Customized manufacturing seems to be steering our world, and increasingly so. Creating products that fit the customer’s exact expectations is the need of the hour. 3D printing is a major factor in this, bringing tailored solutions to an entirely new level.

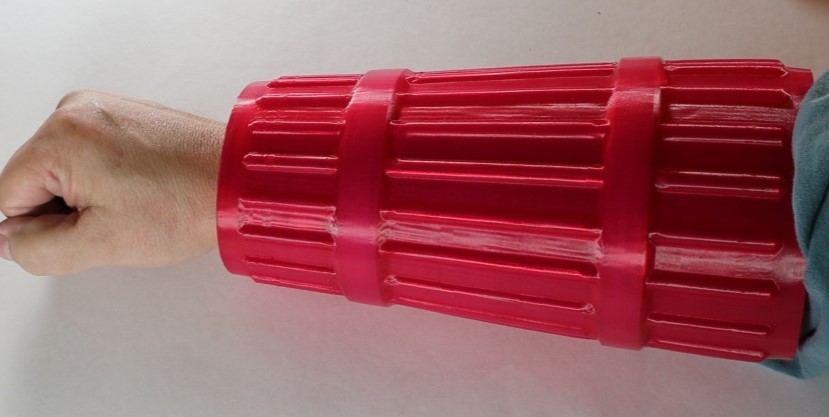

Just take a look at 3D printed fashion or the various medical applications to get an idea of how 3D printing can be used to give the end user a truly custom-made experience. However, the common 3D printing filaments that we’re familiar with, such as PLA or ABS, are too rigid and unyielding for skin contact applications and shock absorption, for example.

When it comes to flexible and elastic applications, rubber is the ideal choice. But is rubber 3D printable? The short answer is no. This drives the development of alternative materials that are similar to rubber but can be 3D printed. And, luckily, some clever chemists and material scientists have come up with many printable options to choose from over the years.

In this article, we’ll look at the various types of soft and flexible filaments on the market so you can judge which is best for your needs! To get started, let’s take a deeper look at exactly how flexible filaments are characterized.

Overview of TPE

In order to decide which material we should use, we need to understand a little more about what these flexible filaments are and how they compare to other filaments and everyday materials. Most of the filaments we’ll explore here fit into a class of materials known as TPE, or thermoplastic elastomers.

