3D printing is a unique method of bringing almost any digital design into the physical world without the need for particularly specialized tooling or high production costs. As you can imagine, the diversity of this technology can be monetized, and that’s what we’ll be focusing on in this article.

Whether it’s one-off models or small-scale batch production, with a 3D printer, you can meet many different needs, which is the perfect basis to start a business on. Prototyping models that will be manufactured via other means, creating custom-ordered models, producing duplicate models, and bringing ideas to life are just a few of the tasks that you can find yourself tackling with your own small 3D printing business.

It may sound a little intimidating to design a part based on the customer’s description and a few quick measurements, then printing it, cleaning it up, and returning it to the customer, but with a little guidance, it can be more than doable.

In this article, we’ll provide an overview of what you need to know if you’re thinking about starting your own venture, whatever scale or goals you may have in mind. From a quick review of the main (and most accessible) technologies and materials available, to different production models you may be interested in, we’ll cover quite a bit of ground.

And if you don’t have a 3D printer but want to dip your toes into the whole process, with Craftcloud, you’ll have the best options available to 3D print your designs of choice. You might also gain a little inspiration!

Intellectual Property & Attribution

Before we start looking in detail at what you’ll need for your venture, a word of caution.

Maybe you’re thinking about designing your own models, or you want to commercialize 3D prints based off existing ones. Unless the models are your own creation, always check which attribution licenses are attached to the models found online. If a license doesn’t restrict you from using the model commercially, you may still need to credit the original designer.

Be careful of intellectual property rights such as this if you plan to sell models that you have not designed yourself. This also applies when you modify an existing design; you must still credit the original designer. Conforming to all intellectual property standards can be a hassle, so the popular alternative is to only sell original designs.

And, of course, you’ll want to have a clear idea of how you can best protect your own rights as a designer by ensuring that your creations are also protected.

If you’re interested in a slightly different venture – offering 3D printing services – then you also need to know that you could be found liable if a customer is hiring you to replicate a model that they don’t own the rights for. A cautionary way of proceeding would be to ask them to confirm, when they submit the quote request or confirm the project, that they own the necessary rights.

With that said, let’s look at what you’ll need to 3D print and sell objects.

What You'll Need

There are two key elements that you’ll need in order to create your models before you can sell them. These are a good set of programs (and the skills to use them) and one or more trustworthy 3D printers.

Let’s look a little deeper into each of these key aspects.

Designing & Slicing

Before you can 3D print anything, it has to be designed. File sharing sites like Thingiverse are great for finding open-source 3D models, although you may have to abide by certain procedures for design attribution (as mentioned before). The alternative is to design your own models, which is necessary if you plan on selling a lot of custom mechanical components or if you’re in any way producing models based on a customer’s specifications.

3D Modeling Software

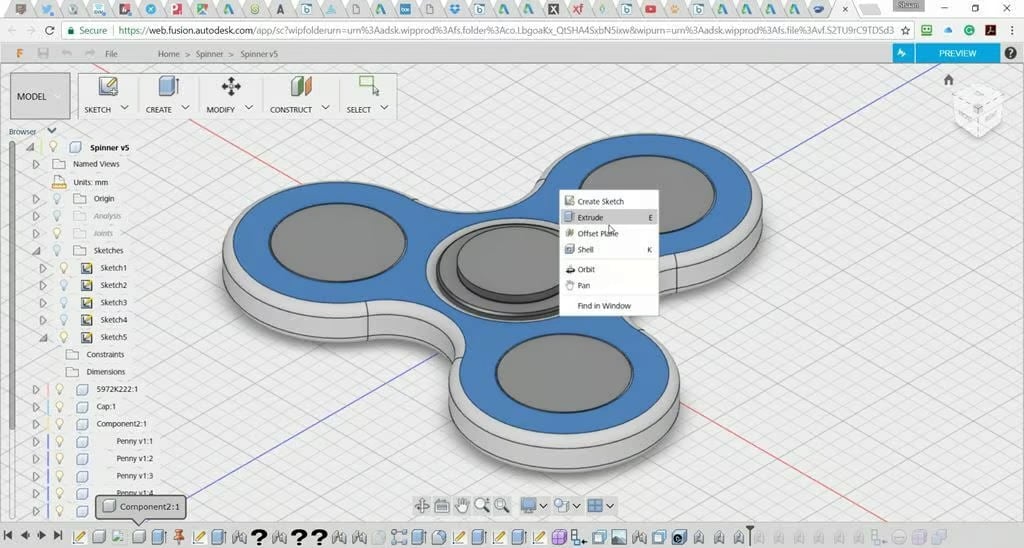

If you’re going to be designing or tweaking models, you’ll obviously need a good software arsenal. In general, 3D design programs can be divided into one of two categories: Solid modeling and mesh (surface) modeling.

