Have you ever printed with old filament or material that’s been exposed to humidity? If you have, you probably ran into some print quality issues. Most likely, that’s because of hygroscopy, which with respect to 3D printing, is the occurrence of filament absorbing moisture.

Most filaments are naturally hygroscopic – some more than others. This means that, when there’s moisture in the air (humidity), filament naturally absorbs it. Though difficult to spot beforehand, hygroscopy is a factor that negatively affects 3D print quality.

Moisture within printing material can’t be seen, but when you heat it up in the hot end of a 3D printer, you can. Essentially, the water boils as the filament melts, and this causes bubbling.

In this article, we’ll go into more detail about how hygroscopy affects print quality, which materials are hygroscopic, which ones are less so, and how you can prevent hygroscopy from ruining your prints.

Effects on Print Quality

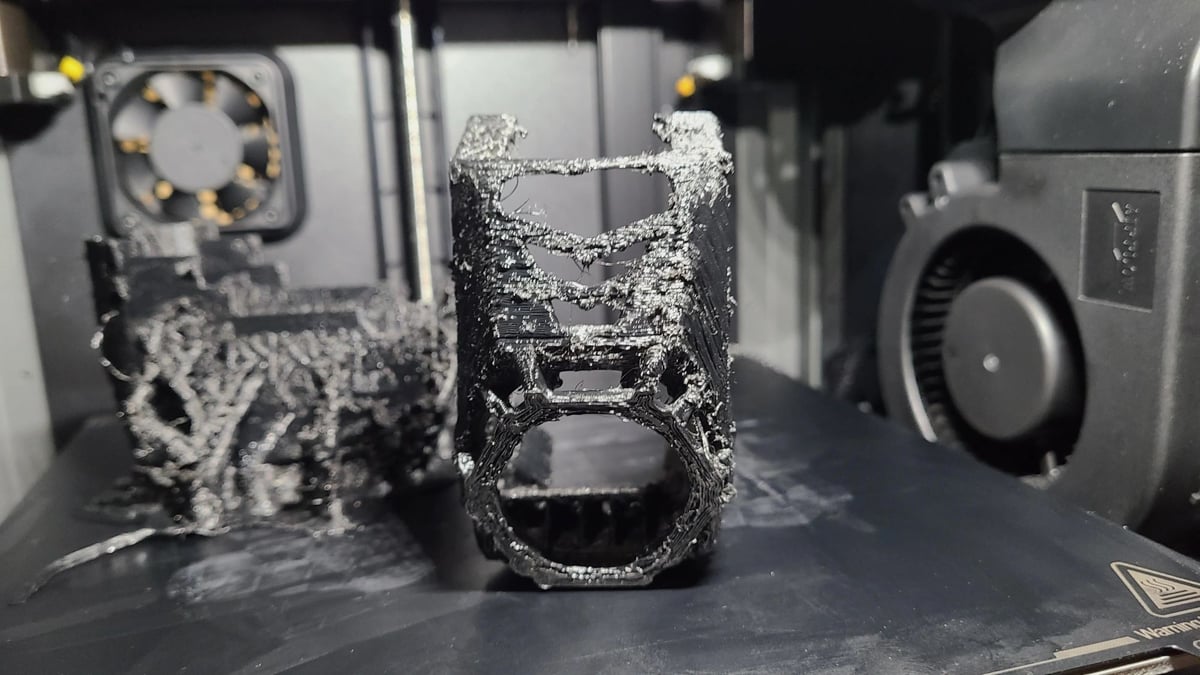

When a hygroscopic material absorbs water, printing with the “wet” filament can lead to an abundance of print errors. Some of the most common signs for moist filament include the following:

