Ear and Now

When someone mentions 3D printing, it might conjure images of plastic filament spools and all the cool things you can print, but the technology is capable of so much more. If you’ve ever heard the stories of people losing an ear in an accident or having microtia, only to get a replacement that was grown in their arm, you might not be surprised to find that 3D printing is being used to even print whole ears!

There’s more to it than simply putting bioink into a printer and selecting the size of ear. Now we even have 3D printed ears that pick up radio signals! If that perked your ears up, keep reading to learn about the most exciting developments in 3D printed ears.

But first, a quick note on bioprinting…

Bioprinting

3D bioprinting usually works much like other forms of 3D printing, with one of the biggest differences being live tissue is used as a material. So-called bioinks are made up of cultures of live cells, such as stem cells, that can be 3D printed or biocompatible material that cells can populate.

Often, bioinks are used when creating a scaffold, which allows cells to grow and form an organ around it. One such example is a 3D printed pancreas created by researchers in Poland. Research has shown that even apples can be used as scaffolds for culturing tissue, though mechanical information can regulate and control how cells behave, all else being equal.

This opens up the possibility that 3D printed organs will someday be designed to mechanically influence precisely how bioinks (or implanted stem cells) grow and behave. While the technology is still very young, it’s rapidly advancing and has massive potential to change the world.

Living Tissue

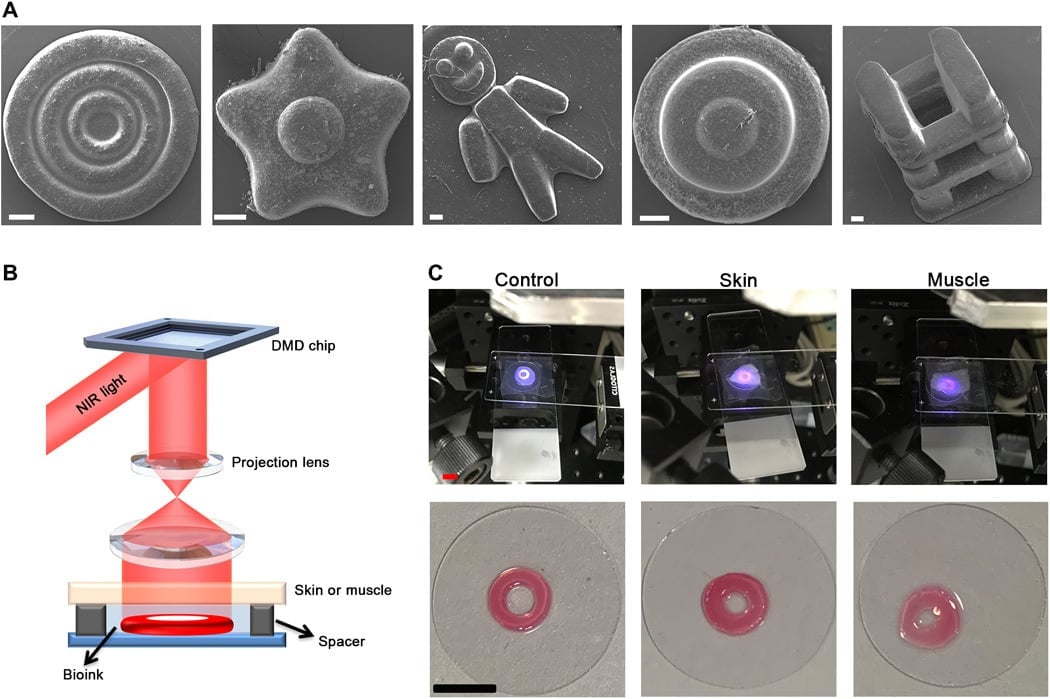

Researchers in China at State Key Laboratory of Biotherapy and Cancer Center have successfully 3D printed structures within living tissue. This means they can print organs without needing to surgically implant them or perform other invasive procedures.