Solid modeling (think Tinkercad or SolidWorks) is best for designing mechanical components using geometric shapes. A good solid modeling program is valuable for someone who makes a lot of functional models or custom parts. There are some great programs for beginners, as well as tutorials that can address different goals.

The other type, mesh or surface modeling (think Blender), is tailored towards natural geometries. This type of software allows the user to stretch, contour, and mold a model into the desired shape. If you plan on selling any figurines or any scanned models, you should have a good mesh modeling program. And if you don’t know what to model, you can always look for some inspiration.

Scanning

In lieu of designing, you may find yourself needing to create digital models of existing objects. In many cases, it can be trickier to produce a printable design using a scanner than a piece of traditional software. That said, their use is application-dependent, and in some scenarios there’s no alternative to a scanner when you need to create a digital version of a complex object.

Whatever the case, there’s good business to be had with this type of work, and you’ll soon find that a reliable scanner is well worth the investment when compared to manually recording dimensions and entering them into your design software. Of course, you can always look for a more accessible option if you’re uncertain of what your setup will look like.

Slicers

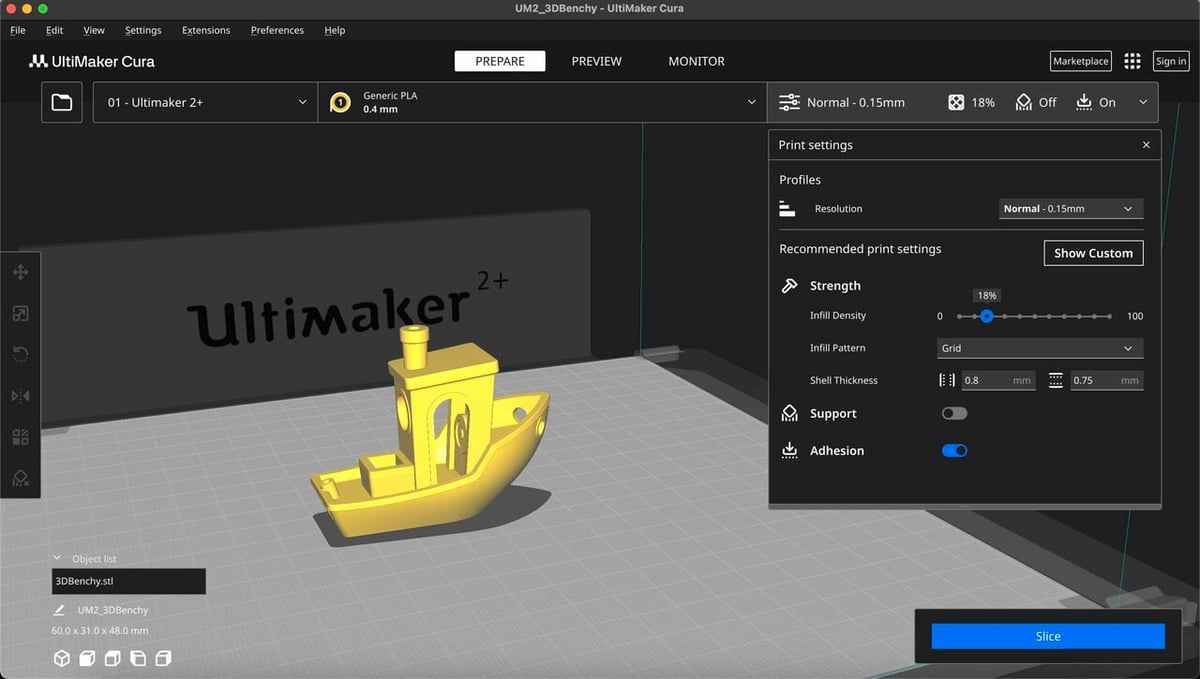

Slicers provide the critical transition from digital model to printable code. You may already be familiar with some of the big names like Cura, PrusaSlicer, and Simplify3D. A good slicer and the knowledge of how to use it are critical elements in ensuring good print quality.

Things like supports, plate adhesion, infill density, and wall thickness can make or break a complex print job. At the end of the day, all slicers preform the same basic function, so it boils down to ease of use, user preference, and whether or not you need any special features. We recommend starting off with a free slicer; there are some pretty good ones out there.

It’s worth noting that your slicer of choice and the specific settings will also depend on the printing technology you opt for (i.e. FDM vs resin-based printing), which we’ll look at further below.

Skills

Operating a business built on 3D design can be very difficult if you don’t know the ins-and-outs. If you’re just getting started with 3D design, you can try a more intuitive program like Tinkercad or SketchUp (both are free) before you commit to an expensive program with a steep learning curve like SolidWorks or Fusion.

Keep in mind that the fundamental skills of 3D design are often transferable between programs. Just because the professionals use the expensive software doesn’t mean that you need to, especially considering that the majority of professional features will go unused by a small 3D printing operation. (Just know that some companies will require you to pay for particular licenses if you make a certain amount of money using their software.)

