Acrylonitrile butadiene styrene, commonly known as ABS, has long been a trusted material in the world of 3D printing. Its remarkable physical properties, durability, and versatility have made it a favorite among makers, designers, and manufacturers alike.

While ABS boasts undeniable advantages, the primary reason for its dominance lies in its affordability. However, there are underlying issues that beg for our attention – issues that threaten it with obsolescence in the ever-evolving landscape of 3D printing.

In this article, we’ll explore the multifaceted aspects of ABS, its contributions to 3D printing, and the compelling reasons why it may be time to reconsider our reliance on this once-indispensable material. As we delve into the challenges and alternatives, we’ll uncover the shifting paradigms within the 3D printing community.

It’s time to question whether ABS’s reign should continue or if it’s time for a new era in 3D printing materials.

Reason #1: Unpleasant Fumes

As plastic is heated and extruded in the process of 3D printing, gas and microscopic particles get released into the surrounding environment. According to peer-reviewed studies, these fumes present the highest health risk associated with 3D printing.

Although there’s not enough evidence (yet) to link these fumes to toxic outcomes, it can cause irritation. What research does show is that ABS fumes negatively impact the ways the cells in our body function. Perhaps you’ve experienced some discomfort from exposure to ABS fumes already without realizing it. Common symptoms are drowsiness, eye irritation, nausea, and headaches.

Not only are fumes from ABS more hazardous than PLA, but ABS also releases more of these harmful fumes while printing. This is attributed to the higher printing temperatures demanded by ABS printing, which is typically between 220-260 °C, as opposed to PLA, which prints between 180-220 °C.

Reason #2: Environmental Concerns

Renewable resources are characterized by their ability to naturally replenish, ensuring a consistent supply over time, such as wind, plants, and sunlight. These materials are often referred to as renewable or plant-based. ABS is inherently non-renewable due to its petrochemical origins.

So, ABS doesn’t have eco-friendly origins, but it’s recyclable, right? In North America, ABS is categorized under the Resin Identification Code (RIC) as #7, a catchall classification encompassing various plastics that don’t fit into other specific categories. Unfortunately, ABS is rarely isolated from plastics labeled as #7 and recycled in an energy-intensive process. Incineration or landfilling is a more likely outcome, depending on your location.

Even iconic products like LEGO bricks, historically associated with ABS, are transitioning away from its use, reflecting a broader shift towards more sustainable and environmentally friendly materials.

Reason #3: Energy Use

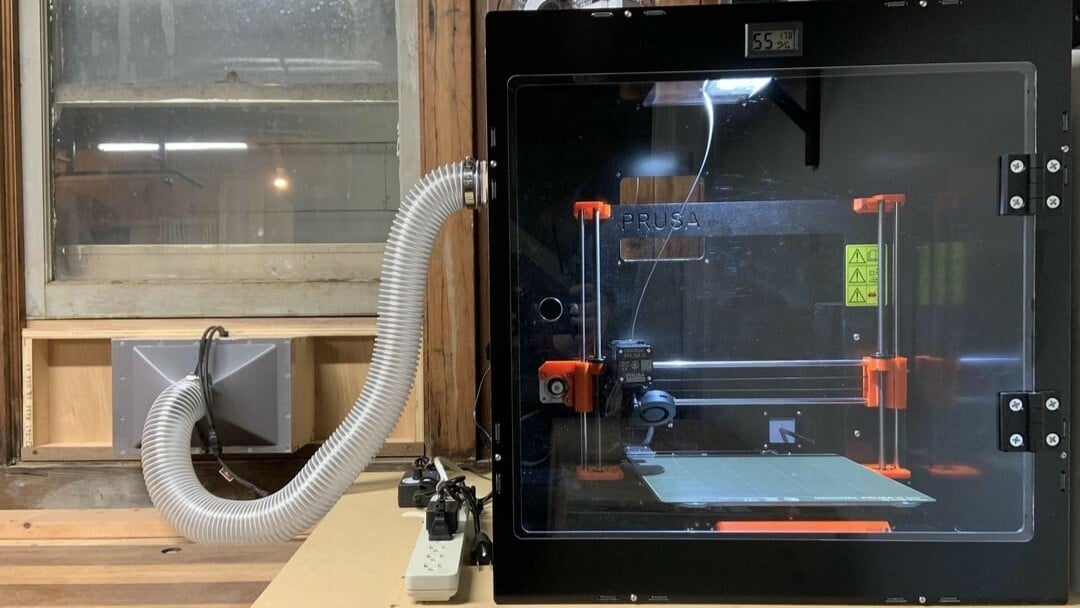

ABS is very sensitive to temperature variation, making it especially tricky to 3D print. Even minor fluctuations in temperature can lead to delamination and warping of your prints, rendering them unusable. It’s essential to keep ambient temperatures elevated – even if doing so draws a significant amount of power during the entire printing process, plus preheating time. If you’re not already using an enclosure, this energy expenditure is even greater.

A heated bed is a must-have when printing ABS, whereas it’s optional for other filament choices, like PLA. Without it, ABS will have a difficult time adhering to the build plate. ABS also requires a higher nozzle temperature compared to PLA, so if you’re looking to save on energy, consider skipping on ABS.

