Filament is the fuel of FDM 3D printers, and today, there are thousands of different filaments available – each made with slightly different materials and additives. But one thing they all share is how they were made: with a filament extruder.

Filament extruders, in the context of filament production, aren’t the same as the extruder assembly on FDM 3D printers. Instead, they’re devices that melt granulated material pellets and push the molten plastic through a nozzle, creating the string-like form of 3D printing filament.

Just like any production machine, filament extruders can vary in size, scale, and features. The extruders used by large-scale filament manufacturers are typically much larger, faster, and more expensive than consumer-grade options. In fact, the latter represents a recent development in the 3D printing space.

Filament extruders enable enthusiasts to make their own filament or venture into small-scale filament manufacturing. Some are even marketed as a means of recycling personal plastic waste. In this article, we’ll be going over the best filament extruders that require minimal assembly and are available to buy. Before we introduce the extruders, though, let’s briefly walk through how these machines actually work.

How Filament Is Made

As we mentioned previously, filament extruders melt plastic pellets and extrude them in the form of a strand. The filament production process, however, is a bit more complicated than just melting and extruding.

First, you have to get pellets of a certain thermoplastic material. The composition of the pellets used in the filament production process must be the same throughout; otherwise, the manufactured filament might not print consistently, compromising print quality.

With the pure pellets in hand, you then load them into the hopper (or intake) mechanism of a filament extruder. On most consumer-grade filament extruders, the hopper is simply a vertically-oriented, hollow container with an open top and bottom so you can continuously add more pellets as the machine produces more filament.

Once the pellets fall into the hopper, the bottom-most ones will be drawn into a rotating screw, similar in shape to an auger bit. This screw is used to keep the flow of pellets consistent and prevent any jams.

To melt the pellets, the screw usually enters a heating zone (or a few), where heating elements are used to melt the pellets. The screw continues to rotate, eventually pushing the molten plastic out of a precisely-machine nozzle, which gives the plastic its string-like filament form.

This is usually the end of the line for most consumer-level filament extruders. However, depending on the machine and its add-ons, there might also be some form of cooling mechanism that rapidly cools the plastic to solidify its form – ensuring tight diameter tolerance. Some extruders even have a spooling mechanism to wrap the final strands around a spool!

Considerations

If you want to start making your own filaments, it’s important to consider some factors when comparing different types of products. Here are a couple of the most important ones.

Speed

A key characteristic of a filament extruder is how fast it can produce filament. Of course, the faster an extruder can pump out a spool of filament, the better! You can usually find the typical speed of a filament extruder in the description of the machine, but it will vary depending on the desired quality and the material of the filament being made.

Supported Materials

Another important consideration is material compatibility. Not every filament extruder can work with any material. The machine’s maximum heating temperature will drive what materials can be used, but other factors – cooling capabilities, for example – can also have an impact. Most filament extruders will be able to handle ABS and PLA pellets, though, which is nice as these are two of the most popular filament materials.

With both of these considerations in mind, let’s check out the list!

Wellzoom Pellet Extruder

Wellzoom is a Chinese developer of 3D printing-focused filament extruders and extruder accessories. Its B2 Desktop Extruder is a pre-assembled filament extruder that only costs around $600.

According to Wellzoom, the B2 can reach 300 °C, meaning it’s capable of working with a fairly wide range of materials. The company also lists the B2 as having a temperature variance of just 1 °C. Despite the machine’s capabilities on paper, it’s important to note that reviewers have experienced issues with its heating system, resulting in high diameter variation and low-quality filament.

A further statement from Wellzoom is that the B2 has an extrusion rate of around 250-650 mm per minute, but again, reviews tell a different story, indicating that the machine tops out closer to 415 mm per minute. Regardless, even 650 mm per minute would be pretty slow for an extruder, equating to around a kilogram of filament every 10 hours.