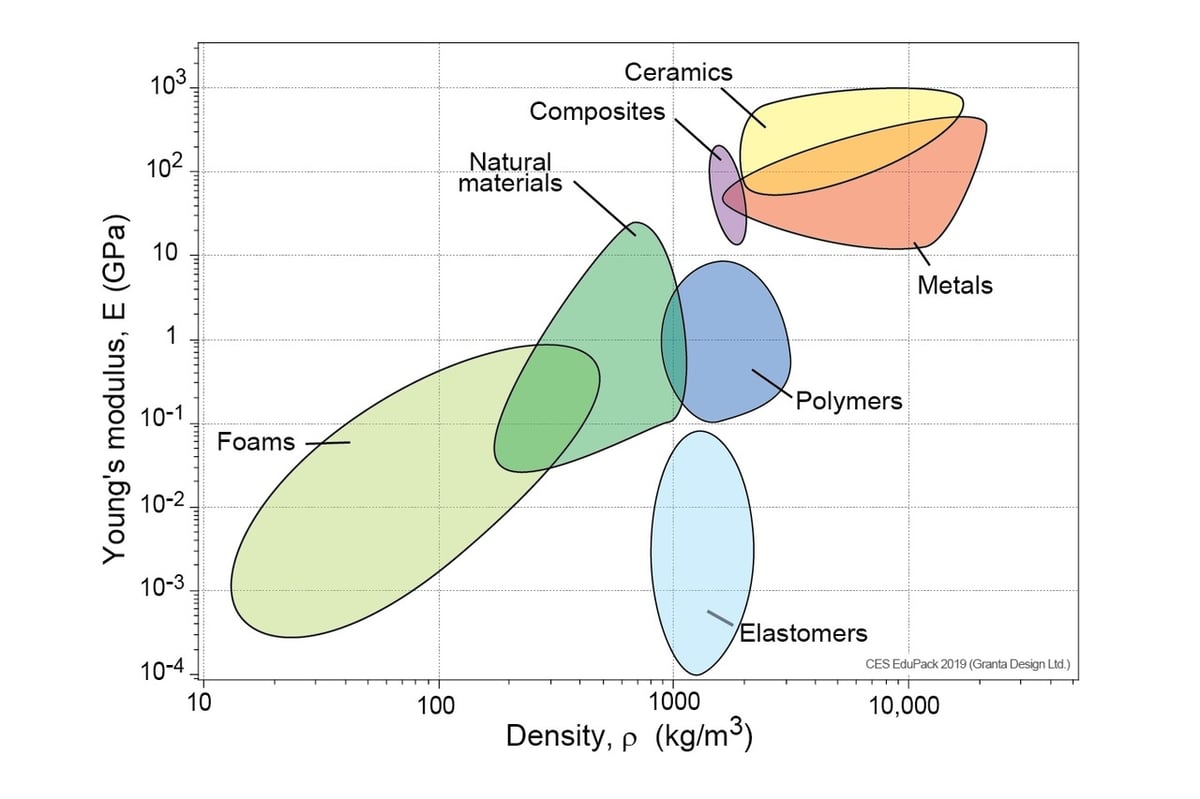

Elastomers are a subgroup of polymers that are generally softer and more flexible compared to the materials that come to mind when we think about plastics. This is due to differences in the way that polymer chains interact with each other.

In the chart above, we quantify this difference in properties using the Young’s modulus. This value is the ratio between how much force is applied to how much the material deforms, otherwise known as stress over strain. For flexible materials that need to stretch and deform, Young’s modulus should be on the lower end.

Some special properties of TPEs include their incredible abrasion resistance, making them ideal for high-wear applications – like shoe soles. TPEs are also electrically non-conductive and can be used like rubber to isolate electrical circuits.

Shore Hardness

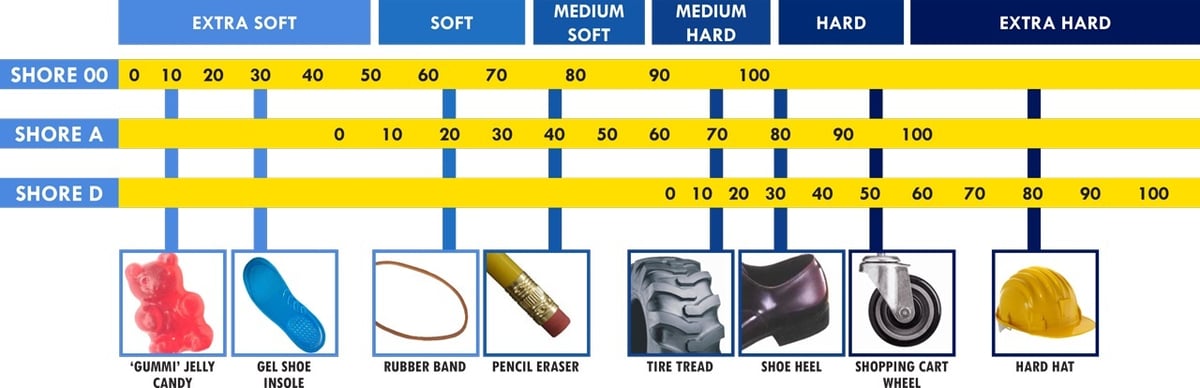

An important measurement used to classify flexible filaments is Shore hardness. Unlike Young’s modulus, Shore hardness is independent of the geometry of the material being tested and is more useful for quantifying the “feel” of the material in question.

Shore hardness rates the material’s resistance to indentation. When you think of rubbers, you can imagine pressing your thumb into the surface and creating a slight depression that bounces back to normal when released. The chart above paints a picture of the Shore hardness scale using some common materials.

There’s a wide selection of Shore hardnesses available within flexible filaments, ranging from 60A at the lower end to 75D at the high end, the most common being 95A. As a point of reference, PLA has a Shore hardness of around 80D and PETG is typically around 70D.

Shore hardness is measured with a Shore durometer. You’ll want to opt for lower durometer materials for applications that need to spring back into place after being flexed over and over again, for example, a living hinge or smartphone case. Higher durometer materials are more suited for parts that will be constantly under strain and need to hold their shape while still having a little give, for example, as a shock-absorbing bushing or spacer.

Printing Experience

One of the major drawbacks of flexible filaments is the challenge of printing them. Extrusion issues like jams or slippage in the extruder filament path require some finesse to get them to feed reliably. Due to their softness, filaments can slip past the extruder gears if the filament tension isn’t tuned properly.

TPE also tends to string a lot, which requires fine-tuning of retraction settings in order to minimize this behavior. Too much retraction, though, can cause the filament to bunch up and jam. This problem is much more pronounced with Bowden extruders, so a direct extruder is highly recommended when using flexible filaments.

