Sweden has given us many great things – ABBA, Ikea, GPS, and even the zipper – but they’re all eclipsed by the marvelous 3D Benchy. Not only is it the most downloaded and most 3D printed item ever, but it’s still one of the most useful benchmarking tools out there and has inspired countless spin-offs and side projects.

This little tug boat was designed by Daniel Noree in 2015 as a model to test the consistency and accuracy of FDM 3D printers. Since then, it’s been downloaded well over 3 million times, and it even has its own website and Facebook fan group.

The model contains a number of difficult-to-print features including overhangs, smooth curved surfaces, numerous other holes and shapes, and very fine details – all at a scale that’s measurable and doesn’t take too long to print. As such, it’s a really useful test piece, but it also looks good when printed. Benchy’s quirky character has won over many ardent followers and secured its position as a 3D printing icon.

Let’s look more closely at why it’s so useful and why it’s become so enormously popular.

Default Settings

This little boat may look like a toy, but its design emerged after several careful, iterations. The brief was to come up with a recognizable design “including a variety of measurable geometric and organic shapes, to challenge the capabilities and reveal limitations of 3D printers”. A further requirement was that it take around an hour to print. The default slicer settings are as follows, but users are encouraged to test and try different resolutions and settings to see what difference they make:

- Scale: 1:1 (unmodified in size, the 3D Benchy measures 60 mm from bow to stern)

- Layer height: 0.2 mm

- Infill: 10%

- Print speed (extrusion): up to 50 mm/s

- Print speed (travel): up to 150 mm/s

- Print nozzle diameter: 0.4 mm

As we’ll see, these recommended settings have been stretched and pulled in every possible dimension by various projects, but they remain the established baseline used by the vast majority of benchmark prints.

The designer didn’t set out to create something that can test or calibrate every aspect of 3D printing, but Benchy does cover the majority of immediately useful points for optimizing print performance. The 3DBenchy.com website has a very useful PDF file setting out the detailed design features it incorporates.

But how, exactly, do we use this and a newly printed tugboat to troubleshoot issues and identify areas for improvement? Good sailors inspect their vessels systematically to check for any issues and problems, and it’s good to do the same with the 3D Benchy.

Check the Overall Print Quality

Our first check is for general quality and obvious printing issues. Your print should look like a boat!