The process starts with injecting bioink into the living tissue. Because near-infrared light can penetrate these tissues, inks are made of monomers such as gelatin methacryloyl, which cure layer by layer (much like a conventional DLP 3D print). This is possible thanks to nanoparticles designed to convert the near-infrared light to UV light, allowing the bioink to cure without UV light, which alone can’t penetrate tissue deep enough.

This game-changing technology may one day enable us to grow or repair organs without the need for any invasive surgery or related health risks!

- Year: 2020

- Technology used: DNP (digital near-infrared processing, similar to DLP)

- Materials used: Bioinks, gelatin methacryloyl, nanoinitiator

- Time to print: 15 seconds per 200-micron layer

Regenerative Cartilage

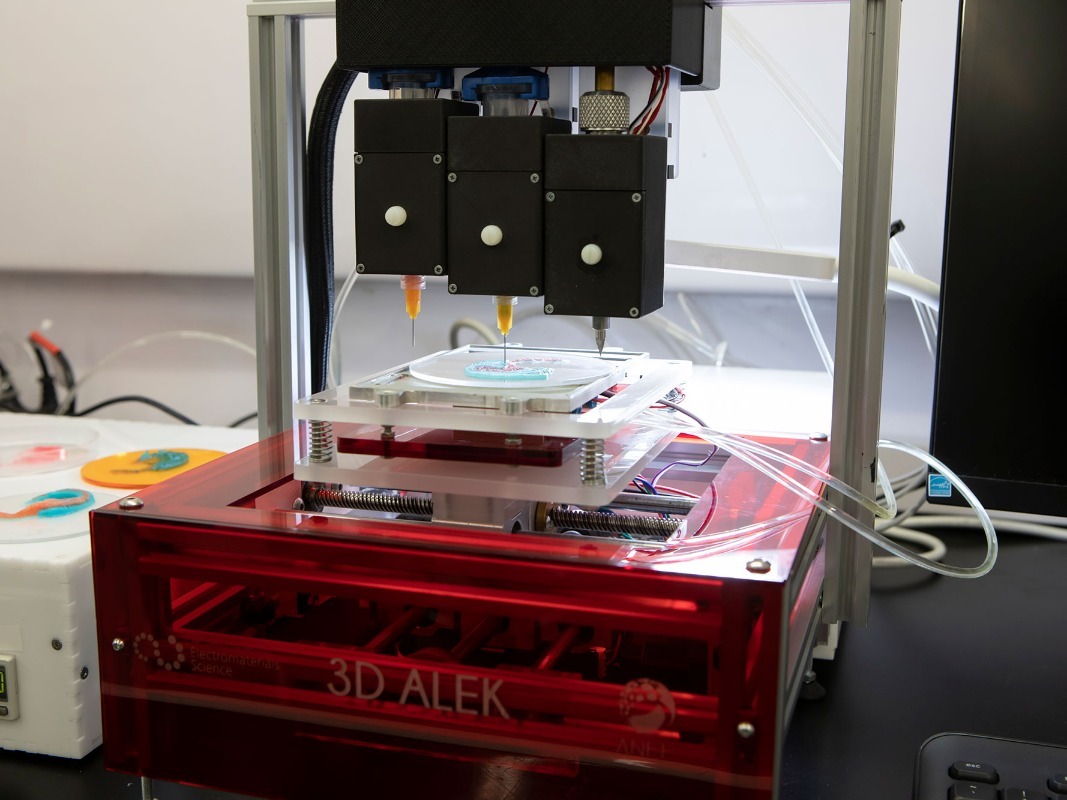

3D Alek is a 3D printer designed specifically to assist with regenerating ear cartilage for people affected by microtia. Dr. Payal Mukherjee from the Sydney Royal Prince Alfred Hospital leads the research effort with the ARC Centre of Excellence for Electromaterials Science at the University of Wollongong.

