All3DP sits down with Ultimaker CEO Jos Burger and CTO Siert Wijnia to learn about their experiences, new machines and their outlook for the 3D printing industry for 2016.

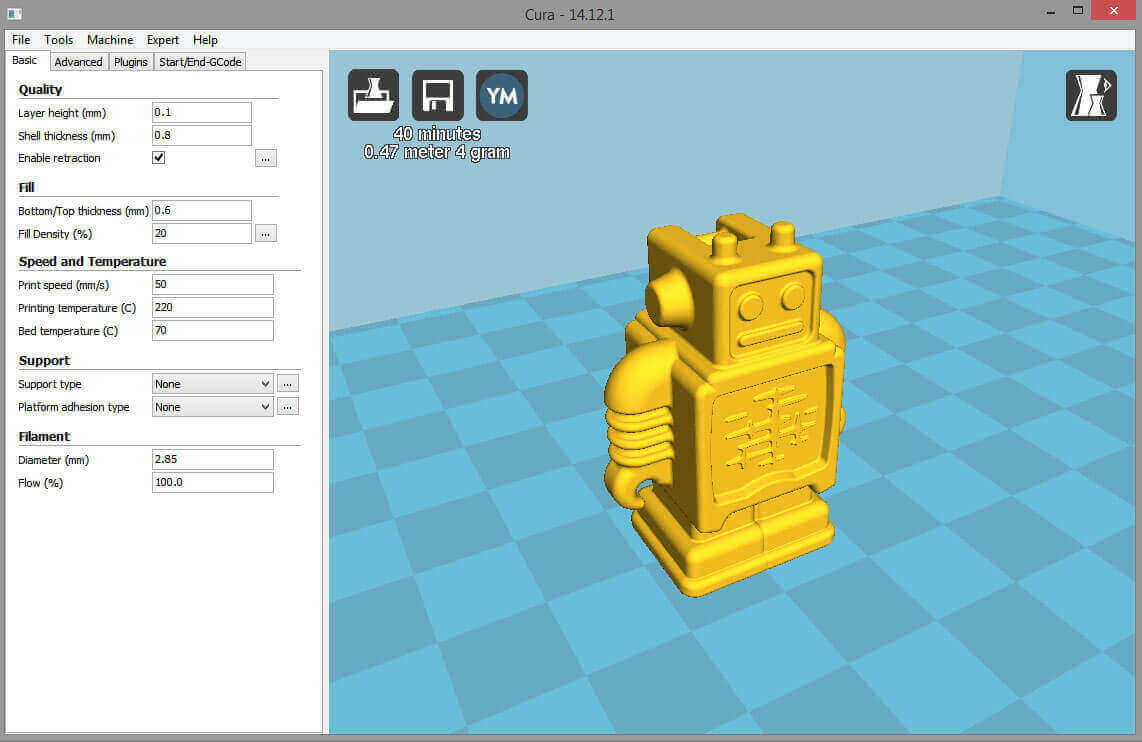

At last week’s CES 2016 in Las Vegas, All3DP’s met with Jos Burger and Siert Wijnia of Ultimaker. As the CEO of the Dutch 3D printer manufacturer, Burger is responsible for the general strategy of the company. Wijnia as CTO is overseeing the technical side, such as the ongoing development of new printers (Ultimaker 2+ review here) and new versions of 3D printing software Cura. Our US correspondent Roland Austinat talked with them about the state of the 3D printing nation, who is buying a surprisingly large amount of 3D printers and why you won’t see a 3D printer that can print up objects of up to one cubic meter any time soon.

All3DP: 2015 was a crazy year in the 3D printing industry. After a meteoric rise, everybody’s darling MakerBot fell out of grace and had to lay off a substantial amount of people. How was the last year for you at Ultimaker?

Jos Burger: You know, we’re a private, self-funded and profitable company and not at the whim of investment companies. We’re acting more like an old-school company: we build something, we sell it at a profit and then reinvest it into the company. Very old-fashioned, but it works.