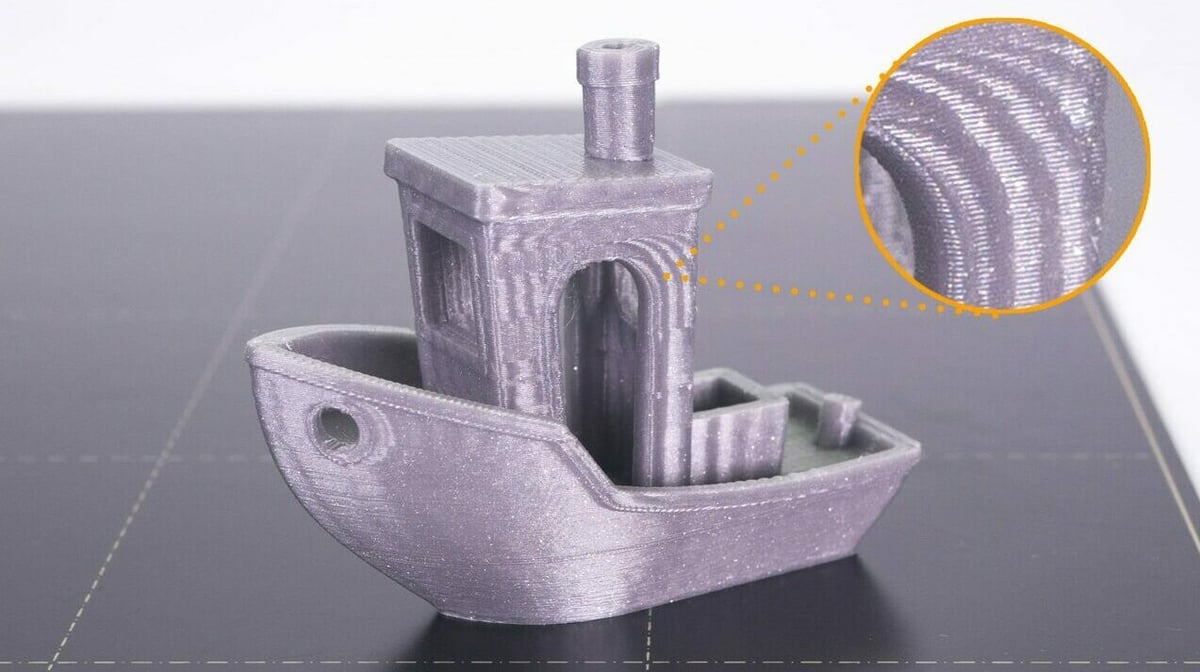

Don’t expect absolute perfection, for example (as seen above) the cabin roof will show clear steps where layer changes occur. (Many images of Benchys on the internet are not real photos but renders of the underlying 3D model. If they have a flat cabin roof, that’s a giveaway!)

- Stringing: If there are thin, hair-like strands of filament between details, such as the deckhouse door and windows, this may indicate nozzle temperature or retraction issues. It can also be associated with partial clogging and is very material-dependent. There are several easy ways to tackle this issue.

- Uneven or shifted layers: Unevenness in layers often points to mechanical issues. If layers are slightly shifted out of line horizontally, the cause is likely to be related to belts and pulleys, and these should be adjusted for smooth and even running. For larger shifts, check that the cooling fans aren’t too close to the print. We’ve produced a simple guide on how to track down and deal with issues such as these. For vertically uneven layers (i.e. some fat, some thin) the underlying issues may be due to stepper motor couplings or issues with the Z-axis rods, depending on the type of printer. On printers with direct extruders, minor layer differences can also be caused by filament being fed directly from above – feeding from the side can sometimes help.

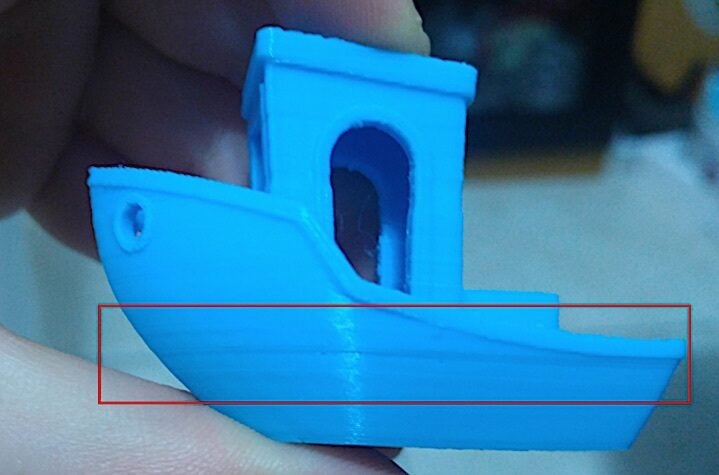

Inspect the Hull

The hull should be evenly round and smooth, and the layer lines shouldn’t be too prominent. Note that even for the same printer and settings, this varies quite a bit with the material and even its color.

- Excessive blobs or dots or extra filament: This could indicate over-extrusion due to too high a flow rate. Calibrating the extruder might help in this case. Slight imperfections, either randomly distributed or in a line, may also be due to Z-seam artifacts.

- Prominent thinning of layer lines: Consistent thinning of lines or uneven gaps along the length of lines points to under-extrusion. There are several potential causes of this, and they need to be systematically worked through to find the underlying cause. It may be due to an incorrect filament temperature, a partial block, slipping of the extruder (or PTFE tube if used), or other issues. Start with our article on simple steps to fix under-extrusion to identify and remedy any problems.