Before you start any jobs (especially time-sensitive ones), make sure that you’re familiar with your software and skills above all else. It doesn’t hurt to set your mind on designing a couple of common objects just to practice your skills.

Printing

After you’ve finalized your 3D design tools, it’s time to bring your ideas into the physical realm through the use of a 3D printer. You should ideally be very comfortable operating (and maintaining and fixing, when necessary) a 3D printer before you rely on one for your business. It’s most likely that you already have a 3D printer, but if not, make sure you purchase something reliable with good print quality.

It’s also not a bad idea to (eventually) have multiple printers. 3D printing is a slow process, and it’s smart to run multiple printers simultaneously in order to print parts faster. You can even have a different printer for each of your favorite materials if you want to avoid time-consuming filament or resin changeovers. And a cost calculator will come in handy once you’ve got your setup.

But first things first: FDM or resin?

FDM Printers

When it comes to small-scale operations, the majority of printing is done on standard fused deposition modeling (FDM) printers. By “standard”, we mean something with a build plate size of at least 200 x 200 mm and a single extruder. FDM printers are a good place to start because of their versatility, low price tags, low costs of operation, and ease of use. A good, reliable FDM printer provides a great place to start for 3D printing entrepreneurs.

Other types of FDM printers that you should consider are large-capacity printers and printers with multiple extruders. All of these have their own benefits, although some may lack the versatility and cost-effectiveness of a simple and inexpensive FDM printer like the Creality Ender 3 V2. Nevertheless, there are plenty of great options to choose from.

It’s important to keep in mind that, depending on the type of FDM printer you choose, different materials, models, and types of post-processing will be required. These will affect your budget and time, and you can decide whether you want to offer certain services (such as vapor smoothing or painting) or not.

Resin Printers

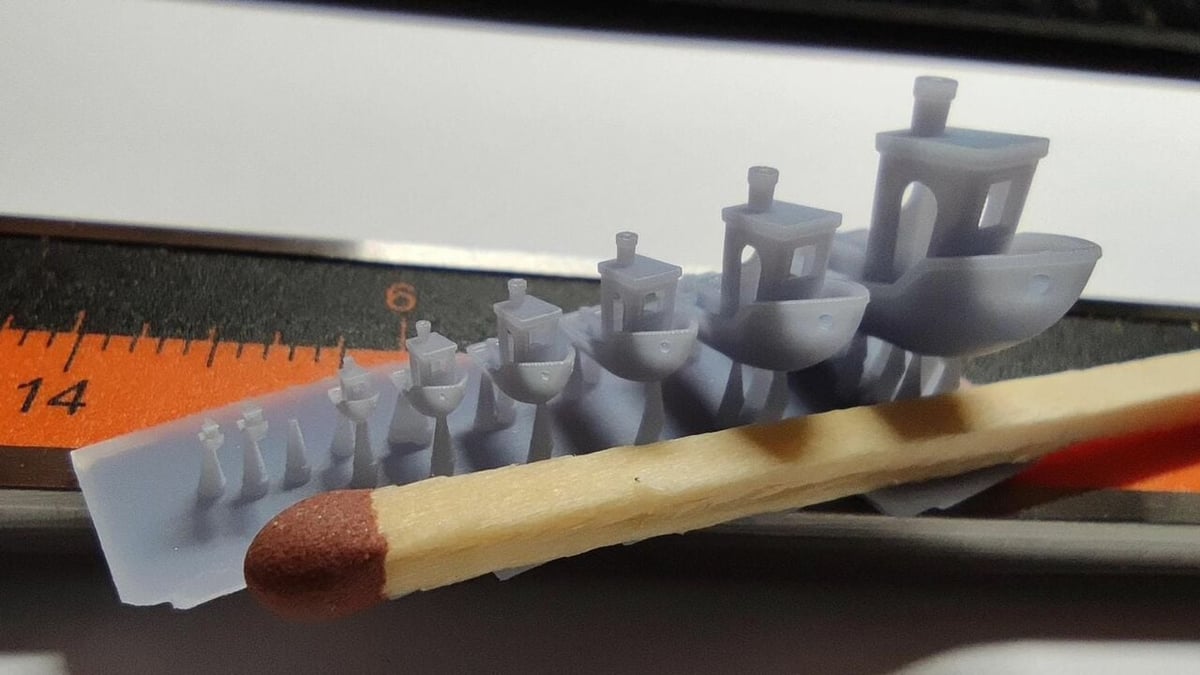

As mentioned above, resin-based printers offer a unique alternative to traditional FDM printers. These machines use liquid resin to form very detailed, delicate models that are typically beyond the reach of even the most precise FDM printers. These days, the most common type are LCD (or mSLA) printers, but there are also machines employing DLP and lasers (i.e. SLA).

