3D printing is often used is for “rapid prototyping”. The slight irony here is that individual prints can take hours or even days to complete! Fortunately, you can adjust printing speed to reduce production time. However, poor or incorrect adjustments may also lead to print imperfections and failures.

In this article, we’ll run you through the common 3D printer speed settings for PLA and other common materials. By the end of this guide, you’ll know how to strike the perfect balance between printing speed and quality. So, fire up your slicing software, and let’s get started!

The Ideal Speed

As with most print settings, there’s no one ideal speed setting for all. Print speed is heavily impacted by the actual construction of your 3D printer, its extruder, your filament, and the size of the nozzle you’re using. Of course, slicer settings play a role, too. What may come as a surprise is the fact that even different brands and colors of PLA may require tweaks to print speed because the additives affect the material properties of the base material.

For all of the above reasons, it’s best do a series of tests to determine the ideal speed for your specific machine and the specific brand of filament you’ll be using. The filament manufacturers’ recommended settings are a good starting point, but many find that they need to tweak these recommendations to achieve better quality prints.

In the following sections, we’ll walk you through a few different test prints and slicer settings that’ll help you achieve the ideal speed for your 3D prints.

Print Speed

Print speed is the main speed setting that will influence your 3D prints. As the name suggests, print speed determines how fast the motors of your printer move. This includes the motors controlling the X- and Y-axes, as well as the extruder motor.

To test for print speed, download a print speed test model. These models generally come with instructions on how to set the correct settings. The model linked here will essentially print the same shape at gradually increasing speeds, allowing you to visually identify the optimal setting.

Too slow of a print speed may cause print deformation due to the nozzle sitting on the plastic for too long. Too fast and there may be other overheating artifacts caused by insufficient cooling, as well as ringing, under-extrusion, and weak layer adhesion. The sweet spot should be as fast as your printer can get without sacrificing too much print quality – and some use cases might demand a higher level of quality than others.

To better refine print speed, this setting is commonly split into additional secondary settings:

- Outer wall/shell speed sets how fast the outermost perimeter of the model is printed. It’s typically decreased slightly to improve surface quality.

- Inner wall/shell speed determines how fast the inner perimeters of the model are printed. It’s typically the same as the overall print speed.

- Infill speed defines how fast the infill of the model is printed. It’s typically the same as the overall print speed.

- Top/bottom speed adjusts how fast the top and bottom surfaces of the model are printed. It’s typically decreased slightly to improve surface quality.

Material-Specific Settings

As already mentioned, specific print speeds depend on your printer, as well as the material you’re using. The ideal speed for your needs has to be found by trial and error. However, there are some general print speed ranges for PLA and other popular materials used in 3D printing that you can use as general guidelines.

PLA is the most popular material, mostly due to its ease of printing. Besides standard PLA, there are some PLA variations that can be obtained by simply inserting additives, such as PLA+, or by creating a new composite filament, such as wood PLA. These modifications in PLA microstructure imply an update in mechanical properties: PLA+ increases layer-to-layer adhesion, compared to PLA, while the same feature decreases in wood PLA. Of course, these modifications may lead to differences in the ideal speed settings.

Additionally, it’s important to be aware of your print’s intended purpose. The settings below consider optimal quality-to-time printing. Even so, print speed tends to affect the strength of your object because, at a higher speed, the nozzle won’t have time to extrude the right amount of material in order to ensure proper deposition and adhesion. Research has shown that above 80 mm/s, the strength of the printed parts in standard PLA starts to decrease.

As for PETG and ABS, these materials have a higher strength and stiffness than PLA, especially ABS. The main issue with ABS is its weak layer adhesion. It requires a slower print speed to ensure proper layer adhesion and that each layer has time to cool. It’s recommended to start with a 20 mm/s speed for the initial layers to ensure ABS adheres well to the build plate, then gradually increase this value for the following layers to a speed between 50 and 60 mm/s. PETG is rather sensitive to speed, so you may need to do some tests to find the sweet spot. You’ll want to start with a slower print speed, such as 15 mm/s, and gradually increase.

Another material we’ll touch on is TPU. The flexibility of this filament can make printing a challenge. High print speeds are not recommended for various reasons, as they increase the possibility of jams and misprints. At slower speeds, the material can be properly molded in the printhead path.

Print Speeds

- PLA: 40-60 mm/s

- PETG: 20-40 mm/s, 60 mm/s maximum

- ABS: 50-60 mm/s

- TPU: 20-35 mm/s

Travel Speed

Travel speed adjusts how fast the printer’s printhead moves when not extruding filament. Increasing travel speed can save significant amounts of print time, but increasing it too much may lead to ringing or ghosting artifacts or even layer shifting (and thus print failure). Travel speed can impact print time and warping. Warping is most likely to occur with ABS if the travel speed is too high.