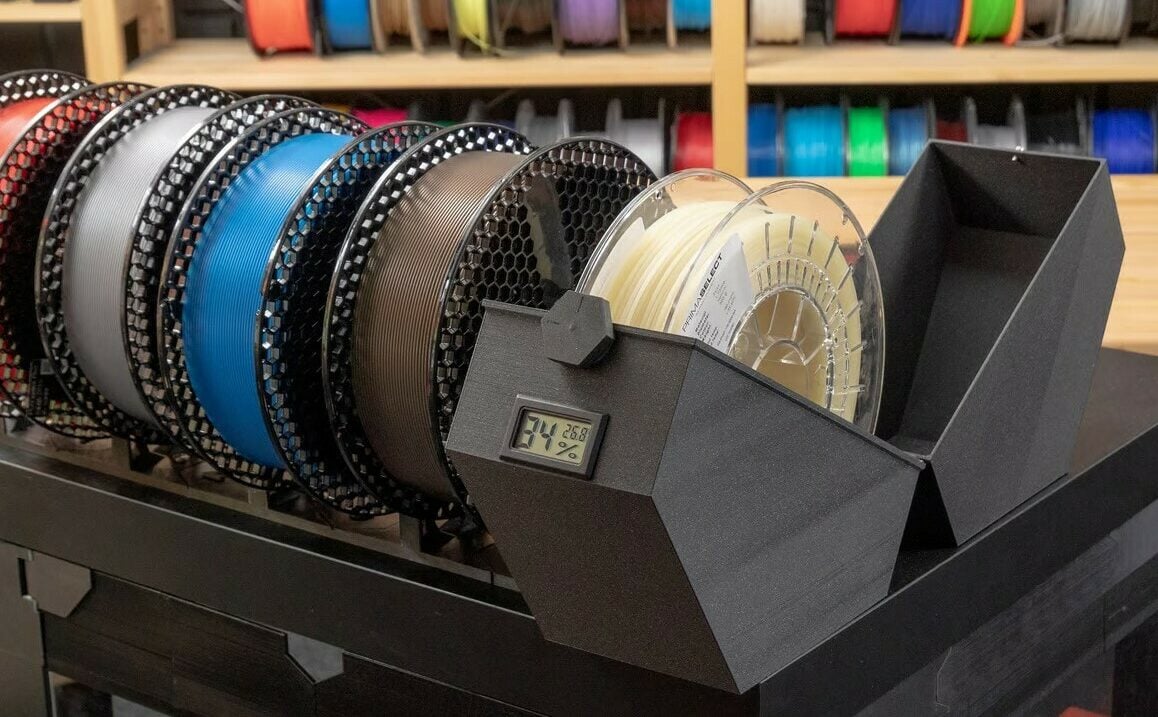

Lastly, it’s a good idea to keep TPE stored in an airtight container with desiccant until it’s time to print due to the hygroscopic nature of many TPEs. A filament dryer could also be handy to dry out any filament just prior to printing.

Classifications

There are several different types of TPEs on the market. In this article, we’ll take a look at the 3D printable versions as well as other flexible filament options. These include the following:

- Thermoplastic polyurethane (TPU)

- Soft PLA

- Thermoplastic polyamide (TPA)

- Polyether block amide (PEBA)

- Thermoplastic copolyester (TPC)

- Thermoplastic styrene block copolymer (TPS)

Let’s take a look at each of these in more detail.

TPU

Thermoplastic polyurethane (TPU) is the most common TPE used in 3D printing. As the name suggests, it’s based on polyurethane but is modified to make it softer. The unique mix of properties has made it great for athletic wear that benefits from its durability and breathability, while industrial machinery also takes advantage of its tough yet flexible nature.

Features

Compared to other flexible filaments, TPU can come with greater rigidity, allowing it to be printed more easily with fewer extrusion issues. TPU comes in a wide range of Shore hardness ratings, as low as 60A and as high as 77D, so don’t expect consistent results from one TPU to another.

There’s a huge variety of color options for TPU out there, including semi-transparent. TPU is also available as a composite filament, for example, with carbon fiber and glass-filled variants.

Challenges

Think about your printer’s capabilities when selecting a TPU filament. The softer the material is, the more difficult it will be to print without jamming up your extruder. A direct extruder will perform better, but it is possible to use Bowden extruders if tuned properly. Within direct extruders, ones with shorter extrusion paths (i.e. less space between the extruder gear and hot end) will perform the best.

