It so happens that 3D printing is a wonderful application for the discipline of robotics as it provides designers with the freedom to add new functionality to their creations. That, and end users can customize a robot for their specific needs.

In this article, you’ll see some of the most impressive and advanced 3D printed robot projects from around the world. Ranging from humanoid to four-legged robots to even insectoid automatons, the field of robotics is booming thanks to additive manufacturing.

You’ll also find some more modest – yet still impressive – 3D printed robot projects, and many of these can be tried at home. You’ll need the right tools and bill of materials to make them, but the thing they all have in common is 3D printing.

If you see something you’d like to try but don’t have the means to do yourself, consider using a 3D printing service. Through Craftcloud by All3DP, you’re guaranteed to benefit from expert-level quality, so small details and tight tolerances shouldn’t be an issue.

All hail our new 3D printed robot overlords!

Humanoids

With robotics and 3D printing combined, people are pushing the boundaries of possibility every day. Humanoid robots are a great example of this.

Humanoid robots are designed to represent or mimic humans in some way, and people are working every day in developing new systems to get as close to reality as possible. These robots may be capable of walking, talking, gesturing, and more, and can be useful for many applications like medicine and caretaking.

Here, we’ve gathered the most advanced, most impressive 3D printed humanoid robots.

Ameca

Created by British company Engineered Arts and presented to the public for the first time in 2021, “Ameca” has surprised many people who did not believe that robots could express emotions like humans. In addition to realistic facial expressions and body movements, Ameca also has microphones, cameras, and speakers that allow for real-time interpersonal interaction.

Artificial intelligence, including OpenAI’s GPT-3, is used for facial recognition and verbal processing, giving the most realistic expressions and reactions achievable to date. Some parts of Ameca, such as the teeth and gums, were made using 3D printing, demonstrating how this technology can be part of future solutions.

Founder and CEO of Engineered Arts, Will Jackson, explains that the first thing you learn when doing something like this is that it will never be exactly the same as a human being. However, the key to getting as real as possible is in the smoothness and precision of organic movements. This includes physical motion, expressing emotions, and reacting to stimuli.

Ameca is currently available for rent and for sale with an estimated cost between $120,000 and $500,000 per unit. It ‘s currently a project dedicated to the educational sector, but the project’s authors emphasize that all of their robots are made with parts that can be easily replaced or improved. This is something very important as advancements are coming rapidly. One current challenge is developing precise hand movements to be able to produce drawings or writing with her hands. Have more questions? Maybe she can answer them for herself.

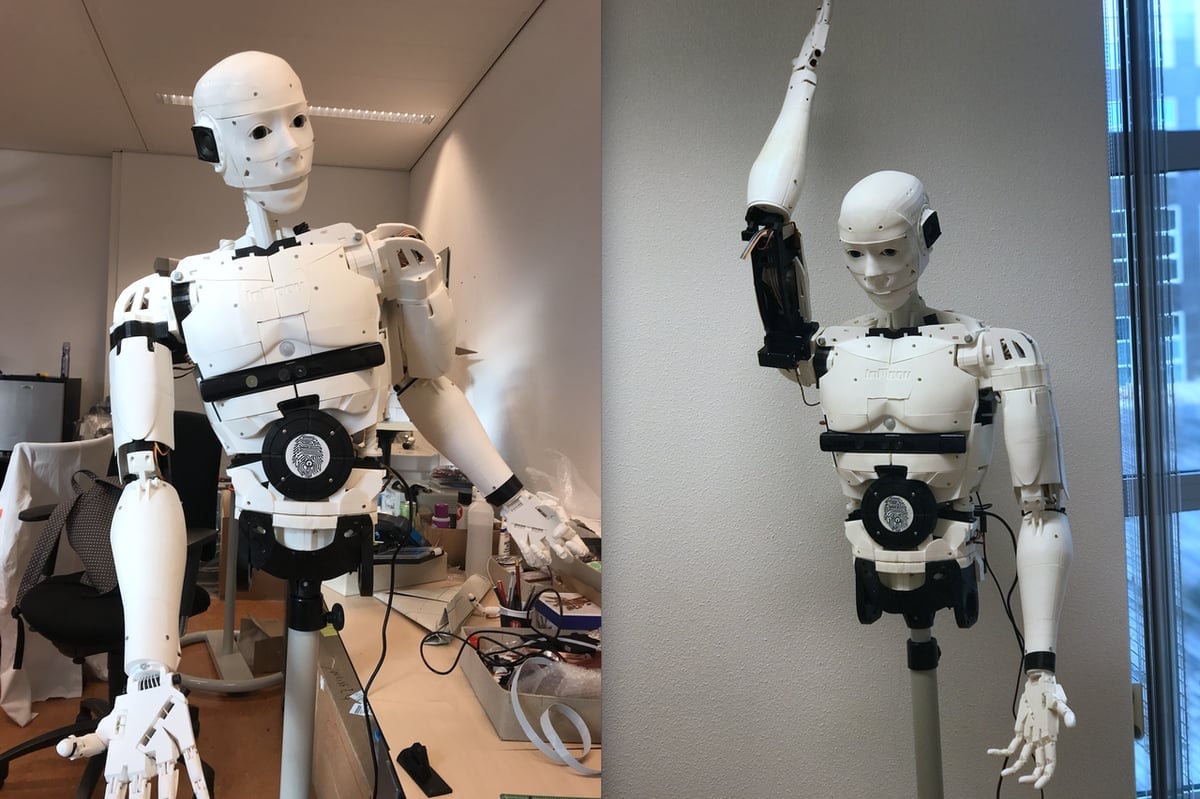

InMoov

InMoov is one of the oldest 3D printed robotics projects around. Created in 2012 by Gael Langevin, a French sculptor and designer, InMoov started as a prosthetic hand.

