Founded in 2019, Bambu Lab is a relatively young company that took the 3D printing community by storm in 2022 with the release of their X1 Carbon 3D printer, a printer designed for “prosumers”. The X1 Carbon packs fast print speeds, high reliability, and the AMS (Automatic Material System) into a neat form factor.

Since 2019, Bambu Lab has continued to innovate and release more 3D printers, including the P1S and P1P. In late 2023, they launched a new range of A-series printers, including the A1 Mini, followed by the A1. These printers are both bed-slingers aimed more at casual consumers than the professional consumers targeted by the X1 and P1 series.

The A1 Mini is a printer designed with beginners in mind, providing a small, portable machine that packs reliability and high quality into a small form factor. On the other hand, the A1 is a larger and more expensive printer targeted at makers looking to print bigger and more functional parts in a wider range of materials.

In this article, we’ll take a look at each of these printers, comparing their similarities and differences in terms of design, software, price, and more. Let’s get started!

At a Glance

Similarities

The A1 and A1 Mini offer a range of features. In this section, we’ll delve into the shared aspects of both printers.

Bed Leveling

The A1 and Ai Mini both feature automatic bed leveling, using a strain gauge sensor in the extruder assembly that calculates the height of the bed based on when the nozzle touches it in the calibration sequence. The calibration sequence can be triggered with the single press of a button, enabling fast and easy automatic bed leveling.

Extrusion

Both the A1 and the A1 Mini use the same easily swappable direct extruder, capable of reaching 300 °C. This lets you print common materials, such as PETG, PLA, ABS, Nylon, and ASA. In addition, both printers come fitted with a filament runout sensor. The extruder also has hardened steel gears and comes equipped with a filament cutter for filament unloading and switching.

This is a very capable extrusion system, although it’s not designed to print abrasive materials, as the stainless steel nozzle will wear down quickly under abrasive loads. You’ll need to upgrade the stock nozzle to a hardened steel one if you wish to print abrasive materials like glow-in-the-dark or carbon fiber-based filaments.

It’s also worth noting that, while the AMS Lite is compatible with both the A1 and A1 Mini, it’ll be necessary to tweak the PTFE tube for the latter as the overall unit matches the former’s lengthier measurements.

Mainboard

Both printers use the same custom proprietary mainboard and stepper drivers from Bambu Lab. The mainboard on both printers includes a dual-core processor, Wi-Fi, RF, and Bluetooth capabilities, as well as dual- and single-core MCUs. These enable you to connect directly to the printer wirelessly and to stream a camera feed straight to your phone or desktop.

The powerful mainboard provides dynamic flow control and calibration, resonance compensation, and active motor noise cancellation. This ensures a constant rate of filament extrusion, a reduction in minor print inaccuracies, and the suppression of overall printer noise, respectively.

UI

Both printers feature a full-color touchscreen LCD display: 3.5-inch for the the A1 and 2.4-inch for the A1 Mini. This screen displays a helpful print status and control menu that enables modification of print settings such as hot end or bed temperatures while printing. The UI also provides quick, easy-to-access shortcuts for bed leveling and enables the use of the AMS Lite.

From here, you can also use Bambu Lab’s handy remote printing service by scanning a barcode with your phone and downloading their mobile app, called Bambu Handy. This enables the syncing of printer settings between your phone and Bambu Studio, from either of which prints can be uploaded. The interface provides a simple and user-friendly introduction to the printer through pages that guide you through the setup and calibration process.

Software

Both the A1 and A1 Mini come with Bambu Studio, the company’s feature-rich slicing software. This cross-platform slicer is based on PrusaSlicer and supports multiple printer profiles and remote printing on network-connected Bambu Lab printers, via a Bambu Lab account.

One unique feature Bambu Studio offers is multiple build plates, enabling you to plan future prints out in advance. It’s possible to add up to 36 plates to your build area. Other great features include the project-based workflow, custom filament profiles, and the Go Live function, which lets users stream their prints in action. Bambu Studio is required to access the full functionality of most Bambu Lab printers.

Differences

Although the A1 and A1 Mini have similar names, they do in fact feature significant differences in terms of their design and capabilities. In this section, we’ll discuss these key differences, covering aspects such as their respective design, build volume, build plate, and price.

Design

Both printers are bed-slingers, also known as Cartesian XZ-head motion systems, in which the bed moves along the Y-axis, the printhead moves along the X-axis, and then gantry containing the printhead moves vertically along a rail. However, the A1 Mini uses a cantilever-style structure, as opposed to the A1’s more classic design.