All3DP: So it helps you not to be located in Silicon Valley where everybody is always on the lookout for the next big thing?

Jos Burger: In Silicon Valley it depends on the VC you have on board. There are those that want to build a long-term, sustainable business. But there are also those looking for a quick buck. In Europe, however, we are forced to go the old-fashioned way.

“There are no financial risk takers across Europe”

All3DP: Going without any venture capital can be a challenge, though. Some say that there are not so many tech startups in Germany because the banks are always asking for equity before they give you a loan – but if you had that equity, you would not need a loan in the first place. Is Holland’s financial sector filled with a few more risk takers?

Jos Burger: Not really. I would even say that it’s the same all across Europe. It’s easy to get some Angel investors for the first one, two, three hundred thousand Euros, but if you are looking for Series A funding, the funnel narrows very quickly.

Siert Wijnia: I think that it’s good to stay with one’s feet on the ground, though. We started the company in 2011 by crowdfunding without a crowdfunding platform – so we could invest every Euro into the business. That gives you the chance to start and grow the company. That is harder than actually launching a 3D printer. That’s easy in comparison, but growing Ultimaker and keeping it together is a much bigger challenge. If you look at us today, we still have the people working for us that came in right at the start. And that’s not a given, not at all.

“We’re not so much a printer company, but a facilitator”

All3DP: The two of you probably did not just come to Las Vegas to chat with journalists such as myself. Most likely you have an announcement about or are launching a new product that our readers will be quite interested in hearing …

Jos Burger: You make a valid point. We are doing this ,but in a different way. You see, we started as a 3D printer company that developed its own printing software Cura – which is being used by 50 percent of our competitors, by the way. Where we position the company now is in the engineering segment. Engineers in middle and large sized companies are the most industrious makers these days. We are also working together with partners in the education segment. We’ve asked our partners where they see the industry in the next twelve months, and many are saying that they see our printers with the use of superior materials – for prototyping, tooling and small-series manufacturing.

