a great DIY version.

- PLA doesn’t require an enclosure.

- ABS is quite susceptible to drafts. While not absolutely necessary, you would seriously benefit from an enclosure. The preservation of heat within the enclosure helps to prevent warping and cracking.

- PETG doesn’t require an enclosure.

Post-Processing

Filling, sanding, and priming are post-processing methods that work across the board, yet because of the properties of each filament, other techniques can be restricted to a particular material.

- PLA: Filling, sanding, and priming are the primary methods. There are no safe chemical agents that can be used to finish PLA prints.

- ABS: It’s relatively easy to smooth out ABS using acetone, and in theory, that’s all you need.

- PETG: MatterHackers reports that ethyl acetate can be used to smooth PETG. Filling, sanding, and priming are tried-and-true methods that work for PETG prints.

Strength & Durability

Depending on the intended use, strength can be a dealbreaker. Of course, in addition to the filaments’ characteristics, there are other 3D printing considerations that can help.

- PLA is considered a low-to-medium strength filament given its low heat and chemical resistance. It also has a tendency to shatter upon impact.

- ABS is considered a medium-to-high strength filament, as it will sooner bend than break and has a higher impact, heat, and chemical resistance than PLA.

- PETG is also considered a medium-to-high strength filament. For the most part, it’s similar to ABS but is superior in strength, especially when it comes to loads applied in the same direction as the layer lines.

Toxicity & Odor

Because you don’t want to have a smelly or harmful environment, it’s good to know what to expect from the filament you’re 3D printing.

- PLA has low odor and no toxicity.

- ABS has considerable odor and some toxicity. Therefore, it’s best printed in a well-ventilated area.

- PETG has no odor or toxicity.

Hygroscopicity

Different filaments can be hygroscopic to different levels – and a material that has absorbed moisture can lead to failed 3D prints. Of course, there are methods to help dry the filament if it’s been exposed to moisture.

- All three are very hygroscopic, so it’s best to keep these filaments in a storage box or dry them out after a long time of no use.

Best Use Cases

There’s plenty to 3D print, yet given each material’s characteristics, specific use cases will benefit the most from a distinct choice.

- PLA is best in applications that don’t have any specific functional requirements. That said, given its ease of printing, there are plenty of useful things to create with it.

- ABS is often used in functional items that see lots of use or simply need to be durable – the frame of a drone, for example. Additionally, because of the possible acetone post-processing, it can be a great option for aesthetic prints like chess sets.

- PETG is a good choice for items that will come in contact with food or drink as well as for those that are exposed to UV light as it’s got higher resistance than PLA and ABS. It’s also a great contender for functional parts.

License: The text of "PLA vs ABS vs PETG: The Main Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.