Anyone can now make and customize things more easily than ever before thanks to 3D printing. From laptop stands to instruments, and even a replica of yourself, accessible production is on the rise.

With all of these plastic parts being manufactured by enthusiasts, one could reasonably wonder, “What about records?” After all, they’re made of vinyl, therefore we should be able to create our own personalized albums out of various types of plastic, right?

In this article, we’ll take a look at what has been accomplished so far, as well as projects you can tackle today in the quest to 3D print just about anything, even a playable record.

If you like one of the projects featured here and your printer is in pieces on the workbench while it waits for an upgrade, check out Craftcloud. Upload your model of choice, select among the wide range of materials and finishes, and have the parts delivered to your doorstep, ready to be assembled.

The Challenge

While vinyl records are making a comeback, manufacturing them has always been outside the capabilities of hobbyists. Makers and audiophiles alike are now wondering if 3D printing is the answer.

The good news is that 3D printing technology can and has been used to print records! But we can’t start printing your favorite tunes just yet… There are a few things to consider and several pretty big challenges you’ll need to overcome before you can get a successful audio record spinning.

Recreating Vinyl

First, it’s called vinyl but in reality, the vinyl used in traditional records is polyvinyl chloride (PVC), a thermoplastic polymer. It’s a type of plastic that becomes pliable and moldable when heated, allowing it to be shaped into a record during the manufacturing process.

PVC is a popular choice for vinyl records due to its desirable properties such as durability, flexibility, and good sound quality when properly processed. Many filaments used in 3D printing are chosen for similar attributes but vary in composition such as PLA, PETG, TPU, and ABS.

Traditional vinyl records are produced through injection molding: Vinyl pellets are heated, injected into a mold, and pressed into the shape of a record.

On the other hand, fused deposition modeling (FDM) 3D printing involves layer-by-layer deposition of your chosen materials, usually from a roll of filament. The flexibility and durability of the PVC used in records is specifically suited for audio playback, whereas FDM filaments have a variety of qualities that can be employed for many types of applications (whether you’re opting for PLA, PETG, or ABS, for example).

Considerations

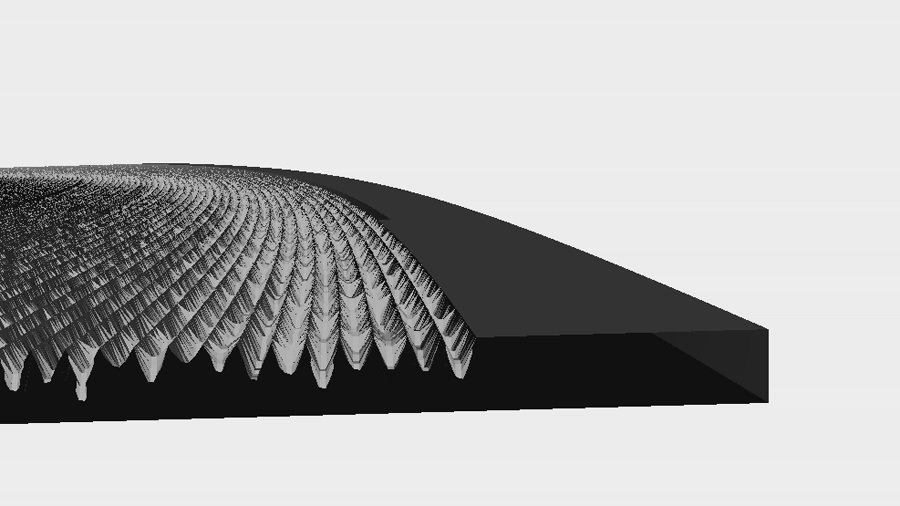

The intricate and fine grooves found on traditional vinyl records are crucial for faithful audio playback. Achieving this level of precision and maintaining such tight tolerances is challenging, especially for hobbyist FDM 3D printers. Your average Creality or Prusa printers have limitations in resolution and layer height, directly affecting the level of detail achievable in the grooves of the printed record.

