When talking about 3D printers, a common question is, what’s the best resolution one can get when printing?

When people think about resolution, they typically think about layer height. But there are different aspects to consider and a variety of factors that affect it, and each 3D printing technology has its own, too.

In this article, we’ll go over different types of resolution, how they can affect the 3D print, and factors that come into play both for fused deposition modeling (FDM) and resin-based 3D printing. We’ll also refer to a few 3D printers and what they’ve got to offer, so you can get an idea of what’s achievable at home and in workshops.

Ready for the deets?

Printer Resolution

When we talk about resolution in 3D printing, we’re typically referring to one of two things.

Horizontal or XY resolution is the smallest horizontal artifact a 3D printer can controllably create. This is usually limited by the belts and stepper driver combination in FDM, the LCD pixel density in LCD (or MSLA), and the laser control in SLA.

Vertical resolution, or layer thickness or layer height, is the smallest thickness of a layer a printer can create. Typically smaller layers can lead to smoother finishes at the cost of increased time. Resin-based printers tend to perform better with vertical resolution than FDM ones, although generalizations when comparing different types of printing are tricky.

Additionally, embossed or engraved details (or minimum feature size) are common to consider when talking about resolution. This is the smallest noticeable feature you can have either recessed into a surface or sticking out from it. It’s linked to the vertical resolution but is typically slightly larger owing to it needing to be visibly noticeable.

The Importance of Resolution

Not all of the above resolutions are relevant for all purposes. In particular, XY resolution is relevant for making sure that parts that are meant to fit together can do so adequately, but it’s unlikely to affect the aesthetics. Meanwhile, vertical resolution and engraved or embossed details are much more likely to be important if you’re interested in the look of the print or if your part has overhangs.

For example, if you’re printing lithophanes, XY resolution and layer height will play equally important roles in ensuring your print comes out looking the best it can. Lithophanes require good XY control and small layer heights to get the truest resolution of the image.

For many personalized gifts, embossed or engraved details are important, too. This is often overlooked but can be vital. If you need fine details on your models, be it an ornate box or just engraved names, you’ll want to keep an eye out for this, to understand what comes out best on your printer.

Having a clearer idea of what resolution can refer to, let’s take a look at how all of it relates to the different 3D printing technologies.

Technological Factors

The chosen 3D printing technology will impact what types of resolution are more important, and it can also affect the quality of your prints – for instance, in general, the XY resolution of resin printers exceeds that of FDM. This is partly because the factors that affect the horizontal resolution on a resin-based machine (optic beam size in SLA, pixel density in LCD) are very different from those that affect an FDM machine (stepper motor precision and belt tension).

That said, different technologies can’t be compared directly, so we’ll be looking at what they have to offer separately.