Another common issue with TPU is stringing, which tends to be more prevalent when temperatures are set higher. For this reason, it’s advisable to print at a lower temperature but without going too low to prevent layer adhesion.

3D Printing Parameters

- Extruder Temperature: 210–230 °C

- Bed Temperature: Unheated–60 °C

- Print speed: 5–30 mm/s

- Bed adhesion: Tape

Example Filament

The Pro Series TPU from MatterHackers is a premium quality TPU with a rather premium price. It’s a great pick if you need to print reliably straight out of the box. Cheaper options may work for you as well but may be more difficult to print and less durable over time.

Soft PLA

Soft PLA, sometimes called flexible PLA, is a generic term applied to PLA blended with softener additives. While typical PLA is quite brittle and can only handle an elongation of 5-10% before breaking, soft PLA pushes this value well beyond 100%, depending on the formulation. This elastic behavior means that soft PLA falls into the TPE filament category, but note that it’s distinct from a TPU.

Features

Compared to other flexible materials, soft PLA is remarkably affordable – a quality likely inherited from PLA. Soft PLA is also easier to print than many other TPEs, as it has a very similar printing profile to normal PLA. Some formulations don’t even require a heated bed to print, but it is recommended for optimal results.

Soft PLAs are especially flexible and are perfect for fun squish toys and other non-demanding applications. These filaments can meet the standards for food-safe plastics, depending on the manufacturer, so this could be a great option for printing kitchen gadgets. You can expect a Shore hardness typically around 90-95A.

Challenges

Although soft PLA is possibly the easiest filament to print on this list, it’s still flexible, which makes it prone to jamming the extruder, especially with Bowden extruders. In any case, slowing down the printing speed can help avoid these jams.

It’s also worth noting that soft PLA may not have the same durability and rigidity that the previous engineering-grade TPEs possess. So if you need a material that can operate well outside of ambient temperatures or retain a certain amount of structural integrity, then you may be better off with TPS or TPA.

3D Printing Parameters

- Extruder temperature: 190–230 °C

- Bed temperature: Unheated–60 °C

- Print speed: 20–60 mm/s

- Bed adhesion: Usually not an issue

Example Filament

Flashforge’s Flexible PLA is a very affordable option at around $30 per kg roll. To make it even better, there are several color options to choose from.

TPA

TPA is the general term for polyamides (nylon-like) chemically combined with elastomers (soft polymers). One of the most common soft polymers used is polyethers to make a class of filaments called PEBAs, which we’ll cover in the next section. With that said, TPA properties can be broad, but the shared nylon component provides a few distinct features.

TPAs share many of the attributes that are associated with nylon, like abrasion resistance and chemical stability. Compared to nylon, TPAs are less dense and more flexible. This makes it useful for items such as treads for a 3D printed robot.

Features

TPAs fall on the more rigid side of the Shore hardness spectrum, typically between 70A and 95A. While slightly bendable, TPAs will retain their shape and may not stretch exceedingly well.

TPAs are one of the more temperature-resistant and durable materials of the flexible filament options. Moisture absorption may be less of an issue for TPAs, but it’s still recommended to store under dry conditions.

Challenges

Similar to regular nylon filament, TPA can be tricky to print. It requires a heated bed and can be tough to achieve good bed adhesion.

The variety of manufacturers is relatively limited for this niche filament. This also means there are fewer colors and variants to choose from as well.

3D Printing Parameters

- Extruder temperature: 230–250 °C

- Bed temperature: 90–110 °C

- Print speed: 5–30 mm/s

- Bed adhesion: PVA-based glue recommended

Example Filament

PCTPE is just Taluman’s unique name for TPA. At around 75$ per kg, the price is in line with some of the other engineering-grade flexible filaments, as well as regular PA (nylon) filament.

PEBA

Polyether block amide (PEBA), an amide-based thermoplastic, is a type of TPA. Its excellent balance of durability and flexibility make it the most popular form of TPA on the global market.

PEBA has similar physical characteristics to silicone rubber and could be used in its place in many cases. Industrial applications take advantage of PEBA’s high impact resistance and low density for use in athletic goods like ski boots. It’s also great for wire insulation coatings and general protection for electronics owing to its antistatic and temperature-resistant properties.

Features

PEBA falls in the center or slightly lower side of the Shore hardness range expected for TPEs, typically around 75A to 90A. PEBA will remain flexible at very low temperatures, as low as -60 °C. This is what makes PEBA perfect for winter sports gear that needs to perform in extremely cold environments.