A resin printer is a great choice if you plan on printing a lot of figurines or other detailed, aesthetically-oriented models. That said, if you plan on producing structural or mechanical components with your printer, then it’s best to stay with the tried-and-true FDM style. SLA printers are typically limited by small build volumes, high costs of operation, and poor durability in printed models when compared to other methods of 3D printing. There are excellent professional 3D printers, but more accessible options may be a better way to get started.

As with FDM printing, resin models will also require some post-processing. Note that different types of resin will have different types of post-processing, and again, you’ll want to consider whether you include additional services like painting.

Printer Farms

It’s every maker’s dream to have their own printer farm. A printer farm is a large array of multiple printers that can produce large batches of models or many different smaller models at once. Whether you plan on keeping your operation small or expanding it to dozens of machines, it’s a good idea to start off with something nice.

You don’t need multiple printers in order to run a successful operation. Checking out influential entrepreneurs like Gabriel Bentz and Josef Prusa can also provide you with useful insight into the world of 3D printing and business.

What to Sell

Before you can design or print anything, you need to know what it is that you’ll be printing. Next, you’ll find a comprehensive categorization of the main types of models that you can find yourself printing commercially.

Custom Mechanical Models

Custom mechanical models are designs that serve a physical function, rather than just an aesthetic one. Everyone is familiar with the nifty life-hacking gadgets all over Thingiverse. While models like these are sure to generate popularity, the monetary value lies in custom components that you as an entrepreneur can design and print specifically for the customer.

This 3D printed Ridgid 18 volt cordless tool battery holder for sale on eBay is a great example of a custom mechanical model that provides a practical function and is manufactured by a 3D printing entrepreneur.

Replacement Parts

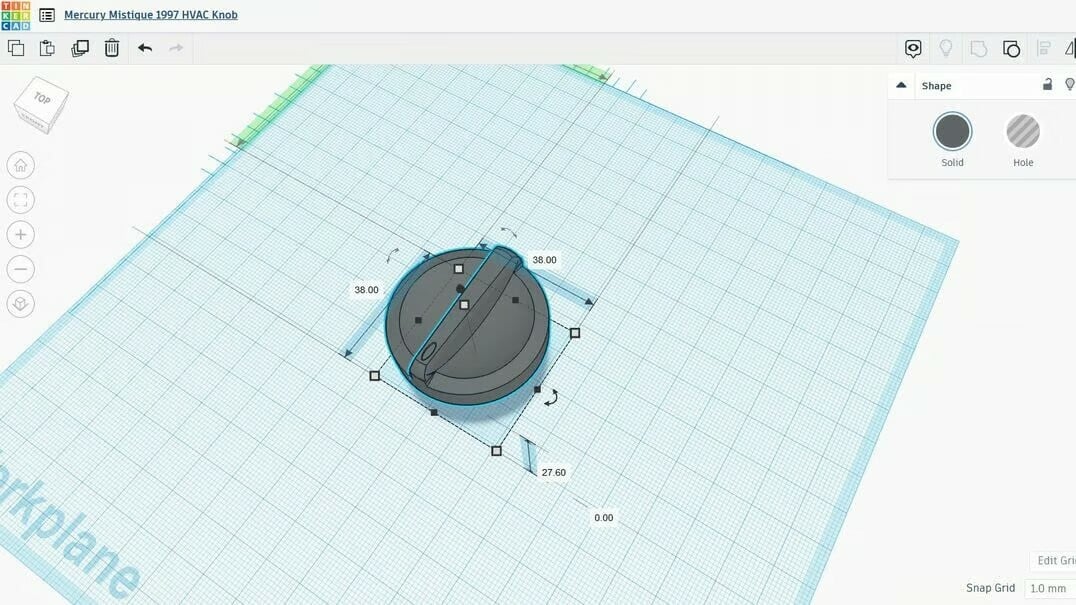

3D printers are great at making replacement parts. Whether for an appliance, device, vehicle, or even a printer, you’re sure to save yourself some money by making repair parts yourself. The monetary aspect comes in when the part that’s needed is discontinued, expensive, or hard to find.

Think of a discontinued plastic knob that controls the heater on an older car: a simple plastic part that’s unavailable through the manufacturer or any aftermarket suppliers. The solution? Print one! A couple hours of design and a few pennies in filament, and you have a perfect replacement part that the customer will be ecstatic about.

Unless commissioned to do a job, part of the trick here will be to anticipate what people will be looking for. You could do this, for example, by targeting common but hard to find parts. 3D Prototypes and Models is an example of a company exploring this market.

