It's Not What You Think

Probably you read the title and were expecting a nerdy listicle about cool 3D printing technologies of the future — a list no doubt referencing 3D printed organs, human augmentation, and life-size homes squirted from a nozzle.

But this article isn’t what you might initially expect. Here, we aim to explore the higher-level impact of 3D printing advancements as it relates to the distribution of manufacturing power, rather than micro-level innovations. The truth is, the most important aspect of 3D printing in the future is not a specific process or technology, it’s democratization.

First, Some Context

What many people don’t realize is that 3D printing has existed since the late 20th century, with Charles “Chuck” Hull inventing stereolithography in 1984. Yet, hardly anyone knew about it for years, because the technology was shuttered behind patents. When those patents expired, 3D printing technology became accessible to more people, and the consumer 3D printing community was born. Helping it spread its wings was another humble innovation called the Internet.

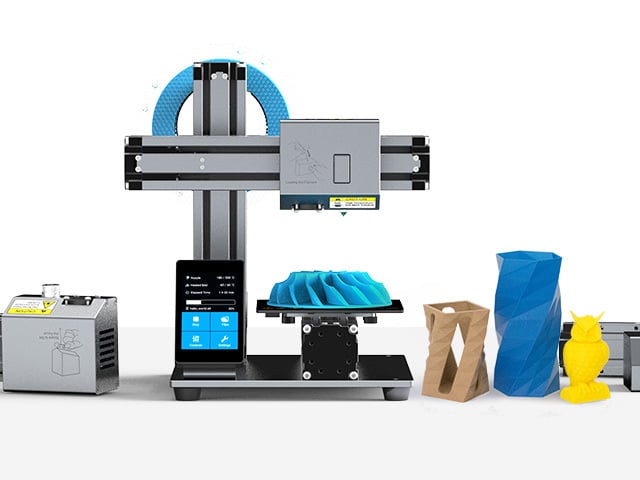

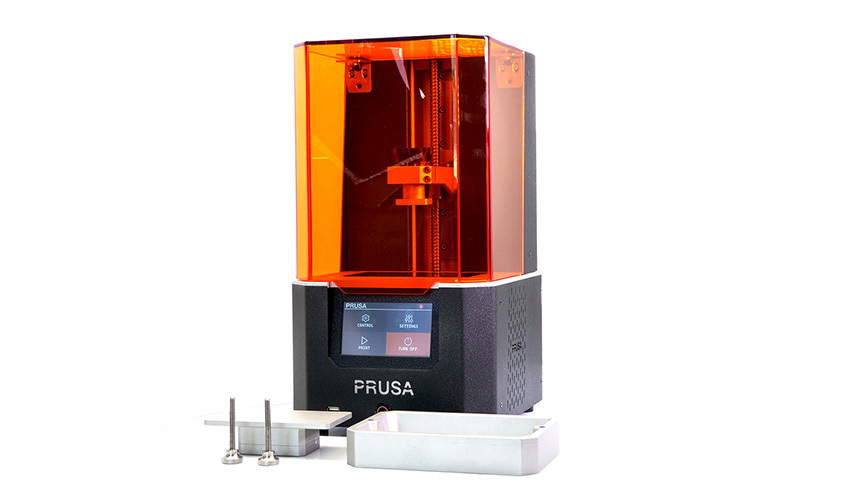

Though some forms of 3D printing remain solidly in the professional manufacturing world, much of it has become accessible to the average consumer. For instance, SLA still has a presence in pro-grade manufacturing — Carbon3D’s patented CLIP technology, for example, is a derivative of SLA –but it’s also made its way into consumer machines like the Formlabs Form 2.

What does this show? Like any technology, 3D printing is being adopted by more and more people over time. It’s already started the classic “adoption lifecycle” and is now entering the “early adopters” phase with consumer 3D printing.

Democratization, Decoded

As more and more people have access to the technology, more and more people have the power to impact 3D printing as a whole. Look no further than the RepRap movement: One person gained access and decided to make a reprintable printer, which quickly spread access to thousands. Now, anyone can buy a 3D printer from Amazon, a remarkable shift for the industry, as a whole.

That’s democratization at work, already.