Studies have shown that to get the ideal combination of softness and strength out of PEBA, it should be printed with a greater-than-normal layer height of 0.3 mm and an infill of 75%.

Challenges

PEBA is considered a relatively easy TPE to print, but it does have its drawbacks. Being one of the softer filament options, PEBA is especially prone to jamming up in the extruder when printed too fast or with too much retraction. It also requires a heated bed and higher than normal printing temperatures, although that should be expected for materials with more temperature resistance.

If you plan on using PEBA for outdoor applications, be aware that PEBA is particularly sensitive to UV exposure in its raw form. So, keep an eye out for manufacturers that formulate for UV protection.

Printing Parameters

- Extruder temperature: 240–260 °C

- Bed temperature: 90–110 °C

- Print speed: 20-60 mm/s

- Bed adhesion: PVA-based glue recommended

Example Filament

The 90A variant of PEBA from Fillamentum is available in a variety of colors. Although this is a bit pricey, around $80 for a 500-g roll, this seems to be the normal going rate for PEBA filament.

TPC

Thermoplastic copolyester (TPC) is a polyester-based elastomer that’s considered an engineering-grade material, which might explain why it doesn’t appear as much in the hobbyist 3D printing world. But if you’re looking for a flexible filament that’s also resistant to the outdoors, TPC might be worth seeking out.

Features

TPC shares most of the common traits found in other TPEs, like flexibility and abrasion resistance, but with some notable exceptions. One of which is its tolerance to higher temperatures – up to 120 °C! This allows it to retain its function in rather hot working environments, like in the engine of a vehicle. Moreover, TPC exhibits excellent resistance to UV light, oil, water, and other solvents.

Challenges

TPC filaments tend to be on the more rigid side of flexible filaments, but this does not mean that printing it will be a breeze from the get-go. TPC’s heat resistance means it will also need a higher temperature to be melted and extruded. Aside from ensuring you have an all-metal hot end, a heated bed and enclosure to keep in the warmth will help you achieve a successful print.

3D Printing Parameters

- Extruder temperature: 220–260 °C

- Bed temperature: 90–110 °C

- Print speed: 5–30 mm/s

- Bed adhesion: PEI print surface and PVA-based glue recommended

Example Filament

FormFutura touts their FlexFil TPC filament as having “flexural memory”, meaning it will spring back to its original shape after being deformed. Although it’s pricey compared to standard filaments at around 28€ per 500-g roll, this is more accessible than some of the more engineering-focused TPC filaments.

TPS

Thermoplastic styrene block copolymers (TPS) have long been used in soft-touch applications like grips for hand tools as well as seals and gaskets.

The TPS structure incorporates polystyrene segments, a material you may be familiar with, as it comprises many consumer products like packaging and foam. As an elastic filament, TPS is lightweight, soft, and flexible while retaining durability and resistant to water and chemicals.

You may also see TPS referred to as SBS (styrene-butadiene-styrene) or SEBS (styrene-ethylene/butadiene-styrene). Although this naming indicates slight differences in the chemical makeup of the polymers, for the purposes of this guide, we’ll be grouping all styrene elastomer variants under the name TPS.

Features

TPS is a particularly soft material with rubber-like qualities. This means it’s best used for applications that need a soft grip or resistance to compression forces but is not ideal for those that require significant stretching. The Shore hardness rating for TPS filaments usually falls between 70A and 90A.

With that said, TPS is highly desirable for skin contact applications, thanks to being non-toxic and resistant to oil, water, and other chemicals. TPS can also be resistant to UV degradation, especially in SEBS formulations. This makes TPS a good choice for outdoor applications or anything that will be exposed to direct sunlight.

Challenges

TPS has a remarkably high printing temperature in comparison to other flexible filaments but not too high as to require a specialized printer. In that light, TPS needs to be printed slower than most filaments so as to not overwhelm the volumetric flow capabilities of the hot end.

Keep in mind that TPS is not a particularly stretchy material, with some formulations being only able to stretch around 1.5 times the original length before breaking.

3D Printing Parameters

- Extruder temperature: 260–280 °C

- Bed temperature: 70–90 °C

- Print speed: 10–30 mm/s

- Bed adhesion: PEI print surface and PVA-based glue recommended

Example Filament

TPS is another filament with limited availability. BASF’s Ultrafuse TPS 90A is one accessible option, but the only color choice is natural white. The price of a 750-g roll is around $60.

License: The text of "Flexible 3D Printer Filament: 7 Types Compared" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.