FDM

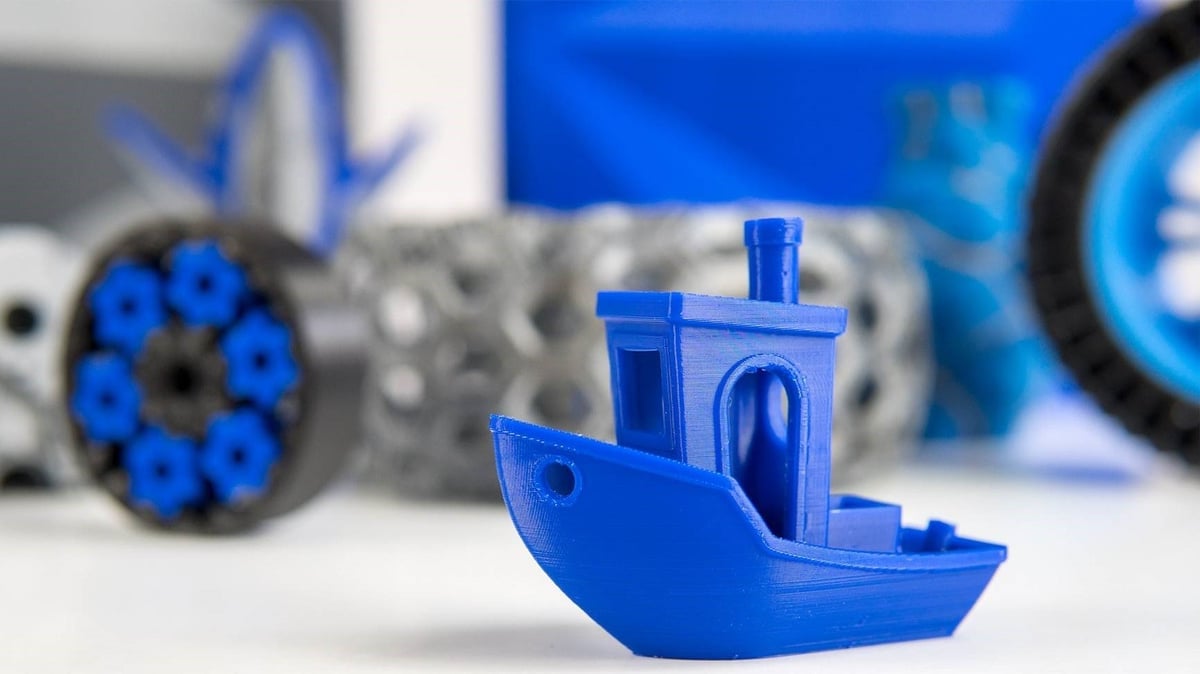

Fusion deposition modeling (FDM) is what may more commonly be referred to when people say “3D printing”, simply because of how much more accessible desktop FDM printers have traditionally been, although this has been changing over the past years.

In essence, when FDM printing, you melt plastic from a filament and then pipe it through a small nozzle onto a surface in a 2D pattern. More 2D layers are built on top of each other until you have your final part.

Horizontal Resolution

When it comes to this resolution, a major factor is stepper motor precision – that is, how small of a fraction of a rotation is accomplished with a single step, which then translates to how little it can push the printhead (or the bed) to and fro. Microstepping can also play a huge part here.

The size (of fineness) of the teeth on the X/Y belt can also make a difference, but to some extent, as long as the teeth are ideally proportioned for the gear attached to the stepper motor, finer teeth won’t make much of a difference.

Less direct factors that nonetheless massively impact XY resolution for FDM printers are the nozzle width, the melted material, and the mechanics of the technology. The nozzle width and the melted filament’s bead size will impact how well the material spreads, and good control over the bead will produce even contours on your print. While this mainly affects the risk of delamination, a byproduct is that extrusion width won’t be consistent, which will affect the horizontal resolution. Furthermore, FDM almost entirely relies on mechanical motion to shape and build up 3D models, where the coordination of so many moving parts, their calibration, and their vibrations will ultimately limit the usefulness of, say, an infinitely precise stepper motor.

Part cooling can also play a minimal role because the plastic can shrink, although this is unlikely to be a noticeable enough factor.

Vertical Resolution

The main factors affecting vertical resolution are available nozzle diameters and plastic material properties: Layer height is of course controlled by stepper motors (where the movement is translated via lead screws), but their precisions aren’t reached to accommodate typical layer heights.

Most nozzles have a diameter of 0.4 mm, but they can typically range between 0.1 and 0.8 mm. Yet, in theory, the diameter shouldn’t limit how low the nozzle can go. Assuming all other print settings (e.g. flow rate, temperature, etc.) are appropriately adjusted, you should be able to “scrape” as little material as you want onto the print bed or previous layer. The limiting factors that are then likely to emerge are whether or not a (near-translucent) layer line will do what it needs to and, well, how long you’re willing to wait for a print to finish.

It’s important to note that layer height shouldn’t exceed 80% of the nozzle diameter, which is why nozzle width affects maximum height. The smallest nozzle possible is 0.1 mm, which will typically afford a 0.12-mm layer height, although users point out how challenging it may be to have successful prints with such hardware and settings.