Now, it’s a life-size 3D printed robot. This automaton is a spectacular achievement, not just because of its size but also because of its fluid and graceful articulation, right down to its fingertips.

This is also an open-source project, envisioned as a development platform for students, makers, and academics. In fact, the hand carries the distinction of being the first open-source 3D printed hand prosthetic.

If you want to make InMoov yourself, you’ll need a desktop 3D printer with a build volume of at least 120 x 120 x 120 mm. You’ll also need Arduino Uno and Mega microcontroller boards, three servo motors (HK15298B, Hitec HS805BB, and MG996), and MyRobot Lab and python scripting software. The website has ample instructions and information, a blog, and an active maker community if you want to attempt the build yourself.

InMoov continues to be a favorite among makers all over the world and each year gains more capabilities, including the recent additions of a vision system and improved mechanics and legs. There’s even a world map that can connect you to InMoov builders from all over the globe.

Reachy

French company Pollen Robotics debuted its highly interactive, AI-powered robot Reachy in 2019. Reachy is a 3D printed robotic torso that’s adaptable enough to play Tic-Tac-Toe or serve coffee, all while looking pretty cute.

The antennae are animated, and its head moves with two “eyes” to help convey emotions. The arms have a wide range of motion, similar in size to an adult human’s, and are able to pick up objects as heavy as 500 grams. You can even use VR to teleoperate Reachy!

Every part of this robot is 3D printed, and Pollen Robotics has made Reachy’s design open source so that anyone can contribute to the development as it moves forward. The idea is for Reachy to be used in the customer service industry.

Reachy can be purchased in a few different configurations, starting with the basic model with one arm and no head all the way up to the advanced Reachy with a head and two arms. You can even choose the design of the shirt!

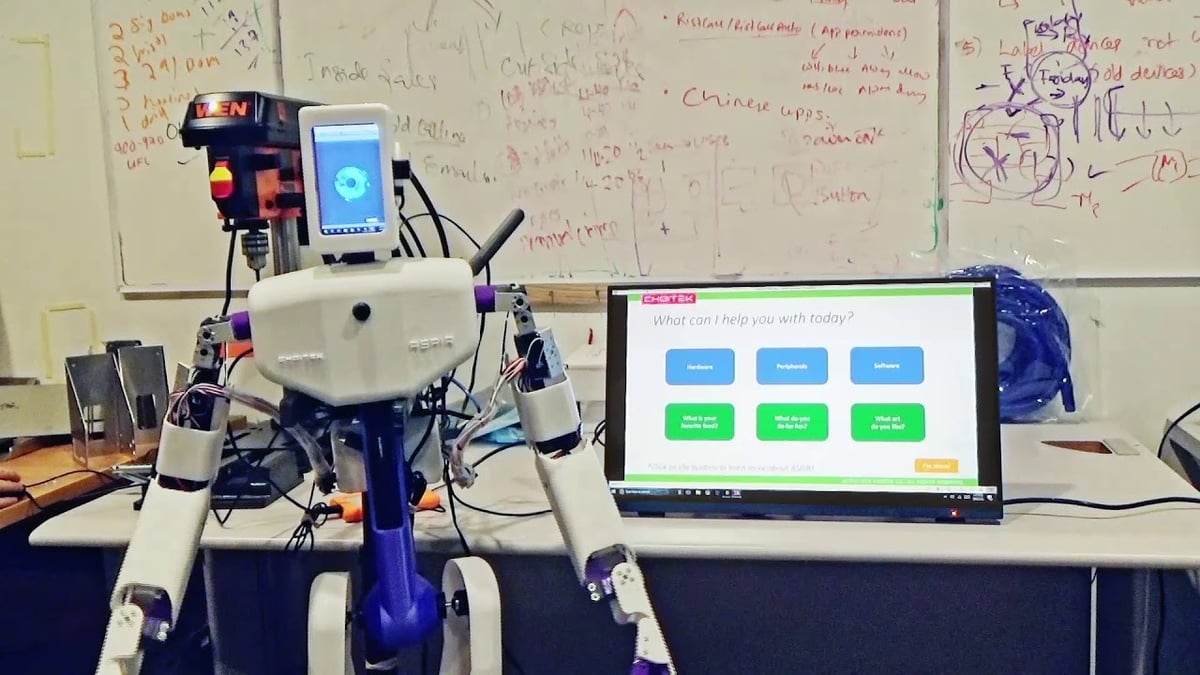

ASPIR V2

This is another open-source 3D printed robot, called ASPIR, which stands for “autonomous support and positive inspiration robot”.

