This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Clash of the CADs

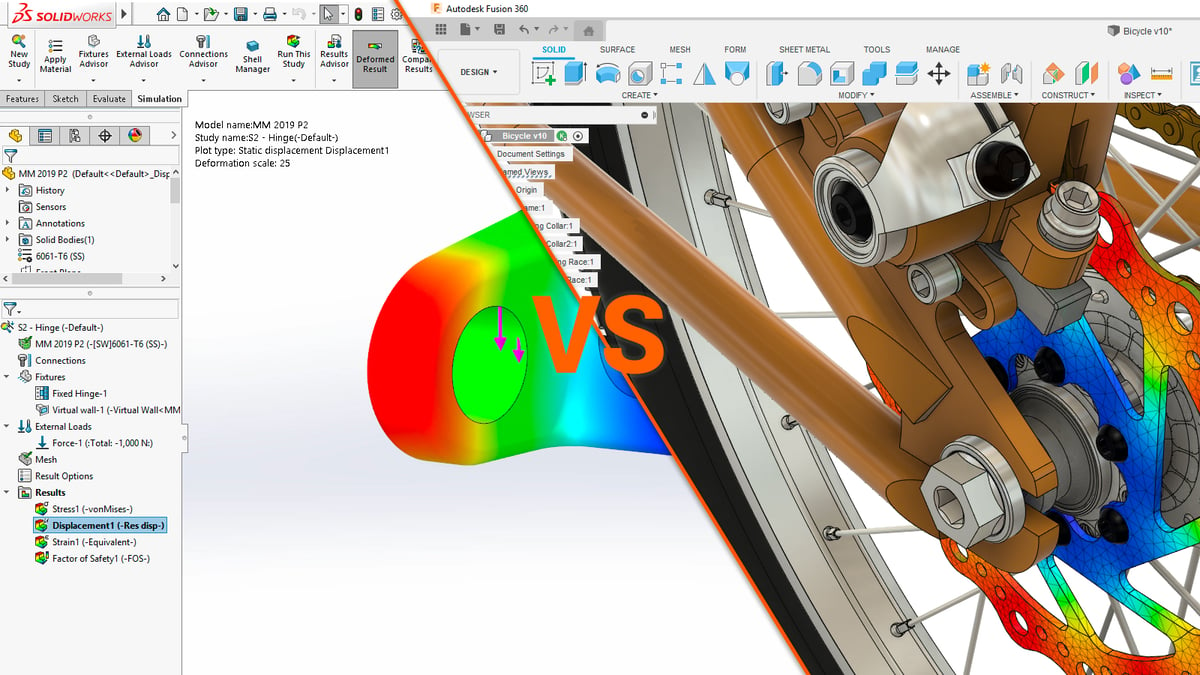

SolidWorks vs Fusion 360: The Differences

SolidWorks vs. Fusion 360: Dive straight in to find out all about the differences and which CAD program is best for your needs.

Advertisement