This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Improving Motor Designs

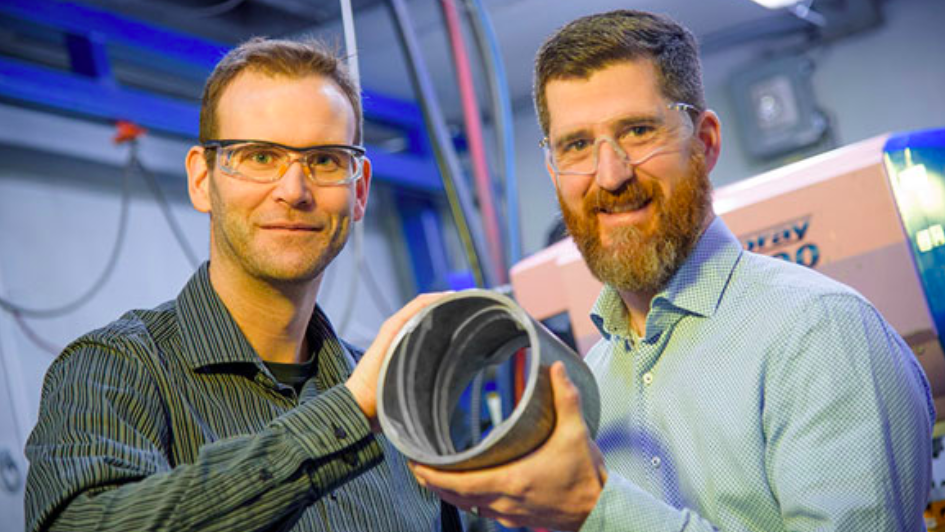

Researchers Create Permanent Magnets with Cold Spray Additive Manufacturing

Advertisement

Advertisement