ASPIR was first published in 2018 by John Choi and evolved from his 2015 “Halley Ambassador Robot”. A year after ASPIR, the second version came out called the ASPIR V2. At 30 pounds and 4 feet tall, this robot is child-sized and requires 22 motors to function.

ASPIR V2 has humanoid automation that’s highly maneuverable. It uses six supersize servos per leg, four high-torque standard servos for each arm, five metal-gear micro servos for each hand, and two additional standard servos for the head’s pan and tilt mechanisms.

Each of the 90 parts that make up its body is 3D printed and will take roughly 300 hours of printing time. If you want to try it for yourself, you’ll need the GitHub files, 5 kg of PLA, and a 3D printer with a build volume of at least 250 x 250 x 250 mm. You can find the full tutorial and materials list on Instructables.

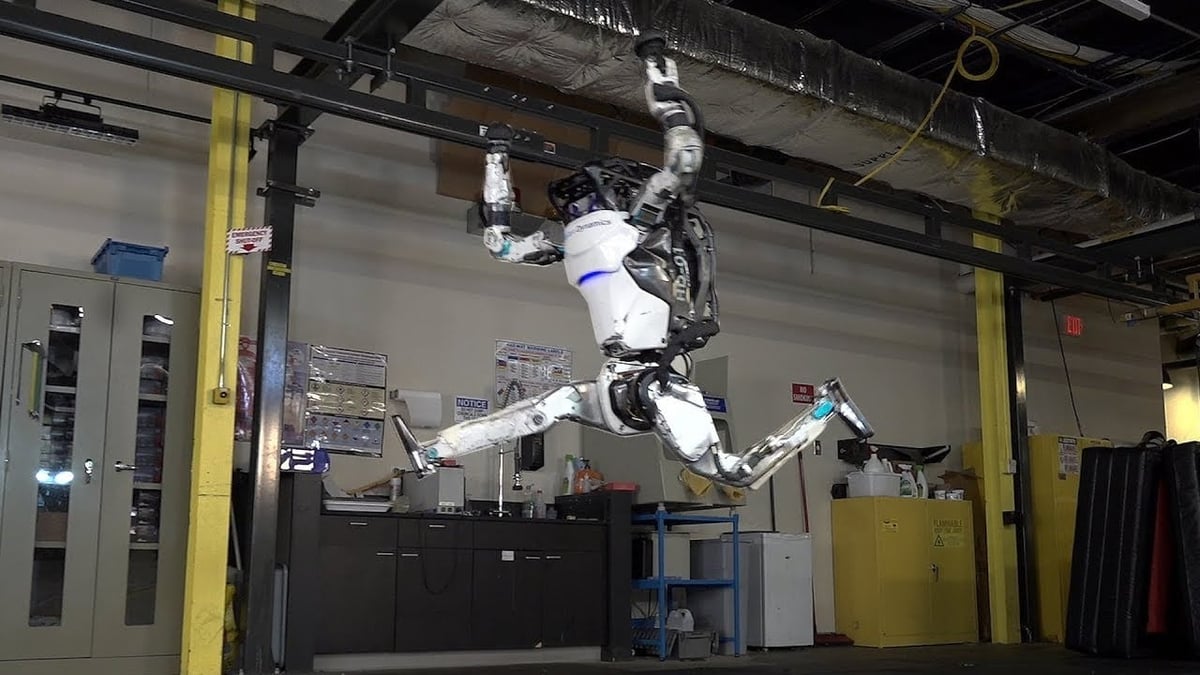

Atlas

It’s not a well-known fact, but one of the internet’s favorite robots is actually partially 3D printed. Based on Boston Dynamics’ earlier humanoid robot Peatman, the Atlas robot was originally designed to perform search and rescue tasks.

According to Boston Dynamics, Atlas was designed to push the limits of “whole-body mobility”. The legs and arms of the Atlas robot are made with metal 3D printing. This was done in order to make them lightweight and strong for the gymnastics that this robot is intended for.

The original versions of Atlas, which debuted in 2013, were only machined. But in recent years, the viability of metal 3D printing reached a point where it became feasible to produce final parts for robots like these.

See for yourself Atlas’ incredible agility:

Robotic Arms

Robotic arms are a mechanical system made up of axes connected to each other to give the arm varying degrees of freedom and to allow different types of movement. The limbs of a robotic arm can rotate or translate to reproduce the required movement.

The software programmed into it depends on the function it is intended for. That said, most robotic arms are very similar, changing only in the transmission method used and the programmed movement.

Until not so long ago, robotic arms were mainly used in industrial settings, but thanks to 3D printing, it’s now possible to have robotic arms at home. Here, we’ll present the best ones to date.

Compact Robot Arm

If you’re looking for a homemade robotic arm that is both easy to make and control, this is an option not to be missed. It has even won Project of the Month on Arduino Project Hub for May 2023! Practically all components can be 3D printed or are readily available for purchase for a total cost of less than $60.

In addition to being a great option for those who want their first robotic arm, it can also be an excellent choice for demonstration or personal development as there’s the possibility for upgrades, such as wireless communication between the controller and the arm.

