Along with time travel, scary alien monsters, and ray guns, the prospect of self-replicating machines is a recurring sci-fi trope.

In 2005, the RepRap project (short for “Replicating Rapid-prototyper”) set out to make at least part of the sci-fi imaginings a reality. It was launched with an ambitious vision: to create a device that could build copies of itself, “humanity’s first general-purpose, self-replicating manufacturing machine.”

RepRap was the catalyst for explosive growth in low-cost 3D printing, generating countless innovations and leading to the creation of many companies that are now significant additive manufacturing players.

By 2007, printers inspired by RepRap were manufacturing components to build improved versions of themselves, closely followed by wildly hyped media coverage of “machines making machines”. The concept of a 3D printer that could print another 3D printer took hold of the public’s imagination, but just how close are we to that reality today?

To answer this question, we’ll take a step back and explore the origins of RepRap, how it evolved, and the enormous impact it’s made on the world of 3D printing and the capabilities of today’s technology. We’ll even allow ourselves to gaze into a 3D-printed crystal ball and make a few predictions about the future.

The RepRap Challenge

RepRap was launched by Dr. Adrian Bowyer, a mechanical engineering professor at the university of Bath in the UK, in 2005 – a time when 3D printers used proprietary technology and cost over $100,000. The primary aim was to create a low-cost 3D printer that could reproduce most of its own components, but Dr. Bowyer also saw a much greater potential.

In a series of articles and conference presentations, he set out a vision of ordinary people, especially in developing countries, benefiting from the ability to make their own cost-effective products. He also released all of the hardware and software designs as open source, encouraging dozens of volunteers from across the world to bring their expertise to bear.

Within a few years, RepRap projects numbered in the hundreds and Adrian’s dream of rapid design evolution through rigorous technical and economic selection became a reality. That journey is well documented in the RepRap project log.

We’ll look at several of the project’s classic innovations and designs below, but first, what about the overarching goal of creating a self-replicating machine?

Even relatively simple desktop 3D printers are the product of multiple different materials and components, including metals and electronics. However, as additive manufacturing technology has advanced, the proportion of components that can be 3D printed has continued to increase.

Below, we look at each component type used in a typical printer and explore how well it’s suited to self-replication, now and in the future.

Plastic Fittings & Housings

Visit Prusa Research, one of the world’s largest 3D printer manufacturers, and you’ll find hundreds of their existing machines making plastic parts for new machines. This allows the company to respond to changes in demand and have the flexibility to quickly modify and improve designs. For similar reasons, many of the most well-regarded DIY printers, such as the Rat Rig and the Voron, rely heavily on 3D printed components, especially those that are made by their customers.

Yet, as volumes increase, conventional manufacturing solutions like injection molding generally become more cost effective and produce “cleaner” parts. Thus, plastic parts for larger scale production tend not to be 3D printed. Indeed, despite strong developments in print speed, improved material properties, and the ability to print complex parts that can’t be made with other techniques, it’s unlikely that the proportion of 3D printed parts will increase for high-volume manufacturing.

Today, all of the plastic parts on a 3D printer (including flexible components like drive belts) can in principle be replicated using 3D printing. In practice, however, for volume production at least, conventional methods remain more cost effective.

Metal Parts (Frames, Bearings, Extruders, etc.)

Two approaches can be taken to replicate parts conventionally made from metal. The first and most obvious is to manufacture them directly using metal 3D printing technologies.

Metal additive manufacturing has advanced to the extent that most of a printer’s metal parts, including finely detailed items like nozzles or bearings, can be printed. Some parts can even be improved with metal 3D printing. For example, a one-piece, generatively designed printer frame could be made much lighter and stiffer. However, in virtually all cases, this approach is extremely difficult to justify from a cost standpoint when compared to mass-producing, conventional alternatives.

The other approach can be seen in RepRap projects like the MulBot and the Snappy (which we’ll take a look at below). They’re designed so that the bulk of metal parts are suitable for FDM plastic printing, a process which has been remarkably successful, with as many as 70-80% of components being replicable. In both cases, however, this comes with the loss of some rigidity, and therefore, printing performance is compromised.

Specialized materials, including carbon fiber, ceramics, and PEEK, could close that performance gap or give designers new ways to build and integrate components. However, cost effectiveness remains a practical challenge for this workaround, too.