Despite lacking some production power, the B2 has many good visual and operating features. The extruder comes in a fairly well-designed and clean-looking orange body, with an integrated hopper. Although, this hopper isn’t very large, so you may have to refill the device frequently.

- Speed: ~1 kg per 10 hours

- Supported materials: PLA, wood-infused PLA, ABS, and more

- Difficulty: Easy

- Price: ~$680

Filabot EX2

Filabot is a developer of filament production machinery, including on-printer pellet extruders, spoolers, and filament extruders. The Filabot EX2 is the company’s least expensive filament extruder, costing about $2,850 – a good deal less than the more advanced EX6 filament extruder, which costs just over $15,000.

The Filabot EX2 is a well-built, pre-assembled machine that gives you a good level of control over filament production. It features an assortment of switches, knobs, and buttons that let you adjust the extruder’s speed, temperature, and power.

The machine has an impressive maximum temperature of 450 °C, meaning you can extrude all sorts of materials, including high-temperature options such as polycarbonate and even PEEK. And if you’re looking to print with more traditional plastics, such as PLA or ABS, the high maximum temperature means you can extrude these lower-temperature materials even faster.

According to Filabot, this filament extruder can produce filaments with diameter tolerances of ±0.05 mm. The output nozzle on this machine is also replaceable, and you can use different sizes to produce different-diameter filaments.

Along with being accurate, the EX2 is also fast, capable of producing a kilogram of filament in around an hour. Unfortunately, the pellet hopper on this machine isn’t huge, so it’s unlikely that you can produce multiple kilograms of filament without having to refill the hopper during extrusion.

For those of you looking for a more professional solution, the EX6 model features an improved hopper design, separate heat zones, and faster speeds. According to the company, around 4.5 kg of filament can be extruded per hour, depending on the material. However, keep in mind that all of those features and more will set you back five figures.

- Speed: ~1 kg per hour

- Supported materials: PLA, ABS, PC, PEEK, and more

- Difficulty: Easy

- Price: ~$2,500

FIXstruder

FIXstruder is a European company that specializes in making filament extruders, and they offer a few models, including the FIXstruder Mini, Mega, and XL. The newest extruder in their assortment is the FIXstruder FB v.2.0, and it features a feedback function that monitors and self-corrects the filament diameter during extrusion. The proper functioning of this feature, however, requires a winding device along with the extruder.

The FIXstruder FB is a very well-built machine with a robust frame. It’s fitted with a small LED screen and various control knobs. A motor control panel alerts users whether motor overload protection has been triggered and includes an emergency stop switch.

As for its extrusion capabilities, the FIXstruder can heat up to 300 °C with its 145-W heater. The extruder can handle PLA, ABS, and HIPS pellets and comes with both a 1.75-mm and 2-mm output nozzle. According to the manufacturer, it can achieve speeds as high as 1.5 meters per minute, which equates to 1 kilogram of filament in just under 4 hours. However, certain materials may require a slower extrusion speed in order to ensure quality results.

The XL model (currently in version 1.1) boasts similar extrusion performance as the FB, but it lacks the feedback function and has a different control interface. The Mega features two independently controlled heaters and performs similarly to the FB and XL models, but the Mini has a slower extrusion rate given its 70-W heater power. Save for the FB, all of the other models come in 110-V and 220-V variations.