Despite the impressive-looking final result, building this project is possible for beginner to intermediate users due to the depth of instruction provided by the creator, Build Some Stuff. Part One of the video series covers the assembly and Part Two covers the wiring setup.

The most impressive part of this build is how precise and smooth the movements are. To make one for yourself, you’ll need an Arduino Uno or Leonardo, servo motors, potentiometers, and, of course, 3D printed parts.

Gesture-Controlled

This robotic arm controlled by hand gestures was designed by Eben Kouao and the structural pieces are 3D printed. The author gives the full code and instructions as open source on his website, as well as the list of parts, so it can be replicated.

This robotic arm is composed of two systems: The first one, a robotic arm; the second one, a 3D printed glove that is used to control the movements of the arm. With motions like movements of a finger, you can open and close the clamp of the hand, and with the movement of the wrist, you can move the whole arm.

The author encourages people to come up with their own functions for the arm and share them in GitHub, so that the arm can become even more advanced.

Thor

A desirable quality of a robotic arm is that it would be able to perform arduous tasks, but the vast majority of open-source projects out there cannot handle large loads. Thor is a robotic arm capable of moving with 6 degrees of freedom and handling objects weighing up to 750 g without problems.

What makes all this force possible is the combination of NEMA motors and smaller stepper motors along with a series of gears to direct torque and weight to the right points. Other differences include the micro-endstop and opto-isolators to establish a home position of the joints but also allow for more than 360° of movement. There are even three different tool attachments that the arm can use!

The size of the arm when fully stretched vertically is 625 mm. With 51 3D printable parts, the total cost to build the project is estimated to be around $400. The project is available on Hackaday, but it is recommended to visit the Thor project website to get all updated files. There you will also find manuals, detailed build instructions, and even a community forum.

SCARA & SCARA Printers

With this item, we’re highlighting SCARAs and SCARA printers. SCARA stands for “selective compliance assembly robotic arm”, and it’s a kind of robotic arm that can be 3D printed as well as used for 3D printing!

This arm’s type of movement allows for great precision, although it’s more limited than other designs in degrees of freedom. It can be used for more traditional robotic arms or for 3D printing specifically, and thanks to the simple geometry of the design, it’s very easy to print one for yourself. You can print a new printer or print a robotic arm with this simple – but clever – system.

If you want to see more of these devices, check out our article on SCARA 3D printers.

Niryo: Niryo One

Introduced in 2016, the Niryo One is a 3D printed 6-axis collaborative educational robot arm. Originally launched on Kickstarter, Niryo has evolved with improvements in software and design.

The Niryo One is meant to be an introduction to industrial robots. It’s very precise and is driven by stepper motors controlled by Arduino and Raspberry Pi. It’s also easy to program – this can be done in less than five minutes with a free desktop application.

Niryo One can no longer be purchased pre-assembled or as a kit and the company is transitioning to the next-gen Ned Two. However, all the build information and code is available on GitHub for those interested in creating one themselves.

Zoomorphic Robots

Zoomorphic robots are robots that use animal features in some way to operate. Some of the most popular at the moment are robots that use crab-like motions to move; these robots are interesting because they use an intricate motion system to move each of their “legs”, one at a time.

Thanks to this kind of movement, these robots can go over many surfaces without much hassle, in comparison to robots that use wheels to move, which are limited in the kinds of ground they can walk on. Below, you can find the most advanced zoomorphic robots, with four or more legs!