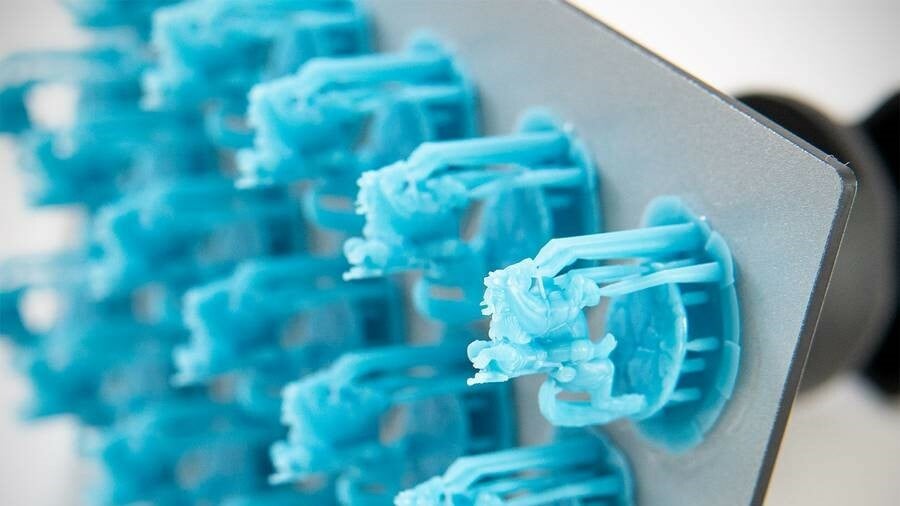

Resin-Based

Resin printers, both LCD and SLA, work by selectively curing UV-sensitive liquid polymer. The machine either projects the shape of the 2D part (LCD) or traces it (SLA) onto a build plate to solidify it there. The surface is then moved to stop additional curing of the polymer, before adding the next 2D layer to make the 3D object.

Once the print is finished, it needs to be washed and cured. But when it comes to resolution…

LCD

Horizontal Resolution

Factors that affect horizontal resolution include the LCD pixel density (or pixels per inch, PPI), defined as the resolution divided by the area of the screen. This means that the same number of pixels in a smaller screen will mean a higher resolution.

The particular resin’s characteristics can also play a part given that, in combination with other settings, more viscous ones can lead to issues – for example, elephant’s foot – and might not cure as intended.

Vertical Resolution

As with FDM printers, while it’s important to have an adequately precise stepper motor and properly pitched lead screw, these factors aren’t likely to be limiting when it comes to layer height.

Although difficult to say, the main factors are likely to be the resin’s ability to cure properly (in such low amounts) and be evenly distributed. Its viscosity is particularly important, and this is where special high-res resins come in (like the Phrozen Aqua 8K). While this difference may be minimal, it’s still something to consider, and it’s worth keeping in mind that different colors require varying curing times, which could lead to fewer details if the settings aren’t properly tweaked.

SLA

Horizontal Resolution

A factor that affects horizontal resolution includes the laser optic beam size, which limits how small a point can be cured. This is determined by the hardware and is unchangeable. Laser kinematic control can play a role but only really be changed if the manufacturer releases a firmware update.

The resin’s characteristics can also be a factor, as above.

Vertical Resolution

Once again, the resin and how it cures is the main limiting factor here.

SLS

Selective laser sintering (SLS) is a process whereby you spread out a very thin layer of a polymer, then laser a 2D shape out of the thin powder layer, melting that shape and sticking it to the layer below. This is done repeatedly, spreading thin layers of powder and melting them, fusing them, leading to the production of the part.

Horizontal and vertical resolution of an SLS printer can be hard to put a definite number on, as they depend on a lot of factors, with the layer height obviously impacting the vertical resolution and arguably being the main aspect for many makers. That said, 50 µm (0.05 mm) is considered to be the standard minimum laser height for SLS, although there’s also micro SLS, which, predictably, offers much smaller layer heights.

It’s also worth noting that most materials’ powders will have a different minimum spreadable thickness, which determines the minimum possible layer height (vertical resolution). The quality of the powder matters too; if the powder particles are ovular, not spherical, they won’t spread well or evenly, directly impacting how thin they can be spread.

In any case, it’s best to always consult the manufacturer and ask for samples.

Having gone over the general factors that affect the different resolutions for FDM, resin printing, and SLS, let’s take a look at what can be achieved, both at home and by professionals.

How Detailed Can They Go?

Next, we’ll take a look at what some hobbyist and entry-level professional 3D printers can achieve. Given their popularity, they should offer a general idea of what can be done at home and in workshops.

We won’t be looking at SLS machines here because these are unlikely to be found in your garage. That said, you can check out a good comparison of the best SLS printers and see what minimum layer thickness they have to offer. (Briefly, from 0.05 mm to 0.11 mm.)