- Repeated patterns: If the hull shows repeating patterns of subtle, wavy lines or “fish scales”, this is likely due to a loose component in the frame, extruder, or drive belt. Typically, such issues get worse with increasing print speed. Collectively, these issues are known as ringing and ghosting. There are some quick fixes that you can try, but for high-speed printing, you may need to consider advanced solutions such as input shaping.

Examine the Underside

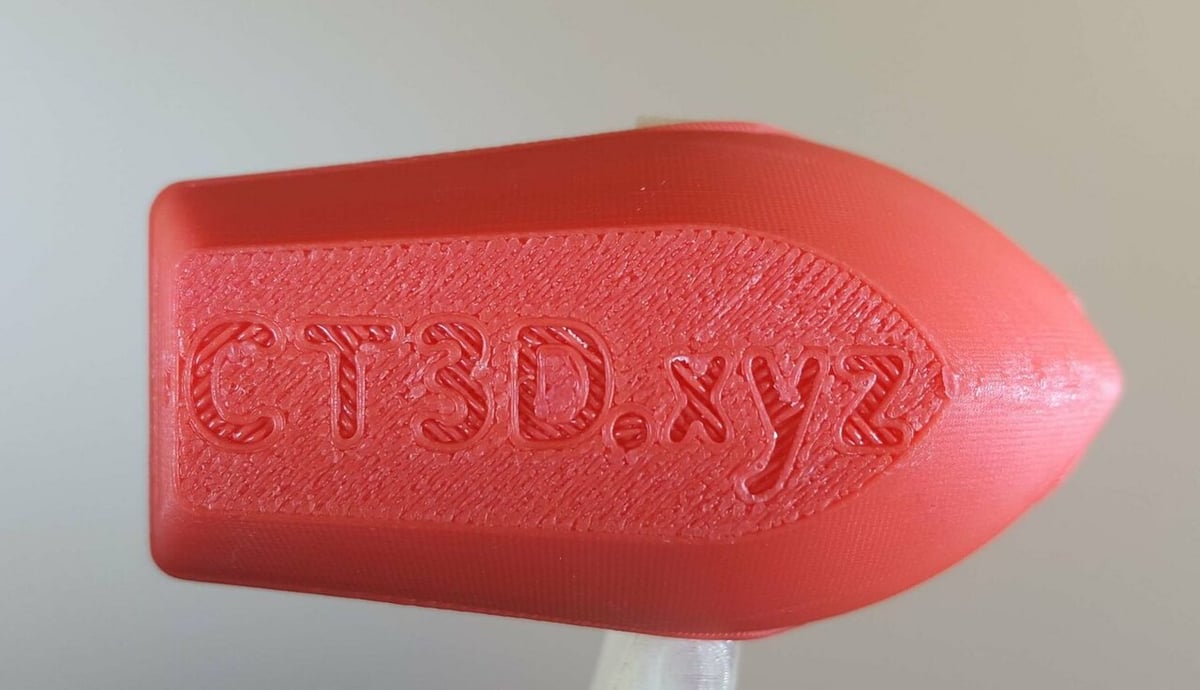

This is a great test of the quality of your first layer. The letters “CT3D.xyz” should be clearly embossed, and the rest of the underside should be smooth (or reflect the surface texture of the printer’s build plate).

- Extrusion lines clearly visible: If lines are very visible, especially if there are gaps between them, it can point to the nozzle being too far from the bed, too low a print temperature, or slicer settings with insufficient (first layer) width. These effects vary by material. Check out our guide on getting a perfect first layer if you experience any of these issues.

- Thin, ill-defined letters: This is the opposite of the points above and can point to the nozzle being too close to the bed, the initial line width being too large, or bed or nozzle temperatures being too high.

- Elephant’s foot: A first layer that’s larger than the one above it or that has a sharp rim around the base can be a sign of elephant’s foot, which is caused by too high a bed or nozzle temperature. If present around only part of the Benchy, it can also point to bed-level issues.