Why You Should Care

The development of 3D printing is remarkably similar to the development of the Internet, especially in terms of impact. In the late 1990s, people thought the Internet was a fad — an experiment for nerds that wouldn’t change anything. Flash forward to 2019, and few people dispute the magnitude of change the Internet has wrought upon humanity.

The Internet democratized information. Now, anyone can start their own “TV show” on YouTube or a business on Shopify. Most importantly, anyone can find the answer to (almost) anything in five seconds thanks to modern search engines.

Of course, there’s a limitation to this democracy (when was the last time you directed a blockbuster?) but the point is that the barrier of entry has almost entirely been torn down. Previously, if you wanted to distribute a TV show, you had to sign a deal with a network, who held the keys to distribution. Now, you can pick up your smartphone and premiere your series about exotic cats on YouTube, thirty minutes after you start filming.

“The Internet Effect” with 3D Printing

The same effect will apply to 3D printing in the future: The power to make will be democratized. More people will be able to make more things. Just like the Internet, there will be limitations — few people will be able to print life-size passenger planes from their garage — but there are mountains of changes that are just waiting to be explored.

Democratization: Creating, Not Replacing

The biggest impact of the democratization of production lies in the new things it will create, not what it will replace. Certain forms of manufacturing won’t go away anytime soon, such as injection molding, which is excellent for large, uniform batches of parts.

To illustrate the idea of new and old coming together, let’s take another page out of the Internet book. Radio has been around for decades, but in recent years, a new form of listening built on the back of the Internet has become mainstream: podcasts.

Previously, you had to pull strings at a radio station in order to share your voice with the masses. Now, starting your own show is as simple (in theory) as downloading an app and recording your first episode.

That doesn’t mean radio has disappeared. Now, podcasts merely exist as a different version of the radio concept, a form that’s more distributed with lower barriers of entry.

Similarly, the democratization of 3D printing won’t eradicate traditional manufacturing with patented technologies. Instead, it will create new opportunities for innovation. In other words, what’s exciting is the opportunities that distributed manufacturing will create, and some current trends already point to possibilities within the next few decades.

Existing Trends to Watch

Finally, it’s time for the most captivating part of the article. In the following, we look at some of the ways the democratization of production might affect different industries. Of course, existing developments are included and used to predict the tangible possibilities in the near future.

Here are the industries we’ll focus on:

- Art and Fashion

- Medicine

- Architecture and Construction

- Automotive and Aerospace

Case Studies: Art and Fashion

Disrupting with a Flourish

3D printing was first invented to improve manufacturing, and as such, the use cases were heavily utilitarian. Once the technology spread to people with less concrete agendas, however, artists saw a new medium to practice their craft in. Now, people have created amazing pieces of artwork with the technology.

As the 3D printing processes that are accessible to consumers become more capable, one can only imagine the kind of artwork that will be produced.

Novel forms of artistic expression will crop up everywhere when better and better 3D printing technology lands in the hands of more and more people.

The Expanding World of Fashion

Designers are already experimenting with 3D printing in the design process, whether that’s by printing directly on fabric, adding printed fixtures to pieces, or incorporating flexible materials to eliminate seams.

But the possibility of advanced personalization in fashion is equally exciting. Personalized soles in footwear is a prime example.

When it comes to the fashion industry, we don’t have to squint to see that better 3D printing is becoming common, and common 3D printing is getting better.

Prototyping is the Future

For most of us, the most familiar 3D printing use case will probably be a significant one in the design world: iterating through a design concept. It’s highly likely that many design hemispheres, including product design studios, furniture shops, and metalworking shops will soon make use of 3D printing in some parts of their workflow, especially if the technology becomes more user-oriented and accessible.

It’s not a stretch to think a machine that can produce accurate prototypes very quickly will be used to offer tighter feedback loops between designers and customers in all kinds of design-centric industries.

Case Study: Medicine

The applications in medicine are far and many. They run the gamut from “distant dream” to “near-reality”.

Bioprinting

Of course, when medical professionals discover a technology capable of producing customized, organic forms with some degree of precision, they decide to manufacture some human organs. It’s only natural.

Currently, bioprinting is used to manufacture relatively simple human tissue, like cartilage or skin, and mostly for research purposes. In the near future, though, more complex structures will likely be possible.