FDM

3D printing resolutions change depending on which printer you’re looking at and the specifics of the technology. Below, we’ve included a few examples of resolutions of fairly popular FDM printers. The information is based on official documentation.

When it comes to horizontal resolution, in addition to the thinnest possible line, we’re including the minimum hole or pin size, which refers to the smallest feature you can expect to be able to make on the printer, while keeping a reliable tolerance. The tolerance is how close to a particular specified measurement you can expect from the machine. For instance, when creating a hole with a 30-mm diameter, a ±0.5-mm tolerance means that, once printed, the hole can end up having a diameter between 29.5 and 30.5 mm.

For vertical resolution, the layer height is the minimum layer height recommended for the specific printer, as well as the minimum engravable details and minimum feature detail it can produce (engraved or embossed).

Ender 3

Despite its age, the Ender 3 is still an extremely popular entry-level printer, even if a variety of alternatives have come along since its 2018 launch. Here’s what you need to know about it in terms of resolutions.

Horizontal Resolution

- Minimum hole/pin size: 2.5 mm

- Machine tolerance: ±0.2 mm

- Horizontal (XY) resolution/thinnest possible line: 0.49 mm

Vertical Resolution

- Layer height (Z) with feature details: ∼0.1 mm

- Minimum embossed/engraved details: 0.1 mm

- Minimum layer height: 0.1 mm

Prusa MK3S

The Prusa MK3S, despite being an old machine, is still very popular, shipping by standard with a 0.4-mm nozzle. It’s also got plenty to offer with its resolutions.

Horizontal Resolution

- Minimum hole/pin size: 2 mm

- Machine tolerance: ±0.15 mm

- Horizontal (XY) resolution/thinnest possible line: 0.48 mm

Vertical Resolution

- Layer height (Z) with feature details: ∼0.1 mm

- Minimum embossed/engraved details: 0.1 mm

- Minimum layer height: 0.05 mm

Qidi Tech X-Max

Qidi is an up-and-coming brand with entry-level professional 3D printers, like the X-Max, yielding excellent resolution. Using PLA, it has about the same results as the Prusa MK3S, but with more advanced materials, it’s able to reach a higher resolution.

Horizontal Resolution

- Minimum hole/pin size: 1 mm

- Machine tolerance: ±0.1 mm

- Horizontal (XY) resolution/thinnest possible line: 0.48 mm

Vertical Resolution

- Layer height (Z) with feature details: ∼0.05 mm

- Minimum embossed/engraved details: 0.05 mm high

- Minimum layer height: 0.05 mm

How Low Can You Go?

A common question might be, what’s the smallest layer height you can manage? Well, one miracle worker achieved a stunning 0.015-mm layer height!

Of course, you might not have the time or hardware to achieve that and instead want to know how you can get higher-quality prints. If you want to get rid of layer lines, you can post-process your print, either by sanding it, smoothing it, or using acetone if you’re printing ABS. There are many ways to make your prints look pretty, but be warned, once you start down this road, it can be addictive!

LCD & SLA

Next, we’re looking at a few examples of popular resin printers, starting with two LCD options and wrapping things up with an SLA one. These resolutions are based on official documentation.

When it comes to horizontal resolution, we talk about the tolerance of the machine (how close to specified size it can get), the minimum layer height, and the minimum embossable or engravable details. For SLA, we’re also referring to the machine’s tolerance.

Elegoo Mars 3

A pretty great 3D printer, the Mars 3 delivers in results for beginners and hobbyists with its 4K screen and LCD technology.

- Horizontal (XY) resolution: ~35 µm (~0.035 mm) (4,098 x 2,560 px)

- Minimum layer height (Z): 10 µm (0.01 mm)

- Minimum embossed/engraved details: 150 µm (0.15 mm) wide, 150 µm (0.15 mm) high

Anycubic Photon M3 Max

With a larger build volume and 7K resolution, the Photon M3 Max is worth a look, too.