- Speed: ~1 kg per 3-4 hours

- Supported materials: ABS, PLA, HIPS

- Difficulty: Easy

- Price: ~$330-$585 depending on the model

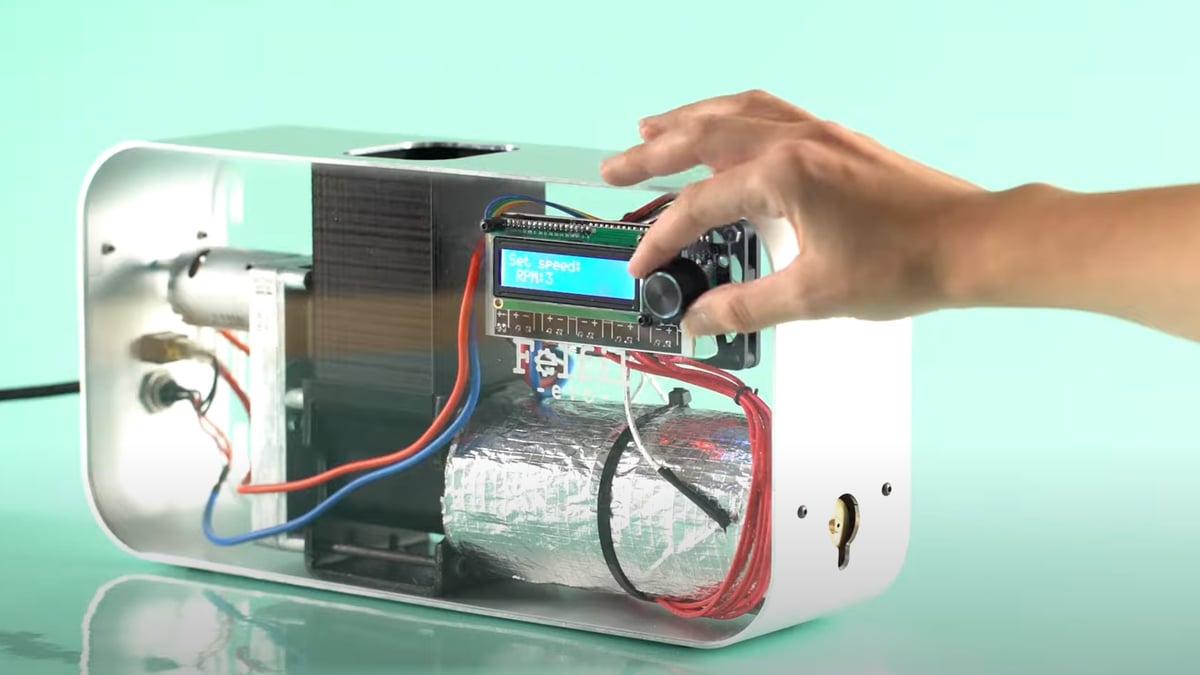

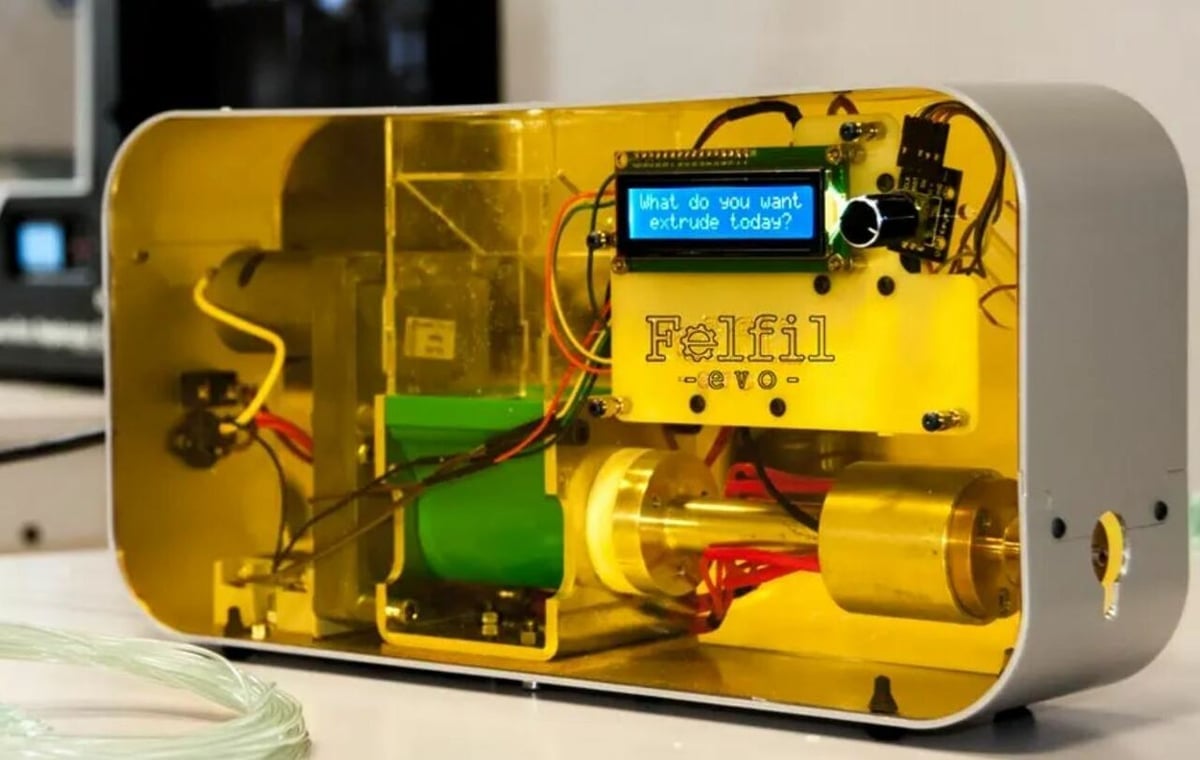

Felfil Evo

The Evo is a purchasable open-source filament extruder made by Felfil, a company that specializes in filament production equipment. The machine comes as a complete kit, fully assembled, or bundled with a shredder and filament spooler for a full extrusion system.

The extruder has three heating zones and a maximum temperature of 250 °C, meaning you should be able to produce most standard 3D printing materials, including PLA, ABS, and PETG. It also comes with two different output extruder nozzles that allow you to produce either 1.75- or 2.85-mm diameter filament.

Users are able to adjust the Evo’s gearmotor speed anywhere between 0 and 9 rpm. Most filaments are able to be extruded in the 5- to 8-rpm range. According to the manufacturer, the Evo’s extrusion speed is about 100 to 150 g per hour.

Of course, the assembly difficulty depends on if you get the pre-assembled or kit version for the machine. Felfil has video tutorials as well as a detailed step-by-step guide for assembling the extruder, so you should be all set if you choose to take the kit route. Also, the company maintains a small repository of 3D printable upgrades for all three parts of the extrusion system.

- Approximate speed: ~1 kg per 7-10 hours

- Supported materials: PLA, ABS, PETG, and more

- Difficulty: Easy to medium

- Price: ~$715 for complete kit, ~$825 assembled, $2,640-$2,915 for full extrusion system

