You may know a material’s melting point and ideal nozzle temperature, but glass transition temperature is an entirely different measure for 3D printing filament. Glass transition temperature describes the point at which a material transitions between a rigid and a more flexible state.

Knowing the glass transition temperature is helpful for a few reasons. Mainly, it indicates a significant change in a material’s physical and mechanical properties.

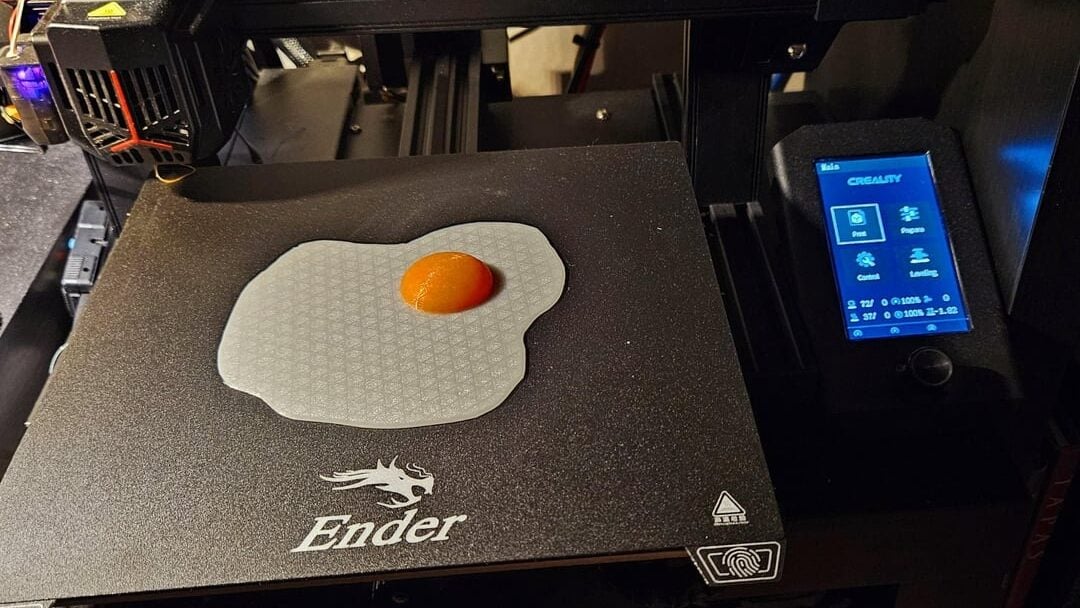

You can apply this information to decide if parts made in a certain material are capable of performing specific tasks. For example, if you’re 3D printing a part that’ll come in contact with boiling water, like a kitchen tool, you should check the glass transition temperature of filaments to choose the right material for the job.

In this article, we’ll go over the glass transition temperatures of PLA, PETG, and ABS filaments and how this information can be used. Before we get to the specific values, we’ll discuss how glass transition temperatures relate to 3D printing and filament in general.

What Is It?

To better understand glass transition temperature, perhaps it’s best to start with an example. Have you ever put a rubber band or plastic take-out container in your freezer, only to notice that they are much more susceptible to cracking or breaking when cold? That’s because the material is below its glass transition temperature, no longer behaving like a soft, bendable material but rather a stiff, brittle one.

It’s important to know that the glass transition temperature doesn’t define a material’s usability, only its use cases. Many materials we use every day have a glass transition temperature below room temperature, such as TPU, TPE, and HDPE, meaning we’re using it in its rubbery state. This gives us flexible and even stretchable properties. On the other hand, materials with a high glass transition temperature, such as polycarbonate, can be expected to maintain their rigid properties even in hot environments.

The glass transition temperature represents a significant change in a material’s properties. It’s important to know this value for the material you’re working with and be sure it’s not within the range of temperatures it may be exposed to while in use. You wouldn’t want your RC car tires to be glassy or your shelves to start bending!

Effects on Filament

The glass transition temperature can be especially useful in 3D printing to find a reliable bed temperature.

Typically, the glass transition temperature of a filament should be the bed temperature that you print the filament with. That’s because, above the glass transition temperature, the material remains in a softer, slightly expanded state that helps maintain adhesion to the print bed. Below the glass transition temperature, the part may shrink slightly and become more prone to warping.

You should definitely not be printing on a bed set significantly higher than the glass transition temperature because you don’t want the filament to soften too much, as this could lead to defects like elephant’s foot.

Note that the glass transition of a material is distinctly different from the melting point of a material, which is another thermal transition where it goes from a solid to a viscous liquid state. This temperature is related to the hot end temperature required to process and extrude the molten material. The temperature at which a part is exposed should always be well below the melting temperature.

Now that we know a bit more about glass transition temperatures in 3D printing, let’s find out what they are for PLA, PETG, and ABS!

The Numbers

To get right into it, the glass transition temperatures of PLA, PETG, and ABS are summarized in the table below and compared to their melting points.

You may notice that the numbers have a large range. This is due to a material’s thermal properties being dependent on factors like thermal history, processing conditions, and other additives, so the exact glass transition temperature and melting point will vary from spool to spool. For a more accurate glass transition temperature, you can always check with the manufacturer of the specific filament you’re using.

As a reminder, below the glass transition temperature, materials are in a glassy state and can experience brittle failure. Heating to above the glass transition temperature means materials become flexible and may even be able to stretch before breaking. However, they also won’t have the same amount of strength as at lower temperatures.

Unsurprisingly, PLA‘s glass transition temperature is the lowest, usually falling between 55 to 60 °C. This means it will soften at temperatures one may experience in a hot car during summer, for example. PETG and ABS resist thermally-induced softening until around 80 °C and 100 °C, respectively.

License: The text of "Glass Transition Temperatures of PLA, PETG & ABS" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.