- Horizontal (XY) resolution: ~28.5 µm (~0.0285 mm) (6,480 x 3,600 px)

- Minimum layer height (Z): 10 µm (0.01 mm)

- Minimum embossed/engraved details: 120 µm (0.12 mm) wide, 120 µm (0.12 mm) high

Formlabs 3+

At a significantly higher price point, but with different technology, Formlabs’ Form 3+ caters to the SLA audience.

- Horizontal (XY) resolution: 25 µm (0.025 mm)

- Minimum layer height (Z): 25 µm (0.025 mm)

- Minimum embossed/engraved details: 1 µm (0.1 mm) wide

Can We Go Further?

It’s worth noting that, in addition to 4K, there are a number of new market entries for LCD that offer 8K screens. While some may have larger LCD screens, these will be lower resolution than the smaller LCD screens offering 8K.

While sanding, painting, and coating can be useful post-processing ways of decreasing even more the (often barely perceptible) layers, caution must be taken as not all processes work the same way with all resins, and the curing step might also have to be changed depending on the goal.

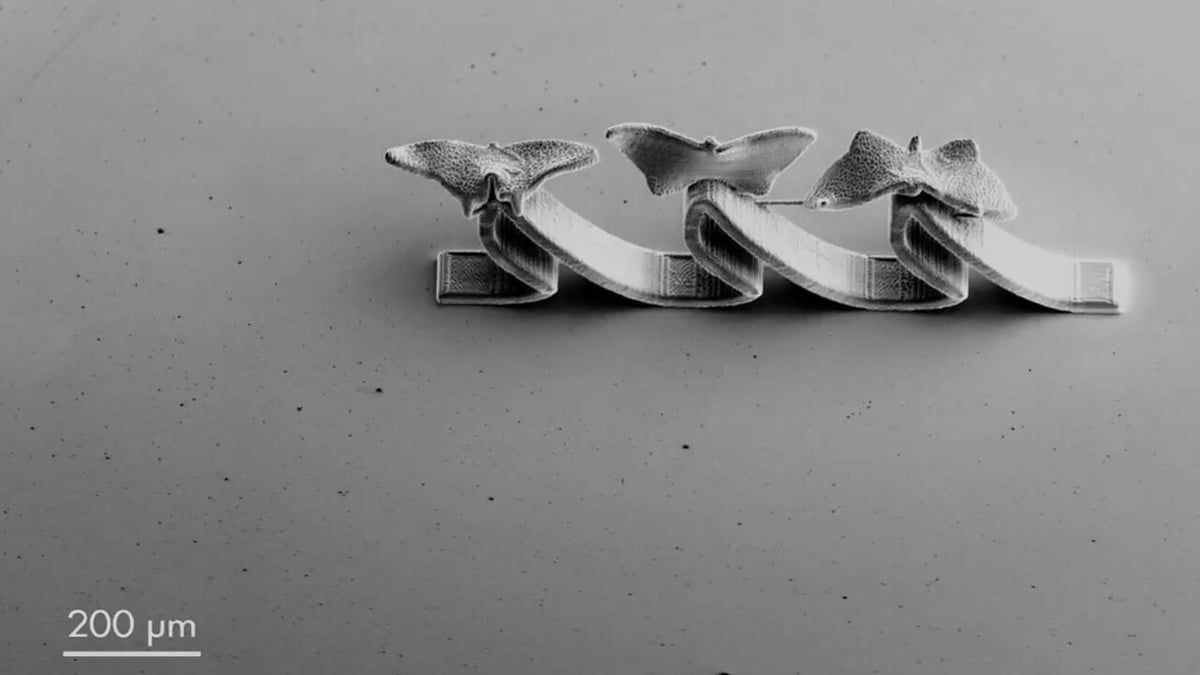

Micro 3D Printing

Sometimes it’s not just about how detailed prints can get, but also, how small can we print. This varies based on the technology used, and beyond the mentioned ones before, there are some less common 3D printing methods that can allow you to print very, very small parts.

There are a few very niche original equipment manufacturers (OEMs) making micro 3D printers. These aren’t really small printers, but they achieve really small prints. To do this, they use a totally different mechanism that allows them to print really small parts.

One example is the Exaddon Ceres, which can achieve a 0.005 μm (0.000005 mm) Z and 0.6 μm (0.0006 mm) XY resolutions.

License: The text of "3D Printer Resolution: How Detailed Can a 3D Print Be?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.