Check the Deck House & Deck Details

Next, look for how your printer handles detail, overhangs, bridging, and other fine features such as the writing on the back of the Benchy.

Look first at the top of the deck-house windows. The front (square) window should be straight and flat and the side windows should be cleanly arched.

- Top of deckhouse windows are drooping: This points to inadequate part cooling or printing too fast and too hot. Take a look at our article on tips and tricks for perfect bridges to identify ways the improve this part of your printer’s performance.

- Corners of deckhouse are rounded or bulge outwards: If all else is good with the print, this can usually be fixed simply by slowing printing speed. However, if this isn’t an option, there are firmware changes that can be made to improve corner accuracy. Depending on your firmware, look for how to set linear or pressure advance or how to adjust acceleration and jerk settings.

Next, look at the chimney. It shows how your printer handles the fast laying down of detailed layers.

- Chimney is not round: This can be hard to measure, especially if the filament hasn’t been laid down cleanly. However, if the hole at the top is distinctly oval, it points to dimensional issues. See the section below on this topic.

- Chimney is vertically uneven or lower quality than other parts: As the uppermost part of the model, each layer of the chimney is added to the one below almost immediately. This emphasizes issues with part cooling or printing too fast that might not be apparent elsewhere and can lead to “slouched” or compressed features.

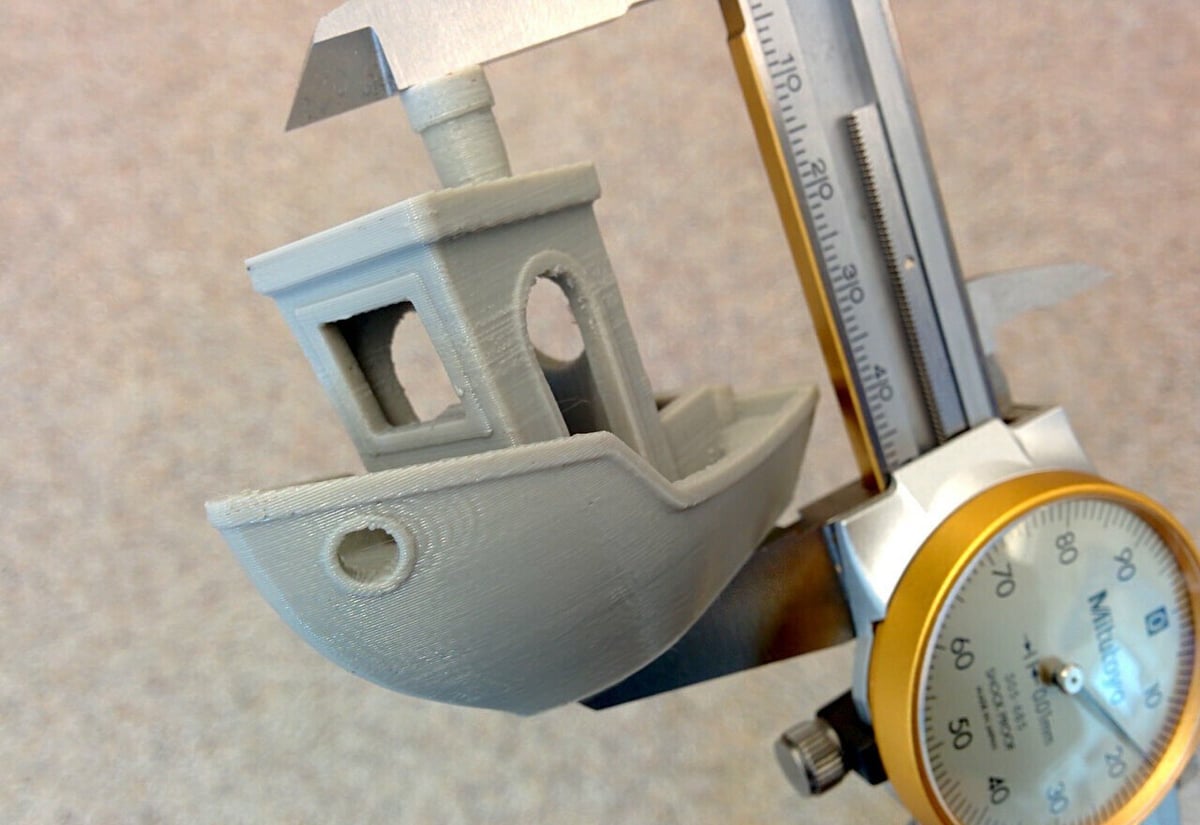

Measure & Calibrate

The 3D Benchy should be printed to the precise size it was designed. It’s quite hard to measure this with a ruler or tape, so a caliper is really required. Detailed dimensions can be found in the “measure and calibrate” chart.

- Bow-to-stern dimension isn’t 60 mm, or beam-to-beam width isn’t 31 mm: Depending on the orientation used to print the Benchy, this indicates that the Y- or X-axis calibration is out. If only one is out of calibration, the holes chimney and flag post will appear oval rather than round. There may be several reasons for issues with dimensional accuracy. However, if you’ve got this far with no other issues, it’s likely that the steps per unit (typically a “last-resort” fix) may need attention.

- Base to tip of chimney isn’t 48 mm: This is a little more tricky. If the difference is slight, the first thing to rule out is first-layer issues or poor printing of the chimney. Otherwise, follow the guidance suggested for the XY-axes case above.

Old Sailors' Tales

Our story doesn’t end there. Like old sea tales, the 3D Benchy has its own myths.