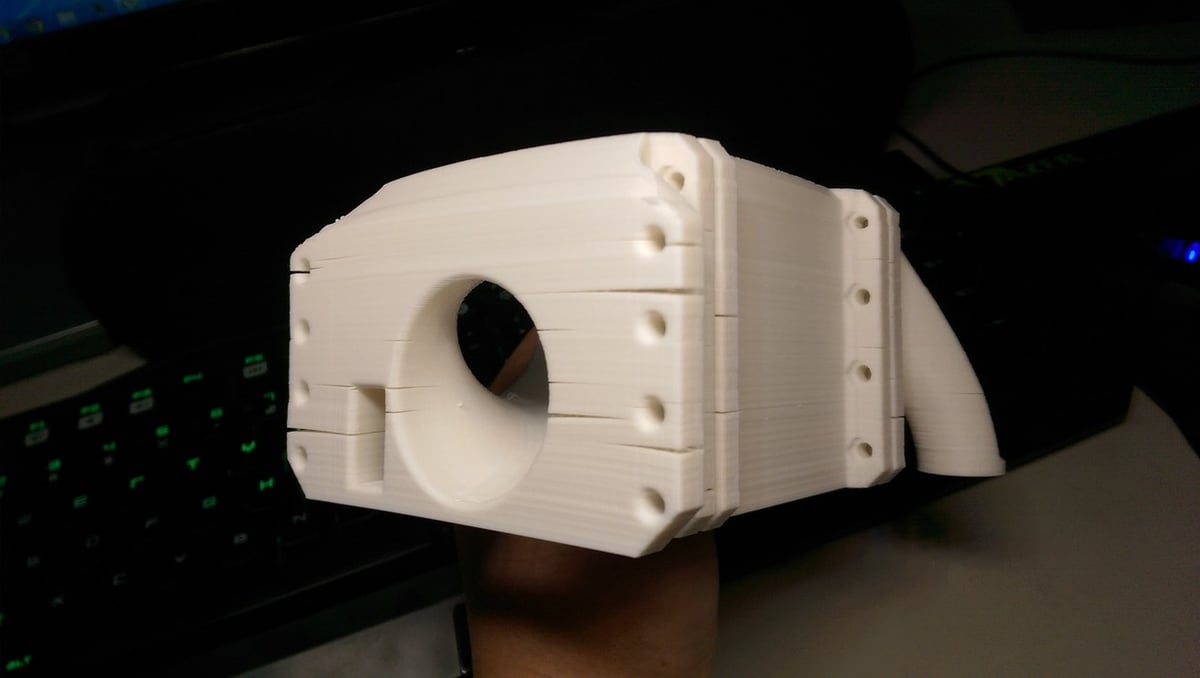

Reason #4: Post-Processing Is Not Easy

Due to the higher frequency of layer delamination and warping issues, post-processing ABS can be particularly laborious, especially if you intend to paint. It often requires filling in cracks and imperfections to achieve a smooth surface, but that’s only for aesthetic parts.

If a weight-bearing part has layer delamination, that’s a failure waiting to happen and you might as well print it again. Warping will also totally ruin your part to the point of having to print it again, aesthetic or otherwise. Now, that’s just a waste of filament, time, and energy.

One common method for smoothing ABS prints involves the use of acetone. This vapor treatment can produce a glossy finish, which is aesthetically appealing for some people. However, it’s essential to exercise caution when working with large amounts of acetone, as inhaling its fumes can cause serious irritation. When utilizing acetone for post-processing ABS, you need to do so in an environment with proper ventilation to ensure safety and minimize health risks. If you don’t have access to those conditions, there are other options out there for achieving smooth prints.

Reason #5: There Are Better Alternatives

In the early days of consumer 3D printing, the filament market as we know it today didn’t exist. Therefore, the 3D printing community had to rely on the materials available at the time, and ABS was widely available and inexpensive.

As the 3D printing industry has evolved, there has been significant research and development dedicated to creating specialized materials for 3D printing. These new options offer greater strength, reduced or no warping issues, and improved printability on a wide range of machines.

To start, PETG filaments are easier to work with and offer similar properties to ABS that work for many functional parts. For decorative pieces, PLA is usually the best choice for its ease of printing and availability in a wide range of colors and types.

Additionally, options such as nylon and carbon fiber composites are now available for technical prints that require enhanced strength and durability. TPE (thermoplastic elastomer) is another viable choice when you need parts with impact or vibration resistance.

Considering these factors and the ever-increasing variety of alternatives, ABS may find itself diminishing in relevance within the world or 3D printing.

Final Thoughts

There isn’t one perfect filament for everything and everyone. The wide selection of filament options out there means we can choose a material with the performance we are looking for, although it’s admittedly difficult for low-cost filaments to compete with the durability of ABS.

The only filament that might truly be able to substitute ABS is ASA, but recycling options for ASA are close to non-existent, and its similar chemical origins to ABS and higher printing temperature suggest that ASA printing fumes are still a concern. Many agree that ASA offers an easier printing experience than ABS so if that’s your primary consideration, give ASA a try. If you’d like to go more in-depth, please check out our ABS vs. ASA comparative guide.

At the end of the day, some of the downsides of ABS can be mitigated and ABS will sometimes be the right material for the job, for lack of truly better options at this time and age. However, it never hurts to be conscious of your material choice and to swap ABS with more eco-friendly filaments whenever possible.

License: The text of "5 Reasons Why ABS Plastic Needs to Go Away" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.