What Is It?

Acrylonitrile butadiene styrene (ABS) is a very common 3D printing material. One of the first thermoplastics ever adopted in extrusion printing, it has good mechanical performance, resistance to high temperature, and is reasonably priced. Given that the vast majority of filament manufacturers produce this material, it is available in a wide variety of formats and colors.

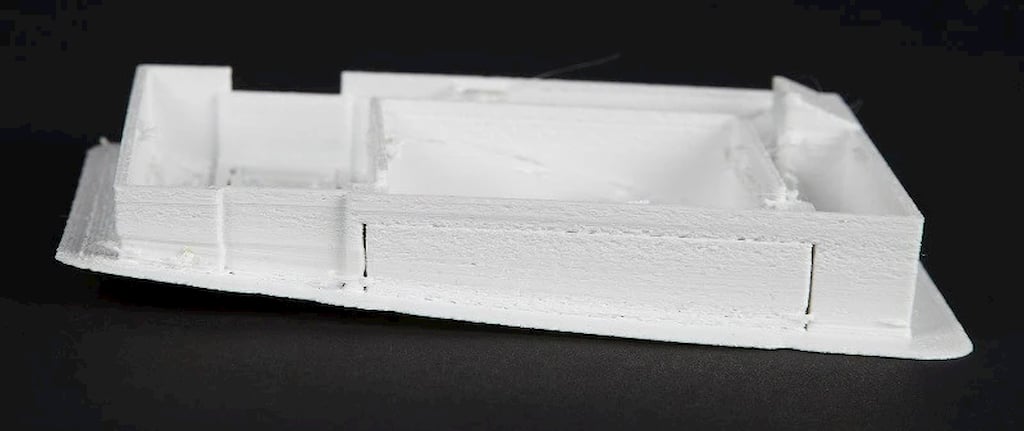

While the polymer has its pros, it definitely has a series of cons. One of the first challenges that a new user will face trying to print ABS is related to its tendency to shrink while cooling. This shrinkage frequently causes warping of the base of the print, with localized detachment from the bed.

While there are several things that you can do to prevent warping, such as building an enclosure around an open printer, some users may prefer a more forgiving and easier-to-work-with filament.

One option is switching to a different material altogether, such as PETG. However, if one requires certain features typical of ABS, the change may not be possible. Enter ABS+.

ABS+, or ABS Plus, aims to reduce the sensitivity to shrinkage and warping of ABS, while preserving most of its performance advantages. In this article, we’ll explore if this is actually true, what options are available on the market, and if it’s worth it to invest in this “upgraded” version of ABS.

One Goal, Different Names

Just like PLA+, ABS+ is merely a commercial designation that doesn’t offer further indications on the material composition. Here, we’ll use the term of ABS+ as a general identifier for all of the “low-warp” ABS filaments available in the market. We’ll see, however, that several manufacturers offer similar performance under different commercial names.

For Hobbyists

ABS+ is a name usually associated with the brand eSun, but several other companies have it on offer as well. A few other options include:

