This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Space: The 3-Dimensional Frontier

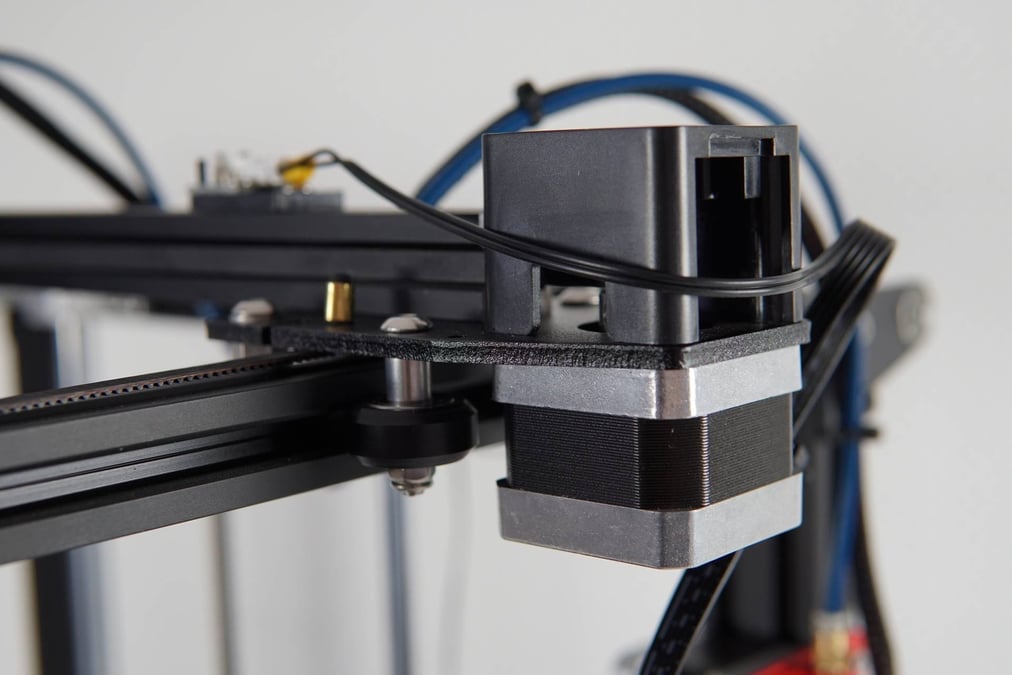

3D Printer Axis: The Basics Simply Explained

A 3D printer must move in three-dimensional space to create 3D objects. Read on to learn all about how 3D printer axis systems work.

Advertisement

Advertisement