RobotDigg SJ25

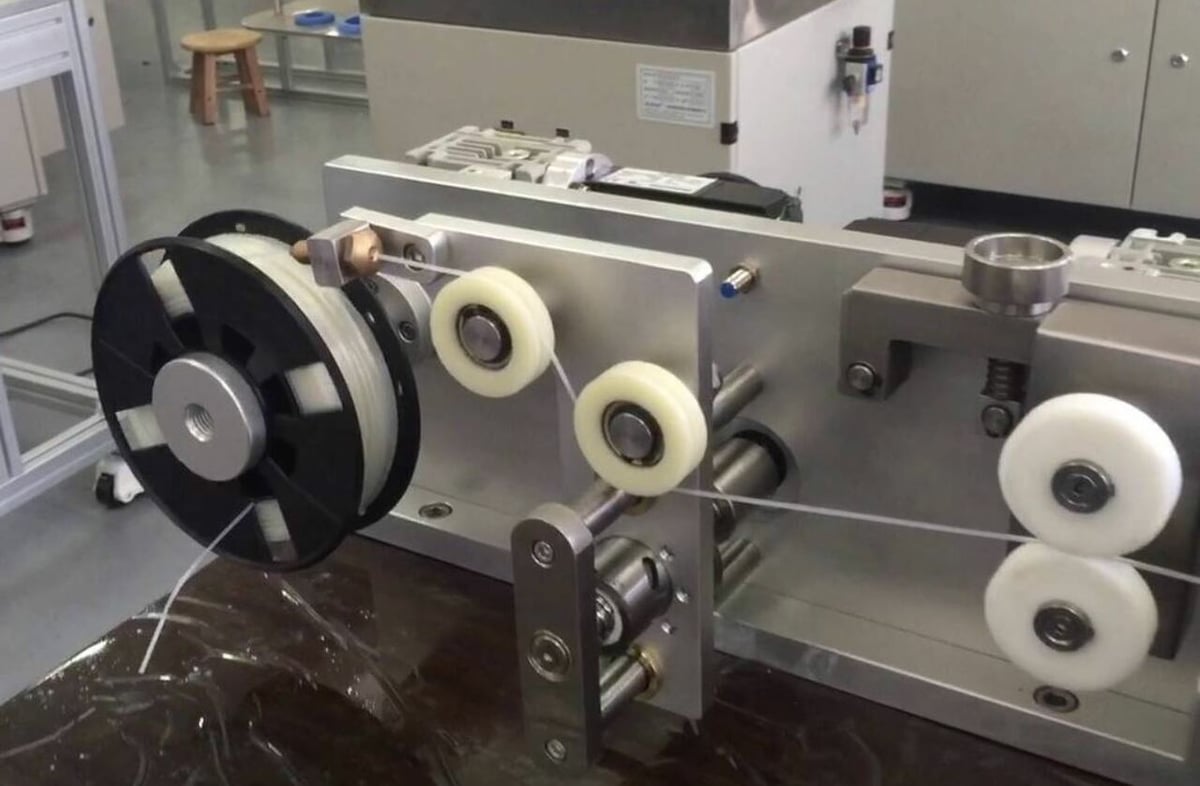

RobotDigg is a company that makes all sorts of electronics, from power supplies to filament extruders. The RobotDigg SJ25 is a filament extruder that, like the FIXstruder, has an all-metal body.

While not much information has been provided about the RobotDigg SJ25, the manufacturer has stated that the device can produce filament as fast as 2 kg per hour. Of course, this extrusion speed is probably on the higher end of the spectrum of the SJ25’s speed settings, but it’s still very impressive.

RobotDigg also mentioned that the SJ25 can produce a variety of different filament materials, including PLA, ABS, PETG, and more. Though they didn’t provide the maximum temperature of the SJ25, it’s likely to be at least 300 °C, given the compatible materials and maximum speed.

To use the SJ25, there’s a dial for adjusting the temperature, as well as a few buttons and an LCD panel. And the hopper, where you insert the plastic pellets, is pretty big, so you can make a lot of filament without having to reload the device.

- Speed: ~1 kg per 0.5 hours

- Supported materials: PLA, ABS, PETG

- Difficulty: Medium

- Price: ~$1,000

Noztek Pro Desktop Extruder

Noztek is another company centered around 3D printing filament production, and the Pro Desktop extruder is a great machine that costs less than many other pre-assembled options. It’s considered a plug-and-play extruder and not just because it looks cool with its slick red sheet metal frame that hides the underlying complexity – the company boasts that you can set this machine up and start extruding filament in only 15 minutes.

The base model of the Noztek Pro can achieve a maximum temperature of 300 °C, but the Pro HT model gives the temperature a boost up to 600 °C. If you want to produce multiple spools of filament, you can upgrade your Pro Desktop extruder with Noztek’s extended vertical hopper and filament winder to store more pellets and spool the filament as it’s produced.

Yet, one of the best parts of this machine is its precision. The Noztek Pro can maintain a diameter tolerance of just ±0.04 mm – better than many filaments made from more expensive professional machines. You can also make filaments in both 1.75- and 2.85-mm diameters using Noztek’s swappable output nozzles.

