This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

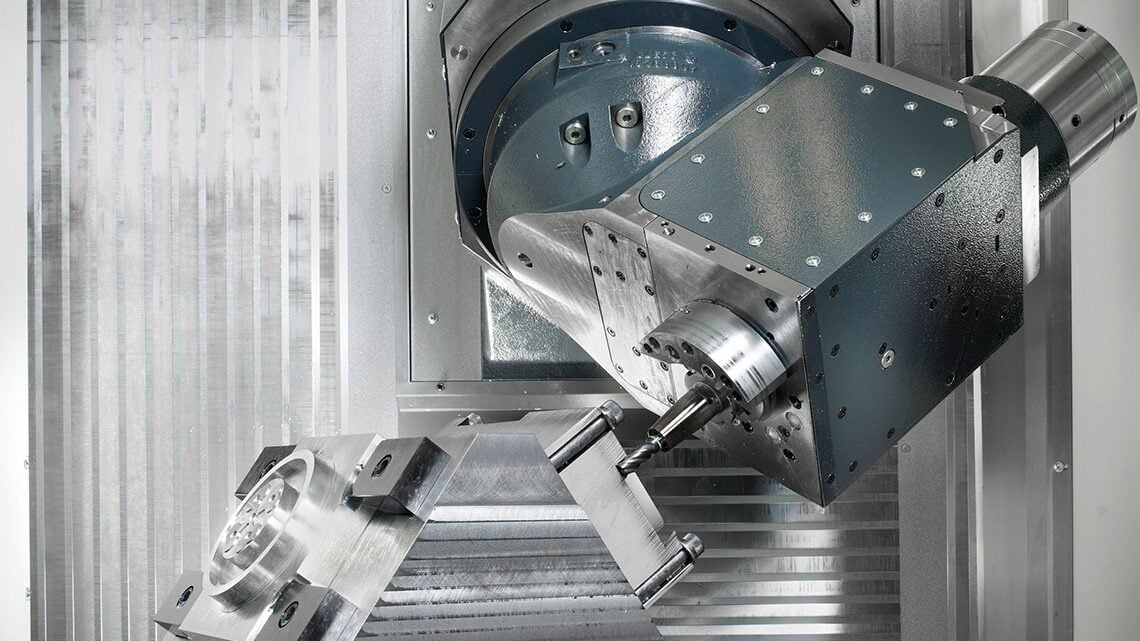

CNC + Rotation = Epic

5-Axis CNC Machine: All You Need to Know

Garage-dwelling makers are familiar with CNC routers. Read on to learn how desktop mills pale in comparison to 5-axis CNC mills!

Advertisement

Advertisement