They’ve made 3D Alek to utilize a system of three extruders and three bioinks, including gelatin methacroloyl. Because reconstructive surgery for patients with microtia typically involves multiple stages and can have complications, 3D Alek has the potential to greatly improve outcomes.

Existing options for surgical intervention involve cartilage taken from a patient’s ribcage, an invasive and unpleasant process. But now researchers can grow cartilage on a scaffold made with 3D Alek, seeding the scaffold with stem cells or patient-specific cartilage cells.

- Year: 2019

- Technology used: A customized 3D printer (3D Alek) with three extruders

- Material used: Three specially-designed bioinks

- Time to print: Unknown

Cartilage-Covered Implants

Dr. Anthony Atala’s team at Wake Forest Baptist Medical Center managed to 3D print scaffolds that could be implanted into mice, allowing cells to populate them and grow a replacement ear. Before this advancement, only structures on the order of 200 microns could survive this process. They also say that even without further development, this technique can be used to stabilize organs and living tissue that can be implanted surgically.

This is possible thanks in large part to the design of micro-channels in the scaffolds, which allow for nutrients and oxygen to keep cells alive long enough for blood vessels to form. As the tissue has its own system of blood vessels and begins to grow, the scaffold is designed to dissolve, leaving a brand new ear in its place.

- Year: 2016

- Technologies used: Custom-designed printer, optimized micro-channels

- Material used: Custom-designed bioinks

- Time to print: Unknown

Scaffold

Scientists at SRM University in Chennai, India have grown an ear on a 3D printed scaffold as well. By taking a sample of cartilage from a rabbit and culturing the cartilage cells in the lab, they were able to implant these cells into the 3D printed scaffold. Finally, the scaffold was implanted into the rabbit. The implanted cells survived and grew in the rabbit, and the scaffold dissolved, suggesting this procedure is viable.

The team worked on their project for two years, but other than a press release, they did not disclose specific blueprints or other details. The project was given permission to experiment on 18 more rabbits, but no further results or details have been published to date.

- Year: 2018

- Technologies used: 3D printed biodegradable scaffold, tissue culture

- Materials used: Biocompatible scaffold, cartilage cells

- Time to print: Unknown

3D Scanned

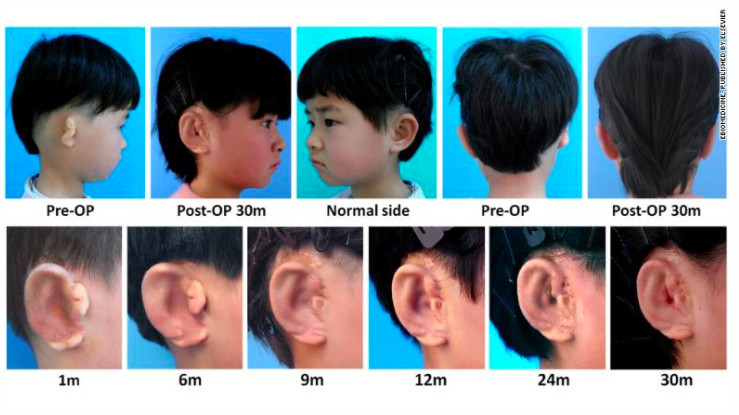

As mentioned previously, microtia patients have a bit of cartilage taken from their rib and carved into an ear to be implanted. This can be a very challenging process, but 3D printing has allowed researchers at The Royal Hospital for Sick Children in Edinburgh to precisely carve the cartilage into the proper shape using a 3D scanned and printed model as a template. The increase in precision and symmetry lead to better results with this type of procedure.

While advanced imaging techniques have vastly improved the quality of this procedure, future advancements could use stem cells and biocompatible polymers to print entire ears without the need to extract and carve rib cartilage. This technology isn’t far off, seeing as the team has already extracted such stem cells from fat.

