Bridging is an important tool for anybody with an FDM 3D printer. It can save time and money by reducing the number of supports needed to print objects and make it possible to print overhangs and slots in 3D printed walls.

Unfortunately, if a 3D printer isn’t well tuned, bridges can end up as stringy messes that compromise the integrity of the printed part.

This guide will help you eliminate bad bridging from your 3D printer so you can use less filament and save time during your 3D printing projects, as well as avoid having to post-process the parts to get rid of stringing.

Let’s get bridging!

What Is It?

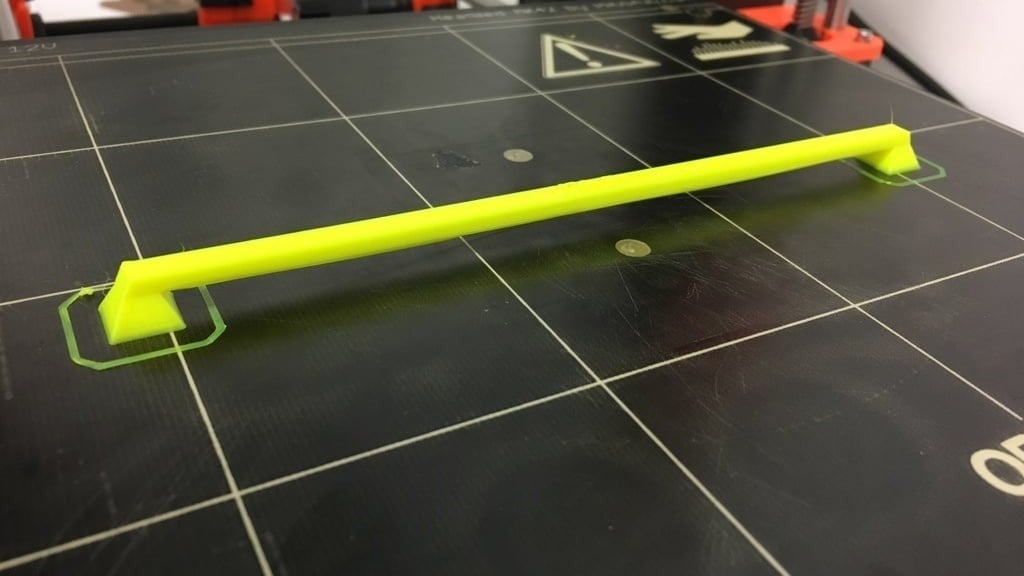

3D printer bridges refer to segments where the extruder releases filament over the air between two supported positions in the same layer as the bridge. It allows makers to print over thin air without supports, eliminating the need for filament underneath the bridge. So what’s the difference between good bridging and bad bridging?

