This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Distasteful at Best

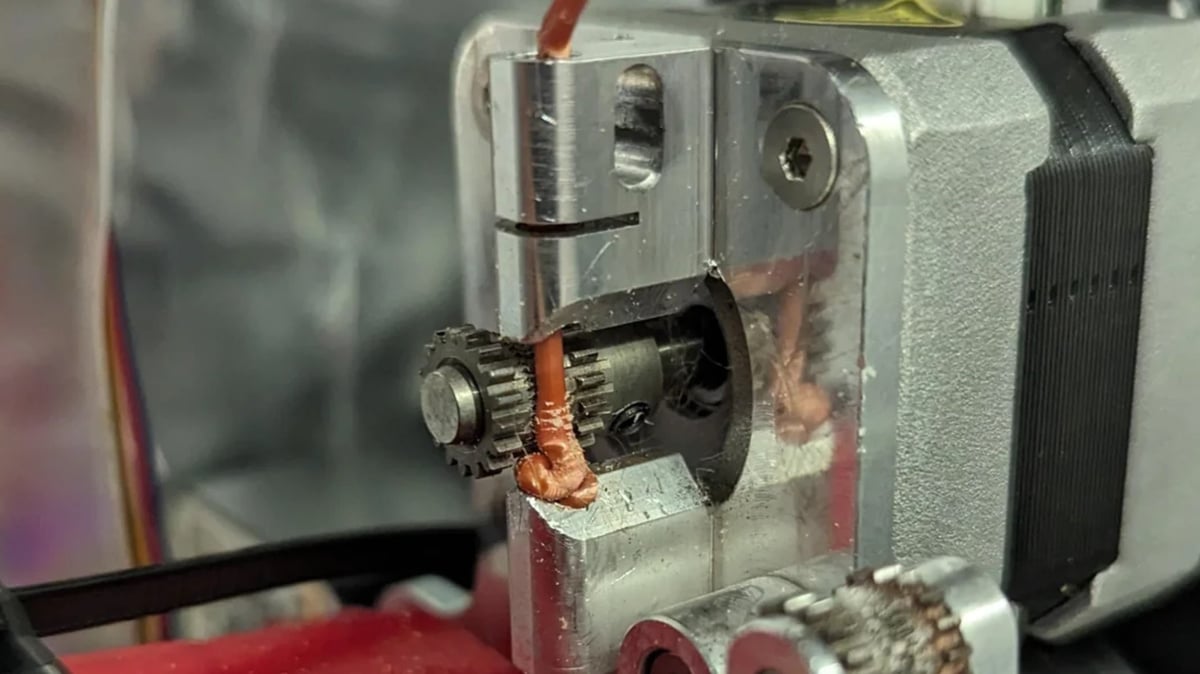

Filament Jam: Filament Stuck in Extruder – 3 Easy Fixes

Is the filament stuck in the extruder again? Check out our simple guide to stop filament jams from ruining your day and your 3D printer.

Advertisement

Advertisement