Theoretically and practically, the majority of metal components on a 3D printer can be replicated using 3D metal printing or alternative materials and designs. But even more so than in the case of plastic components, the cost and performance penalties make it not commercially viable. Instead, most printers make use of easily sourced metal components, like screws, bolts, bearings, and extruded aluminum.

Electronics, Sensors, & Motors

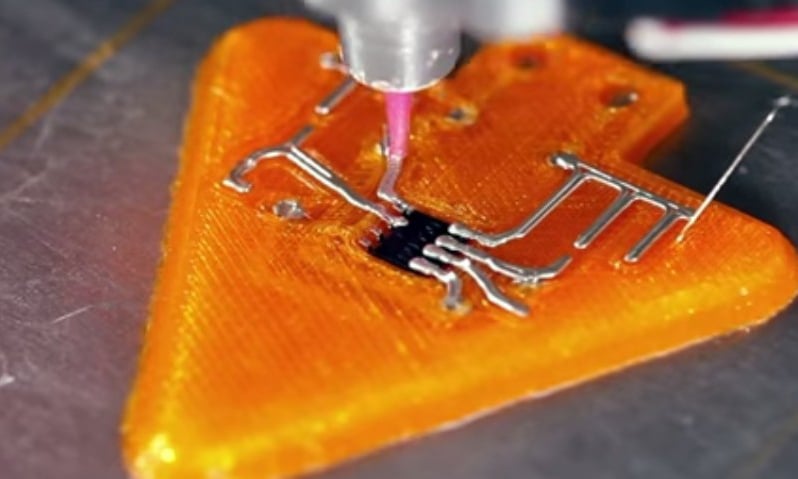

Today, it’s already possible to 3D print electronic circuit boards and connect electrical components with conductive filament. (It’s an area that Dr. Bowyer is especially keen to encourage.) Popular YouTube 3D printing channels, such as Teaching Tech, have explored how to do this with hobby-level printers, and companies such as Nano Dimension are actively conducting research and development into printing more sophisticated components, including antennas, capacitors, and sensors.

Yet, the main challenge lies in 3D printing the complex integrated circuits (ICs) at the heart of a printer’s controller board, although it is being worked on. The University of Hamburg and DESY, for example, have experimented with nano-scale wiring and primitive ICs, while the University of Austin has 3D printed transistors at a scale on par with chips from the early 70s. Unfortunately, despite steady progress, practical 3D printed ICs are realistically still decades away.

The story behind 3D printed electric motors is a little more encouraging, though. We’ve previously reported how 3D printing can be used for the structures of simple motors and even how an entirely 3D printed motor is possible. In this case, it’s the ability to 3D print complex (but still macro) structures that lends itself well to motor design. Several start-ups, such as Additive Drives, are actively exploring this. However, their initial focus is on high-performance drives, and so the practical application to 3D printers is very limited for the foreseeable future.

Despite impressive development, electrical components of all sorts are the least replicable parts on a typical 3D printer. Practical examples are few and far between, and useful 3D printed ICs are beyond even the most advanced theoretical designs at present.

Firmware

The majority of firmware in use by today’s FDM printers stems from RepRap’s work, including the ubiquitous Marlin.

Assuming that a technology could be developed to print ICs with erasable, programmable memory, new firmware could be “hard coded” as part of this process. Alternatively, there would need to be some method to establish a connection with and transfer a copy of firmware to a newly replicated machine, like we do manually today. Regardless, this train of thought properly strays into the realm of science fiction, raising questions about what other capabilities a truly self-replicating machine would need beyond “just” printing.

Furthermore, 3D printer firmware is frequently adjusted and modified. In talks with YouTuber Joel Telling (3D Printing Nerd), Dr. Bowyer has mused on the topic and realized that self-replicating machines would need a symbiotic relationship with humans, or be doomed to create exact, unchanging, copies forever more!

Production & Assembly

The most extreme media interpretations of RepRap’s goal have over the years envisaged a Star Trek-like “replicator” – a single multi-material machine able to print, layer-by-layer, a functional copy of itself. In an interview with New Scientist, Dr. Bowyer clarified that this was never his intention. The aim was to build a machine “producing all the necessary parts, with the exception of the microprocessors and the lubricating grease” that could then be assembled by hand. “I am not interested in self-assembly, just self-copying,” he added, to be clear.