That said, bioprinting will likely run into many ethical hurdles in the next few years, so it won’t become commonplace for a while. Besides, the technology has a ways to catch up before it’s capable of making tissue that will be part of a living human being. In research labs, however, expect bioprinting to be commonplace for the manufacturing of standardized test samples.

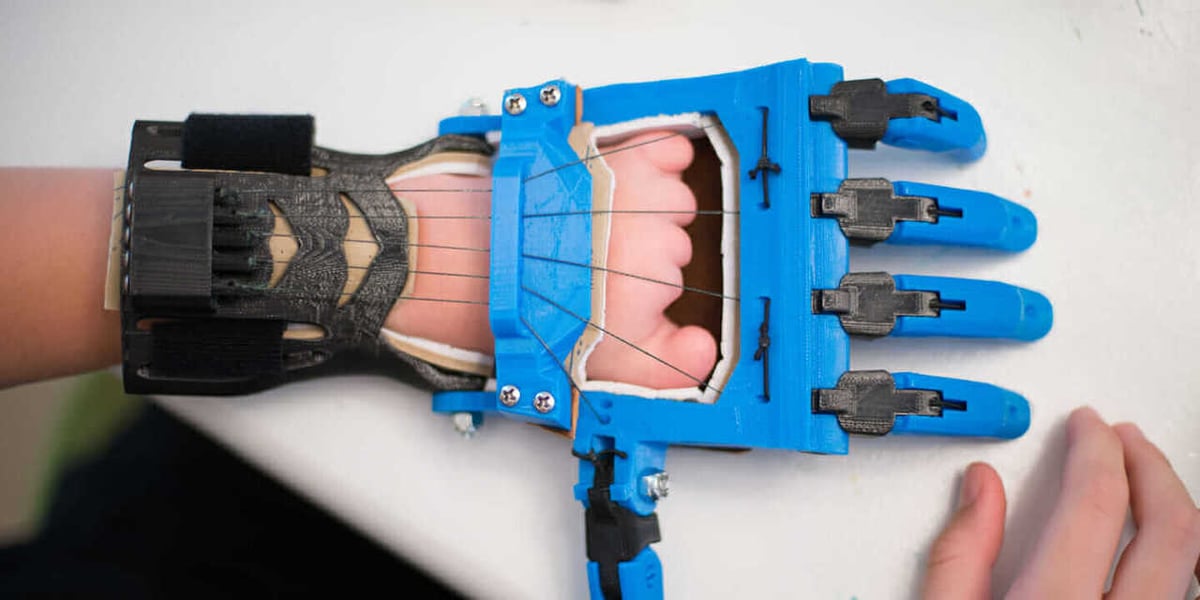

Prosthetics

Many professionals already use this technology to produce durable, customized parts, and prosthetics are a great example of such an application. Not only is production quick, but the designs can also be easily shared and tweaked to provide the best value to patients.

3D printed prosthetics are already pretty common, with projects like e-NABLE gaining traction around the globe. In the next few years, expect to see customized prosthetics in more professional use cases, like the Paralympics.

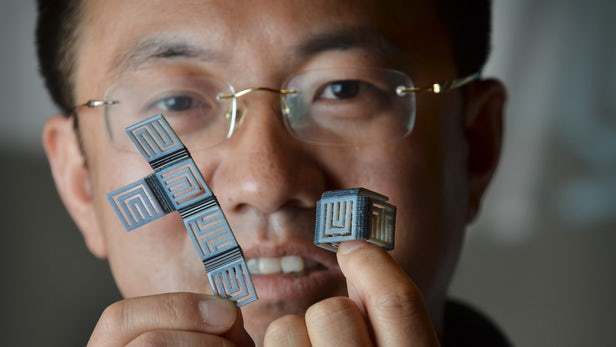

Drugs

Recently, scientists have designed and distributed compact rigs that can manufacture a single type of drug, which would create a distributed production scenario. Technically, in this case, the drugs themselves wouldn’t be 3D printed, per se. What we’re talking about here are “3D printed chemical reaction vessels”, which are responsible for making the drugs. This type of apparatus is called “reactionware” by some researchers.