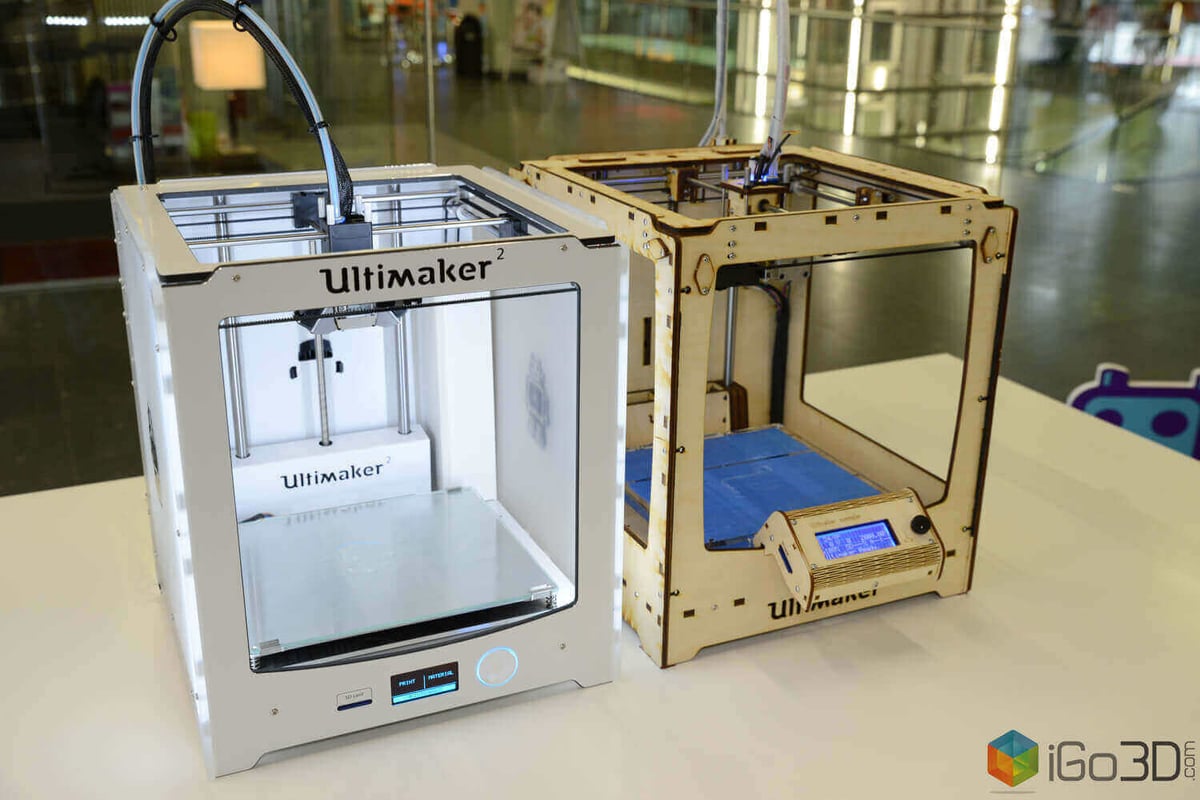

So we are a utility company delivering a toolkit for these purposes. In that sense, we are not so much a printer company, but a facilitator. Similar to SolidWorks - a software that has 10.000 functions, but you as the user decide which ones to pick. Same thing with Excel – nobody is using every feature of that program. But we know that to keep that position, we have to keep improving the platform. That’s a continuous process, not throwing out new machines constantly. Look at our Ultimaker 2+ (Ultimaker 2+ review here) and its interchangeable nozzles – that was an idea of one of the members of our community. And we are seeing a lot of those ideas coming from our user base.

“Being open to our users is key to getting better and better”

Siert Wijnia: Even though we have a lot of people working on our hardware and software, we don’t have all the ideas. But by providing an open platform, people are eager to fiddle around with the machine and make it better for a reason. If we can see the reason benefitting a larger user base, then it makes a lot of sense – because we are not the ones telling our users what to do with a 3D printer. Being open to our users is key to getting better and better time and again.

Jos Burger: We have close to 15.000 people in our community – and it’s amazing to see all the specialists from all the different areas.

Siert Wijnia: A lot of universities are using our machine because they can fiddle around with all the parameters and the even the firmware. They can also use it for research on how this technology is being used and can help to improve the quality of the resulting products. And then they give us all their knowledge back – being open is really amazing even down to a person to person interaction.

Jos Burger: Which also translates into the choices we make for our resellers. We don’t go for the box movers. We want to have people who have an understanding about 3D printing and the deployment. Quite often they are very fanatic users of our printers themselves.

“No Media Markt. No Staples. No Best Buy”

All3DP: So when you have a question, you can come back to the vendor who is knowledgeable about it – not just selling you a piece of gear at a big store like Media Markt …

Jos Burger: Absolutely. No Media Markt. No Staples. No Best Buy. We deliberately made a choice not to go after those kinds of resellers. Another reason for us to be at CES is that about 35 percent of our revenue is already coming from the USA. And 30 percent of that revenue comes from educational facilities – whether it’s Duke, Harvard or Yale, we are all the top universities. And we have great endorsements from key partners like SolidWorks or Autodesk. That alone is quite a good reason for spending more time in the USA.

All3DP: You mentioned Excel earlier on. Microsoft might bring out incremental patches and updates for the software, but every few years the software engineers are not just coming up with a point release but a full new version. Wouldn’t it make sense to come up with a new printer after many evolutionary improvements every few years?

“We will launch new machines this year”

Jos Burger: One thing that we learned as a company is to be extremely careful to talk about launching a new machine. If we don’t feel a hundred percent comfortable about it, we won’t even talk about the launch date. But we will launch new machines this year with new functionalities and new software. Even sooner than a lot of people would expect it.

Siert Wijnia: At the same time, we will not be launching new machines for the sake of launching new machines …

Jos Burger: … or make shareholders happy, or increase the hype.