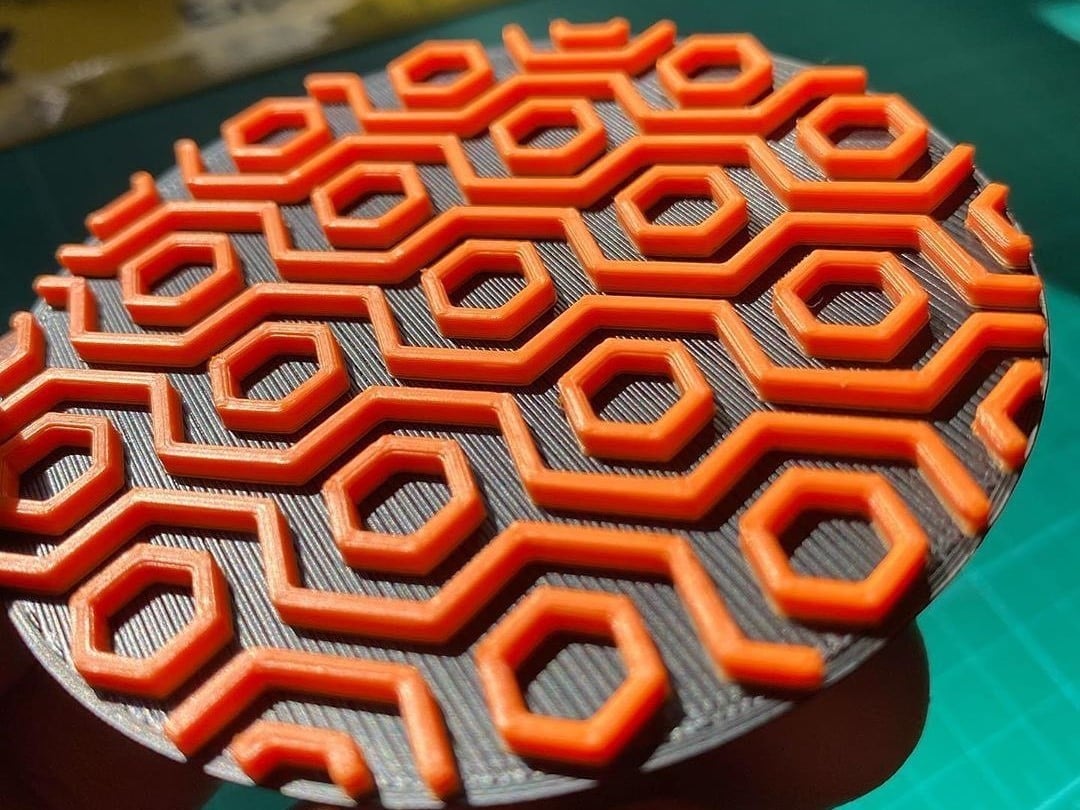

- Trideus’ ICE filaments ABS+ has fun colors like gold, silver, and orange.

- Fiberology’s ABS Plus has “increased hardness, less warping, and [is] printable with open build space.”

- 3D Prima’s PrimaSelect ABS+ has similar claims on ease of use.

While it’s not technically called ABS+, there are a few other notable ABS variants that could be classified as having plus-like qualities:

- Gizmo Dorks’s low-odor ABS claims to maintain the strength of ABS but not emit toxic fumes when printing.

- 3D Fuel’s Workday ABS is promoted as the “easiest ABS filament to print with.”

- BASF’s Ultrafuse ABS Fusion+ is part of BASF’s Ultrafuse line of filaments and is marketed as an “easy-to-print engineering material.”

For Professionals

Stratasys has in its product line an optimized ABS called ABSplus. The filament is specifically designed for industrial production and printing with equipment such as the F123 Series. Despite the familiar name, it is fair to assume that the concerns of hobbyist makers are not driving the ABS optimization here.

Is It Really ABS?

While ABS comes from a well-known basic chemical formula, filament manufacturers don’t offer us much information on what makes their filaments “Plus”. Some brands claim reduced odor and toxic fumes, which may be related to a lower percentage of styrene.

As an example, eSun’s ABS+ is significantly less soluble in acetone than regular ABS. Such behaviors, while potentially positive for the user, raise doubt on how much actual ABS is actually left in the composition. At the same time, as long as the performance of the printed object meets your requirements, it should be fine.

Some companies, such as BASF, are transparent in the composition of their ABS+ filaments, offering information on the material properties and safety. In the case of the Ultrafuse ABS Fusion+, it’s actually called acetonitrile butadiene styrene, instead of acrylonitrile butadiene styrene.

For manufactures who don’t publish technical data, the presence of unknown additives may raise concerns about safety or the long-term life of the part.

Print the Difference

Now that we know about the spectrum of what ABS+ can include, let’s take a closer look at the differences between ABS and ABS+.