The benefit of such a setup is twofold:

- Protection against counterfeiting: When reactionware produces legitimate drugs that are widely distributed, genuine drugs become easier to produce. As a result, counterfeit drug producers, who replace active elements in medicine with inert or dangerous substances to make a profit, will find it more difficult to take advantage of shortages in supply. There’s also a technological check in place with the reactionware approach: Each rig can only produce the drug it was designed for, thus it cannot be misused.

- Cost savings: Drugs that are used less often regularly face supply shortages. The current methods of mass-producing medicine have no economic incentive to produce small batches of drugs on-demand. Reactionware will address this problem because the apparatus to produce the drug on-demand will be more widely distributed, enabling more people and hospitals to produce medicine as they require it.

This approach to 3D printing medicine, however, might face some regulatory hurdles, as well, since the FDA is involved and making drugs for human consumption is a high-stakes use case. In addition, the equipment needed to produce reactionware must adhere to a high standard of accuracy and consistency, which limits accessibility.

More Drugs

Of course, we can’t really discuss 3D printed drugs without talking about drugs that are actually 3D printed, because there’s progress on that front too. The gist of it is that researchers are currently trying to fabricate consumable medicine using a number of technologies like SLA, SLS, and inkjet printing.

Once again, customization is the main benefit that comes with 3D printing medicine. This could include integrating multiple patient-specific drugs into a single form as well as adjusting the rates at which various medications dissolve.

The landscape of 3D printed drugs as of 2019, however, is mostly composed of research institutions and start-ups. We can reasonably predict that it will take a while longer for 3D printing to revolutionize this sector compared to others. Nevertheless, expect many proof-of-concept breakthroughs and a gradual inching of regulators within the next ten years.

Case Studies: Architecture and Construction

The main benefits of 3D printing in this field are enhanced modeling phases and cheaper projects.

Sophisticated Models

Architects periodically produce scale models to communicate their visions to colleagues and clients, and 3D printing is a prime technology for this use case. There’s no doubt that, as the technology becomes cheaper and more common, the benefits that 3D printing bring to the architectural modeling process will only increase.