Many report that the original 3D Benchy STL files caused some slicers to report errors. Today, 3DBenchy.com claims that the STL file topology is “100% water-tight and contains no mesh errors such as manifold areas, flipped normals, holes, etc.”, however, several STL repair tools still report “degenerate faces” and make changes to the STL file. These are negligible and make no obvious difference to the resulting benchmark. Now, there’s also a 3MF version of the design available, which is smaller and free from any potential design confusion.

More interesting are the mysterious “hull lines” that can appear. These faint horizontal lines typically only show when the print quality is otherwise already quite good and have been the topic of debate for years. This Prusa article gives an excellent explanation for this strange phenomenon and what (if anything) can be done about it. This also highlights that apparently subtle changes to slicer settings can make notable differences to the final print in unexpected ways, so it’s worth experimenting and testing.

Final Thoughts

We noted above that the 3D Benchy was designed to take just over an hour to print on a typical FDM printer. But just how quickly can an acceptable Benchy actually be made? One hour, 30 minutes, 10 minutes? The 3D Benchy #Speedboatrace challenge has inspired enthusiastic 3D printers across the world to push the envelope of current printer technology and print Benchys at very high speed. This is the ultimate benchmark test and highlights what drives print quality in a striking way. Sub 5 mins anyone?

Of course, you could also change the “proper” dimensions and print very small or large. In 2020, physicists at Leiden University in the Netherlands created a 3DBenchy around 40 μm long (1/10th the size of a human hair) using the group’s Nanoscribe Photonic printer. At the other end of the scale are versions nearly 200 times larger! Each brings its own technical challenges and its own nuanced analysis of the finished Benchy.

Even if speed isn’t your thing, you may still find that you accumulate many (sometimes hundreds) of Benchys very quickly. These can serve as a very useful point of reference for different materials, slicer settings, and even gauging the impact of printer aging. There are many designs for 3D Benchy holders to keep these organized – such as this practical one designed by MasterNBC as well as other fun and artistic designs, too.

It’s often said that “imitation is the sincerest form of flattery”, in which case the 3D Benchy should feel very flattered. A quick search of STL sharing sites will reveal dozens of Benchy-inspired designs. None of them improve on its use as a benchmark tool, but many are good fun!

License: The text of "Troubleshooting Your 3D Printer with a Benchy" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.