Along with PLA and ABS, PETG is a very popular filament in the 3D printing community. It’s strong, flexible, and durable, making it a great filament choice for a variety of applications.

PETG is similar to the polyethylene terephthalate (PET) that we all know and love to use for our water bottles and other food packaging. The ‘G’ in PETG stands for “glycol-modified” – in other words, a modification of the typical PET structure with glycol. This alters the properties of PETG compared to the classic PET, making it a bit more flexible and lowering the melting temperature. What we end up with is a printable PET-based filament with excellent properties that set it apart from the more brittle PLA and ABS.

The strength, flexibility, and durability of PETG make it the ideal choice for 3D printing functional parts. To improve its appearance in these applications, many seek to smooth the part’s surface after printing. Smoothing reduces the visibility of layer lines and deformities in the print, resulting in a more visually pleasing part.

A Prettier Print

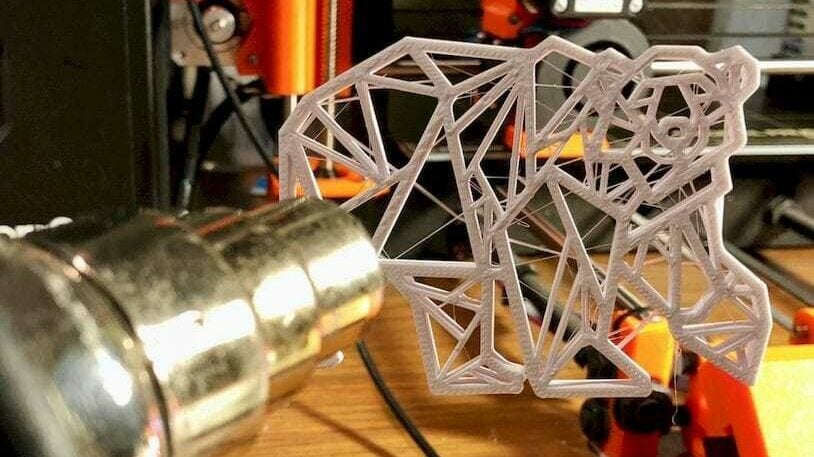

As we’ve mentioned, many makers wish to reduce the visible layer lines in their PETG prints by smoothing the part after printing. However, due to the chemical properties of the material, it can’t be smoothed using some common methods, like acetone smoothing.

Specifically, it’s the chemical structure of the PETG polymer that gives it good chemical resistance, which makes it difficult to dissolve using many common solvents. As such, you’ll have to use different substances than the ones you’d use with other filaments.

But that doesn’t mean it can’t be smoothed! Let’s take a look at some great ways to smooth PETG.

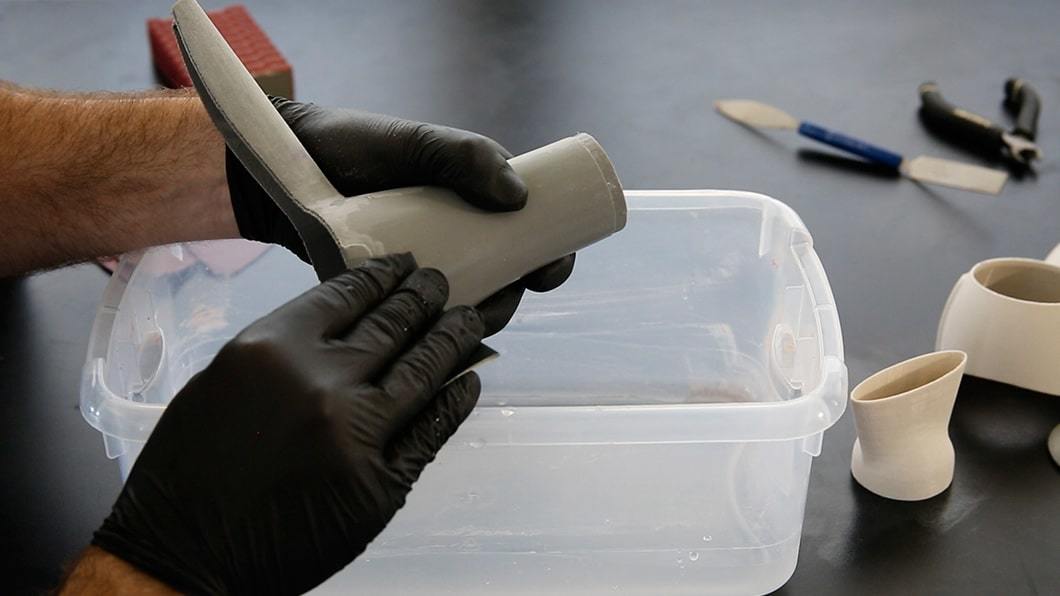

Sanding

Sanding is one of the most common methods for smoothing 3D printed parts, as it works well on all kinds of filament. It can eliminate unwanted protrusions on a part (such as support marks and zits), as well as reduce the visibility of layer lines. However, it can be rather time-consuming if the part is very large or intricate.