Good Bridging & Bad Bridging

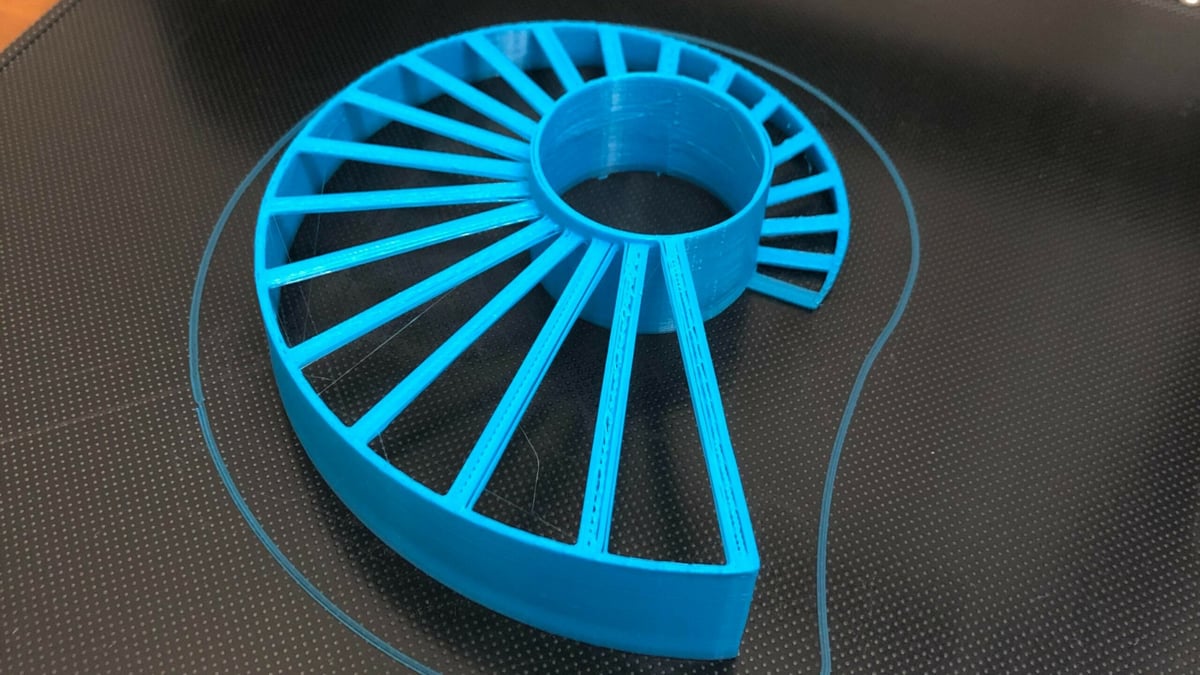

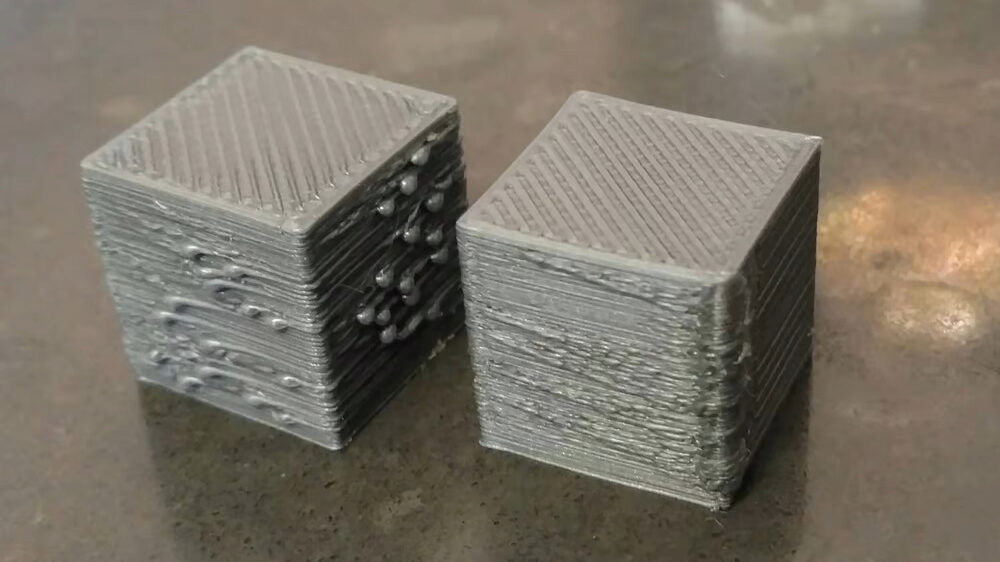

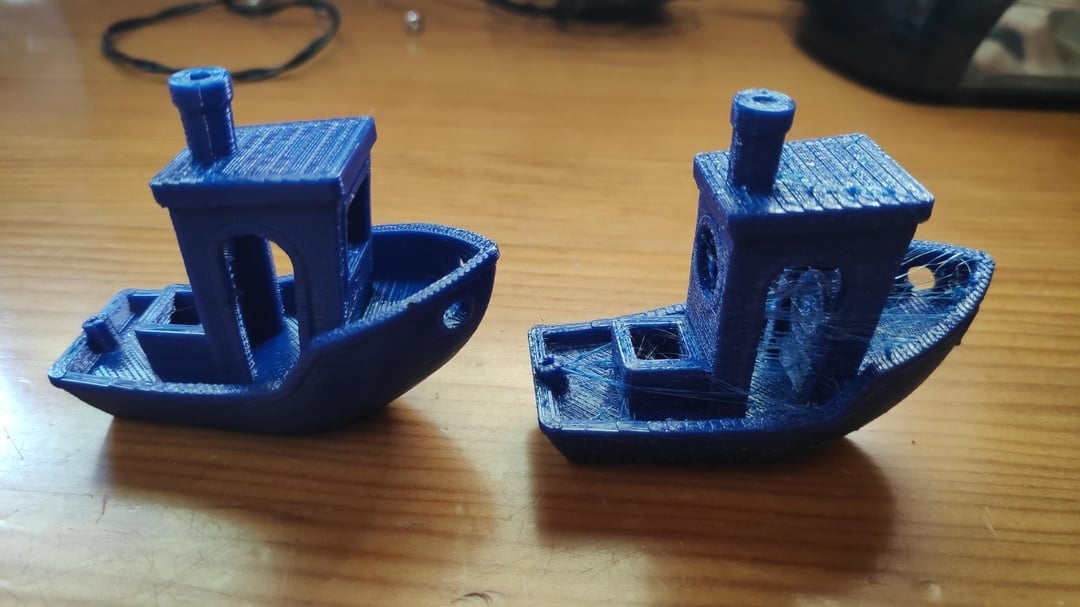

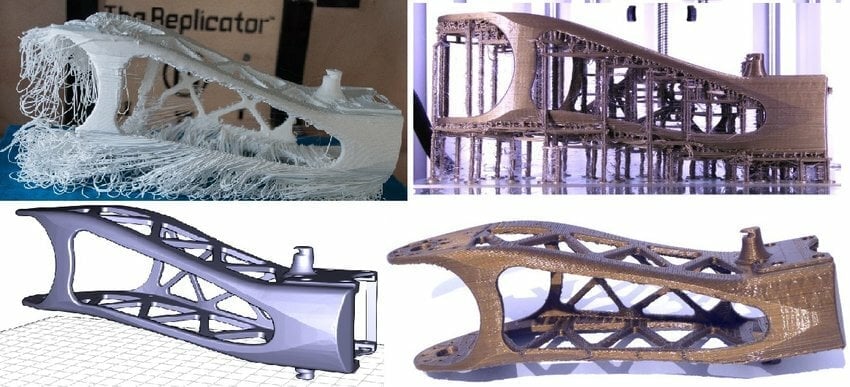

There is a clear difference between good and bad 3D printer bridging. For one, good bridging will have an object print that appears like the version in the slicer. It will look relatively flat underneath the bridge. In addition, the first bridging layer will adhere to the second layer, meaning there will be no loose strands of filament to brush or clip off after the print is complete.

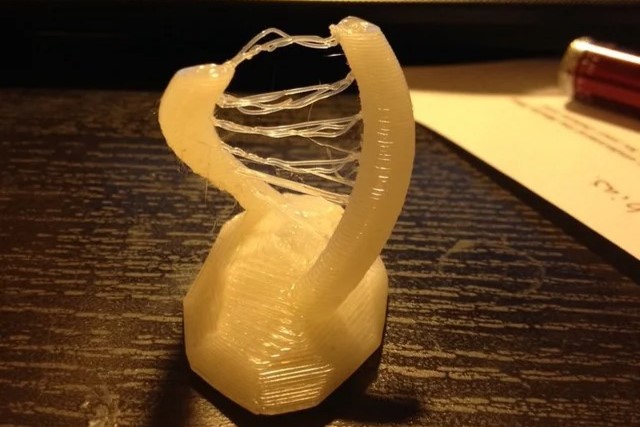

Conversely, bad bridging features loose and sagging strands or layers of filament that don’t complete the bridge. In the worst-case scenario, the bridge can even be missing entirely.

What Causes Poor Bridges?

Several factors may cause an unsatisfactory bridge, including:

- The print head is too hot: Bridging relies on the filament to cool as soon as it’s extruded. Otherwise, the still-molten filament will sag.

- The material isn’t cooling quickly enough: Inadequate cooling could be another reason for bridging issues. If the cooling fan isn’t cooling the filament very quickly, the molten filament will have time to sag before solidifying.

- Too much material is being extruded at once: The filament should extrude at the same rate that the 3D printer moves. If too much filament comes out of the 3D printer, it will physically push the bridge downwards. This sometimes happens when a printer’s extrusion multiplier is too high.

Additionally, some materials work better than others when bridging. For example, PETG strings a lot due to its hygroscopy, which means it’s much more difficult to bridge well with PETG than with other filaments such as PLA. And for the best bridging (and all 3D printing) results, keep your filament dry.