Assemblies

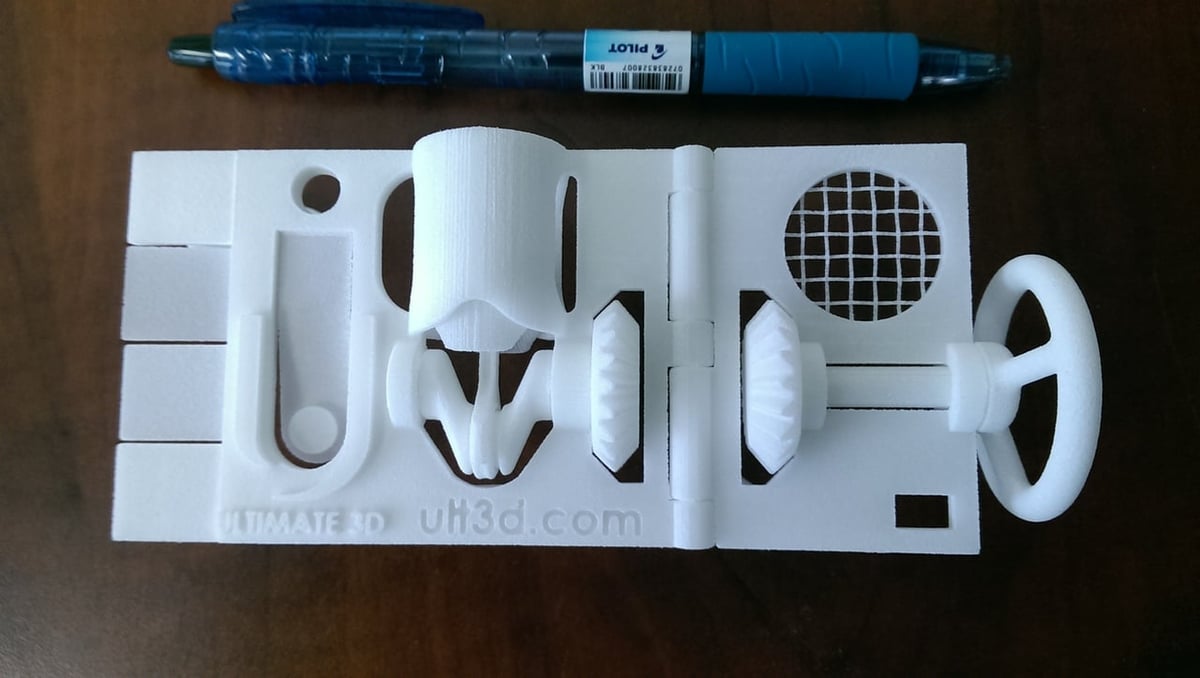

The term “assembly” can be applied very broadly, but we’ll use it to describe a collection of mechanical multiple parts that work in unison to serve a purpose. Print-in-place models fall under this category and are a staple feature of 3D printing, a great way to showcase your printer’s capability.

This also includes designs that consist of multiple, separately printed parts. They can include things like printer upgrades or other mechanical components, like the engineering card shown above. Among others, Ultimate3D is an example of a company that offers this kind of service.

Prototype Models

Since 3D printers can create almost any object without specialized tooling, they’re a great choice for prototyping models that will eventually be produced by other means of manufacturing. Unless you plan on running a full-scale 3D printing lab, jobs of this sort will be few and far between. This is because it’s usually large-scale manufacturers who need this kind of work to be done, and someone who is just starting off is unlikely to get in contact with them.

That said, if you can find someone who’s considering injection molding a part but wants to prove its functionality first, then you’re in business. To see what is being done in the prototyping business, check the Axis Proto website.

Special Geometries

There are special geometries that can easily – or only – be produced via 3D printing. Due to the nature of some models, they’re too complex to be molded and too expensive to be machined. This is where 3D printing comes along to save the day with companies R&D Technologies and Dinsmore.

With 3D printing, one can uniquely manipulate the interior of a part, and thanks to dual extrusion printing and dissolvable printing materials, it’s possible to achieve complex structures. When someone is in need of a model like this, there’s a real opportunity to be had. Stretchy TPU chainmail, anyone?