The use of only one support for the Z-axis could lead to vibration issues in the A1 Mini due to the lack of rigidity compared to the A1. However, the A1 Mini is reported to be surprisingly stable. Bambu Lab doesn’t recommend using an enclosure with either of these printers, although in theory enclosures for similarly-sized printers could be used.

It’s worth noting that, while both have cameras with similar specs that are meant to enable live streaming and to create time-lapse videos, the compatibility is specified for each machine, so they’re not interchangeable (something that’s worth keeping in mind if you need to replace it).

Both the A1 and A1 Mini have a modern and sleek grey aesthetic, matching that of other Bambu Lab printers such as the X1 Carbon. The optional AMS Lite system matches the color scheme and style of the printers, with an almost organic structure. While adding this system makes it possible to print beautiful, multicolor prints, it does massively increase the footprint of the printers, which is a major drawback if you’re looking to purchase an A1 Mini for its small form factor.

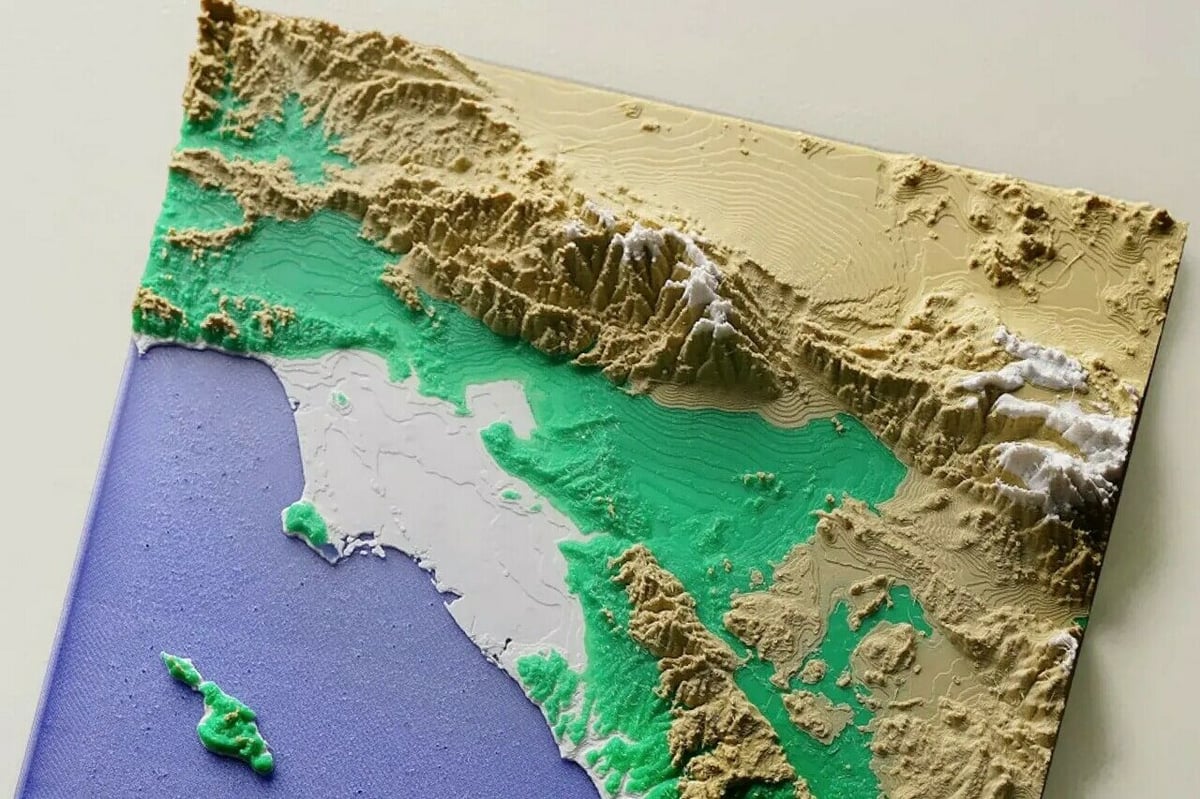

Build Volume

The main difference between these two printers is their build volume. At 256 x 256 x 256 mm, the A1 boasts a build volume larger than the average 3D printer in its weight class. This is slightly larger than the Prusa MK4, which is often considered a competitor. On the other hand, the A1 Mini has a smaller print bed, identical to that of the classic Prusa Mini+. This makes it better suited to smaller prints.