Siert Wijnia: A machine is used for a reason. And we want to know why and where it is used and make improvements for that usage. We started out with a good platform and made a few good choices in the beginning to lay a stable fundament. Changing that fundament just because “we need to do something new” is risky – things need to be changed for a reason. And the only reason is bringing added value to our customers and their needs.

All3DP: Something like a dual extruder, thicker layers or two-color printing …

“We are looking at dual material printing for this year”

Jos Burger: We hear that request a lot, but there is even one that is being mentioned more often: dual material printing, like PLA and a support material. That way one could print extremely complex models. This will be part of the innovation this year, right? (looks at Siert)

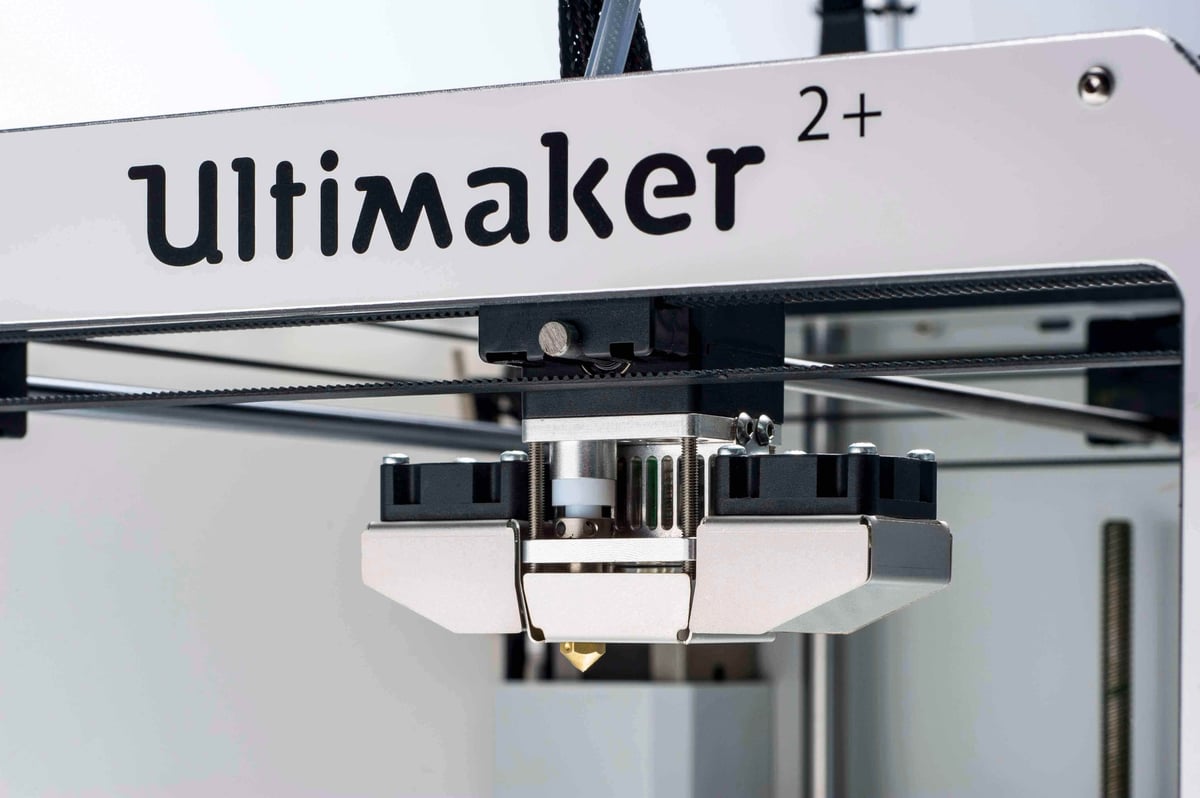

Siert Wijnia: When we originally built the Ultimaker 2, we designed it for two print heads. However, introducing a second head gave a lot of drawbacks on a normal print. And that isn’t just a bigger effort in designing the machine, but also making the user experience not as effortless. An STL model can only be printed in one material. You then have to tell the users that they need to have two STL models in Cura, and they need to be positioned exactly right … But we are working on all those points so that when the customers get the machines, it just works the right way. What I learned is that everything is related to everything: mechanical, electrical, software and material areas all have to cooperate.