To determine the optimal travel speed for your printer, do a test print at various travel speeds, starting at 100 mm/s and adjusting by 5-mm/s increments. Keep bumping up the speed if the surface quality is acceptable, and decrease if print quality suffers. Look out for defects like misaligned layers, as pictured above.

For PLA, you can go for a higher travel speed, due to its quick solidification. PETG tends to drip out of the nozzle, so it’s best to increase the travel speed while taking into account that higher speeds may also increase stringing. A similar kind of balance has to be made with TPU. Due to its flexible nature, the more subtle the movement is, the more the material will react, oscillating like an elastic coil, and increase the probability of stringing. Therefore, it’s best to start with a slower travel speed for TPU.

Travel Speeds

- PLA: 120-180 mm/s

- PETG: 120 mm/s

- ABS: 100-150 mm/s

- TPU: 30-90 mm/s

Retraction Speed

Retraction speed adjusts how fast the printer pulls filament back before travel moves. This setting is critical for reducing stringing and improving print quality. Too slow, and you may be left with unsightly strings and blobs on your prints. Too fast, and you may experience the symptoms of filament grinding, which also include stringing and blobbing.

Just like with travel speed, you’ll want to strike a balance with this setting for TPU and PETG. As TPU is elastic, rapid retraction can cause clogging and jamming in the nozzle, plus stringing and blobbing on the printed object. A similar result can occur with PETG. For PLA and ABS, higher retraction speeds may be more effective.

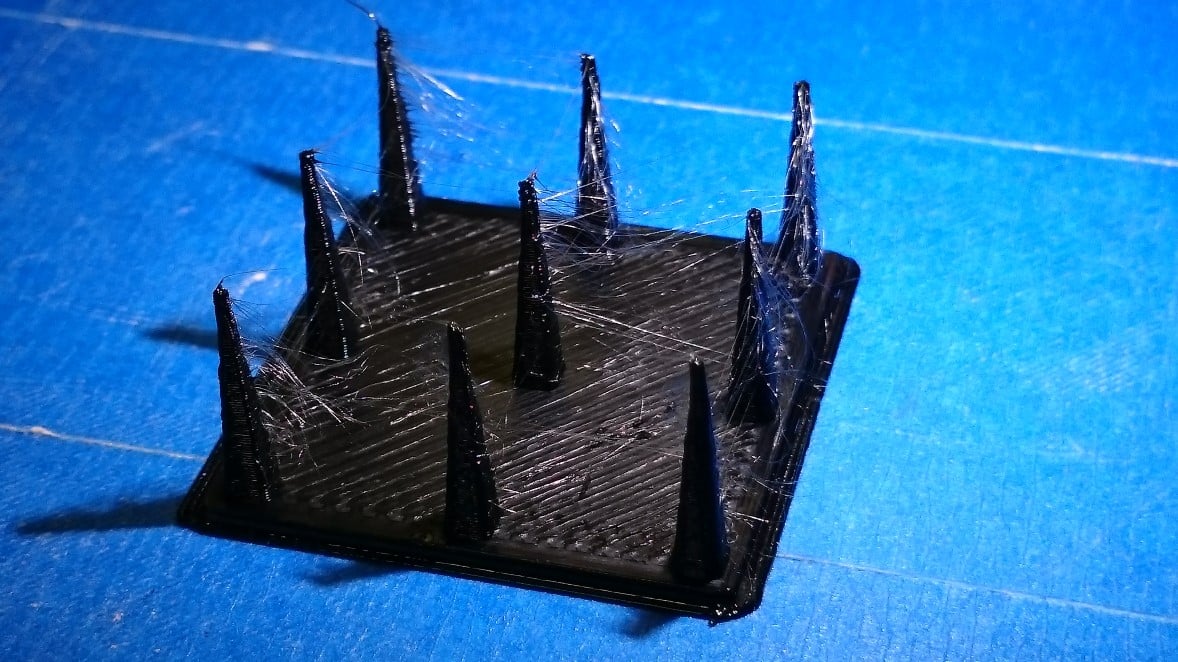

To determine the optimal retraction speed for your printer, print out a retraction test at various retraction speeds, starting at 25 mm/s and adjusting by 5-mm/s increments. Look out for web or tree-like strings stretching between the spikes on the model. The perfect retraction speed should be the highest value that minimizes these artifacts without jeopardizing filament flow.

Along with retraction speed, it’s also necessary to indicate the retraction distance in the slicer software, which is in a range of 1 to 5 mm for most materials.

To better refine retraction speed, this setting is commonly split into two more secondary settings:

- Retract speed defines how fast the retract (the actual pulling back of the filament) occurs. This is usually the same as your overall retraction speed, and tuning it follows the same process.