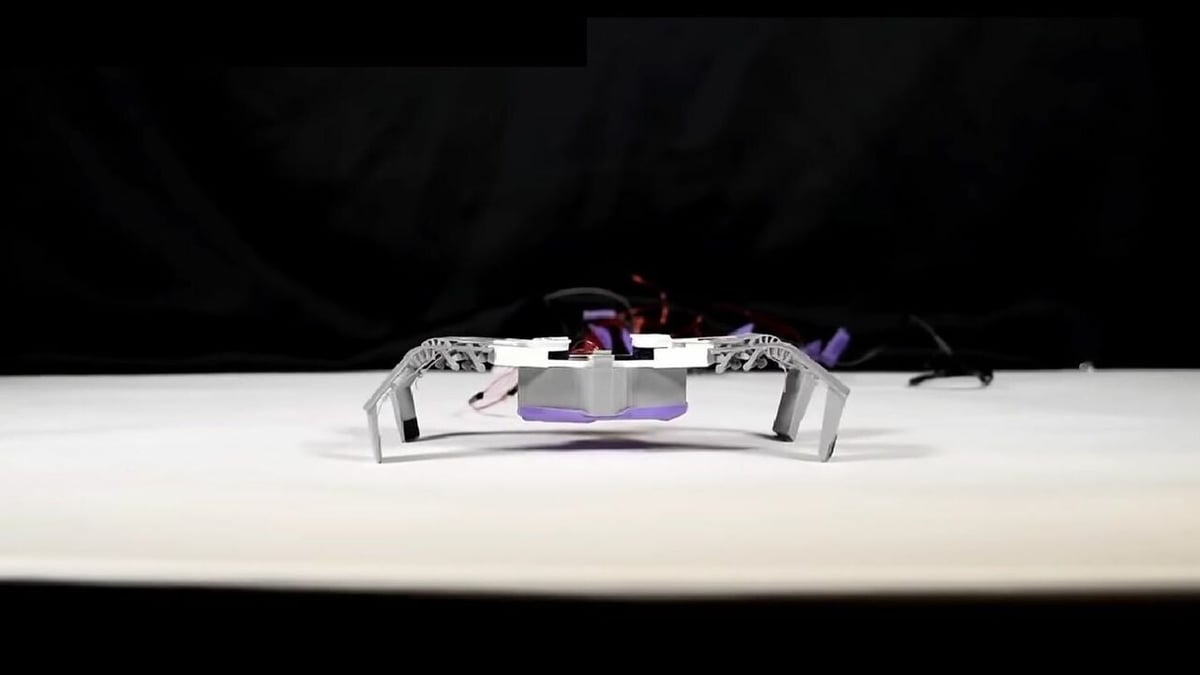

Flexoskeletons

What do you get when you combine compliant mechanisms and bugs? The flexoskeleton! This zoomorphic robot was developed by James Jiang, a Ph.D. student from UC San Diego. The body of the robot is completely 3D printed, and it uses the flexibility of the material to mimic the flexibility of muscles.

Instead of using rods and screws, this robot uses the compliant mechanism principle to move the legs and bring them back to their natural form, eliminating the need for springs, joints, or pistons. The flexibility of the material is its own spring.

As a result, not only do you spend less on materials, but it also creates a more natural gait that resembles that of an actual creature. Besides, it also simplifies the programming, because you don’t have to consider the movement of independent joints. This design shows that sometimes a solution doesn’t need to be more complicated, just thought out differently.

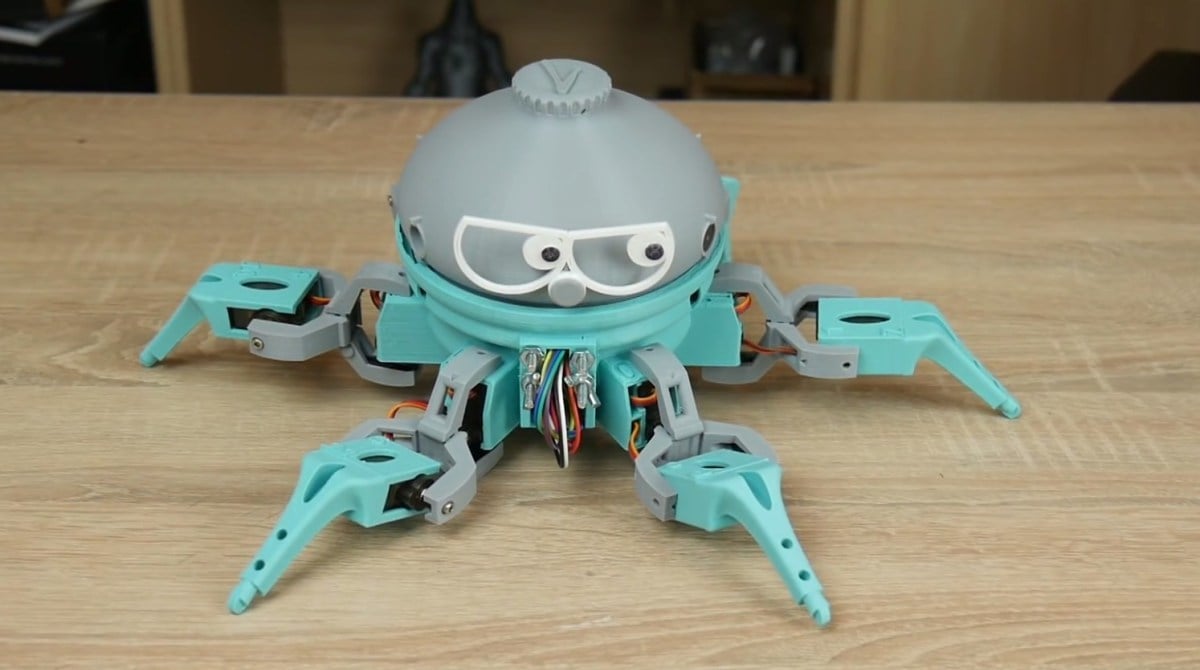

Vorpal

Vorpal is the work of Steve Pendergast. Since its successful crowdfunding campaign in 2018, the Vorpal has continued to be a very unique and cooky 3D printing project for classrooms.

Vorpal is totally open source, able to be programmed from scratch, and controlled via Bluetooth. It’s a great project for kids and adults to be introduced to robotics and coding. You can check out all the resources you’ll need at the Vorpal Robotics site.

If you choose to print it yourself, you can build Vorpal for about $60, otherwise, you can buy different levels of kits or the pre-assembled robot.