Slicer Solutions

First, it’s important to note that different filaments will bridge differently. If you’re experiencing bridging troubles, it’s good to start by looking at your filament manufacturer’s recommended slicer settings. These manufacturers have tested this filament with all sorts of different settings and typically have recommendations for optimal printing. You can usually find these settings on the filament box or the manufacturer’s website.

Perhaps you’ve already tried these settings, and your 3D printer is still not exhibiting good bridging. If this is the case, it’s necessary to make changes to your slicer settings and experiment with the settings until the bridging improves. Below are some settings you can tinker with when optimizing your 3D printer to make perfect bridges. Be sure to save your previous slicer settings in case the bridging quality worsens.

If this is your first time adjusting your print settings, it might be a good idea to go to your slicer’s official website to find out how to make these changes on your particular slicing program.

Lower the Print Head Temperature

First, try lowering the print head temperature by several degrees. Bad bridges are often caused by the extruder being too hot, causing the filament to flow more quickly and fail to cool enough to prevent bowing. This is why you’ll often see bridging tests incorporated into 3D printer temperature towers.

To see if the temperature is causing bridging issues, try a test print that will create a bridge but lower the printing temperature by 5 °C. If this test print fails to bridge properly, try lowering the temperature by another 5 °C (as long as the temperature stays within the manufacturer’s recommendations). If the printer still isn’t bridging correctly, then there’s likely something else about the 3D printer that is causing poor bridging.

And don’t forget that different filaments have different optimal temperatures.