This vision of reproduction with manual assembly endures with the many thousands who continue to build kit printers from components designed and supplied by Creality, Prusa Research, Rat Rig, and many others.

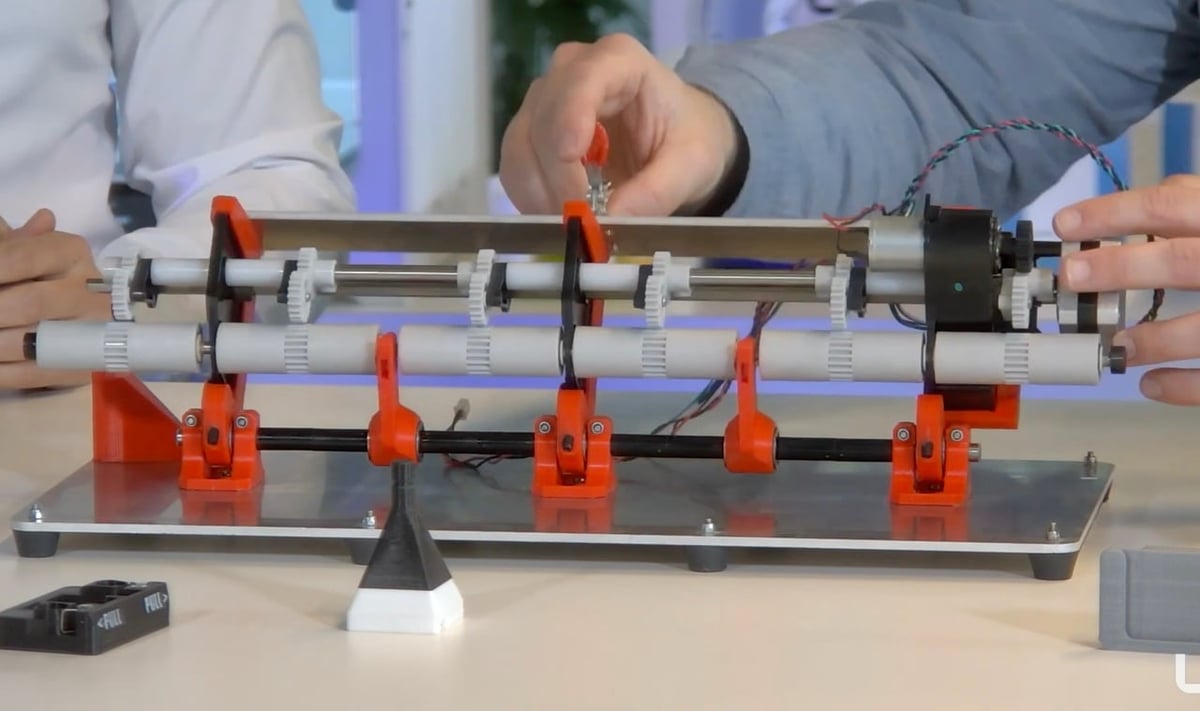

An interesting twist, however, exists for the production of pre-built printers. Here, it’s common to find manufacturers using 3D printing parts to assist with assembly. For example, Ultimaker has over 500 steps in their assembly line supported by different 3D printed solutions. These range from jigs to manage the complex arrangement of springs, gears, and cams found in filament rewinders to test rigs for checking the quality of assembled structures.

As we’ll see below, this raises the prospect of flexible machines that can, semi-automatically, assemble components manufactured by different technologies (including 3D printing) with minimal human intervention.

RepRap's Results & Lasting Legacy

Before considering the future of self-replicating machines, it’s worth looking at what RepRap has achieved and how it continues to shape the broader ecosystem of additive manufacturing.