Print Settings

The nozzle temperature for ABS+ is generally within the range of standard ABS. Most manufacturers suggest 240° C to 260° C, with the exception of eSun, where the lower range starts at 220° C.

While the warping is reduced, a heated bed is still definitely required, with temperatures generally ranging from 90° C to 120° C, depending on the manufacturer. Again, the values are in line with ABS, although leaning towards the higher end of the temperature range.

Printing Performance

This is the main reason that ABS+ exists: Users wanting to see the difference in their prints and move away from troublesome warped ABS prints to easier, better results. While some attention to limiting drafts around the printer may still be required, the consensus is that ABS+ is indeed an improvement in print quality. In fact, some say that the filament is much closer to PLA than to ABS, due to its limited shrinkage.

Bed adhesion may be achieved with the same surfaces that work for ABS. 3D Prima suggests BuildTak or a glass plate coated with adhesive spray or glue stick, however, BASF claims that their Ultrafuse ABS Fusion+ can be printed on plain glass.

Mechanical Properties

Most manufacturers imply that the improvements during printing don’t negatively impact the actual mechanical performance of the material.

At the same time, BASF’s technical datasheets on their filaments show there is a difference between their ABS and the ABS Fusion+. The modified material isn’t as strong as the original nor as rigid, however, its increased flexibility makes it more impact resistant.

Those wanting to post-process their prints with acetone for a smooth surface should verify if the filament supports this. The eSun ABS+, for example, has limited solubility in acetone.

Safety

Respiratory safety is an important consideration whenever working with any filament. It becomes more relevant with ABS and derivatives, however, due to their noxious fumes. The fact that ABS+ may print well without an enclosure doesn’t mean that a printer with an enclosure wouldn’t be a good idea.

When printing with these filaments, a well-ventilated environment is required to minimize the presence of toxic fumes. You may also consider a DIY air purifier or a purchased one in the printer’s vicinity.

Pricing

The pricing of these filaments varies considerably among manufacturers. Plain ABS is generally one of the cheapest types of filaments due to its wide availability, so you can expect to pay a bit of a premium for the optimized formulations.

eSun’s ABS+ can be bought at a price similar to their PETG, while European brands tend to cost more.

Color Options

Manufacturers targeting the hobbyist market, such as eSun and Trideus, offer a wide variety of vibrant color choices. Others, possibly focused more on the prosumer or professional market, limit the availability to few neutral options such as black, white, and beige.

Compared to Other Materials

ASA

A close relative to ABS, acrylonitrile styrene acrylate (ASA) has similar mechanical and thermal performance with improved resistance to UV rays, making it more suitable for outdoor use. While not an easy-to-print filament, it’s still less troublesome than ABS, making a warp-free result more achievable.

ASA, however, still carries the safety concerns of ABS and usually has a higher price tag.

PETG

PETG can be a great alternative to ABS or ABS+ when the user is looking for certain mechanical properties. Indeed, as explained in our article comparing PETG to ABS, PETG is safer and easier to print. At the same time, PETG loses to ABS+ when it comes to resistance to high temperature. So, if your print won’t be exposed to high temperatures, it may indeed be a better option.

PLA

Arguably the most common 3D printing material, PLA is available in an endless variety of flavors. What it lacks in terms of impact and temperature resistance it makes up for in printing beautifully with the highest detail resolution. Moreover, it’s safer to print than styrene-based polymers.

If the parts to be printed with ABS+ don’t require specific mechanical or thermal properties, PLA or PLA+ may be considered instead.

Final Thoughts

If what you’re looking for are certain properties of ABS, like functional parts that may be subject to heat, ABS+ can be a good option. It will perform as the parent material, or reasonably close, while improving the printing experience. The higher cost of the filament will be quickly balanced by time and scrap material saved thanks to the reduced warping issues.

Just remember that ABS+ filaments require the same cautions of ABS, therefore, whenever possible, less harmful alternatives should be considered first.

Lead image source: Zortax

License: The text of "ABS+/Plus Filament: What Is It & Is It Worth It?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.