- Bubbles or blobs in print layers

- Stringing

- Extruder jams

- Brittle, soft, and fragile parts

- Poor bed adhesion

- Extrusion issues

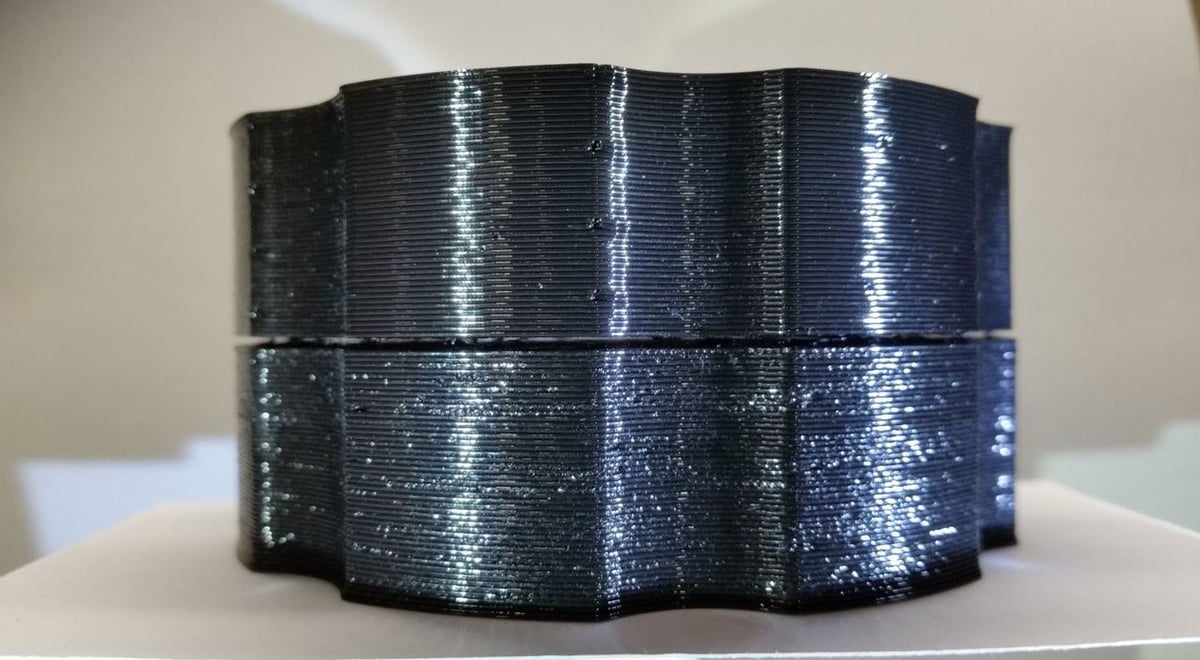

If you look at the picture above, you can see the difference between printing with wet filament (bottom) and dry filament (top).

That’s not to say that moist filament can be the only cause for these issues, but it is among the most likely and should be one of the first aspects you check before looking into the machine itself.

Now that we know what can happen, let’s take a closer look at which filaments are more hygroscopic than others.

Most Affected Materials

As we mentioned above, many of the materials used for 3D printing filament are somewhat hygroscopic. That said, how much and how quickly different materials absorb moisture varies. The following materials are most likely to get wet quickly:

- Nylon as well as other polyamides (PA)

- PVA (commonly used as support material)

- TPU

- PLA

- ABS

- Polycarbonate (PC)

- PETG

- Many flexibles

For anyone interested in a deeper dive, BCN3D conducted research on the effects of humidity on 3D printing filaments and released a white paper detailing their findings. They looked primarily at the three most hygroscopic filaments in their portfolio, namely PA, PVA, and TPU. Of the three, PVA absorbed the most moisture during their experiments and TPU, the least. That being said, TPU fared the worst when it came to its resistance to poor storage conditions.

Which Are Less Hygroscopic?

Compared to the materials listed above, the following are less prone to hygroscopic issues:

- ASA

- Polypropylene (PP)

- HIPS (most commonly used for ABS support material)

This doesn’t mean that they won’t absorb moisture – they will, but not with the same intensity or as quickly as the previously mentioned materials.

Prevention is always warranted, no matter what filament you’ve got. So, let’s take a look at what can be done to limit your filaments’ exposure to moisture.

Storing Filament

Knowing the common symptoms and main culprits, let’s talk about how to actually deal with hygroscopy. Naturally, the first step is prevention, a.k.a., proper storage.

Generally speaking, the key is to keep filament in dry, watertight containment. You should do this as much as possible between prints.

A solid storage option is a dry box, which will physically separate your filament from the surrounding environment. This method works for both long- and short-term storage, as long as there’s some sort of watertight seal at the opening. Note that there’s a difference between a dry box (which keeps the environment… dry) and a dryer box, which actively heats the filament to remove moisture.

If you’re looking to store some filament for up to a few days, a tightly-sealed bag will do just fine. In this case, consider using desiccants to remove oxygen and moisture.

Depending on the storage option you go for, whether purchasable or DIY, you can look into a design that includes a hole (while still keeping the box airtight). This will allow you to use the filament while it’s stored.

Drying Filament

Printing with filament that’s stored in a dry box is a great idea for preventing hygroscopy-related problems. But if you haven’t been vigilant about properly storing your filament, it’s likely to have absorbed some moisture from the air, especially if you’ve had it for a while.

The good news is, you don’t need to buy another spool. Rather, you’ll need to figure if your filament is wet and, if so, dry it.

Detecting Wet Filament

In determining if your filament is “wet”, you’ll want to pay attention to how it prints. Wet filament often results in lower-than-expected print quality.

If a spool of filament has absorbed a decent amount of moisture, you can do a simple test. All you need to do is push some filament through your nozzle and listen closely. You’ll know you have a wet filament if you hear a crackling noise as the filament is extruded. Another indication is if you see steam coming off of a print (when hot meets cold) or any of the previously mentioned print problems.

Drying Filament

You’ve done the tests, and your filament is wet. Time to dry it.

In fact, drying filament is easy. Simply put the spool in the oven and, for PLA, set the temperature to around 40-50 °C (approximately 100-120 °F). Then, leave it there for around 4-6 hours. Other materials, like ABS and nylon, will benefit from higher temperatures (~80 °C or ~176 °F). You can check out Bambu Lab’s suggested temperatures for more materials, but it’s always recommended to check out the manufacturer’s advice.

For even more and better filament drying, you can put desiccants in the oven with the filament too. Also, make sure to avoid over-drying your filament, as it can lead to brittleness.

If the oven’s not an option, you can opt for a dryer box. Creality’s Dry Box 2.0 and Sunlu’s FilaDryer S1 Plus are great options, but you could also take a DIY approach.

License: The text of "Hygroscopy (3D Printing): What It Is & How to Deal With It" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.