This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Start Your...

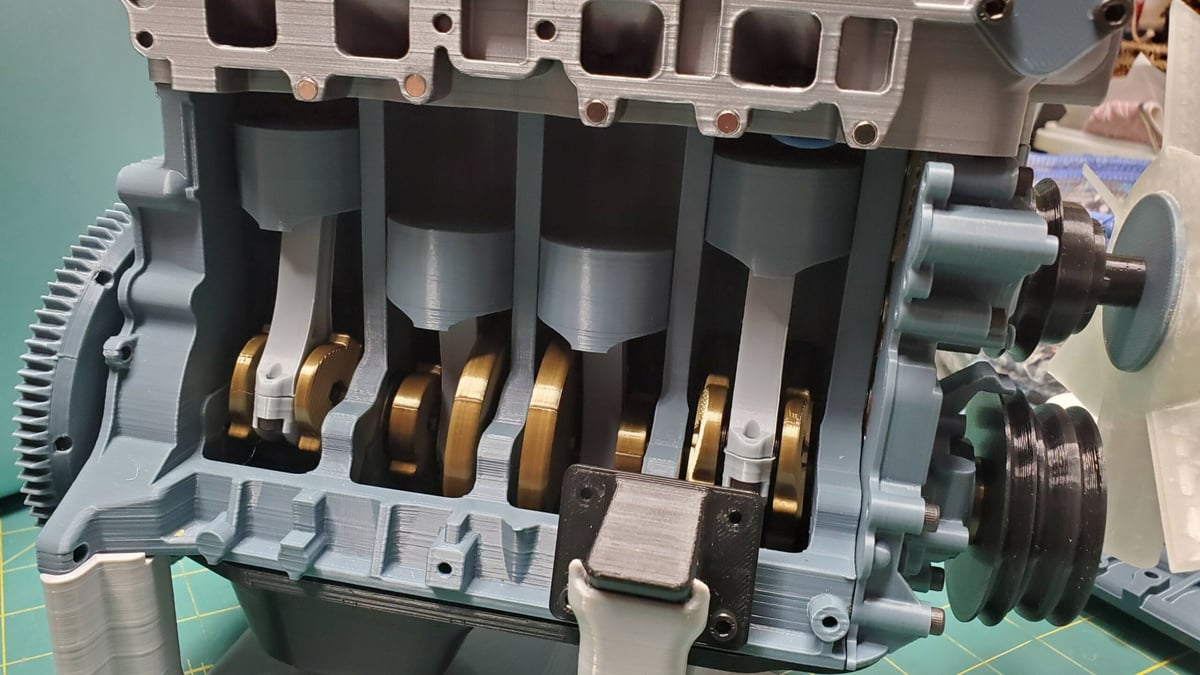

The Most Advanced 3D Printed Engines in 2024

3D printed engines require plenty of knowledge and engineering skills. Check out our list of the most advanced 3D printed engines.

Advertisement

Advertisement