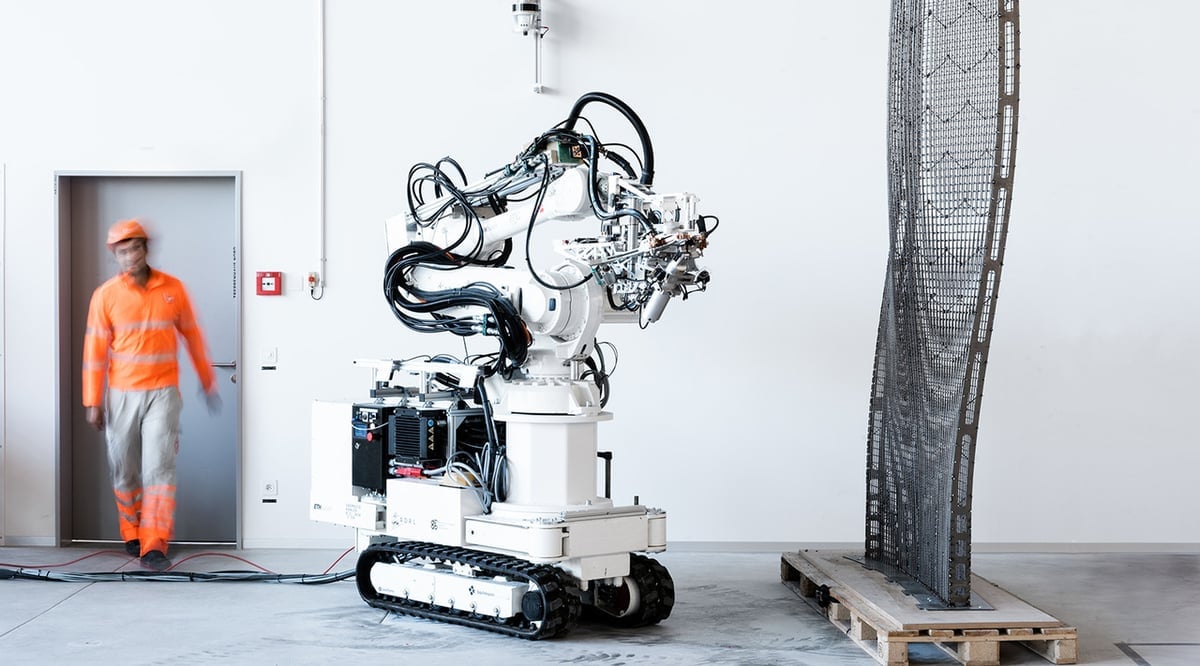

Fast, Efficient Development

Entire homes, livable and human-sized, are already being 3D printed. Here, the key technology is concrete 3D printing, a process in which large nozzles squirt out your future 2-bedroom bungalow, layer-by-layer. It’s so marvelous, you almost have to see it for yourself to believe it. And to help you visualize how much 3D printing will disrupt construction, we’ve compiled a list of quite a few 3D printed buildings.

The benefit of this new construction technology in developing regions of the world also cannot be understated. Homes that are quick and relatively easy to “manufacture” onsite are immensely helpful for emergency relief efforts and temporary housing demand surges in times of crisis. Some companies are investing heavily in exploring this particular application of 3D printing, with varying degree of success.

Complex Designs to Order

Several fascinating 3D printed homes already exist. Most of their structures, with the exception of the windows and smaller fixtures, of course, were squirted out of a nozzle in semi-liquid form.

In the next couple of decades, expect architects to continue experimenting with this new construction method as the technology becomes more mainstream. Watch out for layer lines in the walls of your next AirBnB…

Case Studies: Automotive and Aerospace

Modular Vehicles

The automotive industry isn’t one to sleep on new technology. 3D printing is used rather widely in the industry, already.

We summarized the most interesting developments in another article, but the short of it is that 3D printing is utilized heavily in the design phase (prototyping, product development), assembly (printed jigs for hand-assembly), and even end-user components (brake pads, brackets, wheels). The specific 3D printing technologies used include metal 3D printing and even FDM for less mission-critical jigs.

The production of functional parts with decent strength is already possible using 3D printers today, so we can only imagine the array of on-demand supply chains that will be established in the future. Keep an eye out for customizable cars!

The Final Frontier

The International Space Station orbits the earth, housing a few human astronauts, countless experiments, and a 3D printer. The specially-made machine produces tools that would be expensive and risky to transport from Earth. Other current developments, however, point to even more value 3D printing can add to space exploration.

As for professions on the planet, 3D printing has found its way into some metal shops that use it for the casting of small-batch prototypes before investing in traditional tooling to produce the final components requested by clients.

But perhaps the most ambitious use case of 3D printing in aerospace is rocket engines. Aerospace startup Relativity Space is in the process of testing a rocket engine 3D printed with aluminum, as we noted in a previous article. This application would make rocket construction and operation cheaper, which helps us all because cost is currently a high barrier of entry for that industry.

The Big, Fat Caveats

Having seen a few industries that stand to benefit a great deal from the spread of 3D printing, let’s return to the discussion on democratization.

The Possibility Ceiling

An important caveat to this democratization hypothesis: Though the power to make more things will land in the hands of more people, that doesn’t mean you’ll be able to print your own pet poodle from a packet of gelatin you get from the grocery store.

To build off our Internet analogy, just as you need an internet connection and some decent bandwidth to stream a movie, there are limitations to what 3D printing will be capable of in the next few years. Don’t expect the fabrication of living organisms, either for pets or humans, to be possible anytime soon.

Regulation

Of course, someone will stop you if you’re attempting to 3D print weapons, just as they have in the past. The power to make things will be distributed, but keep in mind that the liberty to make certain items will still be restricted.

Talent

Finally, there’s the talent barrier; just because you buy a machine that can produce designer footwear, doesn’t mean you will actually produce designer footwear. After all, it needs to be designed by someone with the right talent.

Despite this, one thing is certain: The production of many goods, previously impossible on such a personal scale, will be made possible.

A Matter of Time

Like many things, the mass democratization of 3D printing is coming, it’s just a matter of time. The process has already begun, with enthusiasts and early adopters already dabbling in the growing consumer 3D printing industry.

The Pokémon planters and the geometric pencil holders we download from Thingiverse are just the beginning. As 3D printing becomes more distributed and potent, new opportunities for innovation will arise.

Feature image source: Formlabs