Producing a record on a 3D printer with satisfactory audio playback quality is difficult (to put it mildly) due to the likely introduction of surface imperfections and layering artifacts during the printing process. These imperfections can disrupt the smoothness and consistency of the grooves, which leads to distortion in audio fidelity during playback resulting in subpar sound quality at best and unintelligible noise at worst.

Let’s say you’re ready to forge ahead, yet you then run into a host of other issues common to 3D printing – ones that may doom your record before it ever plays. Addressing these issues involves finding a delicate equilibrium between various factors.

The Right Material

The material question is a hurdle that cannot be underestimated. PLA may be easy to print but won’t hold up, while TPU may be flexible and durable but may not achieve the required detail. PETG or ABS may be strong and detailed enough, but without the required finish.

As we indicated before, records are vinyl for a reason. Unfortunately (or fortunately?), PVC isn’t a commonly used material in 3D printing due to its toxic emissions, high print temperature requirements, and corrosiveness. Frankly, there are safer material options for 3D printing.

The Right Print Settings & Adhesion

Balancing printing speed with layer height is crucial, as it impacts time and detail but can be challenging to optimize. Selecting the right material is also important, as it must strike a balance between durability, surface finish, and printability. Achieving a smooth surface on the 3D printed record, vital for playback quality, often requires meticulous post-processing techniques.

Additionally, ensuring proper adhesion to the print bed and minimizing the risk of warping during printing are common concerns that need to be carefully managed. These issues aren’t isolated to printing a record, to be sure. But some can be more of a challenge to overcome than others.

The Right Post-Processing

What post-processing technique will you use to ensure a clean record with good playback? Again, we run into a series of issues. For example, sanding and painting are poor approaches that can destroy playability.

Some may wish to attempt chemical or vapor smoothing. Only certain materials, however, can be chemically smoothed. More importantly, though, the smoothing process may improve the overall appearance of the 3D printed record but, at the same time, render it unplayable.

All in all, post-processing your record will be difficult if not impossible for most commonly used methods.

How to Create Your Own

But let’s say you manage to overcome all of the hurdles described above. What exactly would be the steps to create and print your own record?

Creating a suitable STL file for 3D printing a playable record involves converting audio data (in WAV format) into a format that represents the grooves on the record. The process typically uses a technique known as audio lithography. This is both straightforward and a bit difficult:

- First, you use RIP software to convert the audio WAV file into a high resolution image (like a PNG or TIFF). Each pixel’s brightness represents the amplitude of the audio waveform.

- Next, you have to convert the high resolution image to an STL file using specialized software that translates the image’s brightness levels into depth, creating a 3D representation of the audio waveform.

- Then, you modify parameters such as depth, width of the grooves, and overall design to suit the playback speed (e.g. 33 rpm or 45 rpm).

Sounds easy enough, right? Well, there are quite a few steps before you even get near a 3D printer: audio sampling, quantization and normalization of the audio, image creation, and finally converting the image to STL.

As you can see, the process of printing your own record is still quite a hurdle. A much more straightforward challenge for today’s vinyl enthusiasts would be printing a record player or related accessories. While by no means an easy task, both replacement parts and entire turntables are achievable on most consumer FDM printers.

Below, we’ll present you the brilliant work of some makers who decided to rise to the challenge and create their own 3D printed records as well as incredible turntables and accessories.