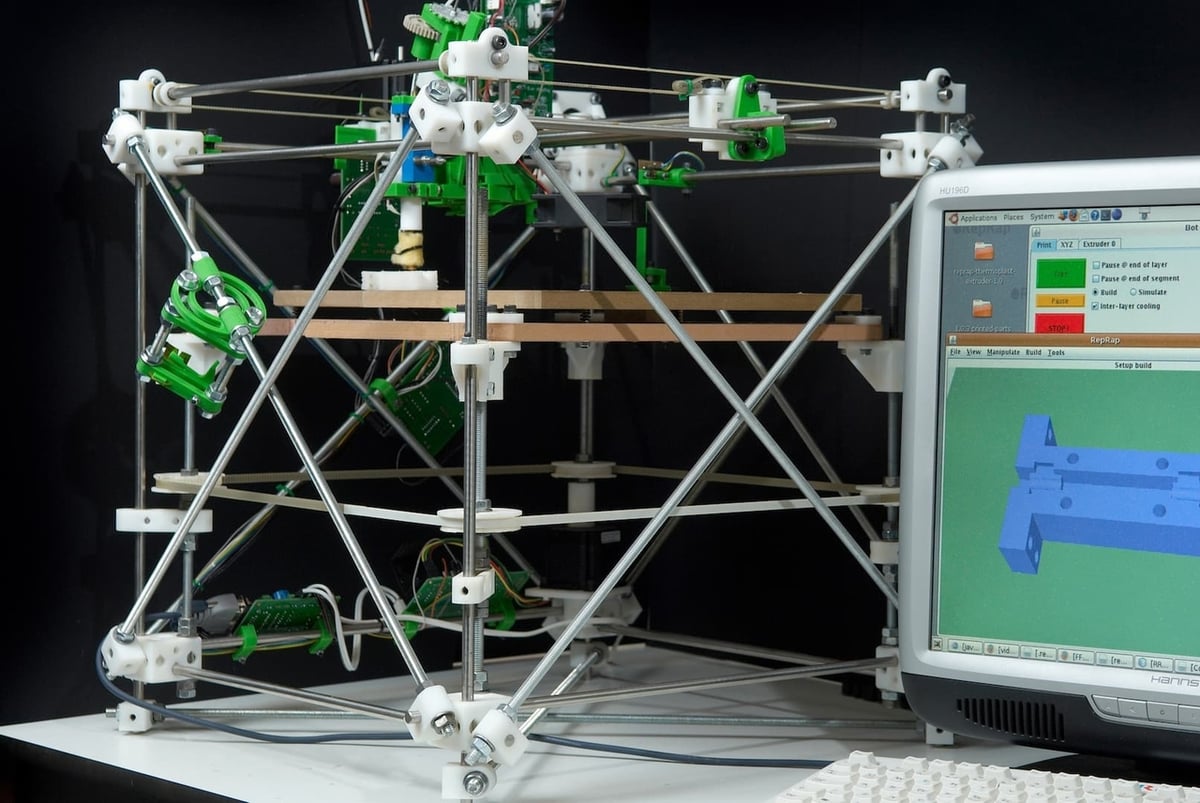

After the initial groundwork, RepRap’s first production 3D printer was built in 2007. Appropriately, it was named “Darwin“. Its open-source design and how it was expected to evolve enlisted the help of many dozens of project volunteers. By 2009, a simplified and improved RepRap machine, “Mendel“, was made, followed by “Huxley” in 2010.

The number of contributing projects exploded to over 2,000, each exploring its own ideas on hardware, firmware, and software (i.e. slicers). The number of RepRap design variants soared, as did their quality. Many of the early volunteers went on to found organizations, including Prusa Research, MakerBot, Ultimaker, LulzBot, E3D, Marlin, and more. Meanwhile, RepRap User Groups meet the world over and continue to shape 3D printing’s future.

Although mainly focused on accessible FDM technology, RepRap’s domain has extended into just about every form of additive manufacturing and touched every industry, from medicine to space exploration. The thinking behind the many innovations continues to evolve, and Dr. Bowyer continues to inject new ideas into the public mind, including for example, the idea of a “single-shot” electric 3D printer (described in an interview with Thomas Sanladerer), which could take 3D printing in a different direction in the future.

All of this happened in a relatively short period of time. Could RepRap have imagined today’s state of play 15 years ago? And what might be realistically achieved within the next 15? In terms of breakthrough thinking, two RepRap designs have stood out on the journey to affordable and generic self-replicating machines. They give us clues as to how things may unfold in the future…