All3DP: And you can’t ship the system with an engineer that sets it up for you and helps you get it work correctly.

Siert Wijnia: No, exactly! If you have two print heads, one hot and one cold, the cold one will just make for an ugly print, so you have to find a solution for that. But those solutions, in turn, will introduce new problems …

“People are not toying around with 3D printers anymore”

Jos Burger: And we have to be careful because we see that many companies are actually using Ultimaker printers for their productions – it’s not just playing around with it anymore. We see companies that allow architects total freedom in the design of building interiors, down to the shape of the light fixtures which right now almost always come in standard sizes and shapes. Special items that are higher margin and difficult to make otherwise – that’s a massive market opportunity. Many other companies don’t even ask for two materials but want us to make a single material machine even better – so we have to make sure to respect their requirements as well. And if they print critical solutions we have to make sure that these can fulfill compliance requirements – that’s quite a shift in our industry.

All3DP: You mentioned Cura. Could you give us a peek into the development? How connected is the team with the hardware engineers within your company? And who’s the one calling the shots, in the end, the hardware or the software team?

Siert Wijnia: We have hundreds of parameters that we want to play around with on the hardware side, so we have to be able to get it into the software as well. And each new material that people want to work with has so many specific properties! That’s why our hardware and software teams really have to work hand in hand – the result is only as good as the work they did together. You can’t really look at the final product and say which department was leading the development of which area – it’s a highly concurrent process. Sometimes we don’t even need new hardware when we can change things in software.

All3DP: This reminds me a bit of the situation with graphics cards and their drivers. Sometimes a new game comes out, and a new driver will then unlock even more power to run this game even smoother – on the same hardware.

“We see painful things out there”

Jos Burger: That’s a very good example. You know, despite the openness of the platform, most people are looking for very specific use cases for very specific hardware, software, and material. For example, we advise our customers to use a specific material for specific end results. There is a lot of material out there because everybody thinks that they can produce plastic, but we see painful things out there. People are putting PLA from whatever company from whatever country into the machines – and who’s to blame when they get jammed? That’s right, they blame us. That led us to work with the leading material manufacturers on a certification system.

All3DP: Like Nintendo did back in the days with their seal of quality – when you bought one of the non-Nintendo games, you knew that they would run on your gaming console.

Jos Burger: That’s exactly what it is. At the same time, we don’t want to lock out material that is not certified – that way people can experiment and try out new things …

All3DP: … that you then can integrate into the next version of your soft- or hardware when you see a market for that kind of material.

“We don’t want to hold our customers hostage.”

Jos Burger: Right. We make recommendations, but our system is open. And we don’t want to produce our own materials. However, we don’t want to hold our customers hostage like ink printer manufacturers sometimes do.

All3DP: Which team is bigger right now, your software or your hardware team?

Jos Burger: Today it’s more or less even, but we will invest more and more into software. For example, we now have a dedicated team that’s responsible for print farm management, caused by a shift in small-series manufacturing. What we see happening is that people install 50 to 150 printers but need the software to manage that amount of machines – so we will develop that.

Siert Wijnia: We might have 200, 300 parameters in a printer, but they are all controlled by software. After we launched the original Ultimaker, all the improvements that happened to it in the first year were done by software changes – and the results were dramatically different.

All3DP: We talked about the tectonic shifts in the 3D printing industry: Makerbot is in the doldrums, the Cube printers aren’t produced anymore – is the 3D printing market still healthy in 2016? Is it still a good business to be in?

“Our segment is growing and growing and growing”

Jos Burger: If you look into our segment that is defined by printers between 2000 and 3500 Euros, then you see that it’s growing and growing and growing – specifically in industrial and educational environments. We even see them eating into the market of bigger machines as smaller machines become more powerful, especially if you install them in a cluster.