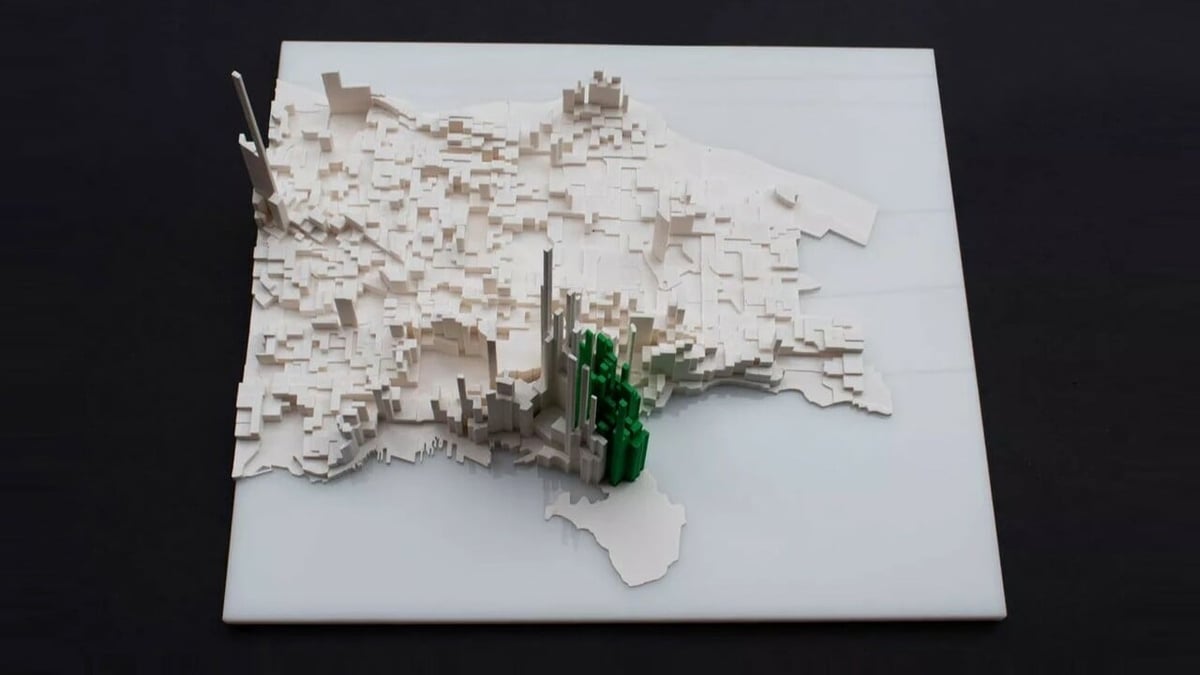

Architectural Models

Architectural models are a physical representation of a construction, such as a commercial building or a house. They help architects to visualize the design beforehand so as to solve construction constraints and project questions, but are especially useful to communicate and sell the development to clients. This kind of work was traditionally hand-crafted with wood or cardboard, which was very artistic but also time-consuming. With 3D printing, this job can be made easier and faster, reducing many hours of labor.

Sometimes an architectural CAD file can be used straightaway to 3D print, and other times it may need some preparation, such as dividing the building into smaller pieces to fit the 3D printing area. To enter this market, a good starting point is to reproduce with adequate scale and fidelity one famous and well-recognized building to understand the workflow and also start a portfolio of models. With that, it might be easier to approach architects and construction firms to pitch your work.

To have an idea of the possibilities 3D printing brings to this craft, check the work from Fixie and Forge Labs.