Records & Record Players

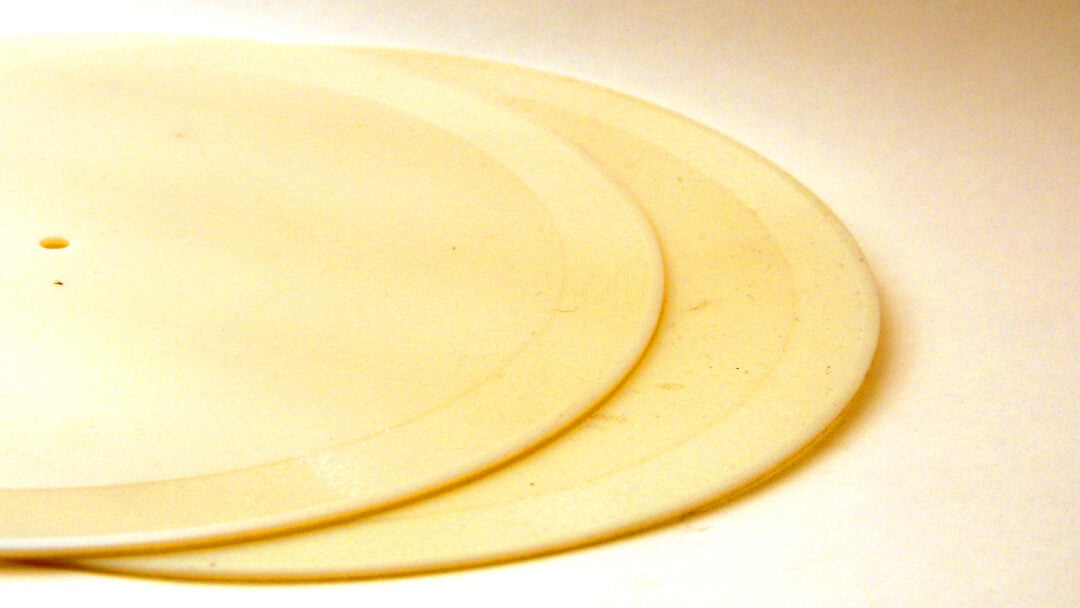

World's First 3D Printed Record

The world’s first 3D printed record was produced more than 10 years ago on an Objet Connex 500 resin 3D printer by Amanda Ghassaei. While successful, the resolution was far from high enough to reproduce the same quality of sound as a commercially produced vinyl record. This record played a song by Nirvana, which was digitized with a process that was developed to convert audio files into 3D record models. At the time, it took over 1 GB of storage to convert an MP3 song to a record like this!

This Instructables project hasn’t been updated in some time but gives a detailed look at the process, with several links now being broken. Nevertheless, if you follow the Instructables guidance, coupled with the information available on GitHub, you’ll find what might be a thorough enough guide to produce your own playable record if you can navigate around the dead links.

The designer has created a number of other works including a laser-cut record version as well. If you have time, you can also check out Amanda’s video.

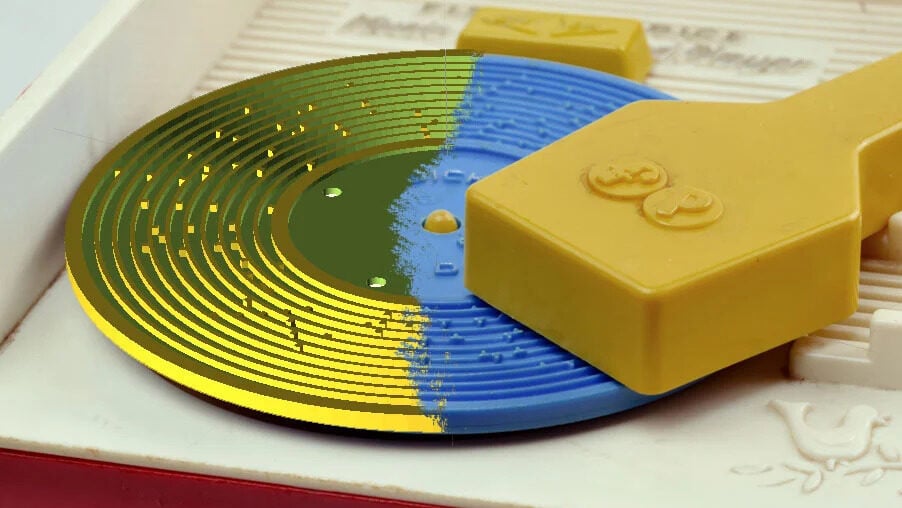

Custom Fisher-Price Disc

Maybe you want to print a record but take a bit of a simpler approach. This 3D printed custom disc for a 1970s-era Fisher-Price “record player” is an excellent project that we just had to include here. If you have one of these old toys at home and want to use the creator’s software to make your own custom disc, it’s pretty neat.

The maker of this project, Instructables user fred27, made a disc that plays the theme music from Star Wars and another that rocks Led Zeppelin’s “Stairway to Heaven”.