Darwin

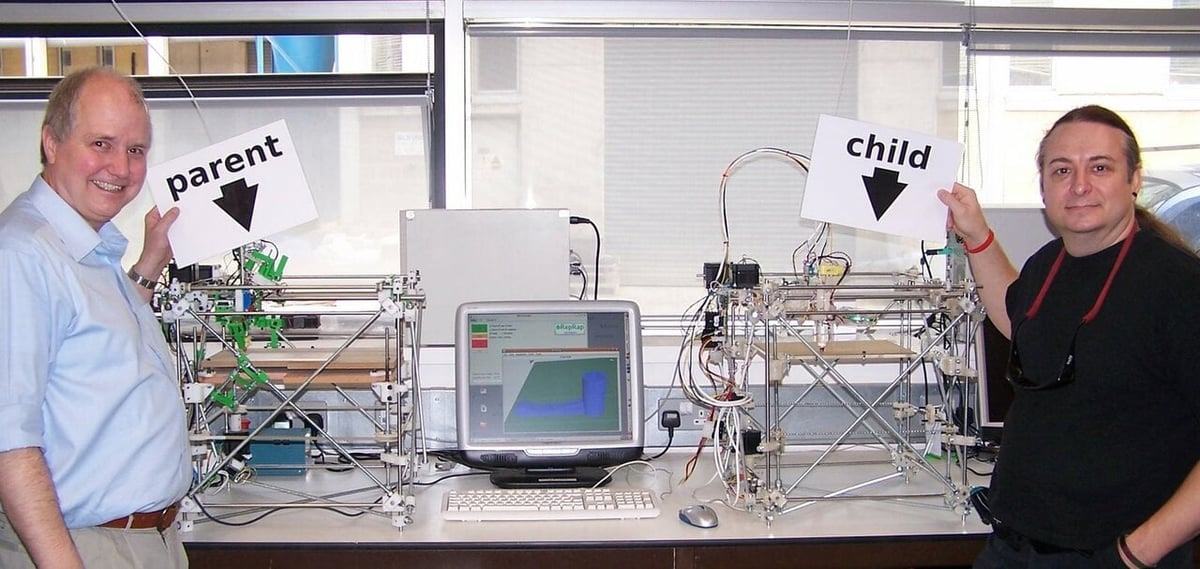

Built in 2007 using parts made by a Stratasys printer that cost 100 times more, the RepRap Darwin was immediately set to work replicating those same parts for a fraction of the cost. (See a fascinating account of this recorded with Dr. Bowyer that same year).

This was an hugely significant milestone on the journey to bringing cost-effective 3D printing to a wide audience and challenged expectations about what 3D printing might enable. The open-source designs, shared alongside an invitation to help make improvements, inspired many to contribute their energy and expertise.

Most of today’s FDM printer designs can trace their DNA back to Darwin. More important, however, is the spirit of collaborative and evolutionary design improvement, which endures within RepRap User Group conversations and tech community challenges, such as the SpeedBoatRace.

Darwin may look primitive today, but might today’s most advanced 3D printers look similarly quaint the same number of years from now?

Snappy

The assumption that parts will always be required from other manufacturing processes has been challenged multiple times. That printer frames and gantries be made of metal has in particular come into question. Some projects, such as the Hangprinter have even tried to get round this by not having a frame at all!