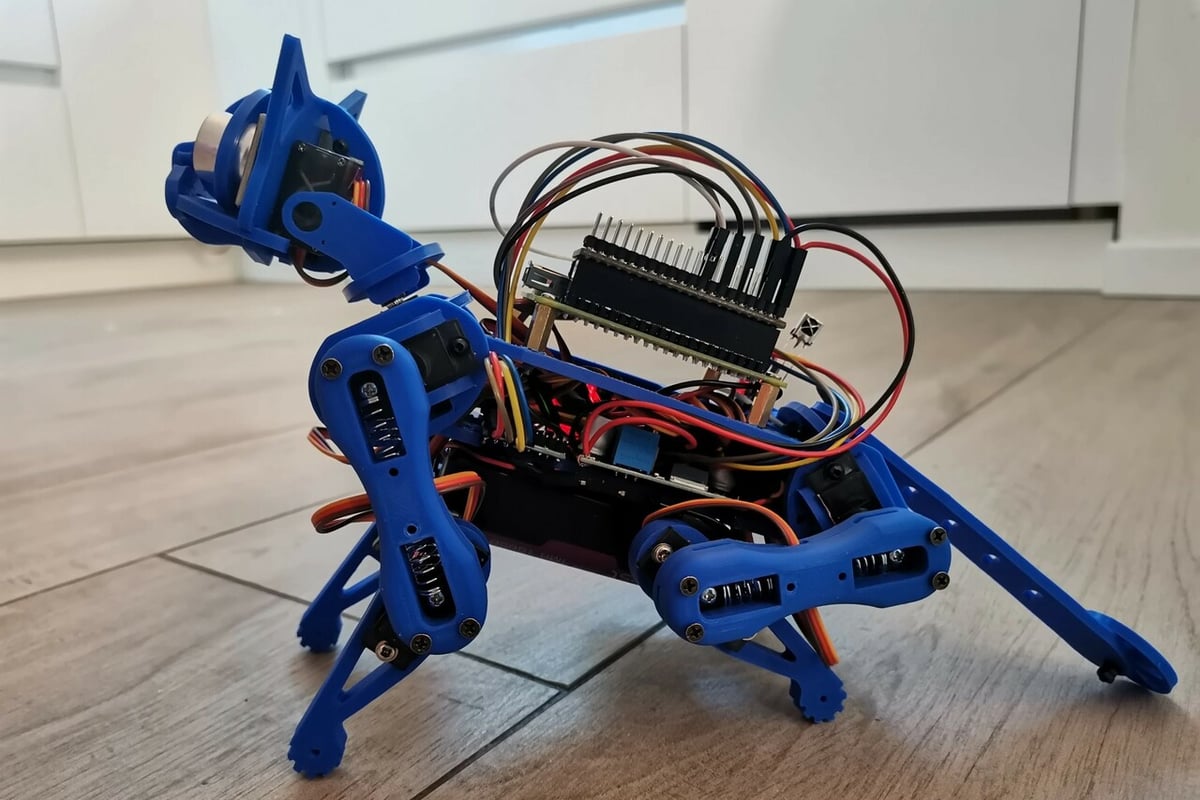

OpenCat

Rongzhong Li is an assistant professor at Wake Forest University in North Carolina and the creator of an open-source 3D printed robot cat. After OpenCat was featured on IEEE Spectrum’s weekly roundup of robot videos, he’s been flooded with possibilities for the future development of his personal project.

On his Hackster page, Dr. Li explains that the project started in the summer of 2016. Since then, the cat has gone through seven iterations, each one increasingly more complex than the last. You can find a full list of materials and GitHub files needed to build this cat. Dr. Li recommends using ABS, rubber (TPU), conductive, and nylon filaments.

Currently, Dr. Li has two working models: A smaller one targeted at STEM education and the maker community that runs on an Arduino module, and a larger model with a Raspberry Pi for AI-enhanced perception. After successfully crowdfunding these two mini robot kits, thousands of units were shipped all over the world. If you’re more of a dog person, the voice-controlled Petoi Bittle X is another great project that you can purchase a kit for or build yourself with the same open-source model as the cat!

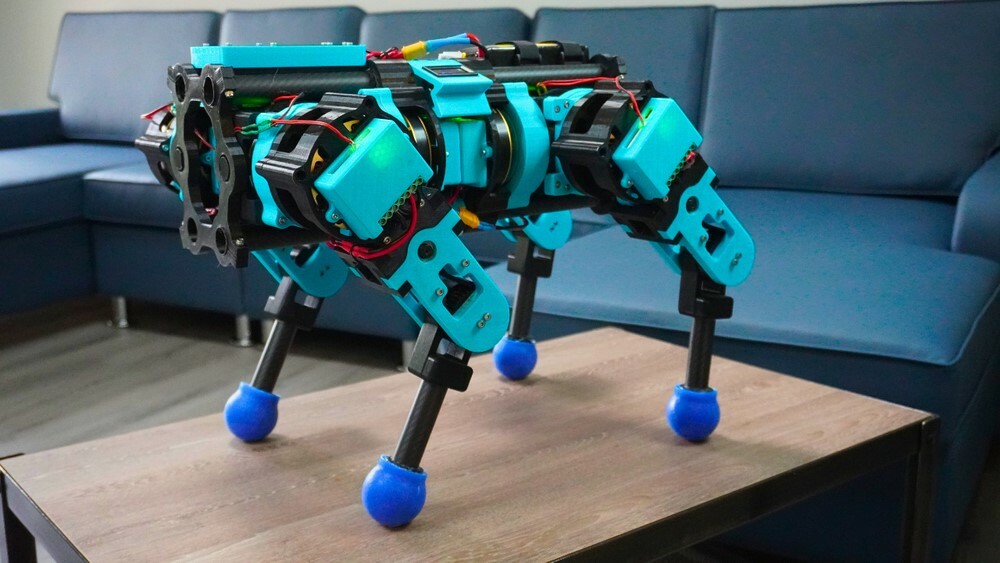

The Dingo

Since Boston Dynamics introduced Spot and defined the state-of-the-art in quadruped robotics, many are looking to apply this concept to a multitude of tasks. However, a huge challenge when pursuing these objectives is navigating the price-quality tradeoff to find a balance between high performance and not breaking the bank.