We think that being able to play your own custom tracks on something like this really showcases what 3D printing can do for old technology. Just imagine what other old stuff is lying around that we could print custom accessories and even songs for!

This project inspired a remake or two as well. Not into messing with audio files or OpensCAD? Then, simply download a finished design like one that plays Baby Shark or Charlie Puth’s One Call Away.

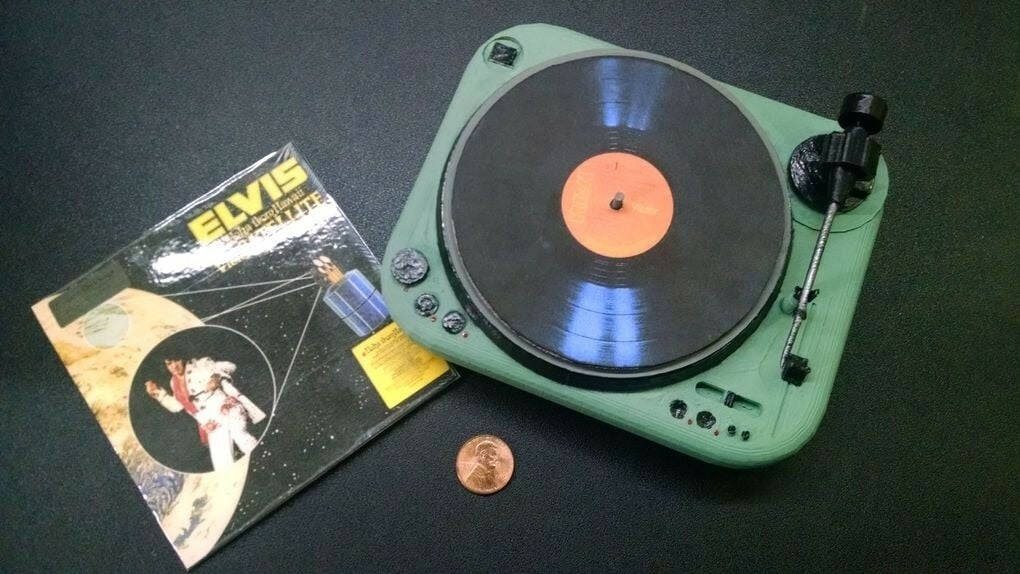

Record Player Turntable

Powered by an Arduino Uno, this fully functional record player turntable is made from 3D printed and 3D printer parts. By utilizing TMC2209 drivers, known for their advanced stepper motor control features, the build emphasizes precision and efficiency in the turntable’s operation.

This project is valuable for enthusiasts, DIYers, and hobbyists keen on understanding and creating a functional turntable or incorporating such components into their custom audio setups, aligning with the increasing interest in analog audio experiences.

The turntable is pretty accessible, as it’s printed out of ABS and TPU. The designer provides a complete parts list of everything needed. They even link to a GitHub for the Arduino source codes and a few additional details as well as YouTube videos of testing.

SongBird Mk3+

The SongBird may be familiar to some from their early Kickstarter days when Frame Theory 3D was selling entire kits. This version can be assembled with your own components and printed parts.

This version includes 3D printable files for all the necessary parts, allowing enthusiasts to 3D print and assemble their unique turntable. Doing so provides an exciting opportunity for makers and audiophiles to experiment with different materials, colors, and customizations, tailoring the turntable to their preferences while appreciating the vintage appeal of vinyl records.

While this can be a challenging build, the end result is an elegant-looking piece of working audio equipment. And there are comprehensive instructions under “Documents Attached” that offer all the necessary information to guide makers to success.

The remix world is also alive and well with this project, giving a few approaches to this idea.

Custom Design Vertical Turntable

This vertical turntable introduces an unconventional and visually striking approach to turntable design. Departing from the traditional horizontal layout, this project explores a vertical orientation for vinyl playback. The design allows records to be played while vertically mounted, providing a unique and space-efficient solution for vinyl enthusiasts.

To create this vertical turntable, the designer offers a detailed step-by-step guide, enabling users to construct the structure, mount the components, and set up the system. Users are encouraged to design and assemble the turntable according to their preferences, adding their own customization.