Siert Wijnia: I believe that we are past the hype phase now. It also means that one needs to be serious about their business – how many Kickstarters have there been making a new printer basically from the same things? For us, the openness of how we operate and the human-to-human interactions are very important. We’re not trying to be big – if there’s something big, it’s our clients. They are creating amazing things, and we always try to put them on stage. In the end, our printers are just a tool.

All3DP: So you don’t see all the Kickstarters as potential rivals who might be eating into your revenue?

Jos Burger: No, to the contrary.

Siert Wijnia: If you look into Kickstarter, 3D printer ones aren’t even funded anymore. If I sit down with a few engineers, we can make a new model, no problem. But scaling up production, putting it into the market with a decent distribution network – how do you do that? And with whom? We have been doing this for over four years already. And you need a backchannel as well. We are not deciding what our clients should use – we hear back from them, and we are trying to figure out what they need from us.

“Kickstarter projects can’t take care of the customers like we can”

Jos Burger: I told you about the kind of customers that we have. When you buy one or two machines, you can put them on an expense account so you can sneakily enter the 3D printing space. Then they are happy what they are seeing and want to order 50 machines. But that’s too big for the expense account, so now they have to go through the purchasing department and the compliance guys. And what about support? Making a 3D printer is about much more than just making the machine, writing the software and having the printing material ready. It’s about the partners you have in the market to support the bigger companies that happily pay ten, 15 percent more for the partner to help them manage their order and install the machines. And there’s no way a Kickstarter project can take care of this.

All3DP: Unless they are lucky … or are called Palmer Luckey and manage to sell their company to a big player like Facebook. And they could also buy a 3D printer Kickstarter and open their own Facebook 3D Print Shop, where they could sell Facebook users relatively simple items like doorknobs or clothes hooks that they could then print at home. Or is this science fiction?

Siert Wijnia: No, that’s a viable thought. But we also discovered that we can dream about a lot of things in some fields, but if the market isn’t ready yet to accept it … You can have the best invention ever, but if the world doesn’t see its purpose or usefulness … It’s all about the right timing – where does it fit and when? We do a sanity check every day – which is very important. Otherwise, you blow up your own company, and then some people might become very rich, but others will become very poor. And that’s not what we are in for.

“We double our revenues every year”

All3DP: You mentioned that some clients are now buying triple-digit amounts of printers. How does this reflect on your finances?

Jos Burger: Let’s put it like this: we double our revenues every year. And we expect to sell about 32.000 machines in 2016.

All3DP: Will that growth rate remain exponential in the long run?

Jos Burger: It’s tough to predict the future. We can just look back at the last years and take it from there. Of course we won’t double forever, eventually the curve will flatten out. And we want to remain relevant – it should be sustainable revenue, which can only come through things we talked about: like being close the customer and translating their needs into functionalities. That’s the most rewarding part of the business: we love visiting people, and we love having customers over. It’s simply fantastic to see what they are doing and what we can jointly do.

Siert Wijnia: Since we started this company, I’ve constantly been amazed what people are doing with our printers. That’s the most rewarding thing of it. It’s not a thing that you give someone to use, but it’s a meta-tool to make everything. When I look at the Enable Project (http://enablingthefuture.org/), I see kids that have had a birth defect but now they have a hand that fits them for a few Euros – wow. Then you see a dad going all out and making his kid a Star Wars or Iron Man hand. These kids had a disability, and now they are the coolest guys in the classroom.

“Surgeons are making body parts for hip surgery with our printers”

Jos Burger: We even know about surgeons who are making body parts for hip replacement surgery with Ultimaker printers – they just do it. Of course, they have to be careful, because it’s a serious application. Others use it to give their patients a preview of what’s going to happen during their heart surgery.

All3DP: Looking at these great cases, is there one model of your printers that sells especially well? Or are the sales all spread out evenly?