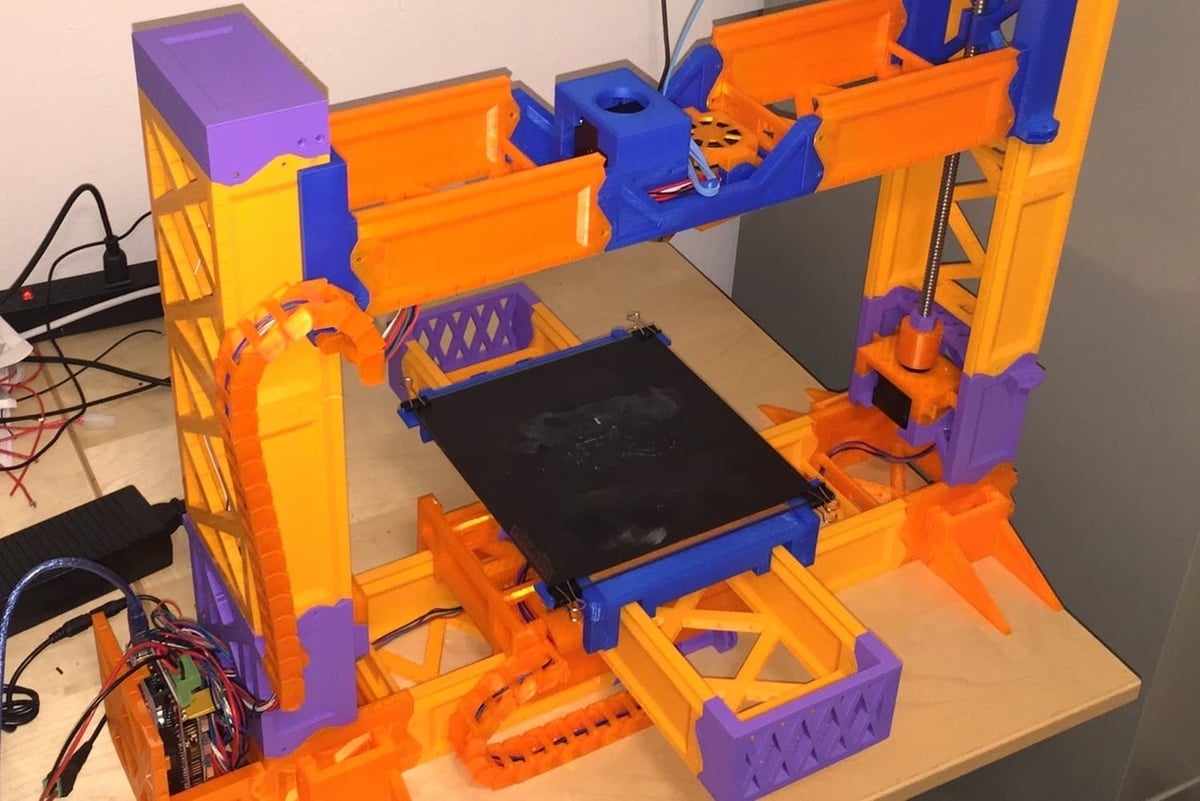

In 2015, Revar Desmera of the Bay Area RepRap User Group tackled the issue by designing the Snappy, which has an entirely 3D printable frame and drive system. With up to 78% of its parts printable by an FDM printer, it became the Guinness Book of World Records’ “Most 3D Printed 3D Printer”.

The design has continued to evolve and is now in its third version. Such inventive thinking points to a future where other design norms are challenged and the percentage of inherent replicability moves into the 80% or 90% regions. It also highlights the gap between what is possible, practical, cost-effective, and performant, making it near impossible to answer the question in the title of this article…

Looking to the Future

To return to our original question, let’s consider where RepRap’s journey has brought us:

- Can a 3D printer (entirely) print another 3D printer? The short answer is “no”. Even with the most advanced technologies currently available, we’re still a very long way from this being possible. Certain components are simply not well suited to the processes at hand.

- Can a 3D printer print most of the parts that can then be assembled into another 3D printer? Impressively, the answer is “yes”, meaning that RepRap’s basic goal has (basically) been achieved! It’s already possible to replicate the majority of parts used in a 3D printer on the same printer, and that percentage increases if we allow different 3D printing technologies to be added to the mix. In theory, almost everything except the ICs (and, as Dr. Bowyer noted, maybe the lubricants) could be printed, although not necessarily cost effectively or with the best performance.

- Can we envisage a single, “self-replicating” machine that combines different (3D printing and other) technologies as well as assemble the parts automatically? This is an intriguing question. We can see the convergence of 3D printing and other automation by companies such as Relativity Space with their “software defined factory” as well as in other flexible manufacturing systems. Impressive though these are, we’re still a long way from a fully self-replicating machine.

In a way, these questions distract form RepRap’s true legacy, which as we’ve seen, has brought easy-to-use production technology to the world. In doing so, it’s accelerated the pace of additive manufacturing in general and opened up new possibilities that we could only dream of a couple of decades ago.

It’s also been an outstanding example of the power of open and collective development, which continues to shape developments in hardware, firmware, and software. The gaps between what is printable in theory and in practice is always shrinking, and the promise of more exciting developments in additive manufacturing is always growing.

What would RepRap be like if it were reborn today? It’s likely the focus would be more on continuing to make 3D printing easier, faster, and even more universally accessible rather than on fully self-replicating or self-assembling machines.

The days when a 3D printer can entirely copy itself are still some way off, but in the meantime, we can all benefit from the enormous advances in additive manufacturing that RepRap has enabled.

License: The text of "Can You 3D Print a 3D Printer?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.