While the project requires basic woodworking skills and familiarity with electronic components like motors and microcontrollers, the provided instructions make the build process accessible for hobbyists and DIY enthusiasts.

Vinyl Record Cleaning Machine

After all that printing and record playing, you might need to tidy things up a bit.

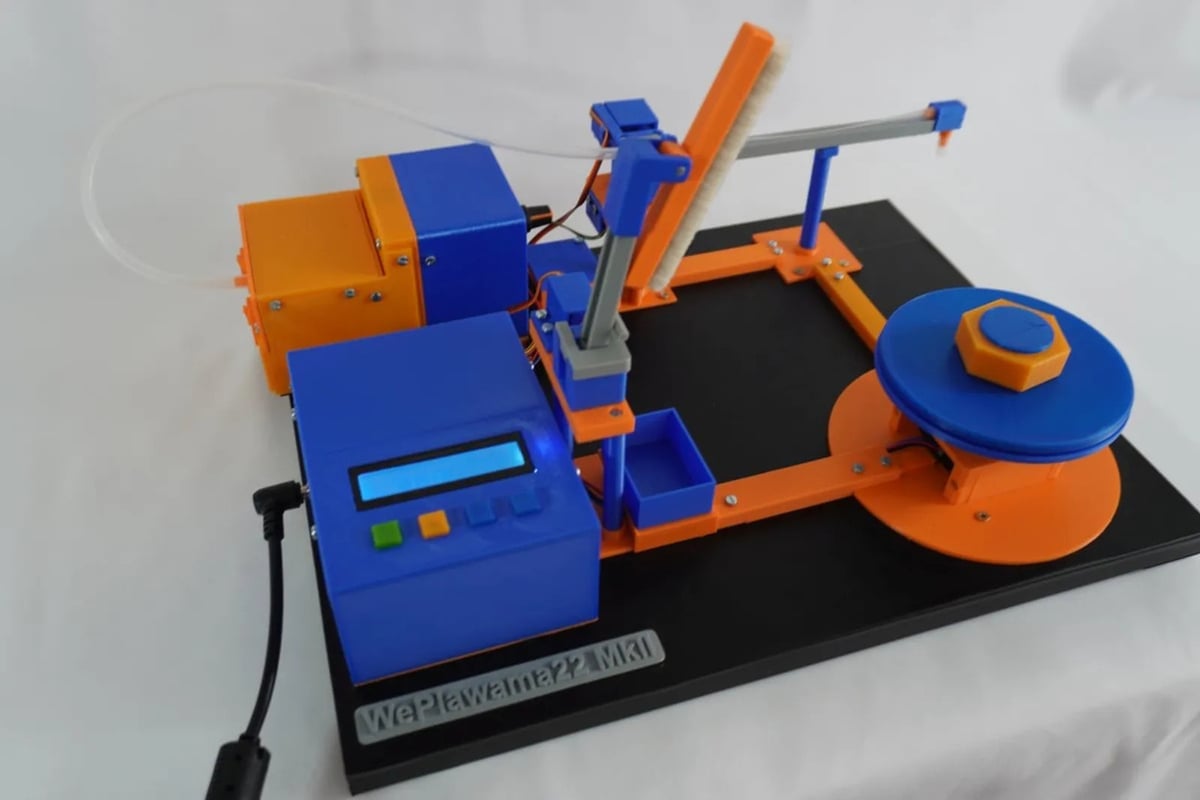

This project is a bonus addition to any 3D printed turntable setup, as it addresses an essential aspect of maintaining audio quality: record cleaning. This print showcases a purpose-built design with the goal of efficiently cleaning vinyl records, a critical step to enhance their longevity and sound quality.

To build this cleaning machine, the project provides the necessary 3D printable files and assembly instructions. With more than 80 printed parts and an extensive electronics parts list as well, this isn’t an undertaking for the faint at heart.

If you’ve printed your turntable or made an attempt at printing your own record, you likely won’t shy away from this in-depth build. Luckily, the designer has a great description of the process and links to parts, the code needed, and videos.

License: The text of "The Coolest 3D Printed Vinyl Records & Record Players" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.