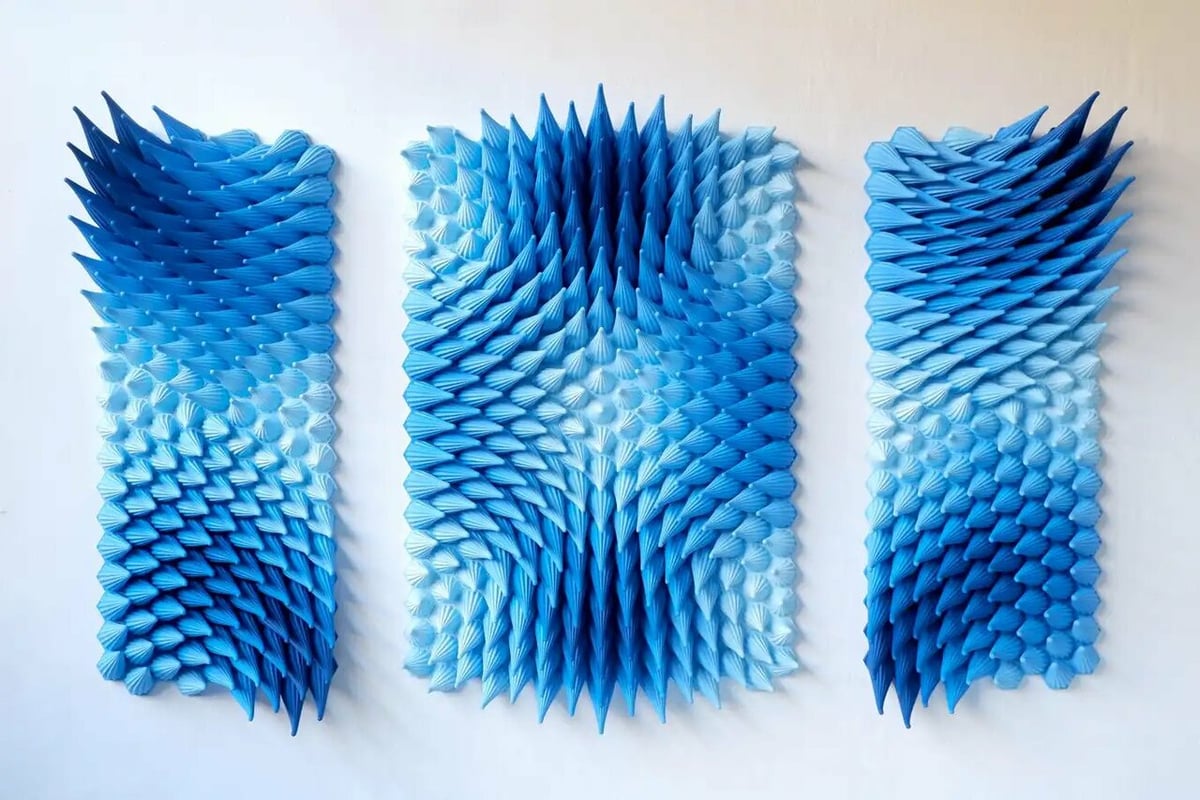

Art

This basically covers everything aesthetic that doesn’t fall under the previous three groups, household trinkets and conversation-starter pieces included. After all, art is anything that appeals to the eye.

Modern lamps, artistic wall hooks, spiral vases, coasters, wall art, and any other eye-catching showcases of 3D printer capability are all fair game. A lot of the models types mentioned here can be found on file-sharing sites, although don’t be scared to design an artistically-oriented model yourself; simple-to-design models can be just as popular as complex ones. For instance, check what Hershel Shapiro can do with a little 3D printing and a lot of talent.

Jewelry

3D printed jewelry is unlike any other type of jewelry in existence. The complex geometries achievable with a 3D printer can be stunning and are unrivaled by most other means of manufacture. It isn’t easy to design the perfect piece, and if you don’t feel up to the task, you can always try advertising existing designs of printed jewelry (with the proper designer attribution, of course).

Delicate models are always tricky to print, but on the plus side, they don’t require large amounts of printing material (resin is usually best) or a printer with a large build volume. 3D printed jewelry would appeal to anyone seeking a gift for a friend, family member, or partner, so advertising it in coordination with the major holidays is a smart idea. While jewelry isn’t the easiest thing to print, it yields one of the coolest end results.

Some companies like Radian Design and Nervous System have really interesting pieces to inspire anyone.

Custom Decorative Models

This category includes models whose main function is aesthetic rather than mechanical. These sorts of models don’t necessarily need to have precise dimensions or a focus on durability. That said, while resilience and longevity aren’t the main goals to the designs, they still need to meet certain minimum requirements depending on intended use.

Here is where 3D printing shines in its ability to produce stunningly complex geometries and high amounts of fine detail. Subcategories under this class include, but aren’t limited to, figurines, cosplay related items, home decor, and other forms of art. We’ll look into these in more detail next.

These customizable 3D printed keychains and zipper pulls available on eBay are a perfect example of this type of work.

Figurines

Figurines are a crucial part of the 3D printing community. Whether for a fantasy game like Dungeons & Dragons or just for display, they’re always in high demand. Character figurines require a great amount of detail and a smooth surface finish, making them rather tricky to print.

Figurines are extremely hard to design, as well. With infinite amounts of detail like flowing clothing and facial features, it takes a master designer to create one from scratch. Thankfully, there are online figurine generators that will generate an STL or OBJ file for a model that meets certain chosen specifications. In many cases, your services will come into play when the customer presents one of these models that needs to be printed.

Cosplay

Cosplay and similar costume-oriented activities form a massive segment of hobbies and entertainment. Months of dedication go into making the perfect costume, and often it will require components that have to be custom made but are too complex for papier-mâché or cardboard. 3D printing plays a crucial role here in its ability to print masks, armor, accessories, and even replica weapons.

As a 3D printing entrepreneur, if you come across anyone trying to complete a cosplay (or similar) costume, see if they need any custom parts printed. There are also companies that sell the STLs and leave the printing up to the consumer (or a 3D printing service). Getting into this might be a more involved process than other ventures, but if you know your stuff, there’s good business to be had in this field of work. For instance, companies like 3D Printed Props and Punished Props are already exploring this field.

Off-the-Shelf Models

A quick way to make a profit selling 3D printed models is to sell pre-printed “off-the-shelf” models. Unlike the other categories, these types of models aren’t designed specifically for any one customer. This allows you to print batches of identical popular models prior to their sale, and when a buyer expresses interest in one you can simply hand the completed model to them without having to design or print anything special.

Models in this category should be kept simple if your intention is to print them in batches. Also, if you have a stock of a certain model, it’s a good idea to advertise it somewhere in order to drum up popularity. Think of things like keychains and other appealing trinkets that would interest the general public. Models found on file-sharing websites such as Thingiverse will fit in this category, but make sure that, when you’re selling unoriginal designs, you follow the proper attribution procedures.

This 3D printed Super Nintendo SNES logo is a good example of this type of printing. The logo belongs to Nintendo, and the design is not original to the seller. That said, the seller made sure to follow intellectual property rights and rights reservation regulations in order to make this sale legal, and specifies rights ownerships in the product’s description.