Like the other manufacturers on this list, Noztek produces multiple filament extruder models. The most expensive ones, the Xcalibur (costing around $10,600) and FusionX (costing around $30,000), both allow for more control thanks to independently controlled heater bands. The former is advertised for big loads and produces around 2 kg of filament per hour, while the latter is specialized for research and development purposes. There’s also a model with a touchscreen display, a compact desktop footprint, as well as new built-in safety features – all of which would set you back about a grand more than the base model of the Noztek Pro.

- Speed: ~1 kg per 2 hours

- Supported materials: PLA, ABS, PP, and more

- Difficulty: Easy

- Price: ~$1,660-$2,440

3devo Precision

3devo is a professional manufacturer of high-end, purchasable filament extruders. The company sells four different filament extruders across its Precision and Composer extruder series, which are intended for filament production and material testing, respectively.

Here, we’ll focus on the Precision 350 and 450 models, as these are the more likely candidates for a filament extruder if you’re focused on making basic filament fast. But don’t worry because we’ll also cover 3devo’s Composer 350 and 450 extruders in the next section.

First off, the two extruders in the 3devo Precision series are equipped with a high-flow extruder screw, which is why we consider them better suited for basic filament production. Additionally, the Precision 350 and 450 models are the more affordable options compared to the two extruders in 3devo’s Composer series. Still, “affordable” is a relative term – the company says prices begin at a little under $6,000, so it might only be ideal if you’re looking to produce and sell filament.

One thing that sets 3devo’s extruders apart from the competition is the exterior. The Precision extruders are undoubtedly one of the best-looking filament extruders around, with a well-organized design that hides the complex mechanisms for making filament.

And, if you’re wondering about the difference between the Precision 350 and 450, it’s all in their temperature limits. The 350 model has a maximum extruding temperature of 350 °C, which is hot enough to produce a wide range of materials from PLA to nylon. And as you might have already guessed, the Precision 450 can reach 450 °C, enabling the production of an even wider range of filament materials, including PEEK, PEI, PSU, and PES.

The extruder uses four heating zones to produce filament as well as a filament diameter sensor with a precision of 43 microns. This makes the produced filament very precise, hence the naming of the two extruders. Plus, both products are very easy to use, with a filament spool holder on the machine that spools your filament after it’s made.

Although expensive, it’s important to remember that the Precision 350 and 450 extruders come pre-assembled, so that’s a nice plus. Moreover, the company provides detailed guidance on how to get the most out of your 3devo filament extruders. They’ve even launched a series of training courses on the ins and outs of filament extrusion.

- Speed: ~1 kg per 2-3 hours

- Supported materials: PLA, ABS, PC, nylon, and more

- Difficulty: Easy

- Price: Starting at ~$6,400; ask for a quote

3devo Composer

3devo‘s Composer series also comes in 350 and 450 models. With a familiar aluminum frame, four independent heating zones, and diameter accuracy, the machines are similar to the Precision series. The model names also align with their maximum heating temperatures: 350 °C and 450 °C, respectively.

What makes the Composer series special is the machines’ ability to mix different materials and additives for making custom filament blends without clogging. If you’re wondering what prevents you from doing this with an extruder from the Precision series, the answer lies with the extrusion screw in the machine. According to 3devo, extruders in the Composer series are equipped with a “material mixing screw”, which isn’t as likely to clog when mixing various materials and additives.

Of course, the ability to make custom filaments comes at a cost. The Composer models are priced higher than their Precision series counterparts, so this purchase might only make sense if you’re interested in selling some of the filament you produce.