- Prime speed sets how fast the filament is reinserted after the initial retraction, in preparation for further printing. Increasing this speed will result in reduced print times and less blobbing from exposing the plastic to heat for too long. Increasing it too much, however, may also result in insufficient heating of the freshly-reinserted filament before printing resumes. For most users, keeping this the same as the general retraction speed setting should work well.

Retraction Speeds

- PLA: 40-60 mm/s

- PETG: 25-45 mm/s

- ABS: 40-60 mm/s

- TPU: 15-30 mm/s

Additional Settings

Your 3D printer’s speed isn’t determined only by “speed” specifically. It’s also significantly affected by how much plastic, and in what thickness, each layer of the 3D print is extruded. These settings are incredibly detailed, so we’ll only go through general information about how each affects print speed. For more, we have specific guides to 3D printing shells, infill, and layer height.

- Shells sets how many perimeters of plastic are extruded to form the outline of your part. Increasing the shell count increases part strength, but also print times.

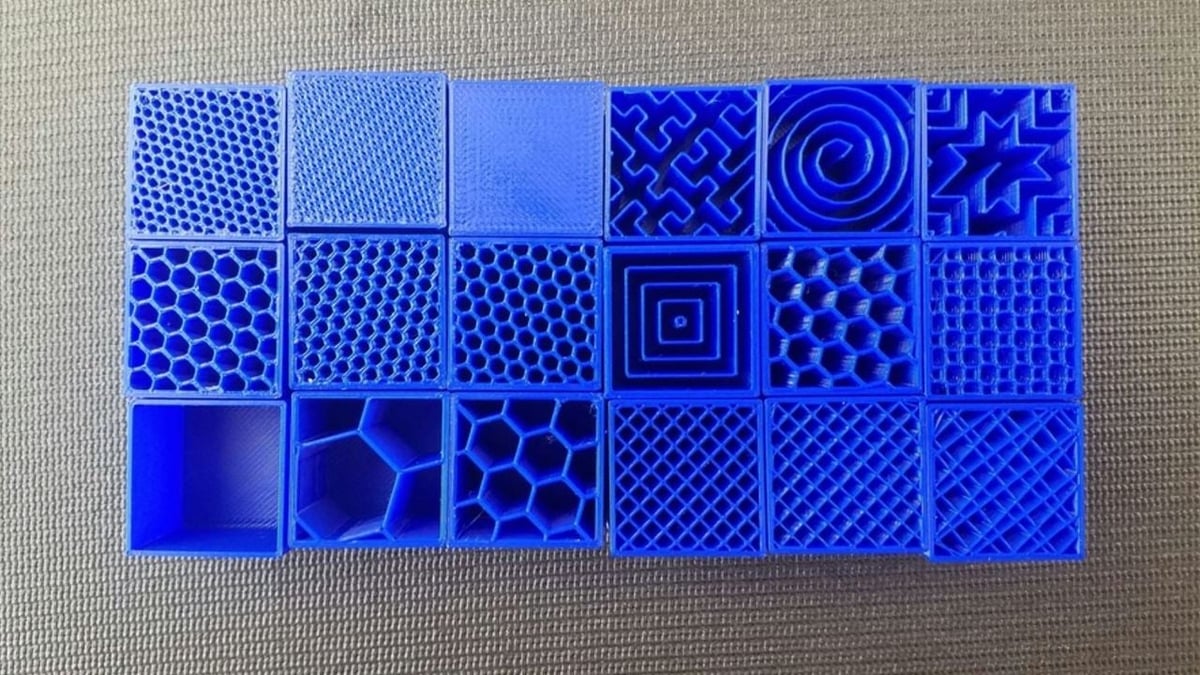

- Infill is the internal structure generated when printing the interior of 3D prints. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. A higher infill density will increase part strength but also print time.

- Layer height has a significant impact on how fast your prints come out. The greater your layer height, the thicker each layer of your 3D print is, and thus, the quicker your print is completed. Adjust this based on how much fine detail your print requires.

For an example of the speeds that can be achieved with settings such as those described above, check out this video from the YouTuber Chep who was able to print 2.5 times faster with a modified Cura profile.

Temperature

Another important consideration is how hot you’re printing. While it won’t impact the speed per se, a hot end temperature insufficient for the speed will definitely affect print quality. Filament needs enough time and heat to melt as it should before being extruded through the nozzle.

The print speed directly affects how much time the filament spends in the hot end. Faster means less melt time, and slower means more time – both of which could lead to extrusion issues when the speed-temperature ratio becomes too imbalanced.

Therefore, the print temperature should be the next setting you should consider after adjusting your speed settings. Faster print speeds may require increased temperature, while slower print speeds may require decreases in temperature.

License: The text of "The Best 3D Print Speed Settings for PLA & More" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.