Although the larger build volume of the A1 enables the printing of multiple parts in one go or larger parts than the A1 Mini, this comes with the added drawback of a larger form factor. It takes up a much larger footprint, which could be problematic in some contexts.

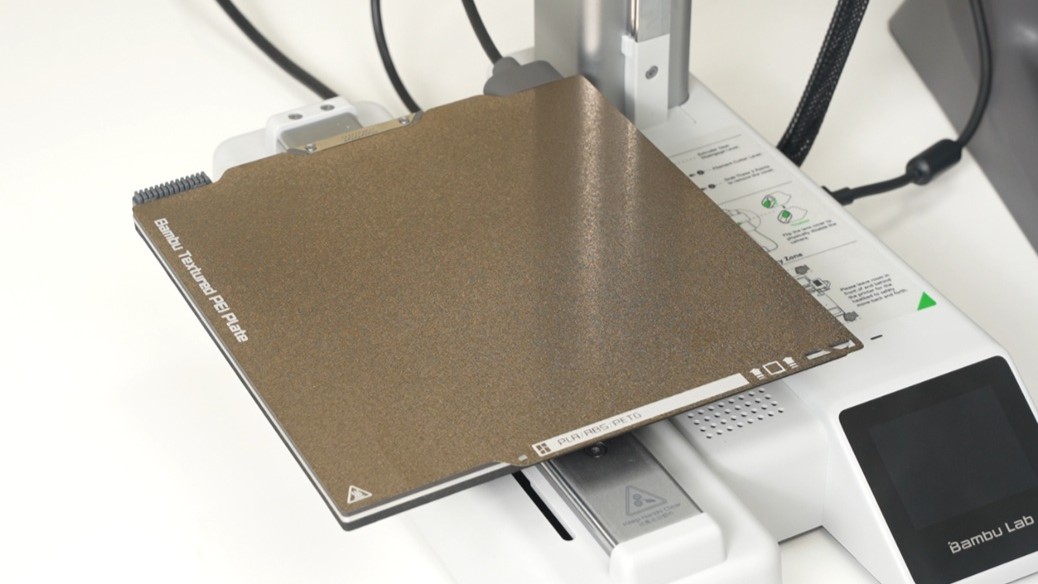

Build Plate

The A1 and A1 Mini are both shipped with a textured PEI build plate that provides excellent adhesion and an easy print-removal process, not to mention a wonderful textured surface finish on the bottom of prints. However, there are some downsides, too. The plate only provides adhesion when heated, and it’s difficult to clean and maintain.

In addition to the textured plate, both printers can be used with the official Bambu Lab smooth PEI build plate. Only the A1, however, is also compatible with their cool plate, which can enhance the print quality of lower-temperature materials, such as PLA and PVA.

Price

The A1 Mini undercuts the A1 by $100, coming in around $300 compared to the A1 at about $400. This makes the A1 Mini better for beginners or hobbyists who don’t require the A1’s additional features, such as a larger build volume, higher bed temperature, bigger screen size, and a more rigid structure – all of which contribute to the price jump. However, both printers are competitively priced compared to similarly-sized printers on the market but with the sophisticated features and user-friendliness that Bambu Lab is known for. Overall, both options are well worth the respective price tags.

The Verdict

Both the Bambu Lab A1 and A1 Mini are extremely capable printers. They’re well-suited to anyone who wants a plug-and-play experience with their printer as opposed to the hands-on tinkering experience that comes with printers like the Ender 3.

Replacement parts are extremely easy to install. For example, the Bambu Lab extruder assembly can be removed and installed quickly without additional tools. This extremely user-friendly process enables beginners to easily repair their printers without extensive knowledge of the sub-systems involved. For those looking to upgrade or modify their printers beyond their base capabilities, however, Bambu Lab’s proprietary ecosystem could limit the extent of modification, as it restricts the installation of third-party components.

The A1 comes at a higher price point than the A1 Mini, but it offers a higher bed temperature and larger build volume, making it more suited for makers who are looking to print larger parts. The more affordable A1 Mini is great for beginners looking to get started with 3D printing at a reasonable price all while still getting high-quality prints. That being said, their bed-slinger design imposes limits on speed, especially compared to more expensive CoreXY printers on the market, such as Bambu Lab’s X1 Carbon or Creality’s K1.

The choice between the A1 and A1 Mini ultimately comes down to your specific needs and preferences, as well as what types of models you’re planning to 3D print.

License: The text of "Bambu Lab A1 vs A1 Mini: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.