When sanding, we recommend starting with low grit sandpaper and moving towards a higher grit as you sand. You can also sand with water as you progress to high grit sandpaper to prevent clogging. Be sure to sand in an even, circular motion to create a smoother finish. For more details on this process, check out our articles on cleaning and post-processing your 3D prints.

Polishing

Using a polishing compound is another great way to smooth PETG prints. In fact, a nice polish will enhance the effects of sanding and further eliminate layer lines from your print.

Before beginning, ensure that your part has been adequately sanded with high grit sandpaper. Otherwise, the polish won’t stick well to the part. We’ve found that liquid metal polishes such as Brasso tend to work well on most brands of PETG.

To apply the polish, pour a small amount onto a soft cleaning cloth. Then, rub the cloth across the entirety of the part until all of the polish has been absorbed. Finish by taking an unused portion of the cloth and buffing the surface into a mirrored shine.

But be warned: you may need to apply a fair bit of force for this to work, so this technique may not be suitable for more fragile parts.

Coating

Coating your PETG print is another great way to smooth the surface and hide deformities. Much like with PLA and ABS, epoxy resin is a popular substance for coating PETG prints.

XTC-3D is a particularly popular choice of epoxy in the 3D printing community. It’s self-leveling, meaning that it’ll flow smoothly over the part and won’t show brush strokes as easily. It also provides a glossy finish once it’s applied, so be sure you finish any sanding before applying the epoxy.

The specifics of coating your print will vary depending on your choice of epoxy. The process typically involves preparing the epoxy-resin mix, then carefully applying it to the print with a small brush. For more details, check the instructions on your specific brand of epoxy.

Heat Treatment

Even though PETG is somewhat heat-resistant, heat treatment is still a viable option for smoothing PETG parts.

It’s important to note that you’ll need a heat gun with very precise temperature control to perform this technique. The recommended temperature for heat treating PETG will vary between brands, however, it typically lies very close to the filament’s melting temperature (normally around 250 °C). This can make it difficult to heat treat your part without ruining the print.

The overall goal of heat treatment is to melt a very thin layer of the print’s surface material. Done properly, this will melt away the layer lines and fill in any undesirable gaps in the print. Ultimately, the result is a smooth, professional-looking part.

The key to heat treating your prints is consistency. When smoothing, try to maintain a constant distance from the print and move in a smooth, continuous motion. If you don’t have much experience using a heat gun, try dialing down the temperature settings to avoid damaging your print. Although heat treatment at a lower temperature will be slower, you’ll be less likely to damage your part.

Dissolving

Although we mentioned that traditional acetone smoothing doesn’t work well with PETG, there are a number of other chemical solvents that are capable of dissolving and smoothing the filament.

Before beginning this technique, it’s important to note that many of the solvents discussed in this section are dangerous and some can only be bought with special permission. As such, they should only be used by experts with proper protection.

Ethyl acetate is one of the most common alternative solvents to acetone, however, it doesn’t react effectively with all varieties of PETG. Dichloromethane, methyl ethyl ketone (MEK), toluene, and cyclohexanone have all been proven to dissolve PETG as well, yet they are all potentially harmful and should only be used with the proper precautions. We recommend trying out ethyl acetate first to see if it works for you before moving on to harsher solvent options.

Application Methods & Options

The most popular method of application is called vapor smoothing. In this method, the print is exposed directly to the vaporized solvent. For more information on this process, check out the steps for ABS vapor smoothing.

You can also place paper towels soaked with diluted solvent around the model to achieve similar results. Applying the solvent with a brush should be done with plenty of control and caution, and directly sinking the print into the solvent is not recommended to avoid severely damaging your print.

If you’re looking for a more professional solution, there are a variety of automated solutions such as the Polymaker Polysher. These machines greatly simplify the smoothing process, however, they aren’t compatible with all types of solvents. As such, be sure to check that the solvent that works for your filament is compatible with the machine before beginning to smooth.

License: The text of "PETG Smoothing: 5 Ways to Smooth PETG" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.