- Year: 2016

- Technologies used: High-resolution 3D scanner (Artec Spider), and Roland ARM-10 3D printer

- Material used: UV-cured resin for the template

- Time to print: Three hours

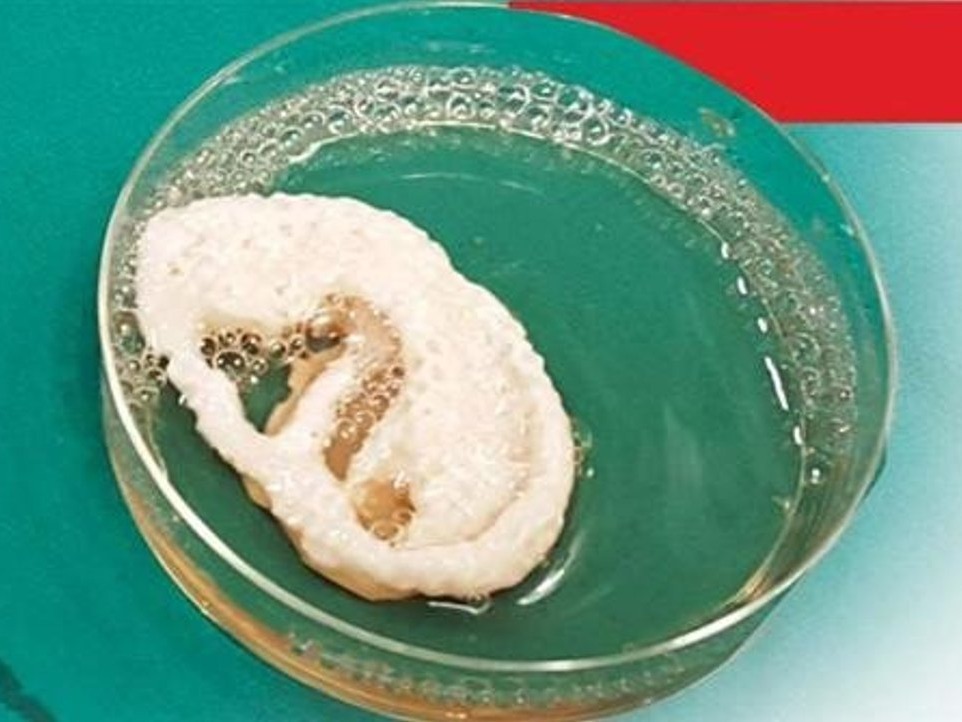

Molds

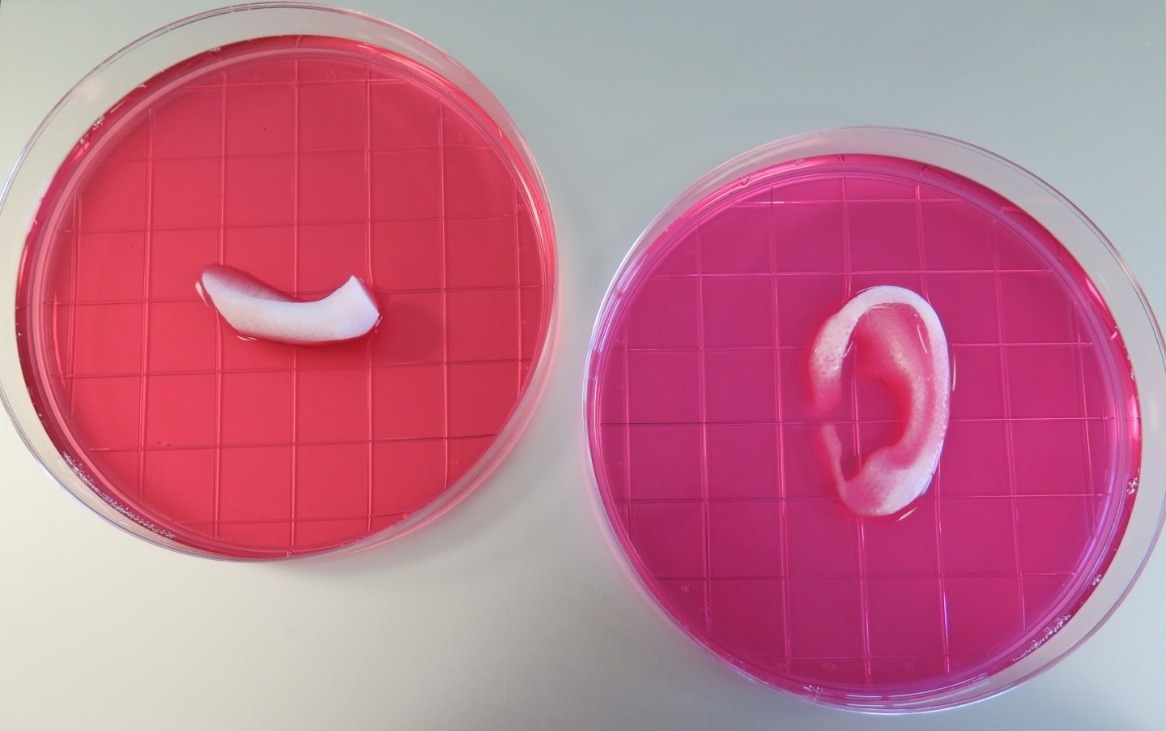

Cornell University researchers have figured out a way to make precise molds that can be injected with collagen and cartilage cells, forming a scaffold. This scaffold is then implanted and allowed to grow into an ear, the cartilage replacing the collagen in the scaffold. This process is unique in its speed: only taking days to go from design to implantation.

While this technology is revolutionary, the team is working on culturing human cartilage cells from the patient so as to reduce the risk of rejection. They’re focusing on parts that are mostly cartilage, as it does not need a blood supply to survive. As such, this technology has the potential to be used for other structures made of cartilage such as noses, ribs, and the disks between the spine.

- Year: 2013

- Technology used: 3D printed molds

- Material used: A gel containing rat tail collagen and cow cartilage

- Time to print: One day to print the mold (about two days from start to finish)

Middle Ear Transplant

If the bones in your middle ear become damaged from an accident, fixing them usually involves surgery with high failure rates as well as steel and ceramic implants. Professor Mashudu Tshifularo and the team at the University of Pretoria’s Steve Biko Academic Hospital were the first to complete a middle ear transplant. They used 3D printed middle-ear bones with help from Bunnycorp, a South African additive manufacturing company.

Because middle-ear bones are some of the smallest bones in the human body, the precision that you get with 3D printing has been an enormous benefit when creating these replacement prosthetics. The previously high failure rate of 25% to 95% for this type of procedure is largely eliminated by a 3D printed prosthesis from a CT scan that’s accurately modeled to the patient.

- Year: 2019

- Technology used: Laser sintering

- Material used: Titanium

- Time to print: Unknown

Bionic

Back in 2013, we learned that a team from Princeton University actually 3D printed an ear with a built-in antenna. This far-out concept isn’t quite as far as you might think, thanks to conducting polymers infused with silver, 3D printable bioinks, and cell culture technology common in the medical world.

While it will take a great deal of testing before this is ready to be implanted in humans, the team already hopes to create bionic ears that can hear sound. Innovations like this are so compelling that we can’t help imagine that perhaps one day we’ll even be able to use this technology to 3D print augmentations for our senses, like characters in the video game series Deus Ex.

- Year: 2013

- Technologies used: 3D printing, in vitro tissue culture

- Materials used: Cell-seeded hydrogel, intertwined conducting polymer infused with silver nanoparticles

- Time to print: Unknown

Lead image source: Lindsay France via Cornell University

License: The text of "3D Printed Ear: The Latest Advancements" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.