- Speed: ~1 kg per 2-3 hours

- Supported materials: PLA, ABS, PC, nylon, and more

- Difficulty: Medium (depends on what blends you make)

- Price: Ask for a quote

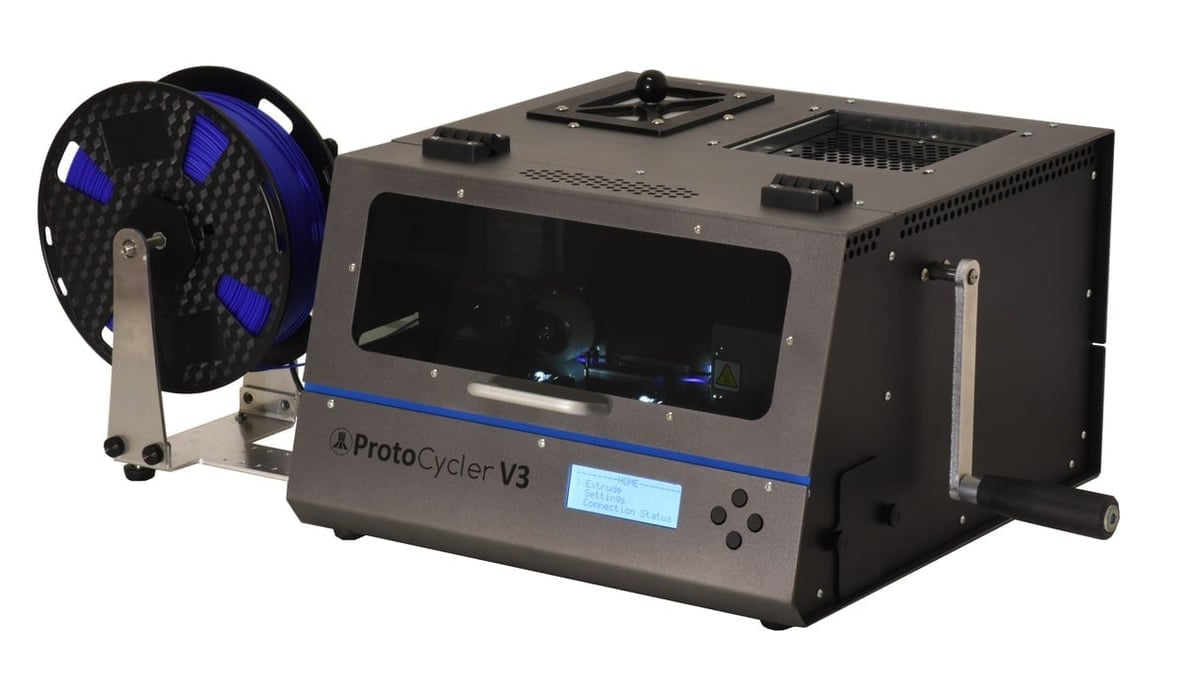

ReDeTec ProtoCycler+

ReDeTec is a company that focuses on developing quality supplies for 3D filament creation. Its ProtoCycler+ was brought to market thanks to a successful IndieGoGo campaign in 2014, and the extruder is now in its third version.

The extruder is fully assembled and has some great features. First off, it can produce filament with a diameter tolerance of ±0.05 mm, the same as most consumer printing filaments. There’s also a model that includes an integrated part grinder. This allows you to deposit old prints of the same material into the machine to turn them into small pellets that can be used to make filament. On top of a shredding system, the ProtoCycler+ also has a spooling system.

ReDeTec states that the ProtoCycler+ can make PLA, ABS, PETG, HIPS, nylon, and over 10 other materials using the company’s patented MixFlow technology. Just note that this extruder can only reach 250 °C, which might mean that you can only produce higher-temperature materials such as nylon at a very slow speed.

As promising as the ProtoCycler+ is, early production and customer service hiccups have resulted in lingering animosity among some makers. It’s not hard to find posts on various community forums from people who were or still are waiting for the fulfillment of their initial campaign backing rewards and pre-orders. Some have even filed complaints with the Better Business Bureau, while others launched a petition in early 2020. Before placing an order, you may want to get assurances on the delivery timeline.

- Speed: ~1 kg per 2 hours

- Supported materials: PLA, ABS, nylon 12, and more

- Difficulty: Easy

- Price: ~$4,000 for base model, ~$6,000 with grinder

License: The text of "The Best Filament Extruders of 2023" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.