Where to Sell

Lastly, once you’ve put everything together and are ready to make some money with your 3D printer, you need to know where to get business. You can’t expect many customers to approach you if you don’t have any advertising or any way of putting yourself out there, but this doesn’t have to be in the form of purchased ads or even a website. To provide you a low-cost and fast solution, we have two main possible paths to show.

Marketplaces

It’s easy to sell off-the-shelf models on websites like eBay or Etsy because you don’t even need a physical store. Online sales are easy and fast for pre-printed models that you can advertise. eBay users such as Art-Webstore and chalmation_creations (just to name a couple) successfully sell customized prints online.

If you plan on angling yourself towards the “3D printing service” side of things by mainly selling custom models, then things can get a little more complicated. While some custom models, such as figurines or costume parts, can be designed, printed, and shipped all while coordinating with the customer via email or phone, mechanical parts typically cannot. If you need to design and print a custom replacement part for a customer, then it’s best that you at least have the old part in your hands while you’re designing the new one, or better yet, that you have access to the assembly in which it fits.

This limitation means that, if you plan on selling a lot of custom mechanical parts, it’s best that you only do it on a local scale. For that, the best options would fall into platforms such as Facebook Marketplace or Craigslist, where one might search the services by the location.

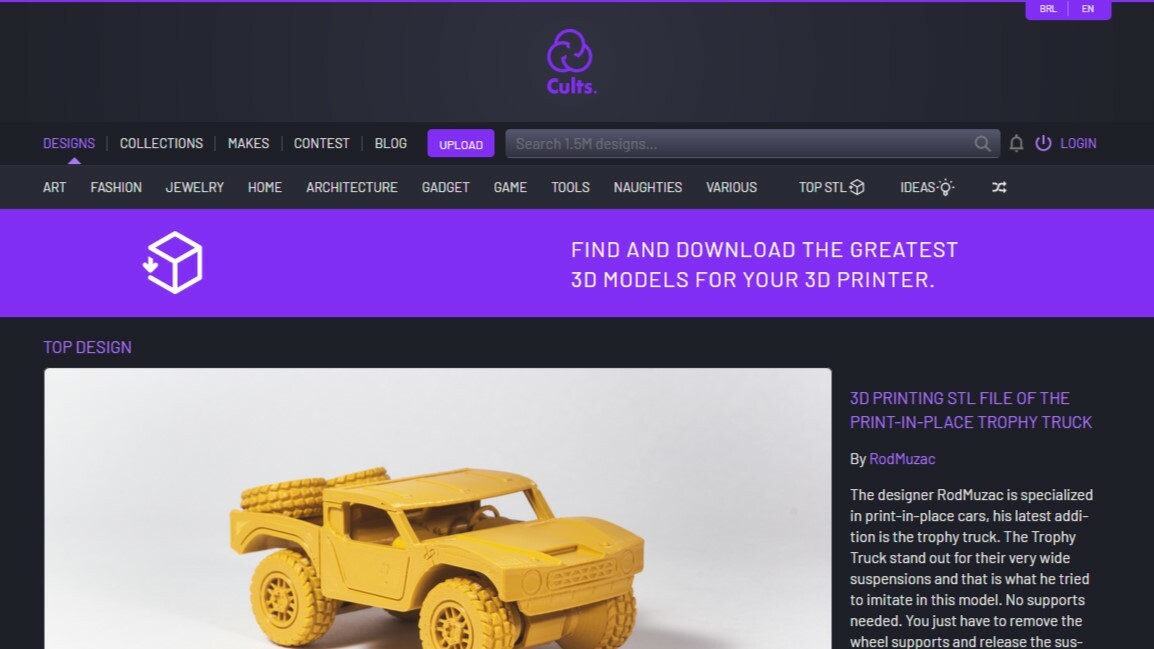

Model Repositories

Another viable option is to sell not the 3D printed object itself, but only the STL file for your clients to print. For that, repositories like Cults, MyMiniFactory, and Thangs are ready to be used: You upload your files and add the price tag. A good call is to add some free models to showcase your work. See what eastman and gazzaladra are making in this field.

The issue with this is that you cannot control what will be done with the files you sell, meaning that you won’t know if buyers will freely redistribute them or will keep a promise of printing a limited quantity per purchase. For that, you have to rely only on the fidelity and good will of your customers.

Lastly, you may be wondering if you need a website for your newly created business. In most cases, the answer is no unless you’re planning on running a large-scale operation. For the most part, you can get all the advertising you’ll need from marketplaces and a professional social media profile.

Making money using your 3D printer can be a challenge, but it’s not an impossible achievement. As long as you know what types of models you want to sell, have the right equipment and skills, and know where to advertise, then you can sit back while the printer does the work and watch your hobby or business prosper.

License: The text of "Things to 3D Print & Sell: 3D Printed Items That Sell" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.