Students at Monash University sought to create a quadruped solution with four main objectives in mind: affordable, robust, expandable for research, and aesthetically pleasing. The resulting bot, named The Dingo, cost just under $900 to build!

The most expensive part of the robot was the 35 kg-cm servo motors mounted in a unique positioning to allow precise movements. Also notable is the compact size, with a total weight of 3 kg (including a carrying handle). The Dingo has a payload capacity of 500 g and a battery that allows for up to 25 minutes of continuous use. All of the 3D printable parts have been shared on GrabCAD and the code, plus explanation, can be found on GitHub.

TOPS The Robot Dog

You may have seen many quadruped robots out there, but this one is special because instead of using typical motors and gears, it uses robotic actuators. This means that movements are more precise, stronger, and more agile compared to similar robots like Boston Dynamics’ Spot. The motor also works in a closed loop, which allows the system to know at what position the engine rotation is at all times.

Nicknamed TOPS (“Traverser of Planar Surfaces”) by its creator, Aaed Musa, the project was heavily inspired by the openDog V3 by James Bruton and cost $3,300 and four months of work to complete. The completed quadrupedal robot came out to be nearly 13.5 kg with 12 custom QDD actuators to give it 12 degrees of freedom.

If you’re still not convinced that actuators can really make a difference to something like this, you should check out its dance moves. Despite having done a wonderful job building this robot with actuators from scratch, there is still room for improvement so keep an eye out for TOPS V2 in the future. For more information on this impressive build, you can check out Aaed Musa’s YouTube channel or website.

Small-Scale Robots

Not all robots have to be complex or big in scale to be considered advanced. Sometimes, the advanced features can be in the programming or they can be used for learning purposes, as well as exploring one specific movement method.

There are still many things to explore and many aspects to experiment with where robots are concerned, and making things smaller is another challenge.

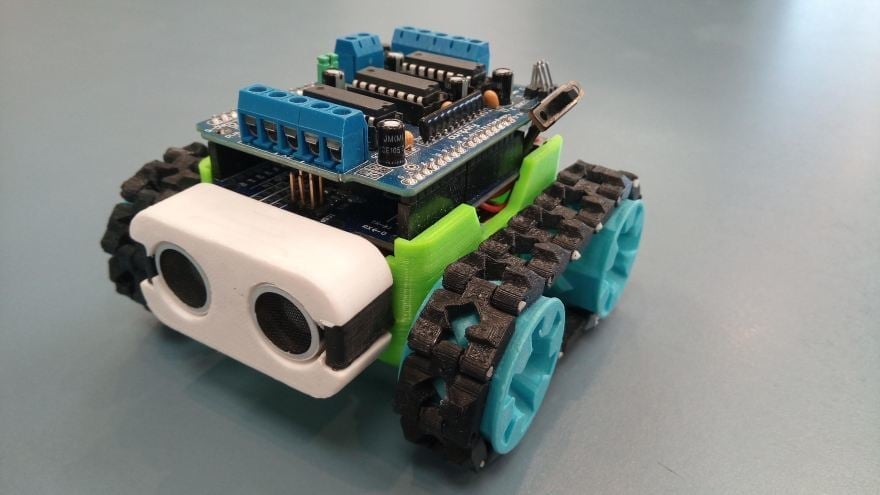

SMARS

SMARS is an acronym for “screwless/screwed modular robotic system” and this simple SMARS 3D printed modular robot was designed for education and learning. SMARS notably has a minimal number of components; it can be assembled without screws, soldering, or glue.

This inexpensive robot has a modular design so makers can easily mount different sensors and tools and even design their own parts; inventor Kevin Thomas is leading by example and has released a huge number of mods. By searching for DLC for SMARS, you can find ways to convert the robot into a quadruped or add a shovel, among other ideas.

Fighting

This 3D printed fighting robot was developed by Matt Cho and is a flexible robot that can make fighting moves like uppercuts and hooks with both hands.

It was a way to experiment with a different type of fighting robot as there are many available out there, although their main focus tends to be around being robust enough to not fall down. Instead, this robot tries to be lighter and more dynamic by having the ability to walk and throw quick punches. Thanks to its design, it can stand back up after it’s been pushed down, bend its legs, and walk sideways and forward. However, due to its extra-stable legs that make it harder to be pushed down, it’s unable to lift its legs to kick.

It’s recommended to print in a strong material so that the robot can withstand being punched without the 3D printed structure suffering damage.