Jos Burger: There is an ongoing need for bigger machines, We started with the Ultimaker 2 and then offered an extended version that was ten centimeters higher. And the market is really buying into these, even though they cost 500 US-Dollars more – because you can make taller things. Right now we are working on a machine that we will launch this year that is not just higher, but bigger in general. But it’s not us defining the size of these printers, but the market. Many are saying: if you can make a shoe-size printer – size 46 in Europe -, that would be great. Our customers are not counting the Cent – they want reliable machines that can do what they want to do, so whether they are 2500 or 3000 US-Dollars doesn’t really make a difference.

All3DP: So you could even say: “Here is our new machine that measures one cubic meter!”

Jos Burger: (laughs) That’s a good question!

“Bigger is better, but it’s not that easy”

Siert Wijnia: (laughs as well) People forget that volume means the power of three. So if you are printing something in the range of a cubic meter with a single nozzle, it takes 10³ times as long – compared to ten centimeters. So you would have to speed up the material flow and the machine, have different layer sizes. But then the cool-down shrinkage of the material will also be bigger … It’s not just scaling up.

We have built large machines like that just for fun, to see what we would encounter, knowing that it would be hard. And we had a few guys from the community at the beginning of the Ultimaker Original making a really huge one. But they had trouble even printing a small Ultimaker logo in that one. So yes: Bigger is better, but it’s not that easy. Did you hear about the 3D printed Canal House in Amsterdam? I was involved in that, and we decided to take a shipping container, set it upright and make a 3D printer out of it. But we started to do completely different calculations. We wanted to be able to carry out the things we printed with four people, so we were wondering: how much can we carry? 50 kilograms each? Aside from not weighing more than 200 kilograms, we wanted results within 24 hours, which means that we have to print about ten kilograms per hour. But then you don’t do it with this small nozzle. Size changes everything.

New at CES: the Ultimaker 2+ and Ultimaker 2 Extended+

Siert Wijnia: The Ultimaker 2+, which we are presenting at CES 2016 for the first time, has swappable nozzles in different sizes. Larger nozzles like the 0.8 mm one allow for much faster printing, but, of course, need different profiles in Cura. But just having a bigger nozzle isn’t the whole story. You have to ask yourself: what layer size do you want to print? Can a 0.8 mm nozzle print at the same accuracy than a 0.25 mm nozzle?

All3DP: Does that mean that we will see a cubic meter machine eventually?

Jos Burger: Oh yeah, we are going to see those. There is actually a German company launching one, and we know of customers wanting to try them out. But that size is endangering something that we call the “overnight factor” in the industry: when it’s five in the afternoon and you start the printing process before going home, you can be sure that the model will be done by early next morning. But if the printer is one cubic meter, it can take three to five days.

Siert Wijnia: It’s a bit like the Internet. Everything I see I want today, not tomorrow. But the longer you wait, the more reliable it will be – and not fail on you on day four of five. In our experiments, we had the huge printer connected to a Windows PC. But when Windows went into sleep mode, it stopped the printer …

“We know who is using our printers, but not how creative they are”

All3DP: Of all the makers out there, can you tell us who the most creative ones are? Are they all from one specific region or country, or is a breakdown like this impossible?

Jos Burger: Let’s look at our customers. 35 percent are in the US, 40 percent in Europe, the rest are countries like Japan, Korea, and Australia. China is catching up, South Africa and Israel are okay. Not too many makers in South America yet. But that has other reasons: if you want to sell to Brazil, for example, you have to have a local office – else the printers are being hit by horrendous import taxes that are putting them out of reach for almost everybody.

All3DP: Do the numbers correlate with creativity?

Siert Wijnia: That’s a tough call to make. Engineers who order a lot of machines are probably very creative people, but their creativity might be different from what we are calling creative in everyday life.

Jos Burger: Take a company like BMW. We know that they are using Ultimaker printers big time, but we have no idea what they are doing. So we don’t know to what extent they are creative or not – and that is true for a lot of companies. (laughs)

All3DP: Jos, Siert, thanks so much for your time and your insights.

License: The text of "Ultimaker CEO: “We will launch new machines this year”" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.