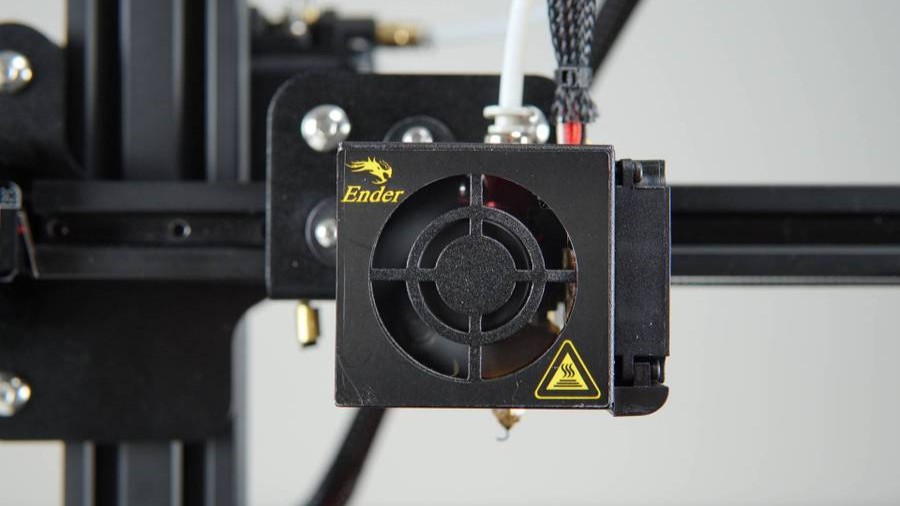

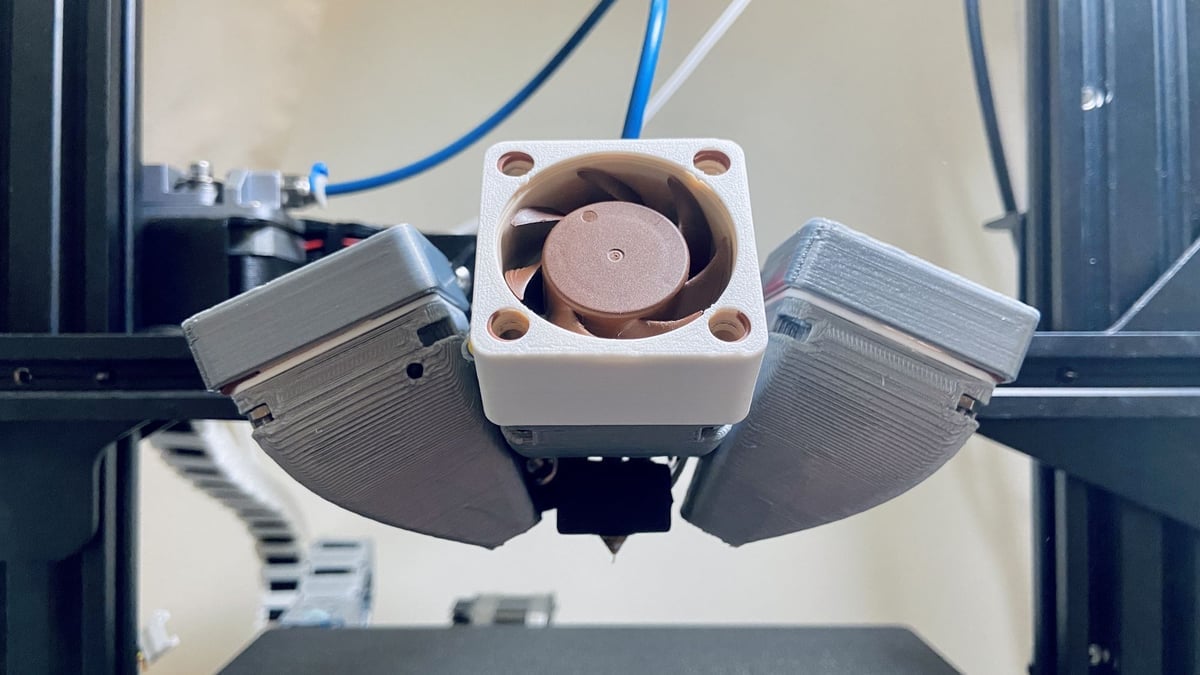

Increase Cooling Fan Rate

If the filament is still sagging at low temperatures or if you’d rather print at higher temperatures for smoother layer lines, it can be a good idea to increase the cooling fan rate of your 3D printer. This will increase the amount of air that the cooling fans blow onto the extruded filament, which will carry heat away from it more quickly. This process will help it to solidify faster, which reduces sagging.

If your 3D printer doesn’t have a dedicated part cooling fan, it might be a good idea to add one to your 3D printer.

Decrease the Extrusion Multiplier

If your prints are still sagging after reducing the extruder temperature and increasing the cooling rate, you could try decreasing the extrusion multiplier. The extrusion multiplier is a proportion that determines the rate at which filament is extruded. If this number is too high, globs of filament will occasionally be extruded.

When printing, this excess filament will push down on the bridge, potentially causing bridging failures. Lowering this number by a small amount (typically no more than 10% from the default extrusion multiplier) might solve your bridging woes.

Decrease Printing Speed

High print speed can also affect bridge quality. If your nozzle is moving too fast, the filament won’t have time to adhere to the previous layer or set in time to bridge a gap. In other words, high print speeds can result in huge messes.

Try decreasing your print speed in 10-mm/s increments until you see some improvement. Don’t go too slow, though. If your nozzle moves too slowly, the filament will be suspended in the air for too long and eventually droop. So, play around with some speeds, and you’re bound to find the perfect one.

Physical Solutions

Sometimes, especially when 3D printing, the solution isn’t in the software.

While a significant part of 3D printing is ensuring that the software is well tuned to the printer and its filament, there are many steps that makers should take to keep their filament and printer in good condition. Otherwise, no matter how finely tuned the slicer is, prints will still turn out more poorly than you would anticipate.

Buy High-Quality Filament

Purchasing high-quality filament with a tighter tolerance means less variation in the filament’s cross-sectional area. This results in more consistent extrusion, which reduces the chance that filament will be extruded unevenly and cause a bridge to sag.

There are many ways to approach 3D printer bridging and various ways to get good results. In addition to bridging, you can fix many other 3D printing quality issues with finely-tuned slicer settings.

Find out more about this free way to improve print quality with our guide on the best 3D printer settings for perfect prints.

Use Dry Filament

When bridging, your 3D printer filament must be in good condition. Many filaments will absorb water from ambient air, especially in more humid climates, creating pockets of moisture in the final print and leading to inconsistent extrusion.

Inconsistent extrusion causes bad bridging, so it’s important to either keep your filament dry when not in use or dry it using a filament dehydrator before using it for your prints.

Cheating: Add Supports

If a bridge is incredibly long and your printer has had trouble bridging in the past, you can consider using manually-added supports. These custom supports will break up one long bridge into several smaller bridges, providing additional foundation and making the bridging process easier for your 3D printer.

While it’s technically cheating as the aim of good bridging is meant to avoid supports, a few sparse selections can help you avoid failed prints or even more time spent on trying to improve a frail or stringy bridge.

License: The text of "3D Printing Bridging: 6 Tips for Perfect Bridges" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.