Otto

This is a great project for those who are fascinated by robots, but don’t yet have enough experience to build one from scratch! Popular for being a modular, open-source robot with an epic personality, the Otto may seem simplistic at first glance, but it is full of interactive and customization possibilities. The graphical programming interface makes everything intuitive and easy to learn, and even suitable for young ones.

Inside the Otto is an Arduino board and simple components such as servos, ultrasonic sensors, and a battery. This leaves room for various expansion options such as a ninja, humanoid robot, and rover style, among others. The project has a great website that houses a blog and several tutorials and models of parts, codes, and even ideas for games and educational courses.

In addition to being very friendly, you can also count on an active and growing community, including a Discord channel with almost 1,600 members named “the most diverse DIY robot community in the world”! All of this has made Otto a superstar, which is why HP will launch its version at the biggest EdTech event in the world, BETT 2024, with interesting news such as ready-to-assemble kits. It is worth keeping in mind that as an open-source project, you can also build your own Otto using an Arduino and 3D printed parts.

Mini Deathroll

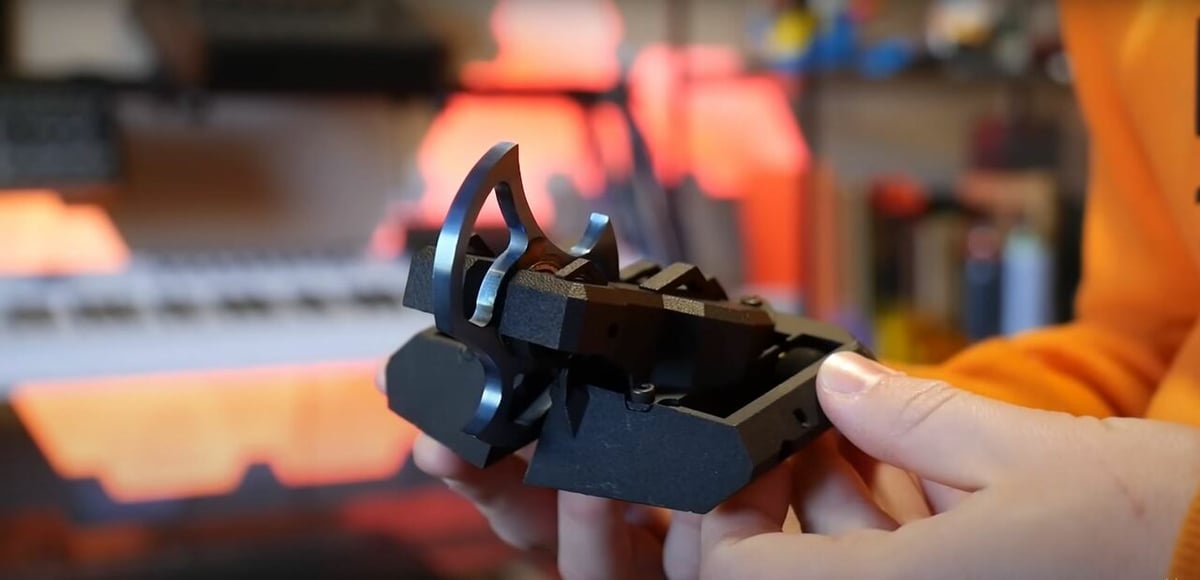

If you love robots but aren’t familiar with BattleBots yet, the UFC of machines, you’re missing out. In a robot battle, two opponents are placed in an arena with the objective of attacking each other until one stops working, or explodes, while the audience watches protected by armored glass. The fights are usually very violent and the arena is treacherous and full of traps.

Each robot uses a different weapon and tactic. As Rocky Balboa would say, is not only how much the robot can hit, but also how much it can take and keep moving forward. Given the huge popularity of the TV show, it’s not hard to imagine that we would soon have miniature versions of these incredible killer robots. As a huge fan of the competition, Maker’s Muse was massively disappointed when HexBug’s miniature line of battle bots did not include his favorite “Deathroll“. So he decided to create one himself.

The big challenge was to maintain the original features and characteristics in a model with a maximum weight of 150 g to meet the entry requirements of a miniature battle competition. Multi Jet Fusion was used to create a durable nylon body, and the signature weapon blade was recreated using aerospace-grade titanium. This little bot really packs a punch! Check out all the details of this incredible project in the YouTube video.

AOSeed X-KIT

The AOSeed X-Kit gives you the possibility to create over 60 different pre-configured robot models that are ready to be made on the 3D printer, then assembled and programmed on your own smartphone or tablet. In addition to various robots such as dinosaurs, cars, and other vehicles, you can also design custom robots, giving you unlimited possibilities. The complete kit, which doesn’t include a 3D printer, costs just under $180.

On the app, you can modify ready-made models or create your own from the modular parts using a kid-friendly drag-and-drop modeling approach. The core of each robot is the “Hub”, which houses the key components, like the motor and battery, and is the starting point for every build. Additional motors and sensors included in the kit can be added to the Hub and control of it all is possible through the app.

Printing the components for each robot can be done on just about any 3D printer as the app includes preset parameters to ensure the parts come out the right size. The programming for the robots is completely graphic and intuitive, which makes the toy educational as well as fun and creative.

License: The text of "3D Printed Robots: The Greatest Projects for 2024" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.